ASTM E1774-96(2002)

(Guide)Standard Guide for Electromagnetic Acoustic Transducers (EMATs)

Standard Guide for Electromagnetic Acoustic Transducers (EMATs)

SCOPE

1.1 This guide is intended primarily for tutorial purposes. It provides an overview of the general principles governing the operation and use of electromagnetic acoustic transducers (EMATs) for ultrasonic examination.

1.2 This guide describes a non-contact technique for coupling ultrasonic energy into an electrically conductive or ferromagnetic material, or both, through the use of electromagnetic fields. This guide describes the theory of operation and basic design considerations as well as the advantages and limitations of the technique.

1.3 This guide is intended to serve as a general reference to assist in determining the usefulness of EMATs for a given application as well as provide fundamental information regarding their design and operation. This guide provides guidance for the generation of longitudinal, shear, Rayleigh, and Lamb wave modes using EMATs.

1.4 This guide does not contain detailed procedures for the use of EMATs in any specific applications; nor does it promote the use of EMATs without thorough testing prior to their use for examination purposes. Some applications in which EMATs have been applied successfully are outlined in Section 9.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1774–96 (Reapproved 2002)

Standard Guide for

Electromagnetic Acoustic Transducers (EMATs)

This standard is issued under the fixed designation E 1774; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

General—The usefulness of ultrasonic techniques is well established in the literature of nonde-

structive examination. The generation of ultrasonic waves is achieved primarily by means of some

form of electromechanical conversion, usually the piezoelectric effect.This highly efficient method of

generating ultrasonic waves has a disadvantage in that a fluid is generally required for mechanical

coupling of the sound into the material being examined. The use of a couplant generally requires that

the material being examined be either immersed in a fluid or covered with a thin layer of fluid.

Principle—An electromagnetic acoustic transducer (EMAT) generates and receives ultrasonic

waves without the need to contact the material in which the acoustic waves are traveling. The use of

an EMAT requires that the material to be examined be electrically conductive or ferromagnetic, or

both.TheEMATasageneratorofultrasonicwavesisbasicallyacoilofwire,excitedbyanalternating

electric current, placed in a uniform magnetic field near the surface of an electrically conductive or

ferromagneticmaterial.Asurfacecurrentisinducedinthematerialbytransformeraction.Thissurface

current in the presence of a magnetic field experiences Lorentz forces that produce oscillating stress

waves. Upon reception of an ultrasonic wave, the surface of the conductor oscillates in the presence

of a magnetic field, thus inducing a voltage in the coil. The transduction process occurs within an

electromagnetic skin depth.An EMAT forms the basis for a very reproducible noncontact system for

generating and detecting ultrasonic waves.

1. Scope 1.4 This guide does not contain detailed procedures for the

use of EMATs in any specific applications; nor does it promote

1.1 This guide is intended primarily for tutorial purposes. It

the use of EMATs without thorough testing prior to their use

provides an overview of the general principles governing the

for examination purposes. Some applications in which EMATs

operation and use of electromagnetic acoustic transducers

have been applied successfully are outlined in Section 9.

(EMATs) for ultrasonic examination.

1.5 This standard does not purport to address all of the

1.2 This guide describes a non-contact technique for cou-

safety concerns, if any, associated with its use. It is the

pling ultrasonic energy into an electrically conductive or

responsibility of the user of this standard to establish appro-

ferromagneticmaterial,orboth,throughtheuseofelectromag-

priate safety and health practices and determine the applica-

netic fields. This guide describes the theory of operation and

bility of regulatory limitations prior to use.

basic design considerations as well as the advantages and

limitations of the technique.

2. Referenced Documents

1.3 This guide is intended to serve as a general reference to

2.1 ASTM Standards:

assist in determining the usefulness of EMATs for a given

E 127 Practice for Fabricating and Checking Aluminum

application as well as provide fundamental information regard-

Alloy Ultrasonic Standard Reference Blocks

ing their design and operation. This guide provides guidance

E 428 Practice for Fabrication and Control of Steel Refer-

for the generation of longitudinal, shear, Rayleigh, and Lamb

ence Blocks Used in Ultrasonic Examination

wave modes using EMATs.

E 1065 Guide for Evaluating Characteristics of Ultrasonic

Search Units

1 E 1316 Terminology for Nondestructive Examinations

This guide is under the jurisdiction of ASTM Committee E07 on Nondestruc-

tive Testing and is the direct responsibility of Subcommittee E07.06 on Ultrasonic 2.2 ASNT Document:

Method.

Current edition approved December 10, 1996. Published February 1997. Origi-

nally published as E 1774 – 95. Last previous edition E 1774 – 95. Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1774–96 (2002)

Recommended Practice SNT-TC-1A Personnel Qualifica- using SH wave modes.)Also, EMATs provide for the capabil-

tions and Certification in Nondestructive Testing ity to steer shear waves electronically.

4.3 Specific Limitations—EMATs have very low efficiency.

3. Terminology

The insertion loss of EMATs can be as much as 40 dB or more

when compared to conventional ultrasonic methods. The

3.1 Definitions—Related terminology is defined in Termi-

nology E 1316. EMAT technique can be used only on materials that are

electrical conductors or ferromagnetic. The design of EMAT

3.2 Definitions of Terms Specific to This Standard:

3.2.1 electromagnetic acoustic transducer (EMAT)—an probes is usually more complex than comparable piezoelectric

search units. Due to their low efficiency, EMATs usually

electromagnetic device for converting electrical energy into

acoustical energy in the presence of a magnetic field. requiremorespecializedinstrumentationforthegenerationand

detection of ultrasonic signals. High transmitting currents,

3.2.2 Lorentz forces—forces applied to electric currents

when placed in a magnetic field. Lorentz forces are perpen- low-noise receivers, and careful electrical matching is impera-

tive in system design. In general, EMAT probes are

dicular to the direction of both the magnetic field and the

current direction. Lorentz forces are the forces behind the application-specific, in the same way as piezoelectric transduc-

principle of electric motors. ers.

3.2.3 magnetostrictiveforces—forcesarisingfrommagnetic

5. Calibration and Standardization

domain wall movements within a magnetic material during

magnetization. 5.1 Reference Standards—As with conventional piezoelec-

3.2.4 meander coil—an EMAT coil consisting of periodic, tric ultrasonic examinations, it is imperative that a set of

winding, non-intersecting, and usually evenly-spaced conduc- reference samples exhibiting the full range of expected mate-

tors. rial defect states be acquired or fabricated and consequently

3.2.5 pancake coil (spiral)—an EMAT coil consisting of examined by the technique to establish sensitivity (see Prac-

spirally-wound, usually evenly-spaced conductors. tices E 127 and E 428).

3.2.6 bulk wave—an ultrasonic wave, either longitudinal or 5.2 Transducer Characterization—Many of the conven-

shear mode, used in nondestructive testing to interrogate the tional contact piezoelectric search unit characterization proce-

volume of a material. dures are generally adaptable to EMAT transducers with

appropriate modifications, or variations thereof (see Guide

4. Significance and Use

E 1065). Specific characterization procedures for EMATs are

not available and are beyond the scope of this document.

4.1 General—Ultrasonic testing is a widely used nonde-

structive method for the examination of a material. The

6. Theory (1-3)

majority of ultrasonic examinations are performed using trans-

ducers that directly convert electrical energy into acoustic 6.1 Nonmagnetic Conducting Materials—The mechanisms

energy through the use of piezoelectric crystals. This guide responsible for the generation of elastic waves in a conducting

describes an alternate technique in which electromagnetic material are dependent on the characteristics of that material.

energy is used to produce acoustic energy inside an electrically The generation of acoustic waves in a nonmagnetic conductive

conductive or ferromagnetic material. EMATs have unique material is a result of the Lorentz force acting on the lattice of

characteristics when compared to conventional piezoelectric thematerial.InanefforttounderstandtheactionoftheLorentz

ultrasonicsearchunits,makingthemasignificanttoolforsome force, one can use the free electron model of solids.According

ultrasonic examination applications. to the free electron model of conductors, the outer valence

4.2 Specific Advantages—Since the EMAT technique is electrons have been stripped from the atomic lattice, leaving a

noncontacting, it requires no fluid couplant. Important conse- lattice of positively charged ions in a sea of free electrons. In

quences of this include applications to moving objects, in order to generate elastic waves in a material, a net force must

remote or hazardous locations, to objects at elevated tempera- be transmitted to the lattice of the material. If only an

tures, or to objects with rough surfaces. The technique is electromagnetic field is generated in a conductor (via an eddy

environmentally safe since it does not use potentially polluting current-type coil), the net force on the lattice is zero because

or hazardous chemicals. The technique facilitates the rapid the forces on the electrons and ions are equal and opposite. For

scanning of components having complex geometries. EMAT example:

signalsarehighlyreproducibleasaconsequenceofthemanner

force on electrons52qE

in which the acoustic waves are generated. EMATs can

force on ions51qE

producehorizontallypolarizedshear(SH)waveswithoutmode

conversion and can accommodate scanning while using SH

where:

waves. (Note that in order to produce this wave mode by q = electron charge, and

conventional ultrasonic techniques, either an epoxy or a highly E = electric field vector of EMAT wave.

viscous couplant is required. Thus, conventional ultrasonic

However, if the same electromagnetic field is generated in

techniques do not lend themselves easily to scanning when the presence of an applied static magnetic field, a net force is

3 4

Available from American Society for Nondestructive Testing, 1711 Arlingate The boldface numbers in parentheses refer to the list of references at the end of

Plaza, Columbus, OH 43228. this guide.

E1774–96 (2002)

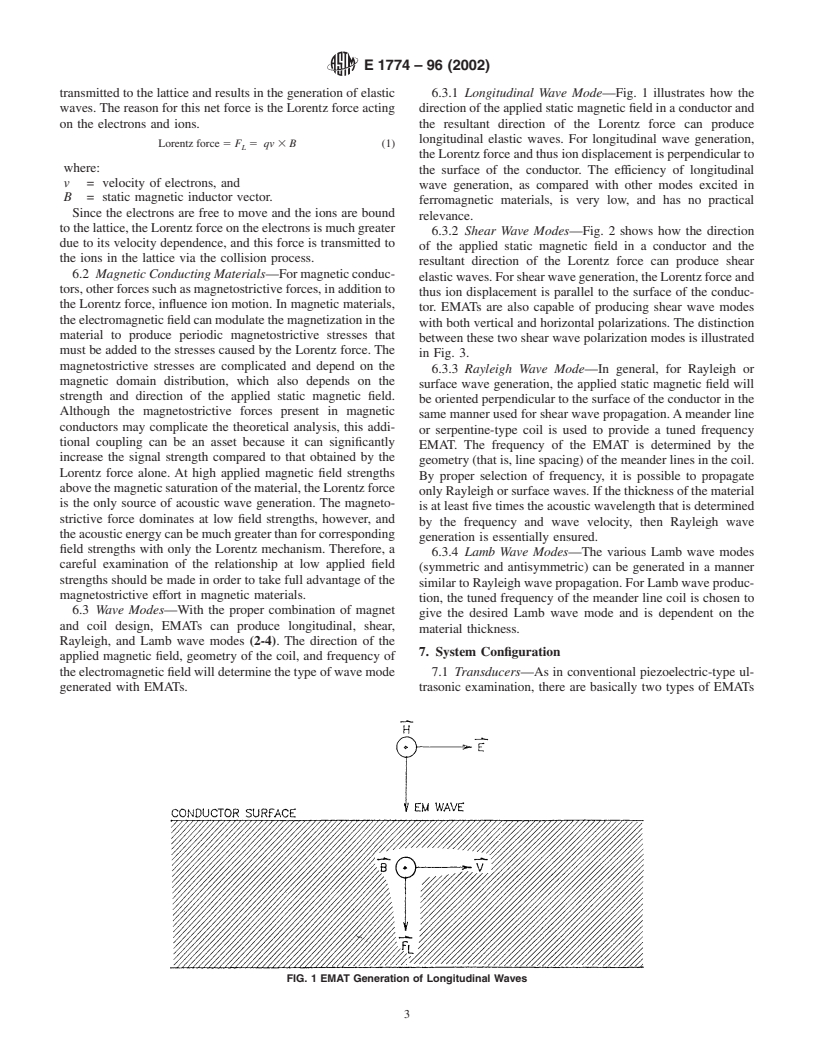

transmitted to the lattice and results in the generation of elastic 6.3.1 Longitudinal Wave Mode—Fig. 1 illustrates how the

waves. The reason for this net force is the Lorentz force acting direction of the applied static magnetic field in a conductor and

on the electrons and ions. the resultant direction of the Lorentz force can produce

longitudinal elastic waves. For longitudinal wave generation,

Lorentz force 5 F 5 qv 3 B (1)

L

the Lorentz force and thus ion displacement is perpendicular to

where:

the surface of the conductor. The efficiency of longitudinal

v = velocity of electrons, and

wave generation, as compared with other modes excited in

B = static magnetic inductor vector.

ferromagnetic materials, is very low, and has no practical

Since the electrons are free to move and the ions are bound

relevance.

tothelattice,theLorentzforceontheelectronsismuchgreater

6.3.2 Shear Wave Modes—Fig. 2 shows how the direction

due to its velocity dependence, and this force is transmitted to

of the applied static magnetic field in a conductor and the

the ions in the lattice via the collision process.

resultant direction of the Lorentz force can produce shear

6.2 MagneticConductingMaterials—Formagneticconduc-

elasticwaves.Forshearwavegeneration,theLorentzforceand

tors,otherforcessuchasmagnetostrictiveforces,inadditionto

thus ion displacement is parallel to the surface of the conduc-

the Lorentz force, influence ion motion. In magnetic materials,

tor. EMATs are also capable of producing shear wave modes

theelectromagneticfieldcanmodulatethemagnetizationinthe

with both vertical and horizontal polarizations. The distinction

material to produce periodic magnetostrictive stresses that

between these two shear wave polarization modes is illustrated

must be added to the stresses caused by the Lorentz force. The

in Fig. 3.

magnetostrictive stresses are complicated and depend on the

6.3.3 Rayleigh Wave Mode—In general, for Rayleigh or

magnetic domain distribution, which also depends on the

surface wave generation, the applied static magnetic field will

strength and direction of the applied static magnetic field.

be oriented perpendicular to the surface of the conductor in the

Although the magnetostrictive forces present in magnetic

same manner used for shear wave propagation.Ameander line

conductors may complicate the theoretical analysis, this addi-

or serpentine-type coil is used to provide a tuned frequency

tional coupling can be an asset because it can significantly

EMAT. The frequency of the EMAT is determined by the

increase the signal strength compared to that obtained by the

geometry(thatis,linespacing)ofthemeanderlinesinthecoil.

Lorentz force alone. At high applied magnetic field strengths

By proper selection of frequency, it is possible to propagate

abovethemagneticsaturationofthematerial,theLorentzforce

onlyRayleighorsurfacewaves.Ifthethicknessofthematerial

is the only source of acoustic wave generation. The magneto-

is at least five times the acoustic wavelength that is determined

strictive force dominates at low field strengths, however, and

by the frequency and wave velocity, then Rayleigh wave

theacousticenergycanbemuchgreaterthanforcorresponding

generation is essentially ensured.

field strengths with only the Lorentz mechanism. Therefore, a

6.3.4 Lamb Wave Modes—The various Lamb wave modes

careful examination of the relationship at low applied field

(symmetric and antisymmetric) can be generated in a manner

strengths should be made in order to take full advantage of the

similar to Rayleigh wave propagation. For Lamb wave produc-

magnetostrictive effort in magnetic materials.

tion, the tuned frequency of the meander line coil is chosen to

6.3 Wave Modes—With the proper combination of magnet

give the desired Lamb wave mode and is dependent on the

and coil design, EMATs can produce longitudinal, shear,

material thickness.

Rayleigh, and Lamb wave modes (2-4). The direction of the

7. System Configuration

applied magnetic field, geometry of the coil, and frequency of

theelectromagneticfieldwilldeterminethetypeofwavemode 7.1 Transducers—As in conventional piezoelectric-type ul-

generated with EMATs. trasonic examination, there are basically two types of EMATs

FIG. 1 EMAT Generation of Longitudinal Waves

E1774–96 (2002)

FIG. 2 EMAT Generation of Shear Waves

FIG. 3 Illustration of Horizontal and Vertical Polarizations for Shear Waves

with respect to beam direction. EMATs can be designed for design of the EMAT.The same holds for butterfly coils, placed

either straight or angle beam examination. Examples of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.