ASTM A958-00

(Specification)Standard Specification for Steel Castings, Carbon, and Alloy, with Tensile Requirements, Chemical Requirements Similar to Standard Wrought Grades

Standard Specification for Steel Castings, Carbon, and Alloy, with Tensile Requirements, Chemical Requirements Similar to Standard Wrought Grades

SCOPE

1.1 This specification covers carbon and low alloy steel castings having chemical analyses similar to that of the standard wrought grades.

1.2 Several classes are covered and are designated by chemical composition shown in Table 1.

1.3 Options for tensile properties are shown in Tables 2 and 3.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. Inch-pound units are applicable for material ordered to Specification A958 and SI units for material ordered to Specification A958M.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 958 – 00

Standard Specification for

Steel Castings, Carbon and Alloy, with Tensile

Requirements, Chemical Requirements Similar to Standard

Wrought Grades

This standard is issued under the fixed designation A 958; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope A 781/A 781M Specification for Castings, Steel andAlloy,

Common Requirements, for General Industrial Use

1.1 This specification covers carbon and low-alloy steel

E 29 Practice for Using Significant Digits in Test Data to

castings having chemical analyses similar to that of the

Determine Conformance with Specifications

standard wrought grades.

1.2 Several classes are covered and are designated by

3. General Conditions for Delivery

chemical composition as shown in Table 1.

3.1 Material furnished to this specification shall conform to

1.3 Options for tensile properties are shown in Tables 2 and

the requirements of Specification A 781/A 781M, including

3.

any supplementary requirements that are indicated in the

1.4 The values stated in either inch-pound units or SI units

purchase order. Failure to comply with the general require-

are to be regarded separately as standard. Within the text, the

ments of Specification A 781/A 781M constitutes nonconfor-

SI units are shown in brackets. The values stated in each

mance with this specification. In case of conflict between the

system are not exact equivalents; therefore, each system must

requirements of this specification and Specification A 781/

be used independently of the other. Combining values from the

A 781M, this specification shall prevail.

two systems may result in nonconformance with the specifica-

tion. Inch-pound units are applicable for material ordered to

4. Ordering Information

Specification A 958 and SI units for material ordered to

4.1 Orders for material under this specification should

Specification A 958.

include the following information.

4.1.1 Quantity,

2. Referenced Documents

4.1.2 Specification, including year and date of issue,

2.1 ASTM Standards:

4.1.3 Grade and class of steel,

A 370 Test Methods and Definitions for MechanicalTesting

2 4.1.4 Description of the casting by pattern number or

of Steel Products

drawing (Dimensional tolerances should be included on the

A 488/A 488M Practice for Steel Castings, Welding, Quali-

2 casting drawing.),

fication of Procedures and Personnel

4.1.5 Options in the specification, and

4.1.6 Supplementary requirements desired, including stan-

ThisspecificationisunderthejurisdictionofASTMCommitteeA01onFerrous dards of acceptance.

Metals and is the direct responsibility of Subcommittee A01.18 on Castings.

Current edition approved Sept. 10, 2000. Published November 2000. Originally

e1

published as A 958 – . Last previous edition A 958 – 96 .

2 3

Annual Book of ASTM Standards, Vol 01.02. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 958

TABLE 1 Chemical Composition, Weight Percent

NOTE 1—Values are maximum unless a range is given.

Grade C Mn P S Si Ni Cr Mo

SC 1020 0.18/0.23 0.40/0.80 0.040 0.040 0.30/0.60 - - -

SC 1025 0.22/0.28 0.40/0.80 0.040 0.040 0.30/0.60 - - -

SC 1030 0.28/0.34 0.50/0.90 0.040 0.040 0.30/0.60 - - -

SC 1040 0.37/0.44 0.50/0.90 0.040 0.040 0.30/0.60 - - -

SC 1045 0.43/0.50 0.50/0.90 0.040 0.040 0.30/0.60 - - -

SC 4130 0.28/0.33 0.40/0.80 0.035 0.040 0.30/0.60 - 0.80/1.10 0.15/0.25

SC 4140 0.38/0.43 0.70/1.10 0.035 0.040 0.30/0.60 - 0.80/1.10 0.15/0.25

SC 4330 0.28/0.33 0.60/0.90 0.035 0.040 0.30/0.60 1.65/2.00 0.70/0.90 0.20/0.30

SC 4340 0.38/0.43 0.60/0.90 0.035 0.040 0.30/0.60 1.65/2.00 0.70/0.90 0.20/0.30

SC 8620 0.18/0.23 0.60/1.00 0.035 0.040 0.30/0.60 0.40/0.70 0.40/0.60 0.15/0.25

SC 8625 0.23/0.28 0.60/1.00 0.035 0.040 0.30/0.60 0.40/0.70 0.40/0.60 0.15/0.25

SC 8630 0.28/0.33 0.60/1.00 0.035 0.040 0.30/0.60 0.40/0.70 0.40/0.60 0.15/0.25

TABLE 2 Tensile Requirements

Class 65/35 70/36 80/40 80/50 90/60 105/85 115/95 130/115 135/125 150/135 160/145 165/150 210/180

Tensile, ksi 65 70 80 80 90 105 115 130 135 150 160 165 210

Tensile, (MPa) (450) (485) (550) (550) (620) (725) (795) (895) (930) (1035) (1105) (1140) (1450)

Yield, ksi 35 36 40 50 60 85 95 115 125 135 145 150 180

Yield, (MPa) (240) (250) (275) (345) (415) (585) (655) (795) (860) (930) (1000) (1035) (1240)

Elongation in 224 22 18 22 18 17 14 11 97654

in.or50mm,

min, %

Reduction of 35 30 30 35 35 35 30 25 22 18 12 10 8

Area, %

TABLE 3 Tensile Requirements/Grade Suitability

Class 65/35 70/36 80/40 80/50 90/60 105/85 115/95 130/115 135/125 150/135 160/145 165/150 210/180

Grade

A

SC 1020 X X

SC 1025 X X

SC 1030 X X X X

B

SC 1040 X XX X X

B B

SC 1045 X X XX X X X

B B

SC 4130 X X XX X X X X X X

B B B B

SC 4140 X X X X X X X X XX XX

B B B B

SC 4330 X X X X X X X X XX XX X

B B B B B

SC 4340 X X X X X XX XX XX XX

B B

SC 8620 X X XX X X X

B B

SC 8625 X X XX X X X X X

B B

SC 8630 X X XX X X X X X X

A

“X” denotes that the properties may be achieved by at least one of the heat treatments referenced in 5. The effect of section thickness should be considered in making

grade selections. The heat treatment requirements do not imply that all section thicknesses will be through hardened.

B

These grades are likely to significantly exceed the minimum strength levels, therefore, problems may be experienced when trying to produce castings to low hardness

values.

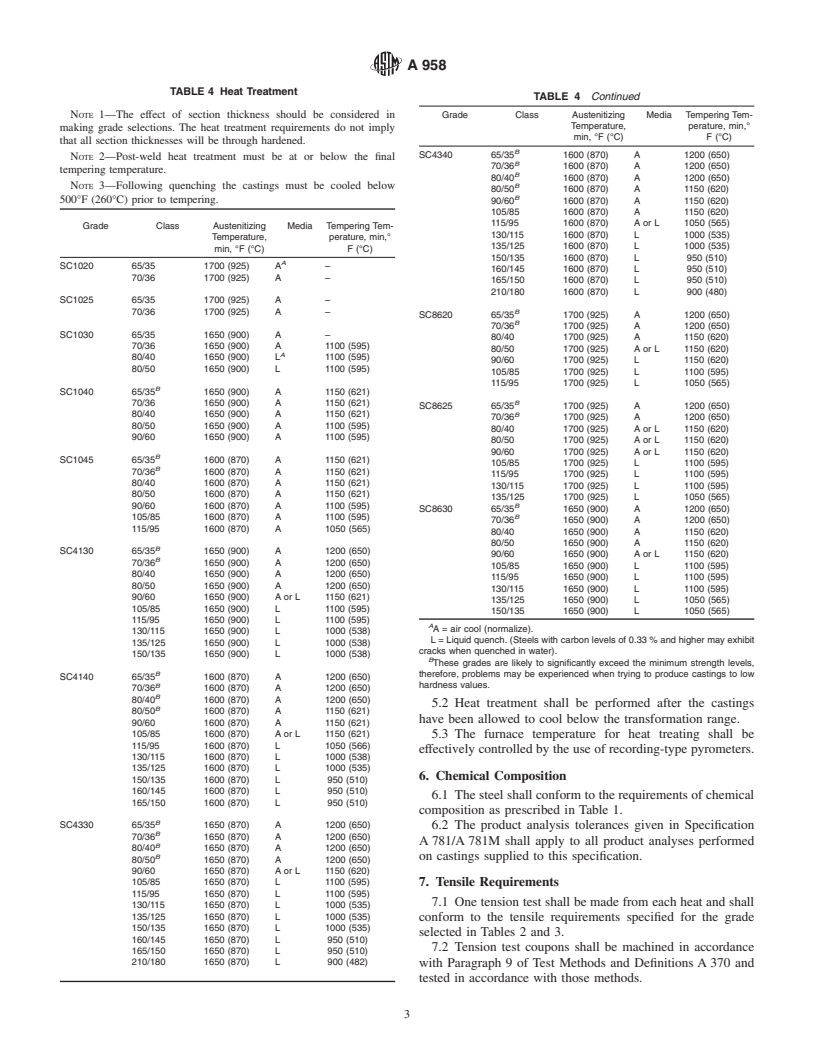

5. Heat Treatment

5.1 All castings shall receive a heat treatment indicated in

Table 4. Preliminary heat treatment prior to final heat treatment

as well as multiple tempering is permitted.

A 958

TABLE 4 Heat Treatment

TABLE 4 Continued

NOTE 1—The effect of section thickness should be considered in Grade Class Austenitizing Media Tempering Tem-

Temperature, perature, min,°

making grade selections. The heat treatment requirements do not imply

min, °F (°C) F (°C)

that all section thicknesses will be through hardened.

B

SC4340 65/35 1600 (870) A 1200 (650)

NOTE 2—Post-weld heat treatment must be at or below the final

B

70/36 1600 (870) A 1200 (650)

tempering temperature.

B

80/40 1600 (870) A 1200 (650)

B

NOTE 3—Following quenching the castings must be cooled below

80/50 1600 (870) A 1150 (620)

B

500°F (260°C) prior to tempering. 90/60 1600 (870) A 1150 (620)

105/85 1600 (870) A 1150 (620)

115/95 1600 (870) A or L 1050 (565)

Grade Class Austenitizing Media Tempering Tem-

130/115 1600 (870) L 1000 (535)

Temperature, perature, min,°

135/125 1600 (870) L 1000 (535)

min, °F (°C) F (°C)

150/135 1600 (870) L 950 (510)

A

SC1020 65/35 1700 (925) A –

160/145 1600 (870) L 950 (510)

70/36 1700 (925) A –

165/150 1600 (870) L 950 (510)

210/180 1600 (870) L 900 (480)

SC1025 65/35 1700 (925) A –

B

70/36 1700 (925) A –

SC8620 65/35 1700 (925) A 1200 (650)

B

70/36 1700 (925) A 1200 (650)

SC1030 65/35 1650 (900) A –

80/40 1700 (925) A 1150 (620)

70/36 1650 (900) A 1100 (595)

80/50 1700 (925) A or L 1150 (620)

A

80/40 1650 (900) L 1100 (595)

90/60 1700 (925) L 1150 (620)

80/50 1650 (900) L 1100 (595)

105/85 1700 (925) L 1100 (595)

115/95 1700 (925) L 1050 (565)

B

SC1040 65/35 1650 (900) A 1150 (621)

B

70/36 1650 (900) A 1150 (621)

SC8625 65/35 1700 (925) A 1200 (650)

B

80/40 1650 (900) A 1150 (621)

70/36 1700 (925) A 1200 (650)

80/50 1650 (900) A 1100 (595)

80/40 1700 (925) A or L 1150 (620)

90/60 1650 (900) A 1100 (595)

80/50 1700 (925) A or L 1150 (620)

90/60 1700 (925) A or L 1150 (620)

B

SC1045 65/35 1600 (870) A 1150 (621)

105/85 1700 (925) L 1100 (595)

B

70/36 1600 (870) A 1150 (621)

115/95 1700 (925) L 1100 (595)

80/40 1600 (870) A 1150 (621)

130/115 1700 (925) L 1100 (595)

80/50 1600 (870) A 1150 (621)

135/125 1700 (925) L 1050 (565)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.