ASTM E976-15(2021)

(Guide)Standard Guide for Determining the Reproducibility of Acoustic Emission Sensor Response

Standard Guide for Determining the Reproducibility of Acoustic Emission Sensor Response

SIGNIFICANCE AND USE

3.1 Acoustic emission data is affected by several characteristics of the instrumentation. The most obvious of these is the system sensitivity. Of all the parameters and components contributing to the sensitivity, the acoustic emission sensor is the one most subject to variation. This variation can be a result of damage or aging, or there can be variations between nominally identical sensors. To detect such variations, it is desirable to have a method for measuring the response of a sensor to an acoustic wave. Specific purposes for checking sensors include: (1) checking the stability of its response with time; (2) checking the sensor for possible damage after accident or abuse; (3) comparing a number of sensors for use in a multichannel system to ensure that their responses are adequately matched; and (4) checking the response after thermal cycling or exposure to a hostile environment. It is very important that the sensor characteristics be always measured with the same sensor cable length and impedance as well as the same preamplifier or equivalent. This guide presents several procedures for measuring sensor response. Some of these procedures require a minimum of special equipment.

3.2 It is not the intent of this guide to evaluate AE system performance. Refer to Practice E750 for characterizing acoustic instrumentation and refer to Guide E2374 for AE system performance verification.

3.3 The procedures given in this guide are designed to measure the response of an acoustic emission sensor to an arbitrary but repeatable acoustic wave. These procedures in no way constitute a calibration of the sensor. The absolute calibration of a sensor requires a complete knowledge of the characteristics of the acoustic wave exciting the sensor or a previously calibrated reference sensor. In either case, such a calibration is beyond the scope of this guide.

3.4 The fundamental requirement for comparing sensor responses is a source of repeatable acoustic waves. The character...

SCOPE

1.1 This guide defines simple economical procedures for testing or comparing the performance of acoustic emission sensors. These procedures allow the user to check for degradation of a sensor or to select sets of sensors with nearly identical performances. The procedures are not capable of providing an absolute calibration of the sensor nor do they assure transferability of data sets between organizations.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E976 − 15 (Reapproved 2021)

Standard Guide for

Determining the Reproducibility of Acoustic Emission

Sensor Response

This standard is issued under the fixed designation E976; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Significance and Use

1.1 This guide defines simple economical procedures for

3.1 Acoustic emission data is affected by several character-

testing or comparing the performance of acoustic emission

istics of the instrumentation. The most obvious of these is the

sensors. These procedures allow the user to check for degra-

system sensitivity. Of all the parameters and components

dation of a sensor or to select sets of sensors with nearly

contributing to the sensitivity, the acoustic emission sensor is

identical performances. The procedures are not capable of

the one most subject to variation. This variation can be a result

providing an absolute calibration of the sensor nor do they

of damage or aging, or there can be variations between

assure transferability of data sets between organizations.

nominally identical sensors. To detect such variations, it is

desirable to have a method for measuring the response of a

1.2 Units—The values stated in SI units are to be regarded

sensor to an acoustic wave. Specific purposes for checking

as standard. No other units of measurement are included in this

sensors include: (1) checking the stability of its response with

standard.

time; (2) checking the sensor for possible damage after

1.3 This standard does not purport to address all of the

accident or abuse; (3) comparing a number of sensors for use

safety concerns, if any, associated with its use. It is the

in a multichannel system to ensure that their responses are

responsibility of the user of this standard to establish appro-

adequately matched; and (4) checking the response after

priate safety, health, and environmental practices and deter-

thermal cycling or exposure to a hostile environment. It is very

mine the applicability of regulatory limitations prior to use.

important that the sensor characteristics be always measured

1.4 This international standard was developed in accor-

with the same sensor cable length and impedance as well as the

dance with internationally recognized principles on standard-

same preamplifier or equivalent. This guide presents several

ization established in the Decision on Principles for the

procedures for measuring sensor response. Some of these

Development of International Standards, Guides and Recom-

procedures require a minimum of special equipment.

mendations issued by the World Trade Organization Technical

3.2 It is not the intent of this guide to evaluate AE system

Barriers to Trade (TBT) Committee.

performance. Refer to Practice E750 for characterizing acous-

tic instrumentation and refer to Guide E2374 for AE system

2. Referenced Documents

performance verification.

2.1 ASTM Standards:

3.3 The procedures given in this guide are designed to

E750 Practice for Characterizing Acoustic Emission Instru-

measure the response of an acoustic emission sensor to an

mentation

arbitrary but repeatable acoustic wave. These procedures in no

E2075 Practice for Verifying the Consistency of AE-Sensor

way constitute a calibration of the sensor. The absolute

Response Using an Acrylic Rod

calibration of a sensor requires a complete knowledge of the

E2374 Guide for Acoustic Emission System Performance

Verification characteristics of the acoustic wave exciting the sensor or a

previously calibrated reference sensor. In either case, such a

calibration is beyond the scope of this guide.

This guide is under the jurisdiction of ASTM Committee E07 on Nondestruc-

3.4 The fundamental requirement for comparing sensor

tive Testing and is the direct responsibility of Subcommittee E07.04 on Acoustic

responses is a source of repeatable acoustic waves. The

Emission Method.

characteristics of the wave do not need to be known as long as

Current edition approved Nov. 1, 2021. Published November 2021. Originally

the wave can be reproduced at will. The sources and geom-

approved in 1984. Last previous edition approved in 2015 as E976 – 15. DOI:

10.1520/E0976-15R21.

etries given in this guide will produce primarily compressional

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

waves. While the sensors will respond differently to different

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

types of waves, changes in the response to one type of wave

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. will imply changes in the responses to other types of waves.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E976 − 15 (2021)

3.5 These procedures use a test block or rod. Such a device use with an ultrasonic transducer and is required when the

provides a convenient mounting surface for the sensor and transducer drive uses any form of coherent electrical signal.

when appropriately marked, can ensure that the source and the

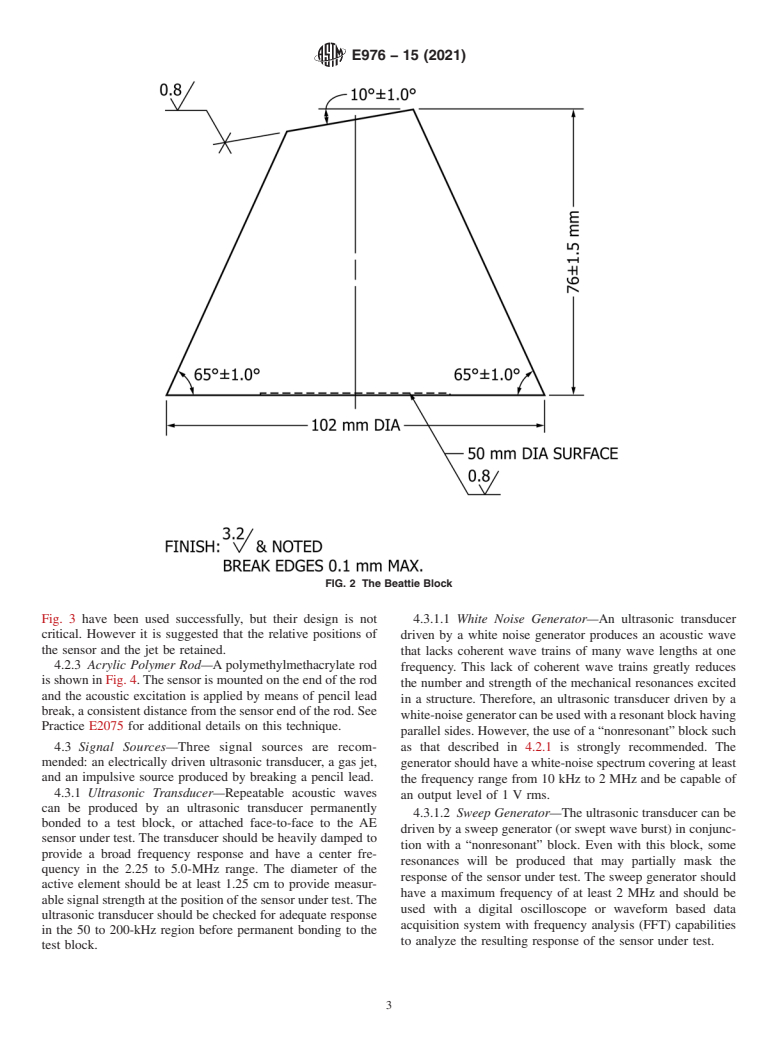

4.2.1 Conical “Nonresonant” Block—The Beattie block,

sensor are always positioned identically with respect to each

shown in Fig. 2, can be machined from a 10-cm diameter metal

other. The device or rod also provides mechanical loading of

billet. The preferred materials are aluminum and low-alloy

the sensor similar to that experienced in actual use. Care must

steel. After the bottom is faced and the taper cut, the block is

be taken when using these devices to minimize resonances so

clamped at a 10° angle and the top face is milled. The

that the characteristics of the sensor are not masked by these

dimensions given will provide an approximate circle just over

resonances.

2.5 cm in diameter for mounting the sensor. The acoustic

3.6 These procedures allow comparison of responses only excitation should be applied at the center of the bottom face.

on the same test setup. No attempt should be made to compare

The conic geometry and lack of any parallel surfaces reduce

responses on different test setups, whether in the same or

the number of mechanical resonances that the block can

separate laboratories.

support.Afurther reduction in possible resonances of the block

can be achieved by roughly machining all surfaces except

4. Apparatus

where the sensor and exciter are mounted and coating them

4.1 The essential elements of the apparatus for these proce- with a layer of metal-filled epoxy.

dures are: (1) the acoustic emission sensor under test; (2)a

4.2.2 Gas-Jet Test Block—Twogas-jettestblocksareshown

block or rod; (3) a signal source; and (4) measuring and

in Fig. 3. The block shown in Fig. 3(a) is used for opposite

recording equipment.

surface comparisons, which produce primarily compressional

4.1.1 Block diagrams of some of the possible experimental

waves. That shown in Fig. 3(b) is for same surface compari-

setups are shown in Fig. 1.

sons which produce primarily surface waves. The “nonreso-

nant” block described in 4.2.1 can also be used with a gas jet

4.2 Blocks—The design of the block is not critical.

However,theuseofa“nonresonant”blockisrecommendedfor in order to avoid exciting many resonant modes. The blocks in

FIG. 1 Block Diagrams of Possible Experimental Setups

E976 − 15 (2021)

FIG. 2 The Beattie Block

Fig. 3 have been used successfully, but their design is not 4.3.1.1 White Noise Generator—An ultrasonic transducer

critical. However it is suggested that the relative positions of driven by a white noise generator produces an acoustic wave

the sensor and the jet be retained.

that lacks coherent wave trains of many wave lengths at one

4.2.3 Acrylic Polymer Rod—A polymethylmethacrylate rod

frequency. This lack of coherent wave trains greatly reduces

is shown in Fig. 4.The sensor is mounted on the end of the rod

the number and strength of the mechanical resonances excited

and the acoustic excitation is applied by means of pencil lead

in a structure. Therefore, an ultrasonic transducer driven by a

break, a consistent distance from the sensor end of the rod. See

white-noisegeneratorcanbeusedwitharesonantblockhaving

Practice E2075 for additional details on this technique.

parallel sides. However, the use of a “nonresonant” block such

4.3 Signal Sources—Three signal sources are recom- as that described in 4.2.1 is strongly recommended. The

mended: an electrically driven ultrasonic transducer, a gas jet, generator should have a white-noise spectrum covering at least

and an impulsive source produced by breaking a pencil lead.

the frequency range from 10 kHz to 2 MHz and be capable of

4.3.1 Ultrasonic Transducer—Repeatable acoustic waves

an output level of 1 V rms.

can be produced by an ultrasonic transducer permanently

4.3.1.2 Sweep Generator—The ultrasonic transducer can be

bonded to a test block, or attached face-to-face to the AE

driven by a sweep generator (or swept wave burst) in conjunc-

sensor under test. The transducer should be heavily damped to

tion with a “nonresonant” block. Even with this block, some

provide a broad frequency response and have a center fre-

resonances will be produced that may partially mask the

quency in the 2.25 to 5.0-MHz range. The diameter of the

response of the sensor under test. The sweep generator should

active element should be at least 1.25 cm to provide measur-

have a maximum frequency of at least 2 MHz and should be

able signal strength at the position of the sensor under test.The

used with a digital oscilloscope or waveform based data

ultrasonic transducer should be checked for adequate response

acquisition system with frequency analysis (FFT) capabilities

in the 50 to 200-kHz region before permanent bonding to the

to analyze the resulting response of the sensor under test.

test block.

E976 − 15 (2021)

(a) Opposite Surface Comparison Setup

(b) Same Surface Comparison Test

FIG. 3 Gas-Jet Test Blocks

slightly less than one-half the period of the center frequency of

the transducer (≤0.22 µs for a 2.25 MHz transducer) or longer

than the damping time of the sensor, block, and transducer

(typically >10 ms). The pulse repetition rate should be low

(<100 pulses/s) so that each acoustic wave train is damped out

before the next one is excited.

4.3.1.4 The pulse generator should be used with a digital

oscilloscope or waveform based data acquisition system (such

asawaveformbasedAEsystem)or,insingle-pu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.