ASTM C1461-00

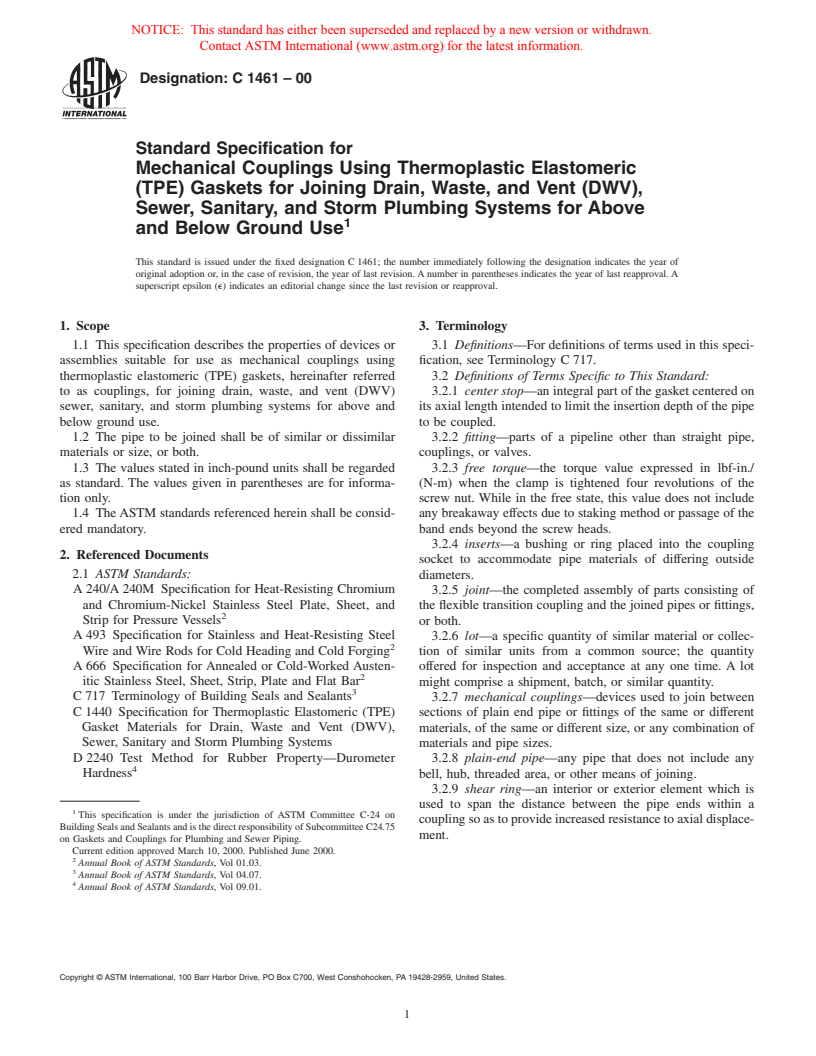

(Specification)Standard Specification for Mechanical Couplings Using Thermoplastic Elastomeric (TPE) Gaskets for Joining Drain, Waste, and Vent (DWV), Sewer, Sanitary, and Storm Plumbing Systems for Above and Below Ground Use

Standard Specification for Mechanical Couplings Using Thermoplastic Elastomeric (TPE) Gaskets for Joining Drain, Waste, and Vent (DWV), Sewer, Sanitary, and Storm Plumbing Systems for Above and Below Ground Use

SCOPE

1.1 This specification describes the properties of devices or assemblies suitable for use as mechanical couplings using thermoplastic elastomeric (TPE) gaskets, hereinafter referred to as couplings, for joining drain, waste, and vent (DWV) sewer, sanitary, and storm plumbing systems for above and below ground use.

1.2 The pipe to be joined shall be of similar or dissimilar materials or size, or both.

1.3 The values stated in inch-pound units shall be regarded as standard. The values given in parentheses are for information only.

1.4 The ASTM standards referenced herein shall be considered mandatory.

General Information

Relations

Buy Standard

Standards Content (Sample)

Designation: C 1461 – 00

Standard Specification for

Mechanical Couplings Using Thermoplastic Elastomeric

(TPE) Gaskets for Joining Drain, Waste, and Vent (DWV),

Sewer, Sanitary, and Storm Plumbing Systems for Above

and Below Ground Use

This standard is issued under the fixed designation C 1461; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification describes the properties of devices or 3.1 Definitions—For definitions of terms used in this speci-

assemblies suitable for use as mechanical couplings using fication, see Terminology C 717.

thermoplastic elastomeric (TPE) gaskets, hereinafter referred 3.2 Definitions of Terms Specific to This Standard:

to as couplings, for joining drain, waste, and vent (DWV) 3.2.1 center stop—an integral part of the gasket centered on

sewer, sanitary, and storm plumbing systems for above and its axial length intended to limit the insertion depth of the pipe

below ground use. to be coupled.

1.2 The pipe to be joined shall be of similar or dissimilar 3.2.2 fitting—parts of a pipeline other than straight pipe,

materials or size, or both. couplings, or valves.

1.3 The values stated in inch-pound units shall be regarded 3.2.3 free torque—the torque value expressed in lbf-in./

as standard. The values given in parentheses are for informa- (N-m) when the clamp is tightened four revolutions of the

tion only. screw nut. While in the free state, this value does not include

1.4 TheASTM standards referenced herein shall be consid- any breakaway effects due to staking method or passage of the

ered mandatory. band ends beyond the screw heads.

3.2.4 inserts—a bushing or ring placed into the coupling

2. Referenced Documents

socket to accommodate pipe materials of differing outside

2.1 ASTM Standards:

diameters.

A 240/A 240M Specification for Heat-Resisting Chromium

3.2.5 joint—the completed assembly of parts consisting of

and Chromium-Nickel Stainless Steel Plate, Sheet, and the flexible transition coupling and the joined pipes or fittings,

Strip for Pressure Vessels

or both.

A 493 Specification for Stainless and Heat-Resisting Steel 3.2.6 lot—a specific quantity of similar material or collec-

Wire and Wire Rods for Cold Heading and Cold Forging

tion of similar units from a common source; the quantity

A 666 Specification for Annealed or Cold-Worked Austen- offered for inspection and acceptance at any one time. A lot

itic Stainless Steel, Sheet, Strip, Plate and Flat Bar

might comprise a shipment, batch, or similar quantity.

C 717 Terminology of Building Seals and Sealants 3.2.7 mechanical couplings—devices used to join between

C 1440 Specification for Thermoplastic Elastomeric (TPE)

sections of plain end pipe or fittings of the same or different

Gasket Materials for Drain, Waste and Vent (DWV), materials, of the same or different size, or any combination of

Sewer, Sanitary and Storm Plumbing Systems

materials and pipe sizes.

D 2240 Test Method for Rubber Property—Durometer 3.2.8 plain-end pipe—any pipe that does not include any

Hardness

bell, hub, threaded area, or other means of joining.

3.2.9 shear ring—an interior or exterior element which is

used to span the distance between the pipe ends within a

This specification is under the jurisdiction of ASTM Committee C-24 on

couplingsoastoprovideincreasedresistancetoaxialdisplace-

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.75

ment.

on Gaskets and Couplings for Plumbing and Sewer Piping.

Current edition approved March 10, 2000. Published June 2000.

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 04.07.

Annual Book of ASTM Standards, Vol 09.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1461–00

4. Classification 8. Sampling, Tests, and Retests

8.1 Test specimens representative of the couplings to be

4.1 The couplings shall have a center stop unless telescop-

used shall be randomly selected from the manufactured lot for

ing of the pipe is necessary for special applications. The

testing.

components shall be designed so that the elastomeric material

8.2 Notlessthantwocouplingsforeachsizeortypeshallbe

is compressed to form a hydrostatic seal when the joint is

tested, unless otherwise specified or waived by the purchaser.

assembled. The couplings shall be of the types described in

8.3 Wherethereisafailureintheoriginaltest,theentiretest

4.1.1-4.1.3.

shallbererunwithtwicethenumberofsamplesandanyfailure

4.1.1 Unshielded—A coupling consisting of an elastomeric

shall be cause for rejection.

sleeve incorporating corrosion-resistant tension bands and a

tightening mechanism. Couplings shall be fabricated without

9. Test Methods

shear rings. Couplings installed without metallic shear rings

9.1 Elastomeric Materials—Physical properties of gaskets

shall not be installed in fire-resistive construction.

shall be in accordance with specificationASTM C 1440. Many

4.1.2 Shielded—A coupling consisting of an elastomeric or

thermoplastic elastomeric gaskets are temperature-sensitive.

rubber sleeve incorporating a metallic corrosion-resistant shear

Refer to Specification C 1440 for the allowable temperature

ring and tension bands or tightening mechanism, or both.

range of materials.

4.1.3 Other—Acoupling (gasket) fabricated for elastomeric

9.2 Tension Band Performance:

compression seals. 9.2.1 Torque Resistance—Stainless steel tension bands shall

be tested to withstand 150 % of the manufacturer’s specified

installation torque without visible signs of failure. The band

5. Materials and Manufacture

shall be tested over a steel mandrel of the appropriate coupling

5.1 Elastomeric materials used in the manufacturing of

diameter and torqued as required.

couplings and inserts shall comply with the requirements in

9.2.2 The maximum free running torque shall be 4 lbf-in.

accordance with Specification C 1440.

(0.45 N-m).

5.2 The stainless steel tension band assembly shall be 300

9.2.2.1 Stainless steel tension bands with torque resistance

series stainless steel, excluding copper bearing alloys, meeting

in excess of 100 lbf-in. shall have a maximum free running

the requirements of the appropriate ASTM standard for stain-

torque of 8 lbf-in.

less steel.

9.2.3 Test Procedure for Free Running Torque:

5.3 Couplings with bushings or inserts, or both, of multi-

9.2.3.1 With the nonstressed clamp hand-held and the slot-

piece construction or with splices shall show no separation,

ted band fully engaged, the screw shall be rotated clockwise

peeling, or other defects when tested in accordance with

four revolutions with the maximum value of the torque meter

Section 9.

recorded.

9.2.3.2 The equipment required

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.