ASTM D2096-11(2019)

(Test Method)Standard Test Method for Colorfastness and Transfer of Color in the Washing of Leather

Standard Test Method for Colorfastness and Transfer of Color in the Washing of Leather

SIGNIFICANCE AND USE

4.1 The procedure is intended, primarily to evaluate the ability of a leather specimen to withstand fixed, and rather strenuous, laundering conditions. This test is not intended as a recommended washing procedure, neither household nor commercial. Although this test concerns itself with colorfastness and transfer of color during washing, the washed leather specimens are available also for comparing other properties (that is, tensile strength, area change, change in outline, etc.) with those of unwashed samples.

SCOPE

1.1 This test method covers the determination of the colorfastness of colored leathers, with or without a surface coating. The leathers to be tested are of the type normally expected to withstand frequent laundering. This test method also covers the simultaneous staining of adjacent textile materials when the leather specimens are washed. This test method does not apply to wet blue. Two procedures are covered depending on the apparatus used:

1.1.1 Procedure A, using the Launder-Ometer,2 and

1.1.2 Procedure B, using an alternative washing machine.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values stated in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2096 − 11 (Reapproved 2019)

Standard Test Method for

Colorfastness and Transfer of Color in the Washing of

Leather

This standard is issued under the fixed designation D2096; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the determination of the color-

D499 Specification for White Floating Toilet Soap (With-

fastness of colored leathers, with or without a surface coating.

drawn 2000)

The leathers to be tested are of the type normally expected to

withstandfrequentlaundering.Thistestmethodalsocoversthe 2.2 ISO Standard:

simultaneous staining of adjacent textile materials when the

ISO R105/I, Part 2 Gray Scale for Evaluating Change in

leather specimens are washed. This test method does not apply Color

to wet blue. Two procedures are covered depending on the ISO R105/I, Part 3 Gray Scale for Evaluating Staining

apparatus used:

2.3 ASTM Adjunct:

1.1.1 Procedure A, using the Launder-Ometer, and

Leather washing apparatus (1 drawing)

1.1.2 Procedure B, using an alternative washing machine.

3. Summary of Test Method

1.2 The values stated in inch-pound units are to be regarded

3.1 Three leather specimens 50 by 80 mm (approximately 2

as the standard. The values stated in parentheses are provided

by 3 in.), and one piece of multifiber test fabric of nearly equal

for information only.

size are washed together in soapy water at 120°F (49°C).After

1.3 This standard does not purport to address all of the 1

⁄2 h of washing, the leather specimens and cloth are removed

safety concerns, if any, associated with its use. It is the

and rinsed carefully in running water at about 95°F (35°C).

responsibility of the user of this standard to establish appro-

One leather specimen and the test cloth are removed and

priate safety, health, and environmental practices and deter-

air-dried. A new piece of test cloth is added to the remaining

mine the applicability of regulatory limitations prior to use. 1

twoleatherspecimensandthesearewashed,asabove,for ⁄2h.

1.4 This international standard was developed in accor- Therinsingisrepeated;againoneleatherspecimenandthetest

dance with internationally recognized principles on standard-

cloth are removed for drying. The remaining leather specimen,

ization established in the Decision on Principles for the with a new piece of test cloth, is washed again for ⁄2 h. This

Development of International Standards, Guides and Recom-

final leather specimen and test cloth are then rinsed and dried

mendations issued by the World Trade Organization Technical as above. When dry, the color of the washed leather specimens

Barriers to Trade (TBT) Committee. is rated by comparing it with an unwashed piece of leather.

Transfer of color to the test fabric is rated by comparison with

an unwashed piece of test fabric. These comparisons are made

with the aid of the proper Gray Scale. All ratings are made on

This test method is under the jurisdiction ofASTM Committee D31 on Leather

dry test specimens.

and is the direct responsibility of Subcommittee D31.04 on Apparel This test

method was developed in cooperation with the American Leather Chemists Assn.

Current edition approved Sept. 1, 2019. Published September 2019. Originally

approved in 1962. Last previous edition approved in 2011 as D2096 – 11. DOI:

10.1520/D2096-11R19. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

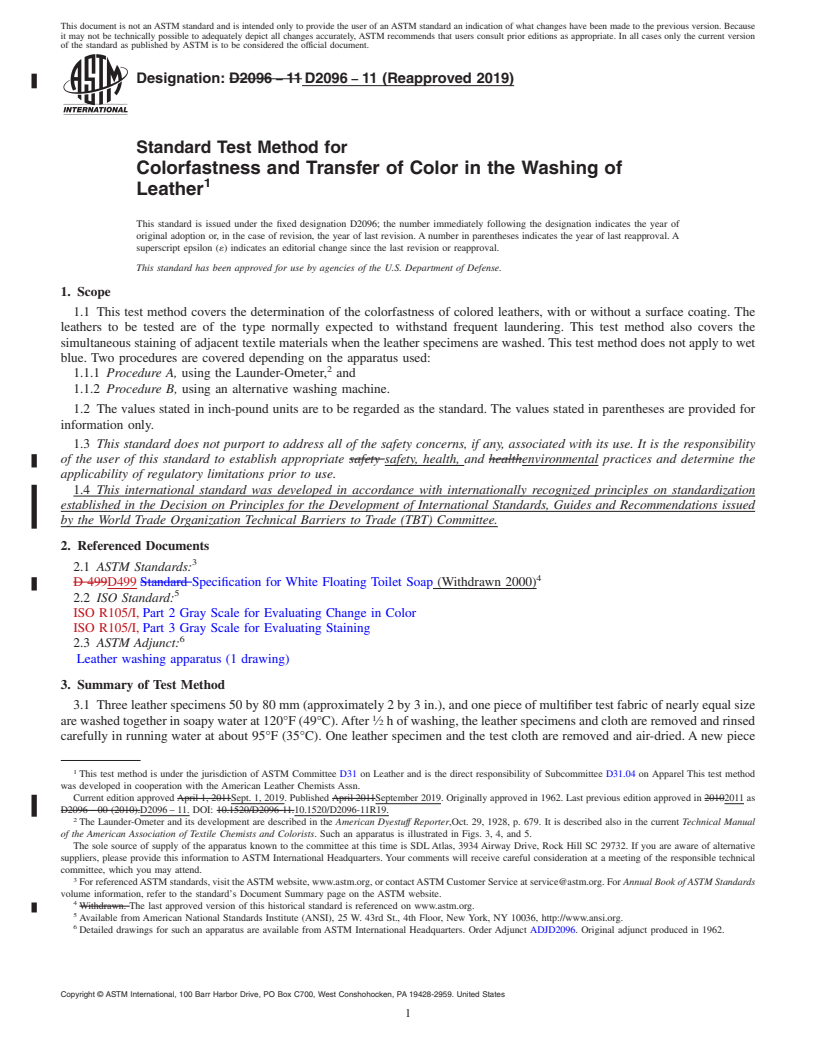

The Launder-Ometer and its development are described in the American contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

DyestuffReporter, Oct. 29, 1928, p. 679. It is described also in the currentTechnical Standards volume information, refer to the standard’s Document Summary page on

Manual of the American Association of Textile Chemists and Colorists. Such an the ASTM website.

apparatus is illustrated in Figs. 3, 4, and 5. The last approved version of this historical standard is referenced on

The sole source of supply of the apparatus known to the committee at this time www.astm.org.

is SDL Atlas, 3934 Airway Drive, Rock Hill SC 29732. If you are aware of Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

alternative suppliers, please provide this information to ASTM International 4th Floor, New York, NY 10036, http://www.ansi.org.

Headquarters.Your comments will receive careful consideration at a meeting of the DetaileddrawingsforsuchanapparatusareavailablefromASTMInternational

responsible technical committee, which you may attend. Headquarters. Order Adjunct ADJD2096. Original adjunct produced in 1962.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2096 − 11 (2019)

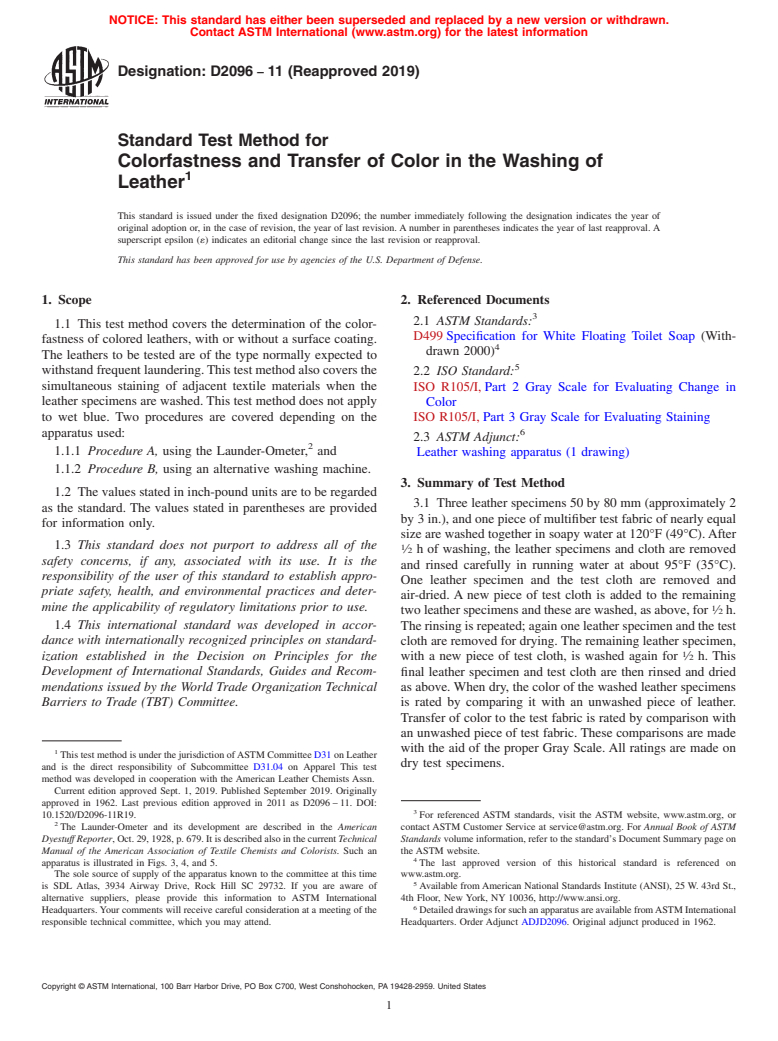

FIG. 1 Washing Machine, Heated Air Bath (Procedure B)

4. Significance and Use 5.3 Balls, type 316 stainless steel, ⁄4-in. (6.4-mm) diameter,

20 per specimen container.

4.1 The procedure is intended, primarily to evaluate the

ability of a leather specimen to withstand fixed, and rather 5.4 Test Cloth, multifiber, 50 by 80 mm, three pieces per

strenuous, laundering conditions. This test is not intended as a test.

recommended washing procedure, neither household nor com-

NOTE2—Multifibertestfabricsareavailablein6-fibercloth,containing

8 8

mercial. Although this test concerns itself with colorfastness

filling strips of wool, Orlon, Dacron, nylon-66, bleached cotton, and

and transfer of color during washing, the washed leather

acetate, assembled in 2-in. (50-mm) repeats. Tests may be run with any

test fabric of special interest and reported accordingly.

specimens are available also for comparing other properties

(that is, tensile strength, area change, change in outline, etc.)

5.5 Gray Scales, consisting of the following:

with those of unwashed samples.

5.5.1 ISO R105/I, Part 2, British, for assessing the effect in

fastness testing, and

5. Apparatus

5.5.2 ISOR105/I,Part3,British,fordeterminingthedegree

of staining in fastness testing.

5.1 Washing Machine—A Launder-Ometer, or an assembly

of apparatus capable of similar test conditions (Note 1). In

6. Reagent

either machine, 1-pt (500-mL) specimen containers are held

with their bases toward a horizontal shaft and 2-in. (50 mm)

6.1 Mild Soap Solution, 0.5 %, such as made from a white,

out from its center of rotation. Speed of rotation shall be 40 to

floating, toilet soap (Specification D499). The solution shall be

45 rpm. Provision shall be made for maintaining the initial

temperature of the specimen containers throughout the test.

The sole source of supply of the test cloth known to the committee at this time

Additional agitation shall be provided by ⁄4-in. (6.4 mm)

is Testfabrics, Inc., 200 Blackford Ave., P.O. Box 420, Middlesex, NJ 08846-0420;

stainless steel balls in the specimen containers.

telephone: (201) 469-6446; fax: (201) 469-1147. If you are aware of alternative

suppliers, please provide this information to ASTM Headquarters. Your comments

NOTE 1—A motor-driven assembly, designed to hold 1-pt (500-mL)

will receive careful consideration at a meeting of the responsible technical

specimen containers so that they are relative to the axis of the motor shaft

committee, which you may attend.

in the same way as in the Launder-Ometer, can be used. The entire

Trademark of E. I. du Pont de Nemours & Co.

assembly, fitted with specimen containers, shall be turned at 40 to 45 rpm

These scales and their use are described in the 1989 Technical Manual of the

inside a simple boxlike container which is heated at 120°F (49°C) with American Association of Textile Chemists and Colorists. Additional references on

thermostatic control. Thus, heat loss from the preheated conte

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2096 − 11 D2096 − 11 (Reapproved 2019)

Standard Test Method for

Colorfastness and Transfer of Color in the Washing of

Leather

This standard is issued under the fixed designation D2096; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the determination of the colorfastness of colored leathers, with or without a surface coating. The

leathers to be tested are of the type normally expected to withstand frequent laundering. This test method also covers the

simultaneous staining of adjacent textile materials when the leather specimens are washed. This test method does not apply to wet

blue. Two procedures are covered depending on the apparatus used:

1.1.1 Procedure A, using the Launder-Ometer, and

1.1.2 Procedure B, using an alternative washing machine.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values stated in parentheses are provided for

information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D 499D499 Standard Specification for White Floating Toilet Soap (Withdrawn 2000)

2.2 ISO Standard:

ISO R105/I, Part 2 Gray Scale for Evaluating Change in Color

ISO R105/I, Part 3 Gray Scale for Evaluating Staining

2.3 ASTM Adjunct:

Leather washing apparatus (1 drawing)

3. Summary of Test Method

3.1 Three leather specimens 50 by 80 mm (approximately 2 by 3 in.), and one piece of multifiber test fabric of nearly equal size

are washed together in soapy water at 120°F (49°C). After ⁄2 h of washing, the leather specimens and cloth are removed and rinsed

carefully in running water at about 95°F (35°C). One leather specimen and the test cloth are removed and air-dried. A new piece

This test method is under the jurisdiction of ASTM Committee D31 on Leather and is the direct responsibility of Subcommittee D31.04 on Apparel This test method

was developed in cooperation with the American Leather Chemists Assn.

Current edition approved April 1, 2011Sept. 1, 2019. Published April 2011September 2019. Originally approved in 1962. Last previous edition approved in 20102011 as

D2096 – 00 (2010).D2096 – 11. DOI: 10.1520/D2096-11.10.1520/D2096-11R19.

The Launder-Ometer and its development are described in the American Dyestuff Reporter,Oct. 29, 1928, p. 679. It is described also in the current Technical Manual

of the American Association of Textile Chemists and Colorists. Such an apparatus is illustrated in Figs. 3, 4, and 5.

The sole source of supply of the apparatus known to the committee at this time is SDL Atlas, 3934 Airway Drive, Rock Hill SC 29732. If you are aware of alternative

suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical

committee, which you may attend.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Withdrawn. The last approved version of this historical standard is referenced on www.astm.org.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Detailed drawings for such an apparatus are available from ASTM International Headquarters. Order Adjunct ADJD2096. Original adjunct produced in 1962.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2096 − 11 (2019)

FIG. 1 Washing Machine, Heated Air Bath (Procedure B)

of test cloth is added to the remaining two leather specimens and these are washed, as above, for ⁄2 h. The rinsing is repeated;

again one leather specimen and the test cloth are removed for drying. The remaining leather specimen, with a new piece of test

cloth, is washed again for ⁄2 h. This final leather specimen and test cloth are then rinsed and dried as above. When dry, the color

of the washed leather specimens is rated by comparing it with an unwashed piece of leather. Transfer of color to the test fabric

is rated by comparison with an unwashed piece of test fabric. These comparisons are made with the aid of the proper Gray Scale.

All ratings are made on dry test specimens.

4. Significance and Use

4.1 The procedure is intended, primarily to evaluate the ability of a leather specimen to withstand fixed, and rather strenuous,

laundering conditions. This test is not intended as a recommended washing procedure, neither household nor commercial. Although

this test concerns itself with colorfastness and transfer of color during washing, the washed leather specimens are available also

for comparing other properties (that is, tensile strength, area change, change in outline, etc.) with those of unwashed samples.

5. Apparatus

5.1 Washing Machine—A Launder-Ometer, or an assembly of apparatus capable of similar test conditions (Note 1). In either

machine, 1-pt (500-mL) specimen containers are held with their bases toward a horizontal shaft and 2-in. (50 mm) out from its

center of rotation. Speed of rotation shall be 40 to 45 rpm. Provision shall be made for maintaining the initial temperature of the

specimen containers throughout the test. Additional agitation shall be provided by ⁄4-in. (6.4 mm) stainless steel balls in the

specimen containers.

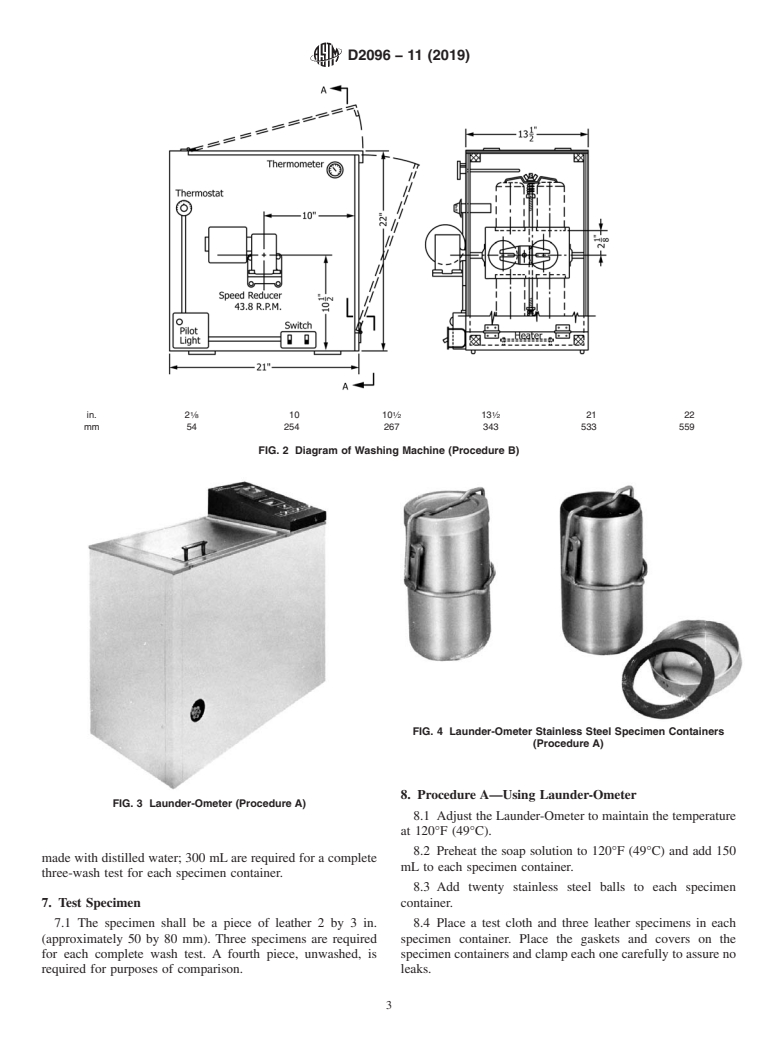

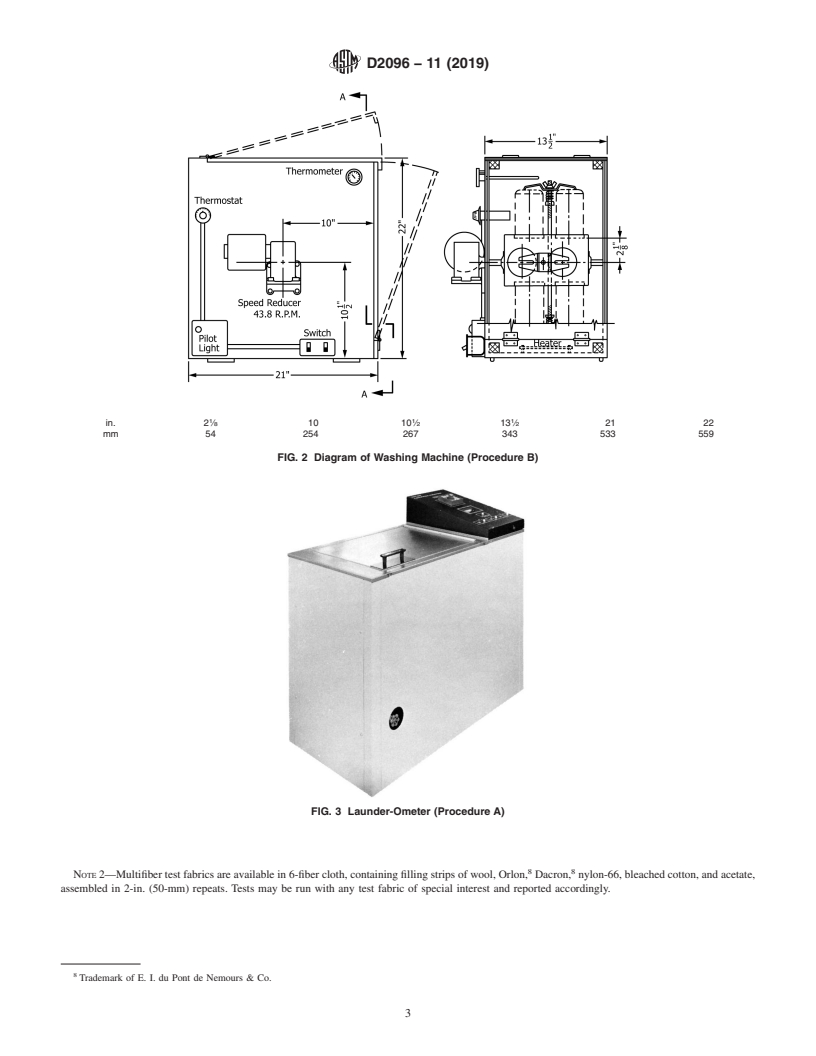

NOTE 1—A motor-driven assembly, designed to hold 1-pt (500-mL) specimen containers so that they are relative to the axis of the motor shaft in the

same way as in the Launder-Ometer, can be used. The entire assembly, fitted with specimen containers, shall be turned at 40 to 45 rpm inside a simple

boxlike container which is heated at 120°F (49°C) with thermostatic control. Thus, heat loss from the preheated contents of the specimen containers is

held at a minimum during the 30-min washing periods. Such an apparatus is illustrated in Figs. 1 and 2.

5.2 Specimen Containers, glass or stainless steel, 1-pt (500-mL), washer, and cap.

5.3 Balls, type 316 stainless steel, ⁄4-in. (6.4-mm) diameter, 20 per specimen container.

5.4 Test Cloth, multifiber, 50 by 80 mm, three pieces per test.

The sole source of supply of the test cloth known to the committee at this time is Testfabrics, Inc., 200 Blackford Ave., P.O. Box 420, Middlesex, NJ 08846-0420;

telephone: (201) 469-6446; fax: (201) 469-1147. If you are aware of alternative suppliers, please provide this information to ASTM Headquarters. Your comments will receive

careful consideration at a meeting of the responsible technical committee, which you may attend.

D2096 − 11 (2019)

1 1 1

in. 2 ⁄8 10 10 ⁄2 13 ⁄2 21 22

mm 54 254 267 343 533 559

FIG. 2 Diagram of Washing Machine (Procedure B)

FIG. 3 Launder-Ometer (Procedure A)

8 8

NOTE 2—Multifiber test fabrics are available in 6-fiber cloth, containing filling strips of wool, Orlon, Dacron, nylon-66, bleached cotton, and acetate,

assembled in 2-in. (50-mm) repeats. Tests may be run with any test fabric of special interest and repor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.