ASTM F2433-05(2013)

(Test Method)Standard Test Method for Determining Thermoplastic Pipe Wall Stiffness

Standard Test Method for Determining Thermoplastic Pipe Wall Stiffness

SIGNIFICANCE AND USE

5.1 The performance under bending and compression load of a thermoplastic plastic pipe wall design obtained by this method can be used for the following:

5.1.1 To determine the stiffness of the pipe wall section. This is a function of the pipe dimensions, the wall design, the arc length tested, and the physical properties of the material of which the pipe is made.

5.1.2 To compare the characteristics of various thermoplastic pipe wall designs.

5.1.3 To compare the characteristics of various plastics in pipe form.

5.1.4 To study the interrelations of dimensions, materials, and deformation properties of thermoplastic pipe designs.

5.1.5 To measure the deformation and load-resistance at any of several significant events which may occur during the test.

5.1.6 To provide a reasonable quality control/quality assurance test for very large diameter plastic pipes.

5.2 The time-dependent pipe wall stiffness of a thermoplastic pipe obtained by this test method may used for the following:

5.2.1 To predict the residual stiffness of the pipe wall in bending and compression at all times after initial loading.

5.2.2 For purposes of design, to determine a modulus of relaxation under sustained loads.

5.2.3 To quantify the influence of material formulations of thermoplastics on the modulus of relaxation.

5.2.4 To study the influence of geometric patterns of wall profiles on the modulus of relaxation.

5.3 The time-independent reduction of wall thickness at springline may be used for the following:

5.3.1 For pipe wall stiffness, to quantify the efficiency of all wall profiles of any material composition and a given geometry with that of a solid uniform thickness wall.

SCOPE

1.1 This test method covers the determination of the load-deflection behavior of thermoplastic pipe wall sections under parallel plate loading conditions.Note 1—These are not full pipe section tests, but pipe wall segment tests. The results of these tests will be different from pipe stiffness tests per Test Method D2412, although they may be proportional. This test provides quite different information, including , stress relaxation under constant strain, and comparisons of the function and stiffness of different pipe wall designs or materials.

1.2 This test method covers a loading test for determining the wall stiffness of a thermoplastic-pipe wall under a combined load of bending and compression. Changes in pipe wall profile geometry under load may also be determined.

1.3 This test method covers thermoplastic pipe.

1.4 The characteristics determined by this test method are wall stiffness and changes in profile wall dimensions at specific deformations.

1.5 The characteristics determined by this test method are wall stiffness, profile wall efficiency, and for some wall elements stability at specific Strain levels.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 The text of this specification references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2433 − 05 (Reapproved 2013)

Standard Test Method for

Determining Thermoplastic Pipe Wall Stiffness

This standard is issued under the fixed designation F2433; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the determination of the load-

D618 Practice for Conditioning Plastics for Testing

deflection behavior of thermoplastic pipe wall sections under

D695 Test Method for Compressive Properties of Rigid

parallel plate loading conditions.

Plastics

NOTE 1—These are not full pipe section tests, but pipe wall segment

D883 Terminology Relating to Plastics

tests.Theresultsofthesetestswillbedifferentfrompipestiffnesstestsper

D1600 Terminology forAbbreviatedTerms Relating to Plas-

TestMethodD2412,althoughtheymaybeproportional.Thistestprovides

quite different information, including , stress relaxation under constant

tics

strain, and comparisons of the function and stiffness of different pipe wall

D2122 Test Method for Determining Dimensions of Ther-

designs or materials.

moplastic Pipe and Fittings

D2412 Test Method for Determination of External Loading

1.2 This test method covers a loading test for determining

Characteristics of Plastic Pipe by Parallel-Plate Loading

the wall stiffness of a thermoplastic-pipe wall under a com-

F412 Terminology Relating to Plastic Piping Systems

bined load of bending and compression. Changes in pipe wall

2.2 AASHTO Standards:

profile geometry under load may also be determined.

M 252 Standard Specification for Corrugated Polyethylene

1.3 This test method covers thermoplastic pipe.

Drainage Pipe

M 294 Standard Specification for Corrugated Polyethylene

1.4 The characteristics determined by this test method are

Pipe, 300- to 1500-mm Diameter

wallstiffnessandchangesinprofilewalldimensionsatspecific

deformations.

3. Terminology

1.5 The characteristics determined by this test method are

3.1 Definitions—Definitions are in accordance with Termi-

wall stiffness, profile wall efficiency, and for some wall

nology F412, and abbreviations are in accordance with Termi-

elements stability at specific Strain levels.

nology D1600, unless otherwise specified.

3.2 Definitions of Terms Specific to This Standard:

1.6 The values stated in SI units are to be regarded as the

3.2.1 chord shortening, n—the ratio of the reduction in pipe

standard. The values given in parentheses are for information

sectionchordshorteningtotheinitialchordlengthexpressedas

only.

a percentage.

1.7 The text of this specification references notes and

3.2.2 ∆y, n—measured change in chord length (in the

footnotes that provide explanatory material. These notes and

directionofloadapplication)expressedinmillimeters(inches).

footnotes (excluding those in tables and figures) shall not be

3.2.2.1 compressive deformation, n—the measured change

considered as requirements of the specification.

of the inside diameter in the direction of load application

1.8 This standard does not purport to address all of the

expressed in millimeters (or inches).

safety concerns, if any, associated with its use. It is the

3.2.3 load (F), n—the force applied to the wall section to

responsibility of the user of this standard to establish appro-

produce or maintain a given percent chord length shortening at

priate safety and health practices and determine the applica-

any given unit of time; expressed as Newtons per meter

bility of regulatory limitations prior to use.

(pounds-force per linear inch).

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This test method is under the jurisdiction of ASTM Committee F17 on Plastic contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Piping Systems and is the direct responsibility of Subcommittee F17.40 on Test Standards volume information, refer to the standard’s Document Summary page on

Methods. the ASTM website.

Current edition approved Aug. 1, 2013. Published October 2013.Originally Available from American Association of State Highway and Transportation

approvedin2005.Lastpreviouseditionapprovedin2009asF2433–05(2009).DOI: Officials (AASHTO), 444 N. Capitol St., NW, Suite 249, Washington, DC 20001,

10.1520/F2433-05R13. http://www.transportation.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2433 − 05 (2013)

3.2.4 meanradius(r),n—themid-wallradiusdeterminedby 5. Significance and Use

subtractingtheaveragewallthicknessfromtheaverageoutside

5.1 The performance under bending and compression load

diameter and dividing the difference by two; expressed in

of a thermoplastic plastic pipe wall design obtained by this

millimeters (or inches).

method can be used for the following:

3.2.5 time-independent pipe stiffness K(0), n—the value

5.1.1 To determine the stiffness of the pipe wall section.

obtained by dividing the force per unit length on the curved

This is a function of the pipe dimensions, the wall design, the

beam specimen by the resulting deflection in the same units at

arc length tested, and the physical properties of the material of

the % deflection prescribed and extrapolating the linear portion

which the pipe is made.

of the curve of stiffness versus % deflection to the moment of

5.1.2 To compare the characteristics of various thermoplas-

application of load.

tic pipe wall designs.

5.1.3 To compare the characteristics of various plastics in

3.2.6 time-dependent residual curved beam stiffness K(t)

pipe form.

and residual pipe stiffness K(t), n—the value obtained by

5.1.4 To study the interrelations of dimensions, materials,

dividing the force per unit length on the curved beam specimen

and deformation properties of thermoplastic pipe designs.

by the constant target deflection in the same units, at any time

5.1.5 To measure the deformation and load-resistance at any

t, t>0.

of several significant events which may occur during the test.

3.2.7 modulus of relaxation, n—the residual pipe stiffness

5.1.6 To provide a reasonable quality control/quality assur-

versus log(time).

ance test for very large diameter plastic pipes.

3.2.8 residual pipe stiffness K(50y), n—the value obtained

5.2 The time-dependent pipe wall stiffness of a thermoplas-

by extrapolating values of residual pipe stiffness versus time to

tic pipe obtained by this test method may used for the

50 years.

following:

3.2.9 compliance C(t), n—the inverse of stiffness K(t).

5.2.1 To predict the residual stiffness of the pipe wall in

3.2.10 liner cracking or crazing, n—the occurrence of a

bending and compression at all times after initial loading.

break or network of fine breaks in the liner visible to the

5.2.2 For purposes of design, to determine a modulus of

unaided eye.

relaxation under sustained loads.

5.2.3 To quantify the influence of material formulations of

3.2.11 wall cracking, n—the occurrence of a break in the

thermoplastics on the modulus of relaxation.

pipe wall visible to the unaided eye.

5.2.4 To study the influence of geometric patterns of wall

3.2.12 wall delamination, n—the occurrence of any separa-

profiles on the modulus of relaxation.

tion in the components of the pipe wall visible to the unaided

5.3 The time-independent reduction of wall thickness at

eye.

springline may be used for the following:

3.2.13 rupture, n—a crack or break extending entirely or

5.3.1 For pipe wall stiffness, to quantify the efficiency of all

partly through the pipe wall.

wallprofilesofanymaterialcompositionandagivengeometry

4. Summary of Test Method

with that of a solid uniform thickness wall.

4.1 The test is conducted by applying a controlled, nearly

6. Apparatus

instantaneous, load to the longitudinally cut edges of curved

6.1 Testing Machine—A properly calibrated compression

beam sections cut from short lengths of pipe until a prescribed

testing machine of the constant-rate-of-crosshead movement

shortening of the chord connecting the longitudinal edges is

type meeting the requirements of Test Method D695 shall be

achieved and held constant for prescribed intervals. Load and

used to make the tests. The rate of head approach shall be 63.5

deformation data establish the time-independent measure of

6 2.5 mm (2.5 6 0.1 in.)/s. The machines must be capable of

curvedbeamwallstiffnessattheinstantofloadapplication,the

holding a required percent chord shorting for an extended

measure of efficiency of the profile wall geometry, stability of

period of time.

the profile wall, a modulus of relaxation and long-term

estimates of residual pipe wall stiffness.

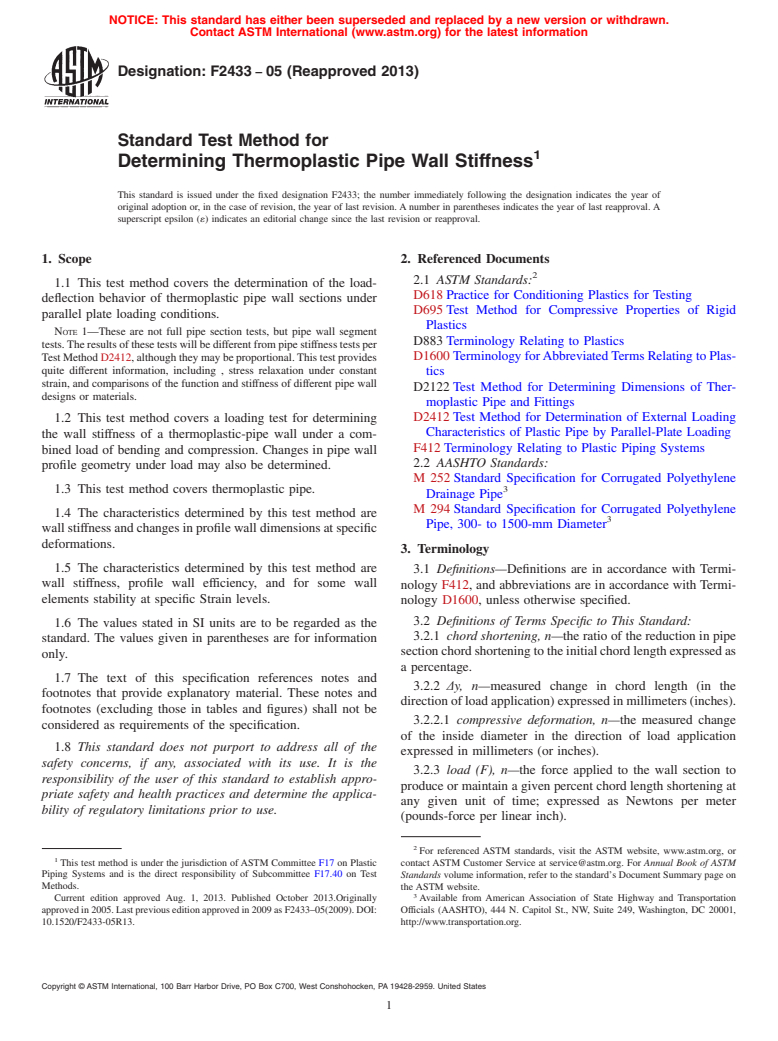

6.2 Loading Grips—The load shall be applied to the speci-

men through two parallel-axis grips. These assemblies shall be

4.2 Alengthofa10to120°arcsegmentofapipewall,from

flat, smooth, and clean. Specimen contact surfaces of platen

onediameterlengthtoonemeterlongisloadedacrossitschord

shall be coated with a PTFE spray lubricant. The thickness of

length between two freely rotating end plates at a controlled

theplatensshallbesufficientsothatnobendingordeformation

rate of approach to one another. Load-deflection data of the

occurs during the test, but it shall not be less than 12 mm (0.5

wall section in combined bending and compression are ob-

in.). The nominal length of each grip shall equal or exceed the

tained. Change in pipe wall thickness at the center of the

specimen length but shall not be less than 1040 mm (41 in.).

section (springline) is determined. If cracking, crazing,

Upper and lower grips shall be free to rotate about an axis in

delamination, rupture, or buckling occurs, the corresponding

the plane of the applied and reacting line loads. Recommended

load, deflection, and/or time are recorded.

NOTE 2—If this test method is incorporated in a product standard it arrangement of loading frame, upper and lower grips with test

would be necessary to define the arc length to be tested. There are,

specimen are shown in Fig. 1.

however, many reasons various arc lengths might be tested, especially as

6.3 Deformation Indicator—The change in total wall (major

a research or product development tool. Large arc lengths are primarily in

bending, while short arc lengths are primarily in compression. wall for profile wall pipe) thickness at springline, shall be

F2433 − 05 (2013)

FIG. 1 Recommended Arrangement of Loading Frame, Upper & Lower Grips, and Test Specimen

measured with a suitable instrument meeting the requirements mm (36 in.), and for corrugated or profile pipe should be

of 4.1.2 of Test Method D695, except that the instrument shall squarely cut in the corrugation or profile valley.

NOTE 3—Standard arc lengths for specimens should be 120°, 90°, and

beaccuratetothenearest0.025mm(0.001in.).Theinstrument

30°, though other arc lengths may be used within the range of 120° to 10°,

shall not affect in any way the load-deflection measurements.

as determined by the needs of the owner, researcher, or testing laboratory.

6.4 Load Sensor—The change of load with time during the

periods of displacement (loading) and during the period of 8. Conditioning

constant displacement shall be digitally recorded with a preci-

8.1 Condition the pipe wall section for at least 24 h in air at

sion of no less than 4 significant figures and at time intervals as

a temperature of 23 6 2°C (73.4 6 3.6°F), and 50 6 5%

noted in 9.3. The sensing element shall have a precision of

relative humidity and conduct the test in a room maintained at

62 % of maximum recorded value.

the same temperature.

6.5 Temperature Recorder—Ambient temperature shall be

8.2 When a referee test is required, condition specimens for

continuously recorded using a sensor capable of recording to

atleast40hat23 62°C(73.4 63.6°F),and50 65 %relative

1°C (1.8°F).

humidity per Practice D618 Procedure A and conduct the test

6.6 Reaction Frame—The reaction frame shall be suffi- under the same conditions.

ciently rigid such that the movement of the stationery platen

9. Procedure

shall not exceed 0.05 % of the displacement of the moving

platen.

9.1 Before placing each test specimen in the test apparatus

make the following measurements:

7. Test Specimens

9.1.1 Measure, to the nearest 1 mm (0.04 in.), the longitu-

7.1 Test specimens shall be cut from the pipe wall, with the dinal length with equally spaced parallel measurements at mid

cuts through the wall radial and parallel through the sample andquarterpointsofthearcofthecurvedbeam.Determinethe

length. Test specimens may be the required arc length in longitudinal length by averaging the three measurements.

degrees 61° arc sections of the wall, as agreeable to the 9.1.2 For specimens prepared from AASHTO M 252M and

manufacturer and the purchaser, but not less than 10 degrees AASHTO M 294M Type C pipes, at each of three points

nor greater than 120 degrees. Test specimens should be a approximately located on a mid-longitudinal line of the corru-

minimum of 600 mm (24 in.) long, and may be as much as 900 gated wall, one point located at mid-length and two points

F2433 − 05 (2013)

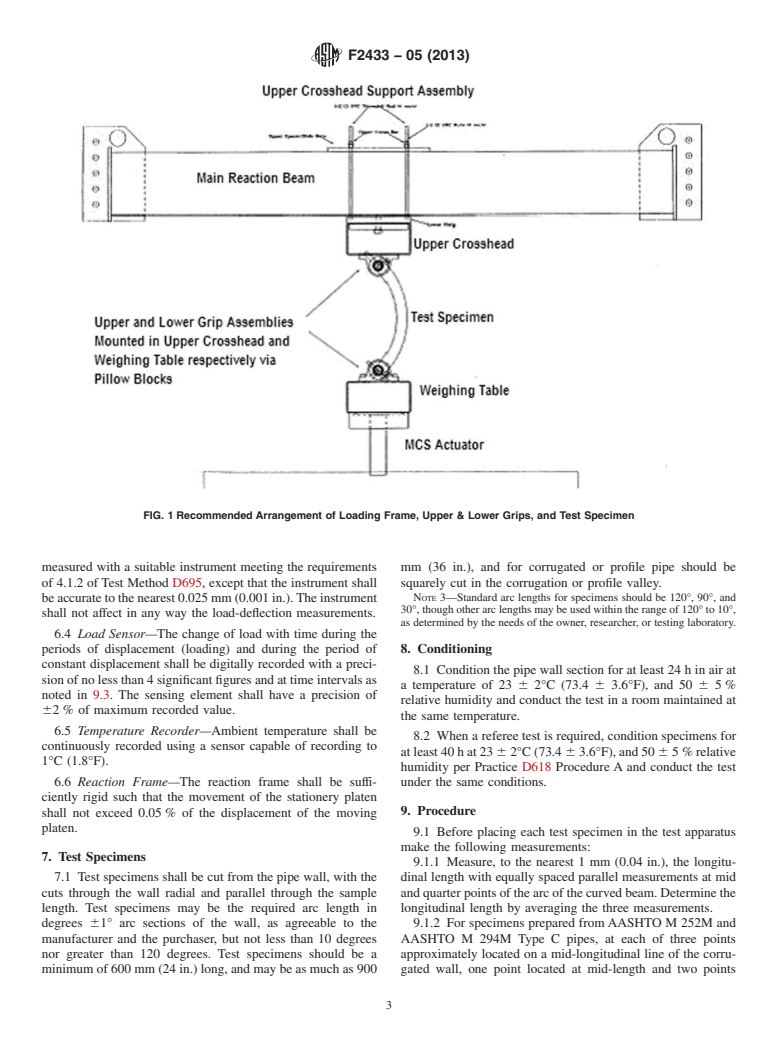

FIG. 2 Photographs of Specimen in Load Frame

located at one-quarter and three-quarter lengths, determine the locations approximately half and quarter lengths along the

out-to-out distance, to the nearest 1 mm (0.04 in.), from the mid-longitudinal line of the curved beam. Determine the

center of the crest to a projection of the center of an adjacent

thickness by averaging the three measurements.

valley on a line perpendicular to the tangent at the center of the

9.1.5 For specimens prepared from AASHTO M 294M

crest. Determine the wall thickness by averaging the three

Type D pipes measure the total wall thickness, to the nearest 1

measurements.

mm (0.04 in.), from the outermost point of the circular web to

9.1.3 For specimens prepared from AASHTO M 252M and

the closest point on the inner surface of the pipe wall.

AASHTO M 294M Type S pipes measure the total wall

Determine the thickness by averaging the three measurements.

thickness, to the nearest 1 mm (0.04 in.), at the center of the

9.2 The test is conducted by applying a nearly instantaneous

crests of the outer wall corrugations, located at approximately

load to the longitudinally cut edges of an arc section of test

half and quarter points along the mid-longitudinal line of the

pipe until 10 % shortening of the chord connecting the longi-

curved beam. Determine the thickness by averaging the three

tudinal edges is achieved. For purposes of design and quality

measure

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.