ASTM D3337-91(2002)

(Test Method)Standard Test Method for Determining Life and Torque of Lubricating Greases in Small Ball Bearings (Withdrawn 2009)

Standard Test Method for Determining Life and Torque of Lubricating Greases in Small Ball Bearings (Withdrawn 2009)

SIGNIFICANCE AND USE

This test method is a screening test to differentiate among the expected life of greases in ball bearings running at high temperatures. If torque is a factor in selection of a grease, the test method provides for measurements at both low (1 r/min) and high (12 000 r/min) speeds.

SCOPE

1.1 This test method describes a procedure for the determination of grease life and torque in small bearings. Although this test method is not the equivalent of a long-time field-service test, it is intended to predict the relative grease life at high temperature in a reasonable period of testing time. In addition, this test method measures the running torque at both low (1 r/min) and high (12 000 r/min) speeds.

1.2 Except for torque, which is measured in gcm, the values stated in inch-pound units are to be regarded as the standard in this test method. The SI values given in parenthesis are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method describes a procedure for the determination of grease life and torque in small bearings. Although this test method is not the equivalent of a long-time ASTM 100HARBOR WEST CONSHOHOCKEN, PAfield-service test, it is intended to predict the relative grease life at high temperature in a reasonable period of testing time. In addition, this test method measures the running torque at both low (1 r/min) and high (12 000 r/min) speeds.

Formerly under the jurisdiction of Committee F34 on Rolling Element Bearings, this test method was withdrawn in July 2009 due to the unavailability of test apparatus. There is no replacement of this test method.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3337–91(Reapproved2002)

Standard Test Method for

Determining Life and Torque of Lubricating Greases in

Small Ball Bearings

This standard is issued under the fixed designation D 3337; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Significance and Use

1.1 This test method describes a procedure for the determi- 4.1 This test method is a screening test to differentiate

nationofgreaselifeandtorqueinsmallbearings.Althoughthis among the expected life of greases in ball bearings running at

test method is not the equivalent of a long-time field-service high temperatures. If torque is a factor in selection of a grease,

test, it is intended to predict the relative grease life at high the test method provides for measurements at both low (1

temperature in a reasonable period of testing time. In addition, r/min) and high (12 000 r/min) speeds.

this test method measures the running torque at both low (1

5. Apparatus

r/min) and high (12 000 r/min) speeds.

5.1 The apparatus required for this test method is described

1.2 Exceptfortorque,whichismeasureding·cm,thevalues

stated in inch-pound units are to be regarded as the standard in in detail inAnnexA1.Anew R-4 bearing is used for each test.

It is run at 12 000 r/min ⁄2-lbf (2.2-N) radial load and 5-lbf

this test method. The SI values given in parenthesis are for

information only. (22-N) axial load.

1.3 This standard does not purport to address all of the

6. Reagents and Materials

safety concerns, if any, associated with its use. It is the

6.1 Grease Sample—Procure the grease sample from below

responsibility of the user of this standard to establish appro-

the surface of the grease container. Do not let separated oil get

priate safety and health practices and determine the applica-

in contact with the sample; pour the excess oil off if present.

bility of regulatory limitations prior to use.

Screen the grease using a 40-µm retention filter. A technique

2. Terminology

for screening is described in Annex A2.

2.1 Definitions of Terms Specific to This Standard: 6.2 Test Bearing:

6.2.1 Specifications—the test bearing is size R-4.

2.1.1 grease life—a measure of the durability of the grease

in a small bearing at elevated temperatures. 6.2.2 Size—0.2500 in. (6.350 mm) bore, 0.6250 in. (15.875

mm) OD, 0.1960 in. (4.978 mm) wide.

2.1.2 grease torque—a measure of the amount of friction

due to viscous shear of the grease. 6.2.3 Material—Type 440C stainless steel, heat stabilized.

6.2.4 Precision Class—AFBMA (Anti-Friction Bearing

2.1.3 running torque—a measure of the amount of friction

in a rotating bearing due to load, speed, and viscous shear of Manufacturers Association) Class 7.

6.2.5 Radial Clearance—0.0003 to 0.0005 in. (0.007 to

the grease.

0.013 mm).

3. Summary of Test Method

6.2.6 Retainer—stainless steel ribbon type.

3.1 Asingle row ball bearing with the test lubricating grease 6.2.7 Shields—removable with snap rings.

is rotated at a high speed under a constant load and selected 6.2.8 Packaging—bearing,shields,andsnapringspackaged

temperature. Total running time is determined at completion of individually in clean and sealed envelopes.

the test as a measure of the durability of the grease.

7. Grease Packing of Test Bearing

3.2 Running torque can be obtained for a single row ball

bearing with the test lubricating grease rotating at 1 r/min and 7.1 Pack the test bearing in a clean environment with a

quantity of test grease to fill one third of the free space in the

12 000 r/min.

bearing.

This test method is under the jurisdiction ofASTM Committee F34 on Rolling

Element Bearings and is the direct responsibility of Subcommittee F34.02 on

Tribology. AsuitablebearingisBardenNo.SR4SSW4,shippedwithoutlubricantandwith

Current edition approved Oct. 10, 2002. Published March 2003. Originally shields and snap rings unassembled, available from O. P. Schuman and Sons, Inc.,

approved in 1974. Last previous edition approved in 1996 as D 3337 - 91 (1996). County Line and Titus Rd., Warrington, PA 18976.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3337–91 (2002)

7.2 If it is necessary to determine the free space of a 8.1.2.1 With the spring-loaded thermocouple retracted, push

weighedbearing,placethebearing(withshieldsandsnaprings a new test bearing into the housing. Use the nose cone to seat

removed)inacontainerofmeltedpetrolatumofknowndensity the test bearing fully. This avoids thumb pressure on the inner

under vacuum. Let the petrolatum harden, remove bearing, and race and shields which can damage the bearing.

replace shields and snap rings. Clean the bearing of excess 8.1.2.2 Hold the housing up above the tester and let the

petrolatum and determine the weight increase. Using the thermocouple plug with wires and the radial bead chain drop

densityofpetrolatumandbearingweightincrease,computethe down through the slot in the mounting plate. Caution: Use

bearing free space. For the Barden bearing No. SR4SSW4, the care to ensure that the transducer-core extension is not bumped

one-third free space is 0.080 mL. and that the thermocouple lead wires are not bent to prevent

7.3 The test bearing may be packed on either a weight or a erroneous data.

volume basis. A small spatula or a small syringe with a short 8.1.2.3 Slidethetestbearingandhousingovertheendofthe

needle can be used to place the test grease between the balls on spindle until the test bearing seats against the slinger.

both sides of the test bearing. 8.1.2.4 Insert the thermocouple plug and attach the radial

7.4 If the test bearing is packed on a weight basis, the bead chain to its cantilever with three beads below the beam.

density of the grease must be known in order to compute the 8.1.2.5 Install the test-bearing lock nut (Note 2) finger tight

weight of test grease equivalent to one-third the free space in with the shoulder end toward the test bearing. Then fully

the test bearing. tighten the nut using two small wrenches and following the

7.5 Immediately after packing the test grease in the test technique in 8.1.1.4.

bearing, install the shields and snap rings. Then turn the

NOTE 2—If the test bearing runs at temperatures above 300°F (150°C),

bearing 100 revolutions in each direction at less than 200 r/min

lubricate the nut and screw threads with a solid lubricant such as

to distribute the test grease.

molybdenum disulfide to prevent thread galling.

8.1.2.6 Attach the nose cone with the bead chain slot

8. Procedure

upward using the four small screws.

8.1 This procedure describes removal of a used test bearing,

8.1.2.7 Attach the axial bead chain to its cantilever beam

installation of a new test bearing, start-up technique, and test

with three beads beyond the beam.

monitoring.

8.1.2.8 Usinga0to 5-lbf (0 to 22-N) spring scale, check the

8.1.1 Test Bearing Removal:

cantilever beams (Note 3) for ⁄2-lbf (2.2-N) radial loading and

8.1.1.1 Remove the heater box.

5-lbf axial loading.

8.1.1.2 Unlatch the radial and axial bead chains from the

NOTE 3—Cantilever beam loads can be changed by bending the beams.

cantilever beams and unplug the test-bearing outer-race ther-

After bending, use a 6-in. (150 mm) machinist square and a straightedge

mocouple cable from the post at the side of the tester.

to ensure that the radial-bead chain is perpendicular to the base and that

8.1.1.3 Remove the nose cone by removing the four screws

the axial bead chain is in line with the centerline of the spindle.

which attach it to the test-bearing housing.

8.1.2.9 Check the thermocouple lead wires to be sure they

8.1.1.4 Using two small wrenches, one on the test-bearing

are freely suspended and smoothly contoured from the torque

lock nut and one on the spindle flats next to the nut, loosen the

arm to the plug.

test-bearing lock nut. This is done safely by having the wrench

8.1.2.10 Carefully place the heater box over the test-bearing

handles about 20 deg apart and squeezing them toward each

housing.

other to avoid a bending moment on the overhung end of the

8.1.3 Start-up Technique:

spindle.

8.1.3.1 To relieve drive-belt tension, prop up the pivoted-

8.1.1.5 Remove the test-bearing lock nut.

drive motor using a block of wood.

8.1.1.6 Slide the test bearing housing off the end of the

8.1.3.2 Turn the run-time meter to zero.

spindle and lift slowly in a vertical direction until the torque

8.1.3.3 Set the cycle timer to 20 % (zero to 17 % is the 4-h

arm,itsbeadchain,andthethermocouplewireswithplugclear

shutdown interval).

the slot in the mounting plate. Do not remove the slinger.

8.1.3.4 Set the torque-meter cut-off at 80 % of full scale.

8.1.1.7 Push (Note 1) the used test bearing out of its

8.1.3.5 Set the temperature controller (left-hand pointer) to

housing.

about 20°F (10°C) below the intended outer-race test-bearing

NOTE 1—A ⁄8-in. (9.5-mm) diameter by 6-in. (150-mm) long wooden

temperature. Set and maintain the over-temperature cut-off

1 3

dowel with one end turned down to ⁄4 in. (6.4 mm) diameter for ⁄16 in.

(right-hand pointer) 15°F (9°C) above the control temperature

(4.8 mm) is useful in pushing out the test bearing.

(the temperature controller is connected to the thermocouple in

8.1.1.8 Rotatetheouterraceoftheusedtestbearingbyhand

the heater box).

to determine roughness, stickiness, etc. Tag the bearing, noting

8.1.3.6 Turn on the following switches: 110 V a-c, torque,

date, run number, grease code, running hours, and condition of

heater, and high-speed motor. Then push the start button to

bearing.

activate circuits.

8.1.2 Test Bearing Installation:

8.1.3.7 Gradually slide the prop out from under the drive-

motor base until the spindle runs at low speed with a slack belt.

Fingerpressureonthespindleaidsinkeepingalowspeed.Run

A suitable micrometer syringe is Catalog No. N-07844-00, 0.2-mL capacity,

for about ⁄2 min at low speed before removing the prop to

manufactured by Cole-Parmer Instruments Co., 7425 North Oak Park Ave.,

Chicago, IL 60648. bring the spindle up to test speed.

D3337–91 (2002)

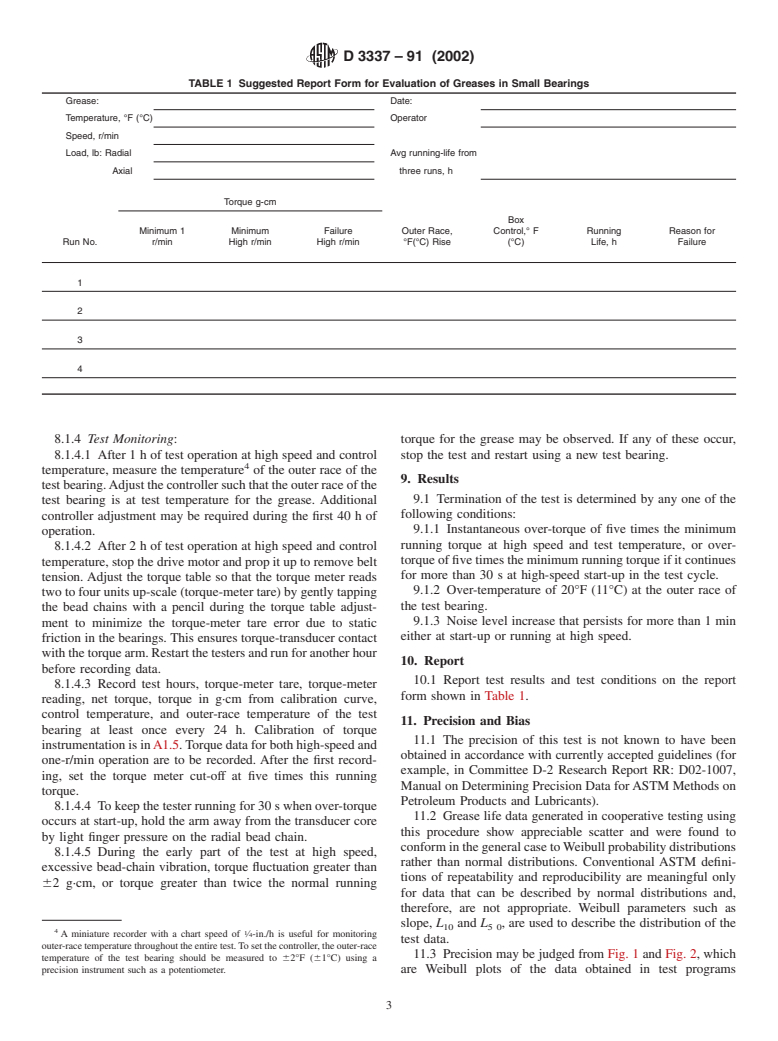

TABLE 1 Suggested Report Form for Evaluation of Greases in Small Bearings

Grease: Date:

Temperature, °F (°C) Operator

Speed, r/min

Load, lb: Radial Avg running-life from

Axial three runs, h

Torque g-cm

Box

Minimum 1 Minimum Failure Outer Race, Control,° F Running Reason for

Run No. r/min High r/min High r/min °F(°C) Rise (°C) Life, h Failure

8.1.4 Test Monitoring: torque for the grease may be observed. If any of these occur,

8.1.4.1 After1hof test operation at high speed and control stop the test and restart using a new test bearing.

temperature, measure the temperature of the outer race of the

9. Results

testbearing.Adjustthecontrollersuchthattheouterraceofthe

9.1 Termination of the test is determined by any one of the

test bearing is at test temperature for the grease. Additional

following conditions:

controller adjustment may be required during the first 40 h of

9.1.1 Instantaneous over-torque of five times the minimum

operation.

running torque at high speed and test temperature, or over-

8.1.4.2 After2hof test operation at high speed and control

torque of five times the minimum running torque if it continues

temperature, stop the drive motor and prop it up to remove belt

for more than 30 s at high-speed start-up in the test cycle.

tension. Adjust the torque table so that the torque meter reads

9.1.2 Over-temperature of 20°F (11°C) at the outer race of

two to four units up-scale (torque-meter tare) by gently tapping

the test bearing.

the bead chains with a pencil during the torque table adjust-

9.1.3 Noise level increase that persists for more than 1 min

ment to minimize the torque-meter tare error due to static

either at start-up or running at high speed.

friction in the bearings. This ensures torque-transducer contact

withthetorquearm.Restartthetestersandrunforanotherhour

10. Report

before recording data.

10.1 Report test results and test conditions on the report

8.1.4.3 Record test hours, torque-meter tare, torque-meter

form shown in Table 1.

reading, net torque, torque in g·cm from calibration curve,

control temperature, and outer-race temperature of the test

11. Precision and Bias

bearing at least once every 24 h. Calibration of torque

11.1 The precision of this test is not known to have been

instrumentationisinA1.5.Torquedataforbothhigh-speedand

obtained in accordance with currently accepted guidelines (for

one-r/min operation are to be recorded. After the first record-

example, in Committee D-2 Research Report RR: D02-1007,

ing, set the torque meter cut-off at five times this running

Manual on Determining Precision Data forASTM Methods on

torque.

Petroleum Products and Lubricants).

8.1.4.4 To keep the tester running for 30 s when over-torque

11.2 Grease life data generated in cooperative testing using

occurs at start-up, hold the arm away from the transducer core

this procedure show appreciable scatter and were found to

by light finger pressure on the radial bead chain.

conforminthegeneralcasetoWeibullprobabilitydistributions

8.1.4.5 During the early part of the test at high speed,

rather than normal distributions. Conventional ASTM defini-

excessive bead-chain vibration, torque fluctuation greater than

tions of repeatability and reproducibility are meaningful only

62 g·cm, or torque greater than twice the normal running

for data that can be described by normal distributions and,

therefore, are not appropriate. Weibull parameters such as

slope, L and L , are used to describe the distribution of the

10 50

A miniature recorder with a chart speed of ⁄4-in./h is useful for monitoring

test data.

outer-racetemperaturethroughouttheentiretest.Tosetthecontroller,theouter-race

11.3 Precision may be judged from Fig. 1 and Fig. 2, which

temperature of the test bearing should be measured to 62°F (61°C) using a

precision instrument such as a potentiometer. are Weibull plots of the data obtained in test programs

D3337–91 (2002)

FIG. 1 Weibull Parameter of Grease A

TABLE 3 Precision—Summary of Cooperative Testing Program

involving two greases and seven cooperators. Weibull param-

eters calculated for the data are summarized in Table 2. Failure Lives, h

Mean Range for Center

50 % of Results

TABLE 2 Precision—Summary of Weibull Parameters

Grease A 151 130 to 180

(Figs. 1 and 2)

Grease B 297 220 to 388

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.