ASTM D4945-17

(Test Method)Standard Test Method for High-Strain Dynamic Testing of Deep Foundations

Standard Test Method for High-Strain Dynamic Testing of Deep Foundations

SIGNIFICANCE AND USE

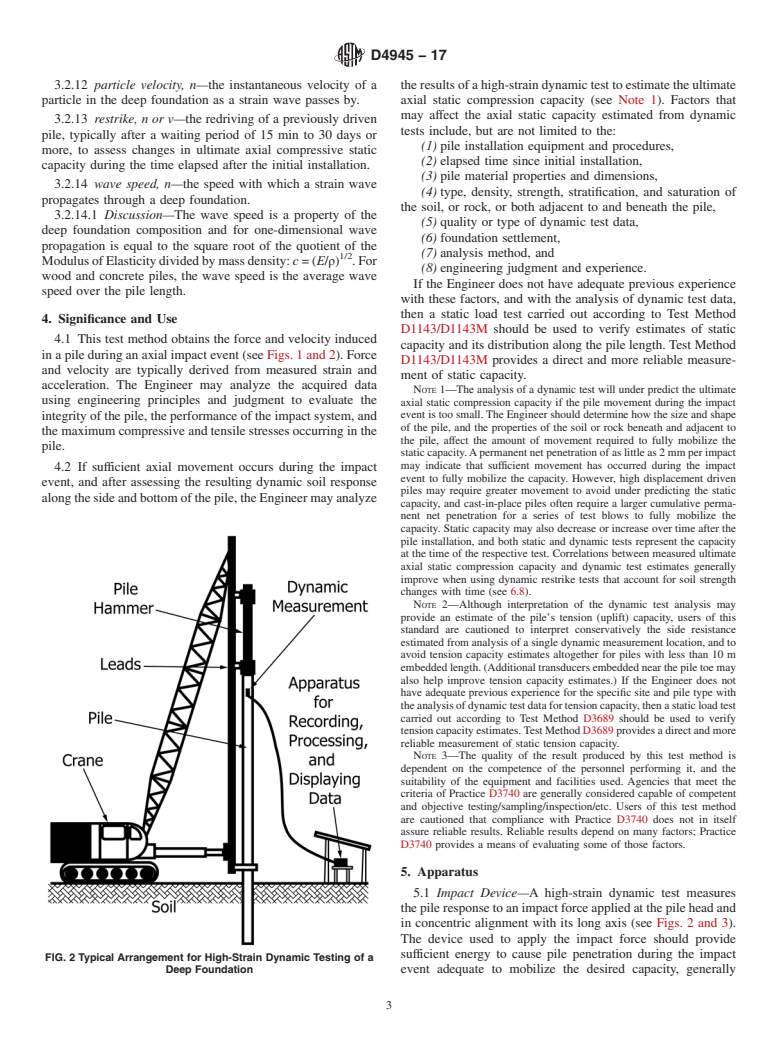

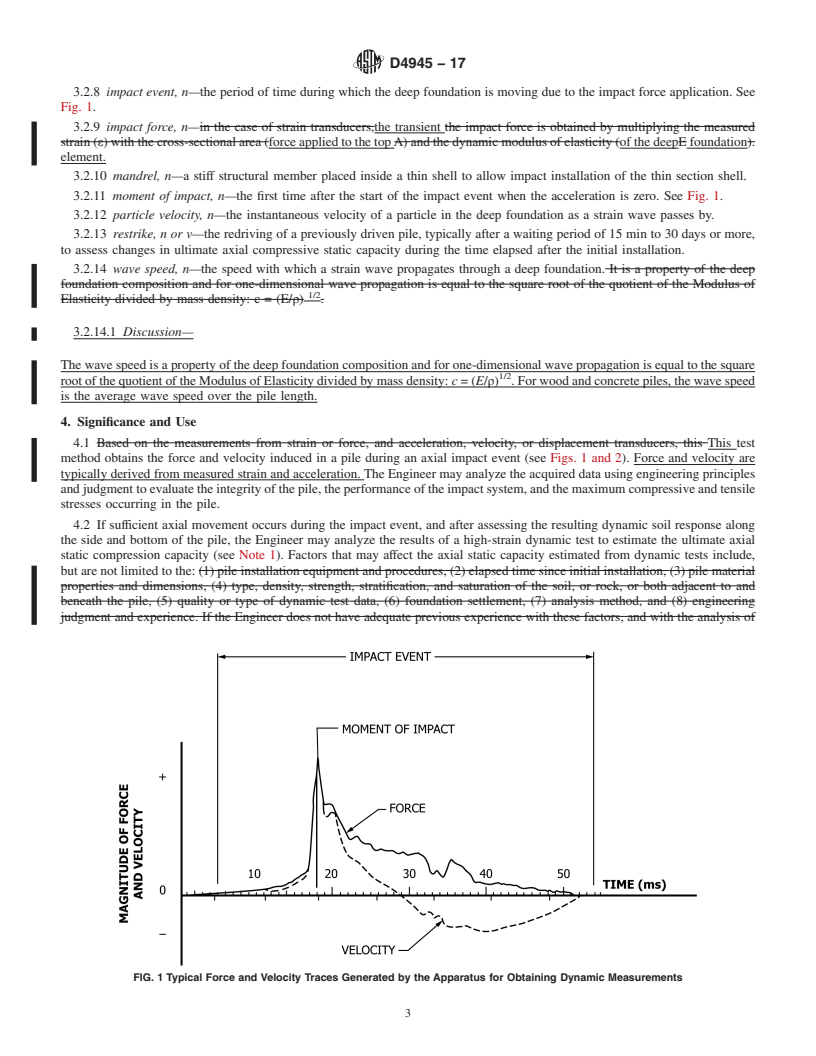

4.1 This test method obtains the force and velocity induced in a pile during an axial impact event (see Figs. 1 and 2). Force and velocity are typically derived from measured strain and acceleration. The Engineer may analyze the acquired data using engineering principles and judgment to evaluate the integrity of the pile, the performance of the impact system, and the maximum compressive and tensile stresses occurring in the pile.

FIG. 2 Typical Arrangement for High-Strain Dynamic Testing of a Deep Foundation

4.2 If sufficient axial movement occurs during the impact event, and after assessing the resulting dynamic soil response along the side and bottom of the pile, the Engineer may analyze the results of a high-strain dynamic test to estimate the ultimate axial static compression capacity (see Note 1). Factors that may affect the axial static capacity estimated from dynamic tests include, but are not limited to the:

(1) pile installation equipment and procedures,

(2) elapsed time since initial installation,

(3) pile material properties and dimensions,

(4) type, density, strength, stratification, and saturation of the soil, or rock, or both adjacent to and beneath the pile,

(5) quality or type of dynamic test data,

(6) foundation settlement,

(7) analysis method, and

(8) engineering judgment and experience.

If the Engineer does not have adequate previous experience with these factors, and with the analysis of dynamic test data, then a static load test carried out according to Test Method D1143/D1143M should be used to verify estimates of static capacity and its distribution along the pile length. Test Method D1143/D1143M provides a direct and more reliable measurement of static capacity.

Note 1: The analysis of a dynamic test will under predict the ultimate axial static compression capacity if the pile movement during the impact event is too small. The Engineer should determine how the size and shape of the pile, and the properties of the s...

SCOPE

1.1 This dynamic test method covers the procedure for applying an axial impact force with a pile driving hammer or a large drop weight that will cause a relatively high strain at the top of an individual vertical or inclined deep foundation unit, and for measuring the subsequent force and velocity response of that deep foundation unit. While in this standard force and velocity are referenced as “measured,” they are typically derived from measured strain and acceleration values. High-strain dynamic testing applies to any deep foundation unit, also referred to herein as a “pile,” which functions in a manner similar to a driven pile or a cast-in-place pile regardless of the method of installation, and which conforms with the requirements of this test method.

1.2 This standard provides minimum requirements for dynamic testing of deep foundations. Plans, specifications, or provisions (or combinations thereof) prepared by a qualified engineer may provide additional requirements and procedures as needed to satisfy the objectives of a particular test program. The engineer in responsible charge of the foundation design, referred to herein as the “Engineer”, shall approve any deviations, deletions, or additions to the requirements of this standard.

1.3 The proper conduct and evaluation of high-strain dynamic tests requires special knowledge and experience. A qualified engineer should directly supervise the acquisition of field data and the interpretation of the test results so as to predict the actual performance and adequacy of deep foundations used in the constructed foundation. A qualified engineer shall approve the apparatus used for applying the impact force, driving appurtenances, test rigging, hoist equipment, support frames, templates, and test procedures.

1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figure...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4945 − 17

Standard Test Method for

1

High-Strain Dynamic Testing of Deep Foundations

This standard is issued under the fixed designation D4945; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* recommended or advisory provision. Imperative sentences

indicate mandatory provisions.

1.1 This dynamic test method covers the procedure for

applying an axial impact force with a pile driving hammer or 1.5 Units—The values stated in SI units are to be regarded

alargedropweightthatwillcausearelativelyhighstrainatthe asstandard.Nootherunitsofmeasurementareincludedinthis

top of an individual vertical or inclined deep foundation unit, standard. Reporting of test results in units other than SI shall

and for measuring the subsequent force and velocity response not be regarded as nonconformance with this test method.

of that deep foundation unit. While in this standard force and

1.6 All observed and calculated values shall conform to the

velocity are referenced as “measured,” they are typically

guidelines for significant digits and rounding established in

derived from measured strain and acceleration values. High-

Practice D6026.

straindynamictestingappliestoanydeepfoundationunit,also

1.6.1 Theproceduresusedtospecifyhowdataarecollected/

referred to herein as a “pile,” which functions in a manner

recorded and calculated in this standard are regarded as the

similar to a driven pile or a cast-in-place pile regardless of the

industry standard. In addition, they are representative of the

method of installation, and which conforms with the require-

significant digits that should generally be retained. The proce-

ments of this test method.

dures used do not consider material variation, purpose for

1.2 This standard provides minimum requirements for dy- obtaining the data, special purpose studies, or any consider-

namic testing of deep foundations. Plans, specifications, or ations for the user’s objectives; and it is common practice to

provisions (or combinations thereof) prepared by a qualified increase or reduce significant digits of reported data to com-

engineer may provide additional requirements and procedures mensurate with these considerations. It is beyond the scope of

as needed to satisfy the objectives of a particular test program. this standard to consider significant digits used in analysis

The engineer in responsible charge of the foundation design, methods for engineering design.

referred to herein as the “Engineer”, shall approve any

1.7 This standard does not purport to address all of the

deviations, deletions, or additions to the requirements of this

safety concerns, if any, associated with its use. It is the

standard.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.3 The proper conduct and evaluation of high-strain dy-

mine the applicability of regulatory limitations prior to use.

namic tests requires special knowledge and experience. A

For a specific precautionary statement, see Note 4.

qualified engineer should directly supervise the acquisition of

1.8 This international standard was developed in accor-

field data and the interpretation of the test results so as to

dance with internationally recognized principles on standard-

predict the actual performance and adequacy of deep founda-

ization established in the Decision on Principles for the

tions used in the constructed foundation. A qualified engineer

Development of International Standards, Guides and Recom-

shallapprovetheapparatususedforapplyingtheimpactforce,

mendations issued by the World Trade Organization Technical

driving appurtenances, test rigging, hoist equipment, support

Barriers to Trade (TBT) Committee.

frames, templates, and test procedures.

1.4 The text of this standard references notes and footnotes

2. Referenced Documents

whichprovideexplanatorymaterial.Thesenotesandfootnotes

2

2.1 ASTM Standards:

(excluding those in tables and figures) shall not be considered

C469Test Method for Static Modulus of Elasticity and

as requirements of the standard. The word “shall” indicates a

Poisson’s Ratio of Concrete in Compression

mandatory provision, and the word “should” indicates a

D198Test Methods of Static Tests of Lumber in Structural

Sizes

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

2

RockandisthedirectresponsibilityofSubcommitteeD18.11onDeepFoundations. For referenced ASTM standa

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4945 − 12 D4945 − 17

Standard Test Method for

1

High-Strain Dynamic Testing of Deep Foundations

This standard is issued under the fixed designation D4945; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This dynamic test method covers the procedure for applying an axial impact force with a pile driving hammer or a large

drop weight that will cause a relatively high strain at the top of an individual vertical or inclined deep foundation unit, and for

measuring the subsequent force and velocity response of that deep foundation unit. While in this standard force and velocity are

referenced as “measured,” they are typically derived from measured strain and acceleration values. High-strain dynamic testing

applies to any deep foundation unit, also referred to herein as a “pile,” which functions in a manner similar to a driven pile or a

cast-in-place pile regardless of the method of installation, and which conforms with the requirements of this test method.

1.2 This standard provides minimum requirements for dynamic testing of deep foundations. Plans, specifications, or provisions

(or combinations thereof) prepared by a qualified engineer may provide additional requirements and procedures as needed to

satisfy the objectives of a particular test program. The engineer in responsible charge of the foundation design, referred to herein

as the “Engineer”, shall approve any deviations, deletions, or additions to the requirements of this standard.

1.3 The proper conduct and evaluation of high-strain dynamic tests requires special knowledge and experience. A qualified

engineer should directly supervise the acquisition of field data and the interpretation of the test results so as to predict the actual

performance and adequacy of deep foundations used in the constructed foundation. A qualified engineer shall approve the apparatus

used for applying the impact force, driving appurtenances, test rigging, hoist equipment, support frames, templates, and test

procedures.

1.4 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard. The word “shall” indicates a

mandatory provision, and the word “should” indicates a recommended or advisory provision. Imperative sentences indicate

mandatory provisions.

1.5 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard. Reporting of test results in units other than SI shall not be regarded as nonconformance with this test method.

1.6 All observed and calculated values shall conform to the guidelines for significant digits and rounding established in Practice

D6026.

1.6.1 The procedures used to specify how data are collected/recorded and calculated in this standard are regarded as the industry

standard. In addition, they are representative of the significant digits that should generally be retained. The procedures used do not

consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user’s objectives;

and it is common practice to increase or reduce significant digits of reported data to commensurate with these considerations. It

is beyond the scope of this standard to consider significant digits used in analysis methods for engineering design.

1.7 The method used to specify how data are collected, calculated, or recorded in this standard is not directly related to the

accuracy to which the data can be applied in design or other uses, or both. How one applies the results obtained using this standard

is beyond its scope.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For a specific precautionary statement, see Note 4.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recom

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.