ASTM E1592-05(2012)

(Test Method)Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference

Standard Test Method for Structural Performance of Sheet Metal Roof and Siding Systems by Uniform Static Air Pressure Difference

SIGNIFICANCE AND USE

This test method provides a standard procedure to evaluate or confirm structural performance under uniform static air pressure difference. This procedure is intended to represent the effects of uniform loads on exterior building surface elements.

It is also permissible to develop data for load-span tables by interpolating between the test results at different spans.

Note 1—When applying the results of tests to determine allowable design loads by application of a factor of safety, bear in mind that the performance of a wall or roof and its components, or both, can be a function of fabrication, installation, and adjustment. The specimen must represent the actual structure closely. In service, the performance can also depend on the rigidity of supporting construction and on the resistance of components to deterioration by various causes, to vibration, to thermal expansion and contraction, and so forth.

SCOPE

1.1 This test method covers the evaluation of the structural performance of sheet metal panels and anchor-to-panel attachments for roof or siding systems under uniform static air pressure differences using a test chamber or support surface.

1.2 The provisions of this test method are applicable to standing seam, trapezoidal, ribbed, or corrugated metal panels in the range of thickness from 0.012 to 0.050-in. (0.3 to 1.3-mm) and apply to the evaluation of uniform pressure applied to single-skin construction or one sheet metal layer of multiple-skin construction. They do not cover requirements for the construction of a specimen to determine the load sharing that can occur with either composite or multiple-layer construction such as: (1) metal cladding over wood sheathing; or (2) field assemblies of insulation sandwiched between corrugated or formed metal panels.

1.3 Proper use of this test method requires knowledge of the principles of pressure and deflection measurement.

1.4 This test method describes optional apparatus and procedures for use in evaluating the structural performance of a given system for a range of support spacings or for confirming the structural performance of a specific installation.

1.5 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units are approximate.

1.6 The text of this standard references notes and footnotes exclusive of those for tables and figures. These notes and footnotes provide explanatory material and shall not be considered as requirements of the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1592 − 05 (Reapproved 2012)

Standard Test Method for

Structural Performance of Sheet Metal Roof and Siding

Systems by Uniform Static Air Pressure Difference

This standard is issued under the fixed designation E1592; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Computations are the accepted method for determining the structural capacity of most metal

products. However, some conditions are outside the scope of analysis by industry specifications.

Methodsofcomputationandadiscussionoftheseconditionsarefoundinthefollowingdocuments:

AISI Specification for the Design of Cold-Formed Steel Structural Members and Load and Resistance

Factor Specification for Cold-Formed Steel Structural Members and Aluminum Association Specifi-

cations for Aluminum Structures.

This test method is not to be considered as a wind design standard. It is a structural capacity test

to determine the ability of a panel system (including attachments) to resist uniform static pressure.

Actual wind pressure is nonuniform and dynamic. These uniform static test results should be used in

conjunction with commonly recognized wind design standards, and will yield highly conservative

results.

Whenadditionalfastenersareinstalledacrosspanelflatsateaves,ridges,orreinforcedendlaps,the

crosswise distortion is eliminated and both flexural capacity and anchor-to-panel attachment strength

can vary with the distance from such conditions. This test procedure can be used to evaluate the

strength of panels and attachments at any distance from end or edge perimeter conditions. The size of

the specimen and limitations on air seals are designed to minimize any interference with the natural

response of the panels under load.

1. Scope struction such as: (1) metal cladding over wood sheathing; or

(2) field assemblies of insulation sandwiched between corru-

1.1 This test method covers the evaluation of the structural

gated or formed metal panels.

performance of sheet metal panels and anchor-to-panel attach-

ments for roof or siding systems under uniform static air

1.3 Proper use of this test method requires knowledge of the

pressure differences using a test chamber or support surface. principles of pressure and deflection measurement.

1.2 The provisions of this test method are applicable to

1.4 This test method describes optional apparatus and pro-

standing seam, trapezoidal, ribbed, or corrugated metal panels

cedures for use in evaluating the structural performance of a

in the range of thickness from 0.012 to 0.050-in. (0.3 to

given system for a range of support spacings or for confirming

1.3-mm) and apply to the evaluation of uniform pressure

the structural performance of a specific installation.

applied to single-skin construction or one sheet metal layer of

1.5 The values stated in inch-pound units are to be regarded

multiple-skin construction.They do not cover requirements for

as the standard. The metric equivalents of inch-pound units are

the construction of a specimen to determine the load sharing

approximate.

that can occur with either composite or multiple-layer con-

1.6 The text of this standard references notes and footnotes

exclusive of those for tables and figures. These notes and

This test method is under the jurisdiction of ASTM Committee E06 on

footnotes provide explanatory material and shall not be con-

Performance of Buildings and is the direct responsibility of Subcommittee E06.57

on Performance of Metal Roof Systems.

sidered as requirements of the standard.

Current edition approved April 1, 2012. Published May 2012. Originally

1.7 This standard does not purport to address all of the

approved in 1995. Last previous edition approved in 2005 as E1592 – 05. DOI:

10.1520/E1592-05R12. safety concerns, if any, associated with its use. It is the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1592 − 05 (2012)

responsibility of the user of this standard to establish appro- 3.1.8 permanent deformation, n—the permanent displace-

priate safety and health practices and determine the applica- ment in any direction from an original position that remains

bility of regulatory limitations prior to use. For specific after an applied load has been removed.

precautionary statements, see Section 7.

3.1.9 reference zero load, n—nominal pressure applied to a

specimen to provide a reference position free of variations

2. Referenced Documents

from internal stresses or friction within the system assembly.

2.1 ASTM Standards:

3.1.10 rib spread, n—panel distortion under load at the base

A370 Test Methods and Definitions for Mechanical Testing

ofariborstandingseamasmeasuredcrosswisetotheribinthe

of Steel Products

plane of the roof or wall surface.

B557 Test Methods for Tension Testing Wrought and Cast

3.1.11 span length, n—thecenter-to-centerdistancebetween

Aluminum- and Magnesium-Alloy Products

anchors or supports measured parallel to the longitudinal axis

2.2 Aluminum Association Standard: of the panel.

Aluminum Formed-Sheet Building Sheathing Design

3.1.12 specimen, n—the entire assembled unit submitted for

Guide, Appendix B of Specifications for Aluminum

testing, as described in Section 8.

Structures, Latest Edition

3.1.13 specimen length, n—the distance from center to

2.3 AISI Standards:

center of the end supports; the sum of individual span lengths.

Specification for the Design of Cold-Formed Steel Struc-

3.1.14 structural element, n—the width of a panel profile as

tural Members, Latest Edition

measured between center lines of repeating longitudinal stiff-

2.4 Other Documents: eners for continuously supported panels in a positive load test

ASCE7 (Formerly ANSI A58.1) Minimum Design Loads or the width between anchor attachments to repeating stiffener

for Buildings and Other Structures elements in a negative load test.

3.1.15 test load, n—the difference in static air pressure

3. Terminology

(positive or negative) between the inside and outside face of

the specimen, expressed in pounds-force per square foot

3.1 Definitions of Terms Specific to This Standard:

(lbf/ft ) or pascals (Pa).

3.1.1 anchor, n—a fastener, bolt, screw, or formed device

such as a clip that connects panels to the support structure.

3.1.16 test panel length, n—specimen length plus over-

hangs.

3.1.2 anchor failure, n—any failure at the anchor device,

including separation of the device from the panel, of the device

3.1.17 ultimate load, n—the difference in static air pressure

itself, or of the connection to the structural support.

(positive or negative) at which failure of the specimen occurs,

expressed in pounds-force per square foot (lbf/ft ) or pascals

3.1.3 crosswise restraint, n—any attachment in the flat of a

(Pa).

panel between structural elements that controls or limits pan

distortion under pressure. 3.1.18 unlatching failure, n—disengagement of a panel

seam or anchor that occurs in an unloaded assembly due to

3.1.4 failure, n—fracture or disengagement of any of the

permanent set or distortion that occurred under a previous load

components where the system is no longer capable of sustain-

condition.

ing load, or the system no longer functions as a weathertight

membrane. 3.1.19 yield load, n—that pressure at which deflection

increases are no longer proportional to the increase in pressure.

3.1.5 interior support, n—any support other than those at

Yielding is not failure.

either extreme in a series of supports for a continuous panel.

3.1.20 zero load, n—the absence of air pressure difference

3.1.6 pan distortion, n—displacement under load of nor-

across the specimen.

mally flat portions of a panel profile normal to the plane of the

roof or wall surface.

4. Summary of Test Method

3.1.7 panel deflection, n—displacement under load mea-

4.1 This test method consists of the following: (1) sealing

sured normal to the plane of the roof or wall surface of a

the test specimen into or against one face of a test chamber; (2)

longitudinalstructuralelementasmeasuredfromastraightline

between structural supports.

Industry design procedures propose different factors of safety on yield and

ultimate strength. Not all permanent distortion is harmful to the structural perfor-

manceofthesystem.Onlypermanentdistortionthatinterfereswiththeperformance

of the system is significant.

2 7

For referenced ASTM standards, visit the ASTM website, www.astm.org, or This permanent set is not always detectable from readings taken normal to the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM panel.

Standards volume information, refer to the standard’s Document Summary page on It is often impractical to take direct measurements on individual elements in an

the ASTM website. assembly of components. Readings made on a panel surface opposite an anchor clip

Available from Aluminum Association, 900 19th Street, NW, Washington, DC include deflection of non-axial loads in the anchor base and panel profile as well as

20006. any slippage that occurs in the panel connection or between segments of a

Available from American Iron and Steel Institute (AISI), 1140 Connecticut multiple-piece clip. They may decrease with increasing pressure and produce a

Ave., NW, Suite 705, Washington, DC 20036, http://www.steel.org. bi-lineal curve. Subsequent small-scale tests may be required to determine whether

Available from American Society of Civil Engineers (ASCE), 1801 Alexander nonlinear deflection readings represent tolerable distortions that do not interfere

Bell Dr., Reston, VA 20191, http://www.asce.org. with long-term anchor performance.

E1592 − 05 (2012)

supplying air to, or exhausting air from, the chamber at the rate

required to maintain the test pressure difference across the

specimen; and (3) observing, measuring, and recording the

deflection,deformations,andnatureofanyfailuresofprincipal

or critical elements of the panel profile or members of the

anchor system.

4.2 The increments of load application shall be chosen such

that a sufficient number of readings will be obtained to

determine the load deformation curve of the system.

4.3 End and edge restraint shall be representative of field

conditions, and the unit shall contain sufficient individual

componentstominimizetheeffectofvariationsinmaterialand

workmanship.

5. Significance and Use

5.1 This test method provides a standard procedure to

evaluate or confirm structural performance under uniform

static air pressure difference. This procedure is intended to

represent the effects of uniform loads on exterior building

surface elements.

5.2 Itisalsopermissibletodevelopdataforload-spantables

by interpolating between the test results at different spans.

NOTE 1—When applying the results of tests to determine allowable

design loads by application of a factor of safety, bear in mind that the

performance of a wall or roof and its components, or both, can be a

function of fabrication, installation, and adjustment. The specimen must

represent the actual structure closely. In service, the performance can also

depend on the rigidity of supporting construction and on the resistance of

components to deterioration by various causes, to vibration, to thermal

expansion and contraction, and so forth.

6. Apparatus

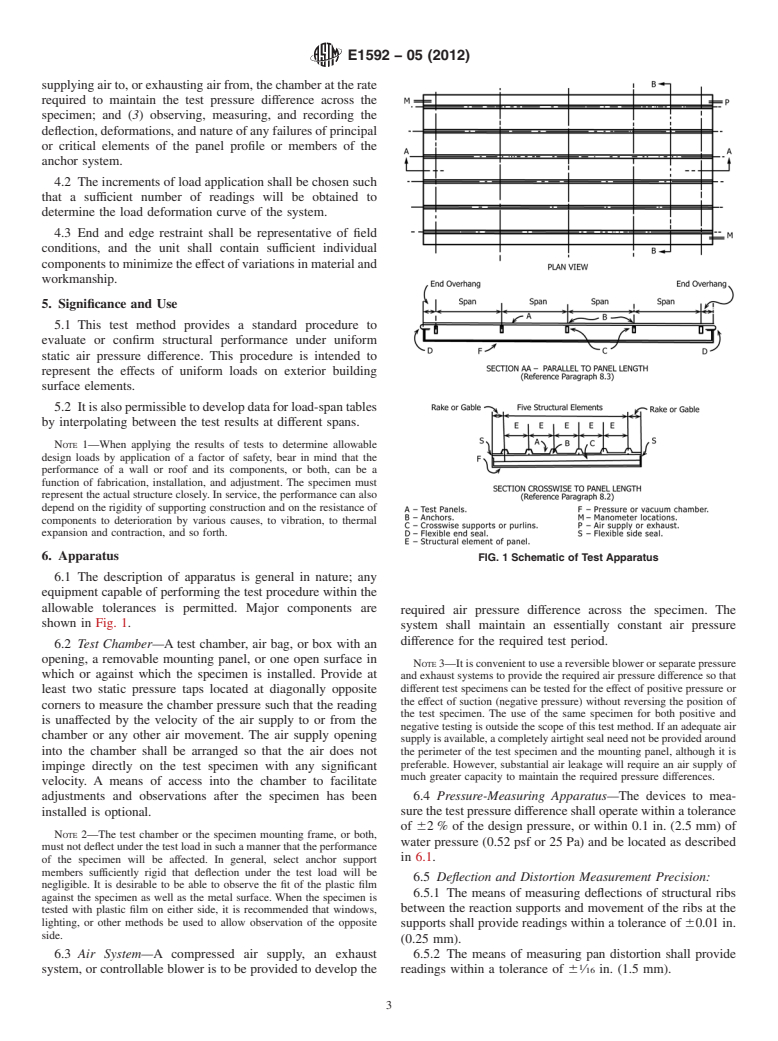

FIG. 1 Schematic of Test Apparatus

6.1 The description of apparatus is general in nature; any

equipment capable of performing the test procedure within the

allowable tolerances is permitted. Major components are

required air pressure difference across the specimen. The

shown in Fig. 1.

system shall maintain an essentially constant air pressure

difference for the required test period.

6.2 Test Chamber—A test chamber, air bag, or box with an

opening, a removable mounting panel, or one open surface in

NOTE3—Itisconvenienttouseareversibleblowerorseparatepressure

which or against which the specimen is installed. Provide at

and exhaust systems to provide the required air pressure difference so that

different test specimens can be tested for the effect of positive pressure or

least two static pressure taps located at diagonally opposite

the effect of suction (negative pressure) without reversing the position of

corners to measure the chamber pressure such that the reading

the test specimen. The use of the same specimen for both positive and

is unaffected by the velocity of the air supply to or from the

negative testing is outside the scope of this test method. If an adequate air

chamber or any other air movement. The air supply opening

supply is available, a completely airtight seal need not be provided around

into the chamber shall be arranged so that the air does not the perimeter of the test specimen and the mounting panel, although it is

preferable. However, substantial air leakage will require an air supply of

impinge directly on the test specimen with any significant

much greater capacity to maintain the required pressure differences.

velocity. A means of access into the chamber to facilitate

adjustments and observations after the specimen has been 6.4 Pressure-Measuring Apparatus—The devices to mea-

surethetestpressuredifferenceshalloperatewithinatolerance

installed is optional.

of 62 % of the design pressure, or within 0.1 in. (2.5 mm) of

NOTE 2—The test chamber or the specimen mounting frame, or both,

water pressure (0.52 psf or 25 Pa) and be located as described

must not deflect under the test load in such a manner that the performance

in 6.1.

of the specimen will be affected. In general, select anchor support

members sufficiently rigid that deflection under the test load will be

6.5 Deflection and Distortion Measurement Precision:

negligible. It is desirable to be able to observe the fit of the plastic film

6.5.1 The means of measuring deflections of structural ribs

against the specimen as well as the metal surface. When the specimen is

between the reaction supports and movement of the ribs at the

tested with plastic film on either side, it is recommended that windows,

lighting, or other methods be used to allow observation of the opposite

supports shall provide readings within a tolerance of 60.01 in.

side.

(0.25 mm).

6.3 Air System—A compressed air supply, an exhaust 6.5.2 The means of measuring pan distortion shall provide

system, or controllable blower is to be provided to develop the readings within a tolerance of 6 ⁄16 in. (1.5 mm).

E1592 − 05 (2012)

A

TABLE 1 Minimum Number of Equal Spans To Comply With

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.