ASTM E1139/E1139M-17

(Practice)Standard Practice for Continuous Monitoring of Acoustic Emission from Metal Pressure Boundaries

Standard Practice for Continuous Monitoring of Acoustic Emission from Metal Pressure Boundaries

SIGNIFICANCE AND USE

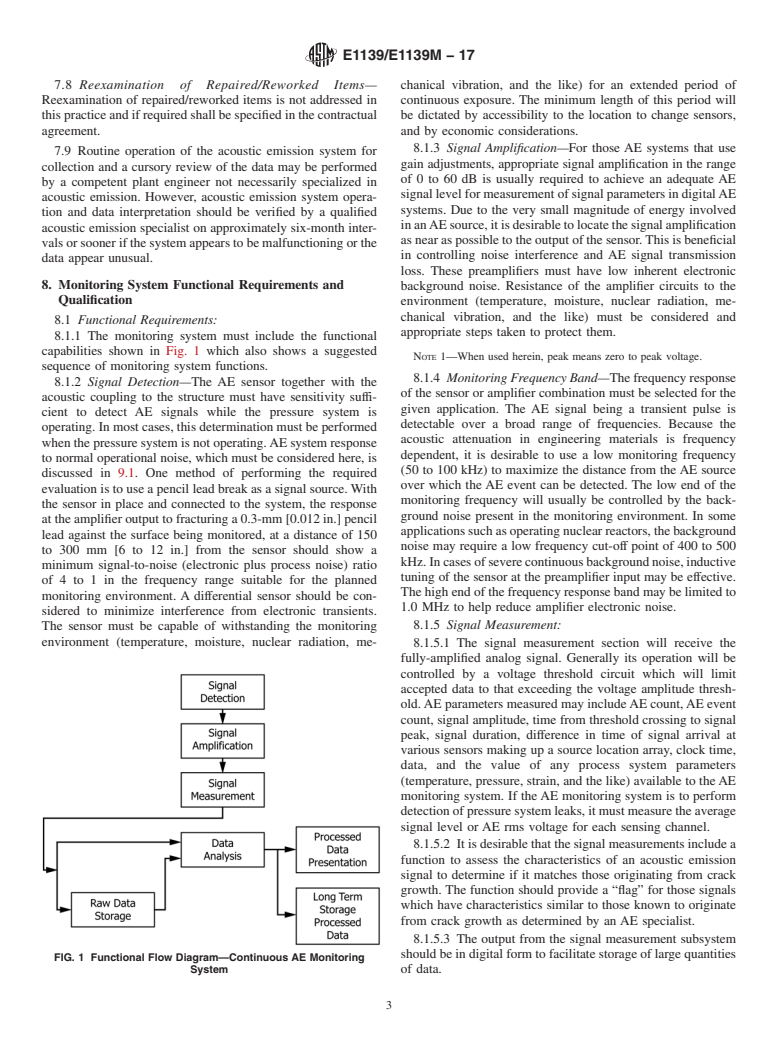

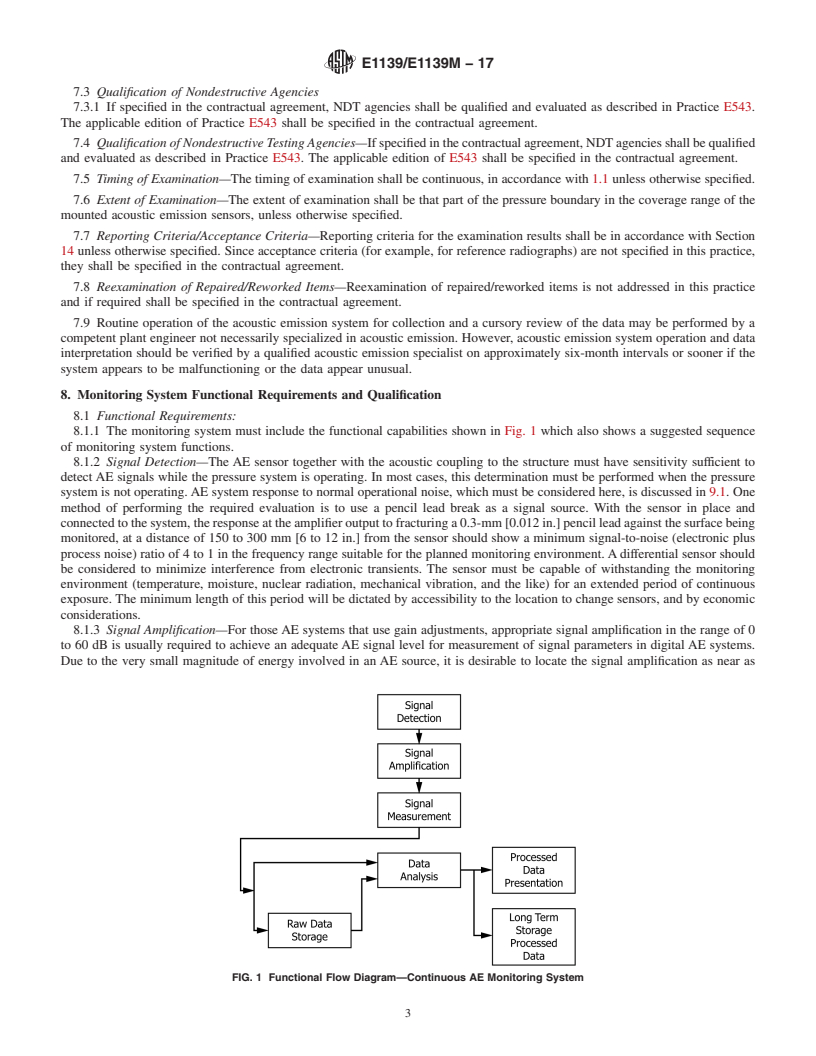

5.1 Acoustic emission examination of a structure requires application of a mechanical or thermal stimulus. In this case, the system operating conditions provide the stimulation. During operation of the pressurized system, AE from active discontinuities such as cracks or from other acoustic sources such as leakage of high-pressure, high-temperature fluids can be detected by an instrumentation system using sensors mounted on the structure. The sensors are acoustically coupled to the surface of the structure by means of a couplant material or pressure on the interface between the sensing device and the structure. This facilitates the transmission of acoustic energy to the sensor. When the sensors are excited by acoustic emission energy, they transform the mechanical excitations into electrical signals. The signals from a detected AE source are electronically conditioned and processed to produce information relative to source location and other parameters needed for AE source characterization and evaluation.

5.2 AE monitoring on a continuous basis is a currently available method for continuous surveillance of a structure to assess its continued integrity. The use of AE monitoring in this context is to identify the existence and location of AE sources. Also, information is provided to facilitate estimating the significance of the detected AE source relative to continued pressure system operation.

5.3 Source location accuracy is influenced by factors that affect elastic wave propagation, by sensor coupling, and by signal processor settings.

5.4 It is possible to measure AE and identify AE source locations of indications that cannot be detected by other NDT methods, due to factors related to methodological, material, or structural characteristics.

5.5 In addition to immediate evaluation of the AE sources, a permanent record of the total data collected (AE plus pressure system parameters measured) provides an archival record which can be re-evaluated.

SCOPE

1.1 This practice provides guidelines for continuous monitoring of acoustic emission (AE) from metal pressure boundaries in industrial systems during operation. Examples are pressure vessels, piping, and other system components which serve to contain system pressure. Pressure boundaries other than metal, such as composites, are specifically not covered by this document.

1.2 The functions of AE monitoring are to detect, locate, and characterize AE sources to provide data to evaluate their significance relative to pressure boundary integrity. These sources are those activated during system operation, that is, no special stimulus is applied to produce AE. Other methods of nondestructive testing (NDT) may be used, when the pressure boundary is accessible, to further evaluate or substantiate the significance of detected AE sources.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standards.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 6.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1139/E1139M − 17

Standard Practice for

Continuous Monitoring of Acoustic Emission from Metal

1

Pressure Boundaries

ThisstandardisissuedunderthefixeddesignationE1139/E1139M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This practice provides guidelines for continuous moni-

E543 Specification for Agencies Performing Nondestructive

toring of acoustic emission (AE) from metal pressure bound-

Testing

aries in industrial systems during operation. Examples are

E569 Practice for Acoustic Emission Monitoring of Struc-

pressure vessels, piping, and other system components which

tures During Controlled Stimulation

serve to contain system pressure. Pressure boundaries other

E650 Guide for Mounting Piezoelectric Acoustic Emission

than metal, such as composites, are specifically not covered by

Sensors

this document.

E750 Practice for Characterizing Acoustic Emission Instru-

1.2 The functions of AE monitoring are to detect, locate,

mentation

and characterize AE sources to provide data to evaluate their

E976 GuideforDeterminingtheReproducibilityofAcoustic

significance relative to pressure boundary integrity. These

Emission Sensor Response

sources are those activated during system operation, that is, no

E1316 Terminology for Nondestructive Examinations

special stimulus is applied to produce AE. Other methods of

E2374 Guide for Acoustic Emission System Performance

nondestructive testing (NDT) may be used, when the pressure

Verification

boundary is accessible, to further evaluate or substantiate the

3

2.2 Aerospace Industries Association:

significance of detected AE sources.

NAS-410 Certification and Qualification of Nondestructive

1.3 Units—The values stated in either SI units or inch-

Testing Personnel

4

pound units are to be regarded as standard.The values stated in

2.3 Other Documents:

each system may not be exact equivalents; therefore, each

SNT-TC-1A Recommended Practice for Nondestructive

system shall be used independently of the other. Combining

Testing Personnel Qualification and Certification

values from the two systems may result in non-conformance

ANSI/ASNT CP-189 ASNT Standard for Qualification and

with the standards.

Certification of Nondestructive Testing Personnel

5

1.4 This standard does not purport to address all of the

2.4 ISO Standard:

safety concerns, if any, associated with its use. It is the ISO 9712 Non-Destructive Testing: Qualification and Certi-

responsibility of the user of this standard to establish appro-

fication of NDT Personnel

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use. For specific

precautionary statements, see Section 6.

3.1 Definitions:

1.5 This international standard was developed in accor-

3.1.1 For definitions of terms used in this practice, refer to

dance with internationally recognized principles on standard- Terminology E1316.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mendations issued by the World Trade Organization Technical

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Barriers to Trade (TBT) Committee.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1000

WilsonBlvd.,Suite1700,Arlington,VA22209-3928,http://www.aia-aerospace.org.

1

This practice is under the jurisdiction of ASTM Committee E07 on Nonde-

4

structive Testing and is the direct responsibility of Subcommittee E07.04 on AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

Acoustic Emission Method. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

5

Current edition approved June 1, 2017. Published June 2017. Originally Available from International Organization for Standardization (ISO), ISO

approved in 1987. Last previous edition approved in 2012 as E1193 - 12. DOI: Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

10.1520/E1139-17. Geneva, Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1139/E1139M − 12 E1139/E1139M − 17

Standard Practice for

Continuous Monitoring of Acoustic Emission from Metal

1

Pressure Boundaries

This standard is issued under the fixed designation E1139/E1139M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice provides guidelines for continuous monitoring of acoustic emission (AE) from metal pressure boundaries in

industrial systems during operation. Examples are pressure vessels, piping, and other system components which serve to contain

system pressure. Pressure boundaries other than metal, such as composites, are specifically not covered by this document.

1.2 The functions of AE monitoring are to detect, locate, and characterize AE sources to provide data to evaluate their

significance relative to pressure boundary integrity. These sources are those activated during system operation, that is, no special

stimulus is applied to produce AE. Other methods of nondestructive testing (NDT) may be used, when the pressure boundary is

accessible, to further evaluate or substantiate the significance of detected AE sources.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standards.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific precautionary statements, see Section 6.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E543 Specification for Agencies Performing Nondestructive Testing

E569 Practice for Acoustic Emission Monitoring of Structures During Controlled Stimulation

E650 Guide for Mounting Piezoelectric Acoustic Emission Sensors

E750 Practice for Characterizing Acoustic Emission Instrumentation

E976 Guide for Determining the Reproducibility of Acoustic Emission Sensor Response

E1316 Terminology for Nondestructive Examinations

E2374 Guide for Acoustic Emission System Performance Verification

3

2.2 Aerospace Industries Association:

NAS-410 Certification and Qualification of Nondestructive Testing Personnel

4

2.3 Other Documents:

SNT-TC-1A Recommended Practice for Nondestructive Testing Personnel Qualification and Certification

ANSI/ASNT CP-189 ASNT Standard for Qualification and Certification of Nondestructive Testing Personnel

5

2.4 ISO Standard:

ISO 9712 Non-Destructive Testing: Qualification and Certification of NDT Personnel

1

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.04 on Acoustic Emission

Method.

Current edition approved June 15, 2012June 1, 2017. Published July 2012June 2017. Originally approved in 1987. Last previous edition approved in 20072012 as

E1193 - 07.E1193 - 12. DOI: 10.1520/E1139-12.10.1520/E1139-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Aerospace Industries Association of America, Inc. (AIA), 1000 Wilson Blvd., Suite 1700, Arlington, VA 22209-3928, http://www.aia-aerospace.org.

4

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

5

Available from International Organization for Standardization (ISO), ISO Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier, Geneva,

Switzerland, http://www.iso.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.