ASTM D4878-08

(Test Method)Standard Test Methods for Polyurethane Raw Materials: Determination of Viscosity of Polyols

Standard Test Methods for Polyurethane Raw Materials: Determination of Viscosity of Polyols

SIGNIFICANCE AND USE

These test methods are suitable for research or as quality control or specification tests.

Viscosity measures the resistance of a fluid to uniformly continuous flow without turbulence or other forces.

SCOPE

1.1 These test methods (A and B) determine the viscosity of polyols in the range from 10 to 100 000 mPa·s(cP) at 25°C or at 50°C. Test Method A also applies to more viscous samples that are soluble in n-butyl acetate. Test Method B is simply a reference to a general procedure for kinematic viscosity, D 445. (See Note 1.)

1.2 The values stated in SI units are to be regarded as the standard. Other equivalent units are provided because of current common usage.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no equivalent ISO standard for Test Method A although ISO 3219 is similar. Test Method B is equivalent to ISO 3104.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4878 − 08

StandardTest Methods for

Polyurethane Raw Materials: Determination of Viscosity of

1

Polyols

This standard is issued under the fixed designation D4878; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 For definitions of terms used in these test methods see

1.1 These test methods (Aand B) determine the viscosity of

Terminology D883.

polyols in the range from 10 to 100 000 mPa·s(cP) at 25°C or

at 50°C. Test Method A also applies to more viscous samples

4. Significance and Use

that are soluble in n-butyl acetate. Test Method B is simply a

reference to a general procedure for kinematic viscosity, D445.

4.1 Thesetestmethodsaresuitableforresearchorasquality

(See Note 1.)

control or specification tests.

1.2 The values stated in SI units are to be regarded as the

4.2 Viscosity measures the resistance of a fluid to uniformly

standard. Other equivalent units are provided because of

continuous flow without turbulence or other forces.

current common usage.

5. Sampling

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5.1 Polyesters and polyethers usually contain molecules

responsibility of the user of this standard to establish appro-

covering an appreciable range of molecular weights. These

priate safety and health practices and determine the applica-

have a tendency to fractionate during solidification. Unless the

bility of regulatory limitations prior to use.

material is a finely ground solid it is necessary to melt (using

no higher temperature than necessary) and mix the resin well

NOTE 1—There is no equivalent ISO standard for Test Method A

before removing a sample for analysis. Many polyols are

although ISO 3219 is similar. Test Method B is equivalent to ISO 3104.

hygroscopic and care should be taken to provide minimum

exposure to atmospheric moisture during the sampling.

2. Referenced Documents

2

2.1 ASTM Standards: TEST METHOD A—BROOKFIELD VISCOSITY

D445 Test Method for Kinematic Viscosity of Transparent

and Opaque Liquids (and Calculation of Dynamic Viscos- 6. Summary of Test Method

ity)

6.1 The viscosity of resins is measured by determining the

D883 Terminology Relating to Plastics

torque on a spindle rotating at constant speed in the liquid

E1 Specification for ASTM Liquid-in-Glass Thermometers

sample which is adjusted to 25 6 0.1°C. Samples with viscosi-

3

2.2 ISO Standards: ties exceeding 100 000 mPa·s(cP) at 50°C are dissolved in

ISO 3104

n-butyl acetate (or other solvent) and the viscosity is deter-

ISO 3219 mined at 25 6 0.1°C.

7. Apparatus

1

These test methods are under the jurisdiction of ASTM Committee D20 on

7.1 Constant-Temperature Bath, capable of maintaining

Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular

temperatures of 25 6 0.1°C and 50 6 0.1°C should be used.

Materials - Plastics and Elastomers.

Water, water and glycerin, or oil may be used as the heating

Current edition approved Nov. 1, 2008. Published November 2008. Originally

approved in 1988. Last previous edition approved in 2003 as D4878 - 03. DOI:

medium and the bath should be provided with heating, stirring,

10.1520/D4878-08.

and thermostatting devices.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

7.2 Bath and Sample Thermometers, graduated in 0.1°C

Standards volume information, refer to the standard’s Document Summary page on

subdivisions and standardized for the range of use to the

the ASTM website.

3

nearest 0.01°C. ASTM Saybolt Viscosity Thermometers hav-

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. ing ranges from 19 to 27°C and 49 to 57°C, as specified, and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4878 − 08

conforming to the requirements for Thermometers 17C and following recommendations should guide in the choice of

19C, respectively, as prescribed in Specification E1 are recom- spindle size and speed to be used for a specific sample. (See

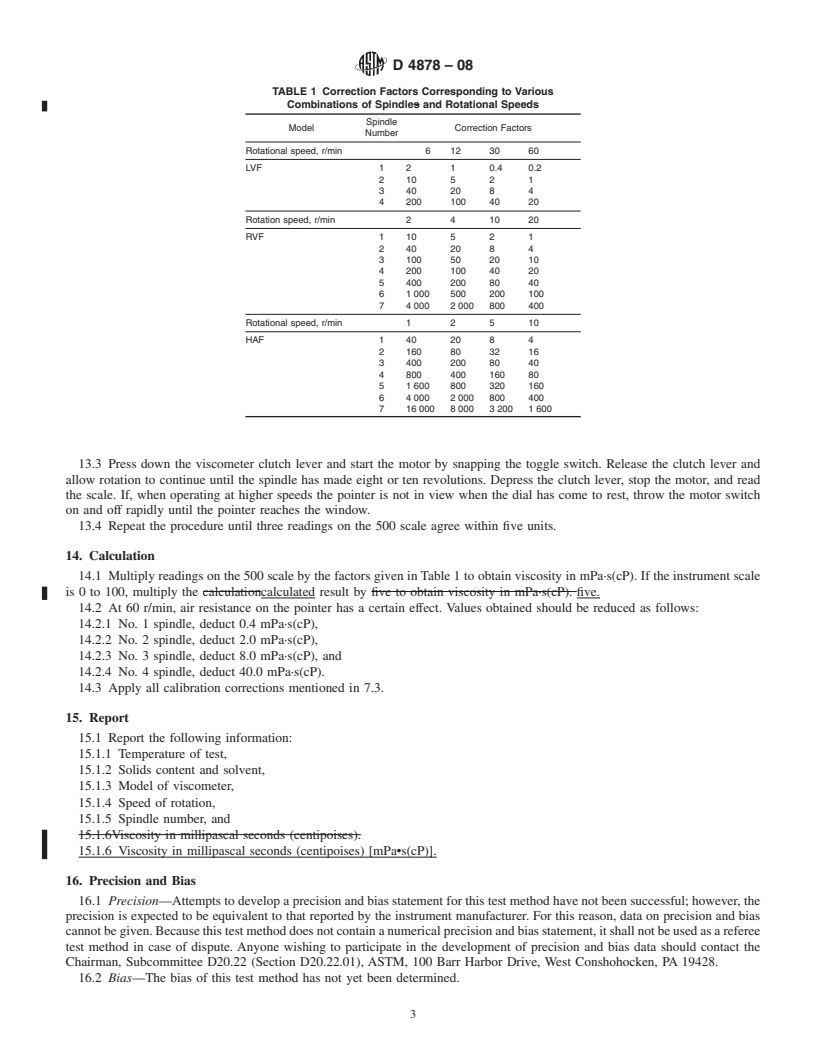

mended. Table 1.)

4 12.1.1 The combination chosen should give an instrument

7.3 Brookfield Synchrolectric Viscometer —Model LVF

reading near the center of the scale (that is, 175 to 325 on the

with speeds of 60, 30, 12, and 6 r/min is to be used when

500 scale).

available. It is applicable to the range of 10 to 100 000

12.1.2 The lowe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D 4878–03 Designation:D 4878–08

Standard Test Methods for

Polyurethane Raw Materials: Determination of Viscosity of

1

Polyols

This standard is issued under the fixed designation D 4878; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope *

1.1 These test methods (A and B) determine the viscositiesviscosity of polyols in the range from 10 to 100 000 mPa·s(cP) at

25°C or at 50°C. Test MethodAalso applies to more viscous samples that are soluble in n-butyl acetate. Test Method B is simply

a reference to a general procedure for kinematic viscosity, D 445. (See Note 1.)

1.2The1.2 ThevaluesstatedinSIunitsaretoberegardedasthestandard.Otherequivalentunitsareprovidedbecauseofcurrent

common usage.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—There is no equivalent ISO standard for Test Method A although ISO 3219 is similar. Test Method B is equivalent to ISO 3104.

2. Referenced Documents

2

2.1 ASTM Standards:

D 445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and the Calculation of Dynamic Viscosity)

D 883 Terminology Relating to Plastics

E 1 Specification for ASTM Liquid-in-Glass Thermometers

3

2.2 ISO Standards:

ISO 3104

ISO 3219

3. Terminology

3.1 For definitions of terms used in these test methods see Terminology D 883.

4. Significance and Use

4.1 These test methods are suitable for research or as quality control or specification tests.

4.2 Viscosity measures the resistance of a fluid to uniformly continuous flow without turbulence or other forces.

5. Sampling

5.1 Polyesters and polyethers usually contain molecules covering an appreciable range of molecular weights. These have a

tendency to fractionate during solidification. Unless the material is a finely ground solid it is necessary to melt (using no higher

temperature than necessary) and mix the resin well before removing a sample for analysis. Many polyols are hygroscopic and care

should be taken to provide minimum exposure to atmospheric moisture during the sampling.

TEST METHOD A—BROOKFIELD VISCOSITY

6. Summary of Test Method

6.1 The viscosity of resins is measured by determining the torque on a spindle rotating at constant speed in the liquid sample

which is adjusted to 25 6 0.1°C. Samples with viscosities exceeding 100 000 mPa·s(cP) at 50°C are dissolved in n-butyl acetate

1

These test methods are under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular Materials -

Plastics and Elastomers.

CurrenteditionapprovedNovemberNov.1,2003.2008.PublishedJanuary2004.November2008.Originallyapprovedin1988.Lastpreviouseditionapprovedin19982003

as D4878-98.D 4878 - 03.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 4878–08

(or other solvent) and the viscosity is determined at 25 6 0.1°C.

7. Apparatus

7.1 Constant-Temperature Bath, capable of maintaining temperatures of 25 6 0.1°C and 50 6 0.1°C should be used. Water,

water and glycerin, or oil may be used as the heating medium and the bath should be provided with heating, stirring, and

thermostatting devices.

7.2 Bath and Sample Thermometers, graduated in 0.1°C subdivisions and standardized for the range of use to the nearest

0.01°C. ASTM Saybolt Viscosity Thermometers having ranges from 19 to 27°C and 49 to 57°C, as specified, and conforming to

the requirements for Thermometers 17C and 19C, respectively, as prescribed in Specification E 1 are recommended.

4

7.3 Brookfield Synchrolectric Viscometer —Model LVF with speeds of 60, 30, 12, and 6 r/min is t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.