ASTM F1820-22

(Test Method)Standard Test Method for Determining the Forces for Disassembly of Modular Acetabular Devices

Standard Test Method for Determining the Forces for Disassembly of Modular Acetabular Devices

SIGNIFICANCE AND USE

5.1 This test method is intended to assess the locking strength of the acetabular liner in a modular acetabular shell when subjected to three different force application conditions.

5.2 This test method may not be appropriate for all implant applications. The user is cautioned to consider the appropriateness of the method in view of the materials and design being tested and their potential application.

5.3 While these test methods may be used to measure the force required to disengage modular acetabular devices, comparison of such data for various device designs must take into consideration the size of the implant and the type of locking mechanism evaluated. The location of the locking mechanism relative to the load application may be dependent upon the size and design of the acetabular device. In addition, the locking mechanism itself may vary with size, particularly if the design is circumferential in nature (for example, a larger diameter implant would have a greater area of acetabular shell and liner interface than a small diameter implant).

5.4 Material failure is possible before locking mechanism failure during either push-out or offset pull-out/lever-out conditions. This is due to the possibility that the shear strength of the material may be exceeded before the locking mechanism is fully tested.

SCOPE

1.1 This test method covers a standard methodology by which to measure the attachment strength between the modular acetabular shell and liner. Although the methodology described does not replicate physiological loading conditions, it has been described as a means of comparing the integrity of various locking mechanisms.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1820 − 22

Standard Test Method for

Determining the Forces for Disassembly of Modular

1

Acetabular Devices

This standard is issued under the fixed designation F1820; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 acetabular liner—portion of the modular acetabular

device with an internal hemispherical socket intended to

1.1 This test method covers a standard methodology by

articulate with a femoral prosthesis. This can include acetabu-

which to measure the attachment strength between the modular

lar liners used for dual mobility or constrained applications.

acetabular shell and liner.Although the methodology described

The external geometry of this component interfaces with the

does not replicate physiological loading conditions, it has been

acetabular shell through a locking mechanism which may be

described as a means of comparing the integrity of various

integral to the design of the acetabular liner and shell or may

locking mechanisms.

rely upon additional components (for example, a metal ring or

1.2 The values stated in SI units are to be regarded as

screws).

standard. No other units of measurement are included in this

3.1.2 acetabular shell—the external, hollow (usually metal)

standard.

structure that provides additional mechanical support or rein-

1.3 This standard does not purport to address all of the

forcement for an acetabular liner and whose external features

safety concerns, if any, associated with its use. It is the

interface directly with the bones of the pelvic socket (for

responsibility of the user of this standard to establish appro-

example, through bone cement, intimate press-fit, coatings for

priate safety, health, and environmental practices and deter-

attachment to bone cement or tissue, integral screw threads,

mine the applicability of regulatory limitations prior to use.

anchoring screws, or pegs). The acetabular shell may be either

1.4 This international standard was developed in accor-

solid or contain holes for fixation, or contain a hole for

dance with internationally recognized principles on standard-

instrumentation.

ization established in the Decision on Principles for the

3.1.3 locking mechanism—any structure, design feature, or

Development of International Standards, Guides and Recom-

combination thereof that provides mechanical resistance to

mendations issued by the World Trade Organization Technical

movement between the acetabular liner and shell.

Barriers to Trade (TBT) Committee.

3.1.4 polar axis—the axis of revolution of the rotationally

symmetric portions of the acetabular liner or shell.

2. Referenced Documents

2

2.1 ASTM Standards:

4. Summary of Test Method

E4 Practices for Force Calibration and Verification of Test-

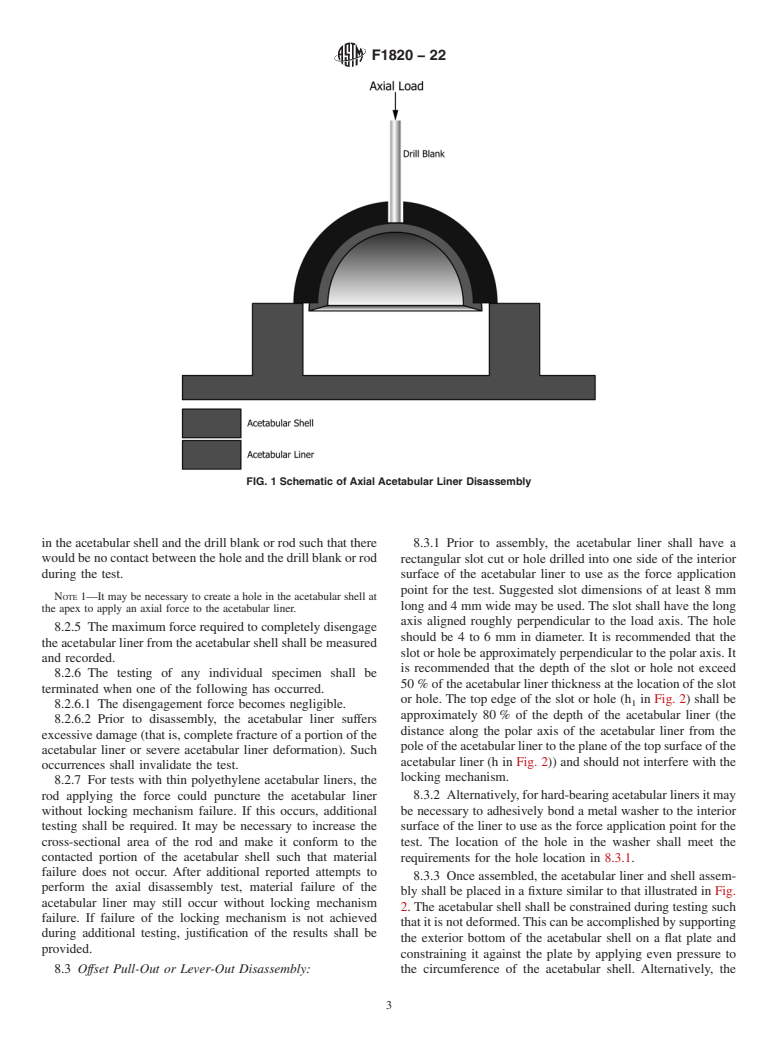

4.1 Axial Disassembly (Push-Out):

ing Machines

4.1.1 The axial disassembly test method of an acetabular

F2345 Test Methods for Determination of Cyclic Fatigue

liner and shell system provides a means to measure the axial

Strength of Ceramic Modular Femoral Heads

locking strength of the acetabular liner for modular acetabular

devices.

3. Terminology

4.2 Offset Pull-Out or Lever-Out Disassembly:

3.1 Definitions of Terms Specific to This Standard:

4.2.1 The offset pull-out or the lever-out disassembly

method is intended to assess the resistance of the locking

1

This test method is under the jurisdiction ofASTM Committee F04 on Medical

mechanism to edge forces that could occur when the neck of a

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

hip prosthesis impinges on the edge of the acetabular liner.An

F04.22 on Arthroplasty.

impinging force could cause the edge of the acetabular liner

Current edition approved March 15, 2022. Published March 2022. Originally

opposite the area of impinging contact to be pushed out of the

approved in 1997. Last previous edition approved in 2013 as F1820 – 13. DOI:

10.1520/F1820-22.

acetabular shell. The resistance of the acetabular liner edge to

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

being pulled loose from the acetabular shell is a measure of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

resistance to impingement causing loosening of the acetabular

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. liner.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1820 − 13 F1820 − 22

Standard Test Method for

Determining the Forces for Disassembly of Modular

1

Acetabular Devices

This standard is issued under the fixed designation F1820; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a standard methodology by which to measure the attachment strength between the modular acetabular

shell and liner. Although the methodology described does not replicate physiological loading conditions, it has been described as

a means of comparing the integrity of various locking mechanisms.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Calibration and Verification of Testing Machines

F2345 Test Methods for Determination of Cyclic Fatigue Strength of Ceramic Modular Femoral Heads

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 acetabular liner—portion of the modular acetabular device with an internal hemispherical socket intended to articulate with

the head of a femoral prosthesis. This can include acetabular liners used for dual mobility or constrained applications. The external

geometry of this component interfaces with the acetabular shell through a locking mechanism which may be integral to the design

of the acetabular liner and shell or may rely upon additional components (for example, metal ring, screws, and so forth).a metal

ring or screws).

3.1.2 acetabular shell—the external, hollow (usually metal) structure that provides additional mechanical support or reinforcement

for an acetabular liner and whose external features interface directly with the bones of the pelvic socket (for example, through bone

1

This test method is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.22 on Arthroplasty.

Current edition approved Feb. 1, 2013March 15, 2022. Published March 2013March 2022. Originally approved in 1997. Last previous edition approved in 20092013 as

F1820 – 97F1820 – 13.(2009). DOI: 10.1520/F1820-13.10.1520/F1820-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1820 − 22

cement, intimate press-fit, porous ingrowth, coatings for attachment to bone cement or tissue, integral screw threads, anchoring

screws, pegs, and so forth). or pegs). The acetabular shell may be either solid or contain holes for fixation, or contain a hole for

instrumentation, or all of these.instrumentation.

3.1.3 locking mechanism—any structure, design feature, or combination thereof,thereof that provides mechanical resistance to

movement between the acetabular liner and shell.

3.1.4 polar axis—the axis of revolution of the rotationally symmetric portions of the acetabular liner or shell.

4. Summary of Test Method

4.1 All acetabular liners shall be inserted into the acetabular shells for testing by applying a force of 2 kN. This value is similar

to the force required to set the head in Test Methods F2345.

4.1 Axial Disassembly: Disassembly (Push-Out):

4.1.1 The axial disassembly test method of an acetabular device test method liner and shell system provides a means to measure

the axial locking strength of the acetabular lin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.