ASTM D1827-92(2002)e1

(Test Method)Standard Test Method for Gas Content (Nonacidic) of Insulating Liquids by Displacement with Carbon Dioxide (Withdrawn 2009)

Standard Test Method for Gas Content (Nonacidic) of Insulating Liquids by Displacement with Carbon Dioxide (Withdrawn 2009)

SIGNIFICANCE AND USE

Electrical insulating liquids, in many applications, require low gas content. This is the case with capacitors and certain types of cable, for example. This test is used as a factory control test and as a control and functional test in installation and maintenance work by utilities. This test requires care in manipulation and trained, careful personnel.

FIG. 1 Semimicro Apparatus for Determination of Gas Content of Insulating Liquids

SCOPE

1.1 This test method describes the determination of the gas content of electrical insulating liquids with a viscosity of 216 cSt or less at 100°C. Any gas that is nonreactive with a strong caustic solution may be determined.

Note 1—The test method has a bias for samples containing gases other than oxygen and nitrogen in atmospheric ratios due to differential solubility effects. Gases which react with KOH such as carbon dioxide will not be measured. Unsaturated hydrocarbons such as acetylene, if present, will react with KOH to a small degree and will result in an underestimation of the total gas present.

1.2 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method describes the determination of the gas content of electrical insulating liquids with a viscosity of 216 cSt or less at 100°C. Any gas that is nonreactive with a strong caustic solution may be determined.

Formerly under the jurisdiction of Committee D27 on Electrical Insulating Liquids and Gases and Subcommittee D27.03 on Physical Tests, this practice was withdrawn in May 2009 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D 1827–92(Reapproved 2002)

Standard Test Method for

Gas Content (Nonacidic) of Insulating Liquids by

Displacement with Carbon Dioxide

This standard is issued under the fixed designation D 1827; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—The mercury warning was editorially added in April 2009.

1. Scope D923 Practices for Sampling Electrical Insulating Liquids

D1193 Specification for Reagent Water

1.1 This test method describes the determination of the gas

D3613 Practice for Sampling Insulating Liquids for Gas

content of electrical insulating liquids with a viscosity of 216

Analysis and Determination of Water Content

cSt or less at 100°C.Any gas that is nonreactive with a strong

caustic solution may be determined.

3. Terminology

NOTE 1—Thetestmethodhasabiasforsamplescontaininggasesother

3.1 Definitions of Terms Specific to This Standard:

than oxygen and nitrogen in atmospheric ratios due to differential

3.1.1 gas content by volume—of an insulating liquid, the

solubility effects. Gases which react with KOH such as carbon dioxide

volume of gas contained in a given volume of liquid. It is

will not be measured. Unsaturated hydrocarbons such as acetylene, if

usually expressed as a percentage at standard atmospheric

present, will react with KOH to a small degree and will result in an

conditions of 760 mm Hg pressure and 0°C temperature.

underestimation of the total gas present.

3.1.2 gas content by weight—theweightofgascontainedin

1.2 Warning—Mercury has been designated by EPA and

agivenweightofliquid,usuallyexpressedinpartspermillion.

many state agencies as a hazardous material that can cause

central nervous system, kidney, and liver damage. Mercury, or

4. Summary of Test Method

its vapor, may be hazardous to health and corrosive to

4.1 This test method consists essentially of purging dis-

materials.Cautionshouldbetakenwhenhandlingmercuryand

solved gases from a small liquid test specimen with pure

mercury-containing products. See the applicable product Ma-

carbon dioxide gas.The dissolved gases are then carried into a

terial Safety Data Sheet (MSDS) for details and EPA’s website

graduated buret (precision nitrometer) filled with a potassium

(http://www.epa.gov/mercury/faq.htm) for additional informa-

hydroxide solution for a precise measurement. The carbon

tion. Users should be aware that selling mercury or mercury-

dioxide is completely absorbed by the potassium hydroxide

containingproducts,orboth,inyourstatemaybeprohibitedby

and the volume of other gases is measured.

state law.

1.3 This standard does not purport to address all of the

5. Significance and Use

safety concerns, if any, associated with its use. It is the

5.1 Electrical insulating liquids, in many applications, re-

responsibility of the user of this standard to establish appro-

quire low gas content. This is the case with capacitors and

priate safety and health practices and determine the applica-

certain types of cable, for example. This test is used as a

bility of regulatory limitations prior to use.

factory control test and as a control and functional test in

installation and maintenance work by utilities. This test re-

2. Referenced Documents

quires care in manipulation and trained, careful personnel.

2.1 ASTM Standards:

D831 Test Method for Gas Content of Cable and Capacitor

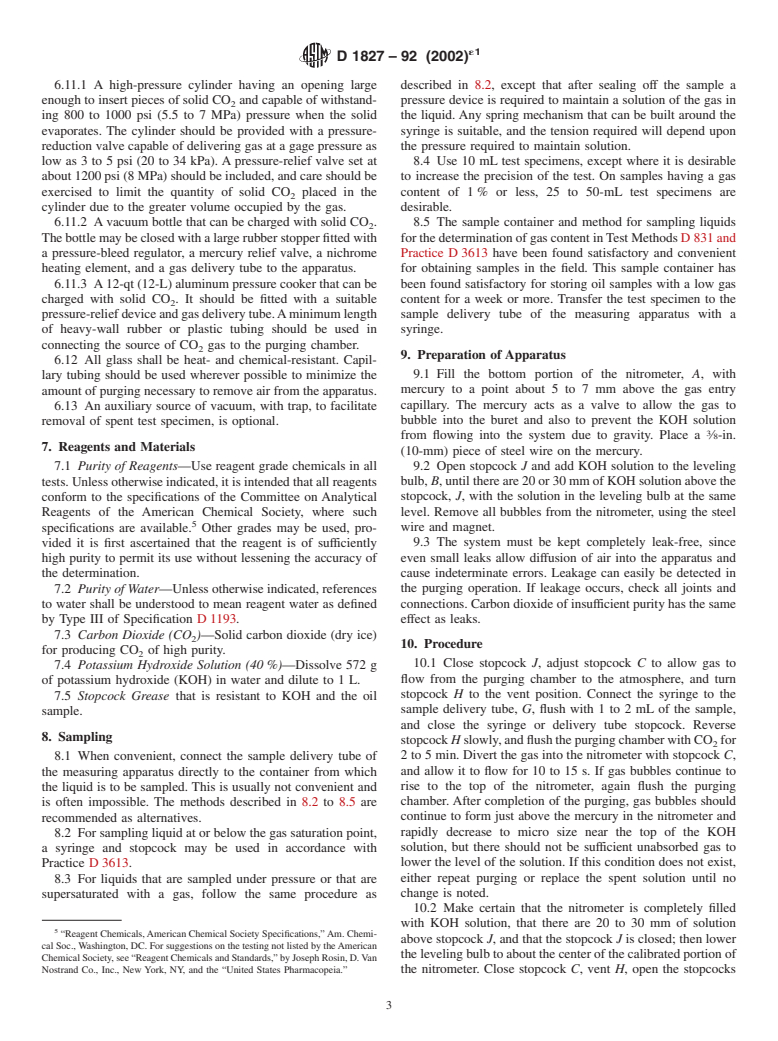

6. Apparatus (see Fig. 1)

Oils

6.1 Precision Nitrometer (azotometer), A, with a calibrated

capacity of 1.5 mL and calibrated in 0.01-mL divisions.

Nitrometers shall have individual calibration correction tables

This test method is under the jurisdiction of ASTM Committee D27 on

that give the correct volume for each 0.01-mL point on the

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom-

scale when a 40% aqueous potassium hydroxide solution is

mittee D27.03 on Physical Tests.

Current edition approved Aug. 15, 1992. Published October 1992. Originally used. The gas inlet shall consist of a 12/2 socket joint. The

published as D1827–61T. Last previous edition D1827–84.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D 1827–92 (2002)

FIG. 1 Semimicro Apparatus for Determination of Gas Content of Insulating Liquids

nitrometer shall be provided with a liquid leveling bulb, B,of 6.7 Sample Delivery Tube, G, made of a length of ⁄16-in.

125-mL capacity. Rubber stoppers, K, with a short piece of (1.6-mm)insidediameterstainlesssteeltubing,tightlyinserted

glass capillary tubing, should be placed in the top of the into one of the holes in the stopper, E, and extending to the

nitrometerandthelevelingbulb, B,topreventspatteringofthe fritted-glassfilter.Asmallsyringestopcockshallbesolderedto

KOH solution. permit the delivery of an accurate volume of liquid and

6.2 Permanent Magnet and Steel Wire,Thesmallsteelwire, subsequent sealing of the purging chamber.

suitably consisting of a ⁄8-in. (10-mm) length of paper clip, 6.8 Sampling Device, consisting of a calibrated glass medi-

shall be placed inside the nitrometer for manipulation by the cal syringe fitted with a syringe stopcock for sealing of the test

small external permanent magnet. specimenduringtransferorstorage.Thesyringefor10-mLtest

6.3 Pregl-Type Micro Stopcock, C, to allow delivery of gas specimens shall have a calibrated capacity of 10 mL, and for

to nitrometer or venting the gas to the atmosphere. This 50-mL test specimens, a calibrated capacity of 50 mL. It shall

stopcockshallbeprovidedwitha12/2balljointattheexitside be capable of accurately delivering a liquid volume within the

and a 12/2 socket joint at the inlet side. accuracy required for the method.

6.4 Elbow Adapter, D, consisting of a 12/2 ball joint and 6.9 Ball-and-Socket Clamps,size12,fortightlysecuringall

having a drawn-down tip suitable for insertion in a small hole joints to prevent leakage.

in the rubber stopper, E. 6.10 Two-Way Stopcock, H, fitted to the inlet side of the

6.5 Stopper, E, of oil-resistant rubber, cut to fit the sample- purging chamber and having a 12/2 socket joint. The single-

purging chamber, F, and provided with two small holes to tubeendofthestopcockshallbeconnectedtothelow-pressure

allowtightfittingoftheelbowadapter, D,andsampledelivery carbon dioxide supply to control the entry of this gas to the

tube, G. apparatus.

6.6 Sample-Purging Chamber, F, with a 10-mm diameter 6.11 Low-Pressure Source of very pure carbon dioxide

fritted-glass disk, L, of medium porosity and a capacity of 15 (CO ) gas. If gas of sufficient purity is not available, one of

mLabove the disk for 10-mLtest specimens, or with a 25-mm the following mechanisms utilizing solid CO shall be used:

diameter fritted glass disk of medium porosity and a capacity

of 75 mL above the disk for 50-mL test specimens. The gas

Cylinders of 99.99% minimum purity liquified carbon dioxide fitted with two

inletshallbecutstraighttofitthestopper, E.Aflexibleheating

stage regulator with stainless steel diaphragms have been found satisfactory.

tape, wrapped around the purging chamber, is necessary for

Cylinders of “Instrument Grade” carbon dioxide and regulators (Model No. 18-5,

holding constant temperature when test specimens are purged

CGA 320) may be obtained from BOC Gases Customer Service Center, 100

at temperatures in excess of room temperature. Corporate Drive, Lebanon, NJ 08833.

´1

D 1827–92 (2002)

6.11.1 A high-pressure cylinder having an opening large described in 8.2, except that after sealing off the sample a

enough to insert pieces of solid CO and capable of withstand- pressure device is required to maintain a solution of the gas in

ing 800 to 1000 psi (5.5 to 7 MPa) pressure when the solid the liquid.Any spring mechanism that can be built around the

evaporates. The cylinder should be provided with a pressure- syringe is suitable, and the tension required will depend upon

reduction valve capable of delivering gas at a gage pressure as the pressure required to maintain solution.

low as 3 to 5 psi (20 to 34 kPa).Apressure-relief valve set at 8.4 Use 10 mL test specimens, except where it is desirable

about1200psi(8MPa)shouldbeincluded,andcareshouldbe to increase the precision of the test. On samples having a gas

exercised to limit the quantity of solid CO placed in the content of 1% or less, 25 to 50-mL test specimens are

cylinder due to the greater volume occupied by the gas. desirable.

6.11.2 Avacuum bottle that can be charged with solid CO . 8.5 The sample container and method for sampling liquids

Thebottlemaybeclosedwithalargerubberstopperfittedwith forthedeterminationofgascontentinTestMethodsD831and

a pressure-bleed regulator, a mercury relief valve, a nichrome Practice D3613 have been found satisfactory and convenient

heating element, and a gas delivery tube to the apparatus. for obtaining samples in the field. This sample container has

6.11.3 A12-qt(12-L)aluminumpressurecookerthatcanbe been found satisfactory for storing oil samples with a low gas

charged with solid CO . It should be fitted with a suitable content for a week or more. Transfer the test specimen to the

pressure-reliefdeviceandgasdeliverytube.Aminimumlength sample delivery tube of the measuring apparatus with a

of heavy-wall rubber or plastic tubing should be used in syringe.

connecting the source of CO gas to the purging chamber.

9. Preparation of Apparatus

6.12 All glass shall be heat- and chemical-resistant. Capil-

lary tubing should be used wherever possible to minimize the 9.1 Fill the bottom portion of the nitrometer, A, with

mercury to a point about 5 to 7 mm above the gas entry

amountofpurgingnecessarytoremoveairfromtheapparatus.

6.13 An auxiliary source of vacuum, with trap, t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.