ASTM D7280-06

(Test Method)Standard Test Method for Quinoline-Insoluble (QI) Content of Tar and Pitch by Stainless Steel Crucible Filtration

Standard Test Method for Quinoline-Insoluble (QI) Content of Tar and Pitch by Stainless Steel Crucible Filtration

SIGNIFICANCE AND USE

This test method is useful in evaluating and characterizing tar and pitch. It is also useful as one element in establishing the uniformity of shipments and sources of supply.

SCOPE

1.1 This test method covers the determination of the quinoline-insoluble matter (QI) in tar and pitch using a stainless steel filtering crucible and a filtration membrane.

1.2 This test method was evaluated in round robin testing using materials in the range of zero to twenty quinoline insoluble weight percent (wt%).

1.3 Since this test method is empirical, strict adherence to all details of the procedure is necessary.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D7280–06

Standard Test Method for

Quinoline-Insoluble (QI) Content of Tar and Pitch by

Stainless Steel Crucible Filtration

This standard is issued under the fixed designation D 7280; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method covers the determination of the

quinoline-insoluble matter (QI) in tar and pitch using a

3. Summary of Test Method

stainless steel filtering crucible and a filtration membrane.

3.1 Thesampleisdigestedinhotquinolineandfiltered.The

1.2 This test method was evaluated in round robin testing

insoluble material is washed, dried, and weighed.

using materials in the range of zero to twenty quinoline

insoluble weight percent (wt%).

4. Significance and Use

1.3 Since this test method is empirical, strict adherence to

4.1 This test method is useful in evaluating and character-

all details of the procedure is necessary.

izing tar and pitch. It is also useful as one element in

1.4 The values stated in SI units are to be regarded as

establishingtheuniformityofshipmentsandsourcesofsupply.

standard. No other units of measurement are included in this

standard.

5. Apparatus

1.5 This standard does not purport to address all of the

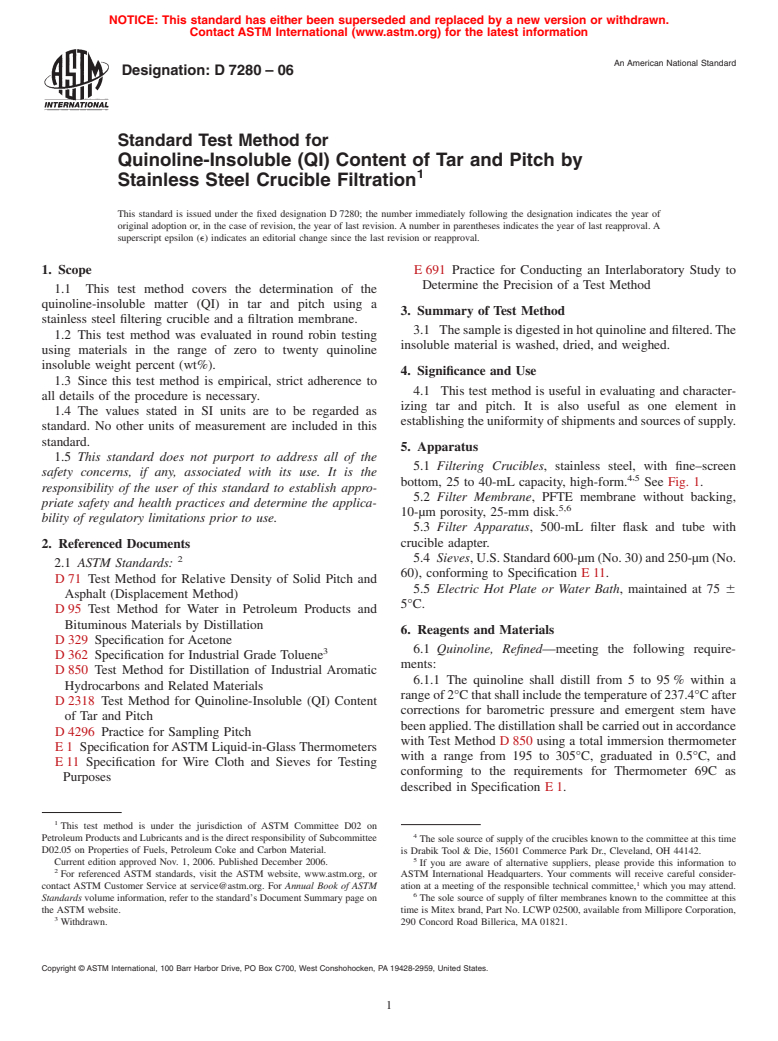

5.1 Filtering Crucibles, stainless steel, with fine–screen

safety concerns, if any, associated with its use. It is the

4,5

bottom, 25 to 40-mL capacity, high-form. See Fig. 1.

responsibility of the user of this standard to establish appro-

5.2 Filter Membrane, PFTE membrane without backing,

priate safety and health practices and determine the applica-

5,6

10-µm porosity, 25-mm disk.

bility of regulatory limitations prior to use.

5.3 Filter Apparatus, 500-mL filter flask and tube with

crucible adapter.

2. Referenced Documents

2 5.4 Sieves,U.S.Standard600-µm(No.30)and250-µm(No.

2.1 ASTM Standards:

60), conforming to SpecificationE11.

D71 Test Method for Relative Density of Solid Pitch and

5.5 Electric Hot Plate or Water Bath, maintained at 75 6

Asphalt (Displacement Method)

5°C.

D95 Test Method for Water in Petroleum Products and

Bituminous Materials by Distillation

6. Reagents and Materials

D 329 Specification for Acetone

6.1 Quinoline, Refined—meeting the following require-

D 362 Specification for Industrial Grade Toluene

ments:

D 850 Test Method for Distillation of Industrial Aromatic

6.1.1 The quinoline shall distill from 5 to 95 % within a

Hydrocarbons and Related Materials

rangeof2°Cthatshallincludethetemperatureof237.4°Cafter

D 2318 Test Method for Quinoline-Insoluble (QI) Content

corrections for barometric pressure and emergent stem have

of Tar and Pitch

beenapplied.Thedistillationshallbecarriedoutinaccordance

D 4296 Practice for Sampling Pitch

with Test Method D 850 using a total immersion thermometer

E1 Specification forASTM Liquid-in-Glass Thermometers

with a range from 195 to 305°C, graduated in 0.5°C, and

E11 Specification for Wire Cloth and Sieves for Testing

conforming to the requirements for Thermometer 69C as

Purposes

described in SpecificationE1.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee The sole source of supply of the crucibles known to the committee at this time

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material. is Drabik Tool & Die, 15601 Commerce Park Dr., Cleveland, OH 44142.

Current edition approved Nov. 1, 2006. Published December 2006. If you are aware of alternative suppliers, please provide this information to

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ASTM International Headquarters. Your comments will receive careful consider-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM ation at a meeting of the responsible technical committee, which you may attend.

Standards volume information, refer to the standard’s Document Summary page on The sole source of supply of filter membranes known to the committee at this

the ASTM website. time is Mitex brand, Part No. LCWP 02500, available from Millipore Corporation,

Withdrawn. 290 Concord Road Billerica, MA 01821.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7280–06

FIG. 1 Stainless Steel Filtering Crucible with Support Disk

6.1.2 The quinoline shall have a specific gravity at 15.5/ color, and contains less than 0.5 % water, filter the quinoline

15.5°C of 1.092 to 1.098, as determined by Test MethodD71, through a crucible containing5gof diatomaceous earth filter

7,6

aid.

or another method of equivalent accuracy.

6.1.4 Store the quinoline in a tightly closed, dark bottle.

6.1.3 Thequinolineshallbeclearandlightincolorandshall

6.2 Toluene, Industrial Pure, meeting Specification D 362.

contain less than 0.5 volume % of water, as determined byTest

Method D95. If not, redistill the quinoline in all-glass appa-

ratus, discarding the first 5 % and collecting the next 90 %. If 7

The sole source of supply of the diatomaceous earth filter aid known to the

the quinoline contains suspended matter but is clear, light in committee at this time is Celite, available fromWorld Minerals, Santa Barbara, CA.

D7280–06

6.3 Acetone, meeting Specification D 329. crusher and a Mullite mortar and pestle. No particle in the

6.4 Filter Aid—Dry to constant weight at 105°C, and store representative sample shall be larger than 5 mm in any

dimension.

in tightly stoppered container.

10.1.1 Crush this sample so that all of it will pass the

NOTE 1—Manville Certified Analytical Filter Aid (CAFA) or Supelco/

250-µm (No. 60) sieve but will have a minimum of fine

Sigma Aldrich (CAFA II) Part #11485U were used in determining

particles.

precision and bias and were found to give acceptable filtration perfor-

mance.Any other grade of filter aid may differ in filtration characteristics. 10.1.2 Store the sieved working sample in a tightly closed

container, and use within 24 h (see 10.4).

7. Hazards

10.2 Soft Pitch—If the pitch is too soft to grind and too

stickytomix,heatarepresentativeportionofthedrysampleto

7.1 Fumes of the solvents should be removed by means of

the lowest temperature that will permit passage through the

proper hoods from all working areas.

600-µm (No. 30) sieve, taking care to avoid excessive loss of

7.2 The working area should be kept free of sparks and

volatile matter. Do not exceed 10 min for this melting period.

flames.

10.2.1 Pass the heated sample through the 600-µm sieve to

7.3 Quinoline fumes should not be inhaled, and prolonged

remove foreign matter.

contact with the skin should be avoided.

10.3 Tar—Heat a representative portion of the dry tar to the

7.4 Toluene is toxic and flammable.

lowest temperature that will permit passage through the

600-µm (No. 30) sieve, then filter through this sieve to remove

8. Bulk Sampling

foreign matter.

8.1 Samples from shipments shall be taken in accordance

10.4 Preservation of Samples—Store samples as large

with Practice D 4296 and shall be free of foreign substances.

lumps or as solidified melts in closed containers. Discard

Thoroughly mix the sample immediately before removing a

working samples 24 h after crushing and sieving as changes in

representative portion for the determination or for dehydration.

composition sometimes occur in pulverized pitch.

9. Dehydration of Sample

11. Filter Crucible Preparation

9.1 Hard Pitch—If the solid bulk sample contains free

11.1 Unscrew the bottom ring of the filtering crucible and

water, air-dry a representative portion in a forced draft oven at

inspect the support disk and the ring surfaces to be certain that

50°C.

they are free of any foreign particles.

9.2 Soft Pitch—If the presence of water is indicated by

11.2 Placethesupportingdiskbackintotheringandseatthe

surface foam on heating, maintain a representative portion of

disk on the inside supporting shoulder of the ring.

the bulk sample at a temperature between 125 and 150°C in an

11.3 Using forceps, carefully place a single membrane over

open container until the surface is free of foam. Take care not

the threaded part of the ring onto the support disk. The

to overheat, and remove heat source immediately when foam

membrane must be centered exactly within the threaded hole.

subsides.

11.4 Screw the barrel into the ring assembly until it is finger

9.3 Tar—Awettarsamplemayeitherbedehydratedorused

tight. Do not overtighten the barrel and ring.

as received as long as conditions stated in 9.3.1 and 9.3.3 are

met.

12. Procedure

9.3.1 Dehydrate a representative portion of the bulk sample

at atmospheric pressure using a simple side-arm distillation 12.1 Make and record all weighings to the nearest 1 mg.

apparatussimilartotheoneinTestMethodD 850,andstopthe

12.2 Select a sample mass that will yield between 75 and

distillation when the temper

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.