ASTM E2207-15(2021)

(Practice)Standard Practice for Strain-Controlled Axial-Torsional Fatigue Testing with Thin-Walled Tubular Specimens

Standard Practice for Strain-Controlled Axial-Torsional Fatigue Testing with Thin-Walled Tubular Specimens

SIGNIFICANCE AND USE

4.1 Multiaxial forces often tend to introduce deformation and damage mechanisms that are unique and quite different from those induced under a simple uniaxial loading condition. Since most engineering components are subjected to cyclic multiaxial forces it is necessary to characterize the deformation and fatigue behaviors of materials in this mode. Such a characterization enables reliable prediction of the fatigue lives of many engineering components. Axial-torsional loading is one of several possible types of multiaxial force systems and is essentially a biaxial type of loading. Thin-walled tubular specimens subjected to axial-torsional loading can be used to explore behavior of materials in two of the four quadrants in principal stress or strain spaces. Axial-torsional loading is more convenient than in-plane biaxial loading because the stress state in the thin-walled tubular specimens is constant over the entire test section and is well-known. This practice is useful for generating fatigue life and cyclic deformation data on homogeneous materials under axial, torsional, and combined in- and out-of-phase axial-torsional loading conditions.

SCOPE

1.1 The standard deals with strain-controlled, axial, torsional, and combined in- and out-of-phase axial torsional fatigue testing with thin-walled, circular cross-section, tubular specimens at isothermal, ambient and elevated temperatures. This standard is limited to symmetric, completely-reversed strains (zero mean strains) and axial and torsional waveforms with the same frequency in combined axial-torsional fatigue testing. This standard is also limited to characterization of homogeneous materials with thin-walled tubular specimens and does not cover testing of either large-scale components or structural elements.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2207 − 15 (Reapproved 2021)

Standard Practice for

Strain-Controlled Axial-Torsional Fatigue Testing with Thin-

1

Walled Tubular Specimens

This standard is issued under the fixed designation E2207; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope rials at Room Temperature

E83 Practice for Verification and Classification of Exten-

1.1 The standard deals with strain-controlled, axial,

someter Systems

torsional, and combined in- and out-of-phase axial torsional

E111 Test Method for Young’s Modulus, Tangent Modulus,

fatigue testing with thin-walled, circular cross-section, tubular

and Chord Modulus

specimens at isothermal, ambient and elevated temperatures.

E112 Test Methods for Determining Average Grain Size

This standard is limited to symmetric, completely-reversed

E143 Test Method for Shear Modulus at Room Temperature

strains (zero mean strains) and axial and torsional waveforms

E209 PracticeforCompressionTestsofMetallicMaterialsat

with the same frequency in combined axial-torsional fatigue

Elevated Temperatures with Conventional or Rapid Heat-

testing. This standard is also limited to characterization of

ing Rates and Strain Rates

homogeneous materials with thin-walled tubular specimens

E467 Practice for Verification of Constant Amplitude Dy-

and does not cover testing of either large-scale components or

namic Forces in an Axial Fatigue Testing System

structural elements.

E606/E606M Test Method for Strain-Controlled Fatigue

1.2 This standard does not purport to address all of the

Testing

safety concerns, if any, associated with its use. It is the

E1012 Practice for Verification of Testing Frame and Speci-

responsibility of the user of this standard to establish appro-

men Alignment Under Tensile and Compressive Axial

priate safety, health, and environmental practices and deter-

Force Application

mine the applicability of regulatory limitations prior to use.

E1417/E1417M Practice for Liquid Penetrant Testing

1.3 This international standard was developed in accor-

E1444/E1444M Practice for Magnetic Particle Testing

dance with internationally recognized principles on standard-

E1823 TerminologyRelatingtoFatigueandFractureTesting

ization established in the Decision on Principles for the

E2624 Practice for Torque Calibration of Testing Machines

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

3. Terminology

Barriers to Trade (TBT) Committee.

3.1 Definitions—The terms specific to this practice are

defined in this section.All other terms used in this practice are

2. Referenced Documents

in accordance with Terminologies E6 and E1823.

2

2.1 ASTM Standards:

3.2 Definitions of Terms Specific to This Standard:

E3 Guide for Preparation of Metallographic Specimens

3.2.1 axial strain—refers to engineering axial strain, ε, and

E4 Practices for Force Verification of Testing Machines

is defined as change in length divided by the original length

E6 Terminology Relating to Methods of Mechanical Testing

(∆L /L ).

E8/E8M Test Methods for Tension Testing of Metallic Ma- g g

terials

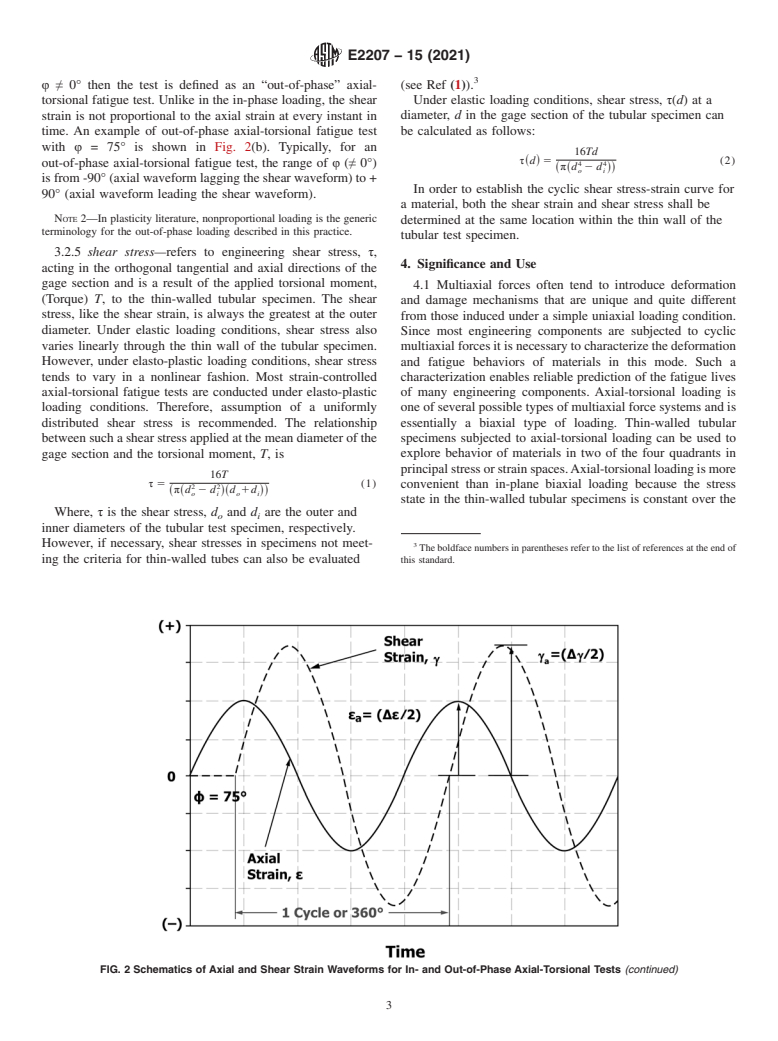

3.2.2 shear strain—refers to engineering shear strain, γ,

E9 Test Methods of Compression Testing of Metallic Mate- resulting from the application of a torsional moment to a

cylindrical specimen. Such a torsional shear strain is simple

shear and is defined similar to axial strain with the exception

1

This practice is under the jurisdiction ofASTM Committee E08 on Fatigue and

that the shearing displacement, ∆L is perpendicular to rather

s

Fracture and is the direct responsibility of Subcommittee E08.05 on Cyclic

thanparalleltothegagelength, L ,thatis,γ=∆L/L (seeFig.

g s g

Deformation and Fatigue Crack Formation.

1).

Current edition approved June 1, 2021. Published June 2021. Originally

3.2.2.1 Discussion—γ= is related to the angles of twist, θ

approved in 2002. Last previous edition approved in 2015 as E2207–15. DOI:

10.1520/E2207-15R21.

and Ψ as follows:

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

γ = tan Ψ, where Ψ is the angle of twist along the gage

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

length of the cylindrical specimen. For small angles ex-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. pressed in radians, tan Ψ approaches Ψ and γ approaches Ψ.

Copyright © ASTM International, 100 Barr Harbor Dr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.