ASTM E235-88(1996)e1

(Specification)Standard Specification for Thermocouples, Sheathed, Type K, for Nuclear or for Other High-Reliability Applications

Standard Specification for Thermocouples, Sheathed, Type K, for Nuclear or for Other High-Reliability Applications

SCOPE

1.1 Intent- This specification presents the requirements for sheathed, Type K thermocouples for nuclear service. Depending on size, these thermocouples are normally suitable for operating temperatures to 1652°F (900°C); special conditions of environment and life expectancy may permit their use at temperatures in excess of 2012°F (1100°C). This specification was prepared specifically to detail requirements for using this type of sheathed thermocouple in nuclear environments. This specification can be used for sheathed thermocouples which are required for laboratory or general commercial applications where the environmental conditions exceed normal service requirements. The intended use of a sheathed thermocouple in a specific nuclear application will require evaluation, by the purchaser, of the compatibility of the thermocouple, including the effect of the temperature, atmosphere, and integrated neutron flux on the materials and accuracy of the thermoelements in the proposed application. This specification does not attempt to include all possible specifications, standards, etc., for materials that may be used as sheathing, insulation, and thermocouple wires for sheathed-type construction. The requirements of this specification include only the austenitic stainless steels for sheathing, magnesium oxide or aluminum oxide as insulation, and Type K thermocouple wires for thermoelements (see Note 2).

1.2 General Design- Nominal sizes of the finished thermocouples shall be 0.0400 in. (1.016 mm), 0.0625 in. (1.588 mm), 0.1875 in. (4.763 mm), 0.125 in. (3.175 mm), or 0.250 in. (6.350 mm). Sheath dimensions and tolerances for each nominal size shall be in accordance with Table 1. The classes of thermocouples covered by this specification are as follows:

1.2.1 Class 1- Measuring junction grounded to sheath, and

1.2.2 Class 2- Measuring junction not grounded to sheath (insulated junction).

1.2.3 See Figs. 1 and 2 and Table 1 for details. Note 1-The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

Designation: E 235 – 88 (Reapproved 1996)

Standard Specification for

Thermocouples, Sheathed, Type K, for Nuclear or for Other

High-Reliability Applications

This standard is issued under the fixed designation E 235; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

ϵ NOTE—Keywords were added editorially in November 1996.

1. Scope 1.3 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

1.1 This specification covers the requirements for sheathed,

information only.

Type K thermocouples for nuclear service. Depending on size,

these thermocouples are normally suitable for operating tem-

2. Referenced Documents

peratures to 1652°F (900°C); special conditions of environ-

2.1 ASTM Standards:

ment and life expectancy may permit their use at temperatures

A 262 Practices for Detecting Susceptibility to Intergranu-

in excess of 2012°F (1100°C). This specification was prepared

lar Attack in Austenitic Stainless Steels

specifically to detail requirements for using this type of

A 632 Specification for Seamless and Welded Austenitic

sheathed thermocouple in nuclear environments. This specifi-

Stainless Steel Tubing (Small Diameter) for General Ser-

cation can be used for sheathed thermocouples which are

vice

required for laboratory or general commercial applications

E2 Methods of Preparation of Micrographs of Metals and

where the environmental conditions exceed normal service

Alloys (Including Recommended Practice for Photography

requirements. The intended use of a sheathed thermocouple in

as Applied to Metallography)

a specific nuclear application will require evaluation, by the

E3 Methods of Preparation of Metallographic Specimens

purchaser, of the compatibility of the thermocouple, including

E45 Test Methods for Determining the Inclusion Content

the effect of the temperature, atmosphere, and integrated

of Steel

neutron flux on the materials and accuracy of the thermoele-

E94 Guide for Radiographic Testing

ments in the proposed application. This specification does not

E112 Test Methods for Determining the Average Grain

attempt to include all possible specifications, standards, etc.,

Size

for materials that may be used as sheathing, insulation, and

E 142 Method for Controlling Quality of Radiographic

thermocouple wires for sheathed-type construction. The re-

Testing

quirements of this specification include only the austenitic

E 165 Test Method for Liquid Penetrant Examination

stainless steels for sheathing, magnesium oxide or aluminum

E 220 Test Method for Calibration of Thermocouples by

oxide as insulation, and Type K thermocouple wires for

Comparison Techniques

thermoelements (see Note 2).

E 230 Specification for Temperature-Electromotive Force

1.2 General Design—Nominal sizes of the finished thermo-

(EMF) Tables for Standardized Thermocouples

couplesshallbe0.0400in.(1.016mm),0.0625in.(1.588mm),

E 344 Terminology Relating to Thermometry and Hydrom-

0.1875 in. (4.763 mm), 0.125 in. (3.175 mm), or 0.250 in.

etry

(6.350 mm). Sheath dimensions and tolerances for each nomi-

E 839 Test Methods for Sheathed Thermocouples and

nal size shall be in accordance with Table 1. The classes of

Sheathed Thermocouple Material

thermocouples covered by this specification are as follows:

2.2 ANSI Standard:

1.2.1 Class 1—Measuring junction grounded to sheath, and

B46.1 Surface Texture

1.2.2 Class 2—Measuring junction not grounded to sheath

(insulated junction).

1.2.3 See Figs. 1 and 2 and Tables 1-3 for details.

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.01.

Discontinued, see 1982 Annual Book of ASTM Standards, Part 11.

1 5

This specification is under the jurisdiction of ASTM Committee E-20 on Annual Book of ASTM Standards, Vol 03.01.

Temperature Measurement and is the direct responsibility of Subcommittee E20.04 Annual Book of ASTM Standards, Vol 03.03.

on Thermocouples. Annual Book of ASTM Standards, Vol 14.03.

Current edition approved Aug. 19, 1988. Published October 1988. Originally Available from American National Standards Institute, 11 W. 42nd St., 13th

published as E 235 – 64 T. Last previous edition E 235 – 82. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

E 235 – 88 (1996)

TABLE 1 Dimensions for Class 1 and 2 Measuring Junctions

Sheath Outside Diameter, A Minimum Minimum Minimum E, Tolerance F, Tolerance

Sheath Insulation Wire

Tolerance min max min max

Wall, Thickness, Diameter,

Nominal

B C D

min max

Inches

0.0400 0.0390 0.0415 0.006 0.004 0.005 0.006 0.020 0.004 0.021

0.0625 0.0615 0.0640 0.009 0.005 0.010 0.009 0.032 0.005 0.032

0.1250 0.1240 0.1265 0.012 0.012 0.020 0.012 0.062 0.012 0.063

0.1875 0.1865 0.1890 0.020 0.022 0.031 0.020 0.093 0.022 0.095

0.2500 0.2480 0.2520 0.030 0.024 0.040 0.030 0.125 0.024 0.125

Millimetres

1.016 0.991 1.054 0.15 0.10 0.13 0.15 0.51 0.10 0.53

1.588 1.562 1.626 0.23 0.13 0.25 0.23 0.81 0.13 0.81

3.175 3.150 3.213 0.30 0.30 0.51 0.30 1.57 0.30 1.60

4.763 4.737 4.801 0.51 0.56 0.79 0.51 2.36 0.56 2.41

6.350 6.299 6.401 0.76 0.61 1.02 0.76 3.18 0.61 3.18

4.1.3 The type of ceramic insulation required, either alu-

mina (Al O ) or magnesia (MgO),

2 3

4.1.4 The type of tubing material and other information

required (see 5.1.1),

4.1.5 The class of thermocouple measuring junction,

4.1.6 The type of dye-penetrant inspection procedure to be

used, and

4.1.7 Any deviations from this specification or the refer-

enced specifications.

FIG. 1 Grounded Measuring Junction, Class 1

5. Materials and Manufacture

5.1 All materials used shall be in accordance with the

following requirements:

5.1.1 Sheath Materials, Austenitic Stainless Steels—

Austenitic stainless-steel tubing used for thermocouple sheath

material shall conform to the requirements given in Specifica-

tion A 632A 632. The purchaser of the thermocouples shall

specify only the name of the material (seamless or welded),

grade, optional requirements, test report required, and ASTM

FIG. 2 Insulated (Ungrounded) Measuring Junction, Class 2

designation. The manufacturer of the thermocouples shall

specify all other options including the supplementary require-

2.3 American Welding Society Standard:

ments listed in Specification A 632A 632, except that alcohol

A59 Specification for Corrosion-Resisting Chromium and

shall be used as the cleaning solvent. (See Section 2 of

Chromium-Nickel Steel-Welding Rods and Bare Elec-

Specification A 632A 632 for ordering requirements.) In addi-

trodes

tion to the requirements of Specification A 632A 632, the

following requirements must be met:

3. Terminology

5.1.1.1 Theinclusionlevelofthetubingshallbedetermined

3.1 The definitions given in Terminology E 344E 344 shall

by mounting a 1-in. minimum length of a longitudinal section

apply to this specification.

of the tubing using Test Methods E 45E45, Microscopical

Method A, for examination. The inclusion level shall be less

4. Ordering Information and Basis of Purchase

than 3 A through D, thin or heavy.

4.1 The purchase order documents shall specify the follow-

5.1.1.2 The grain size of the tubing shall be determined by

ing information:

a specimen taken in accordance with Test Methods

4.1.1 The quantity, length, and nominal size of the sheathed

E112E112. Grain size shall not exceed the maximum speci-

thermocouple,

fied in Table 3 of this standard specification, as determined by

4.1.2 The initial calibration tolerance to be used to replace

the Comparison Procedure of Test Methods E 112E112.

limits of error if other than standard limits (see Specification

5.1.1.3 Each lot of tubing used shall be sampled using

E 230E 230),

Practices A 262A 262 as follows. Samples shall be tested by

Practice A, and further tested as outlined by Table 1, where

screening tests so indicate. Acceptance levels for these tests

AvailablefromtheAmericanWeldingSociety,2501NorthWest7thSt.,Miami,

Fla. 33125. shall be agreed upon between the purchaser and the producer.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

E 235 – 88 (1996)

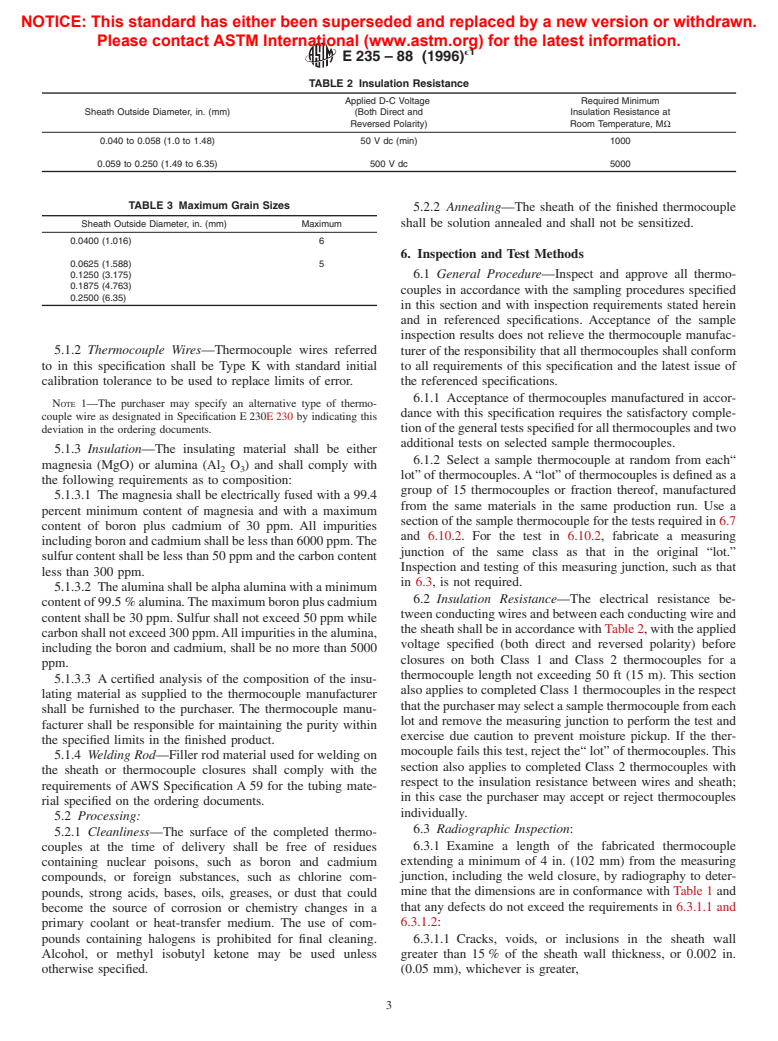

TABLE 2 Insulation Resistance

Applied D-C Voltage Required Minimum

Sheath Outside Diameter, in. (mm) (Both Direct and Insulation Resistance at

Reversed Polarity) Room Temperature, MΩ

0.040 to 0.058 (1.0 to 1.48) 50 V dc (min) 1000

0.059 to 0.250 (1.49 to 6.35) 500 V dc 5000

TABLE 3 Maximum Grain Sizes

5.2.2 Annealing—The sheath of the finished thermocouple

Sheath Outside Diameter, in. (mm) Maximum shall be solution annealed and shall not be sensitized.

0.0400 (1.016) 6

6. Inspection and Test Methods

0.0625 (1.588) 5

0.1250 (3.175) 6.1 General Procedure—Inspect and approve all thermo-

0.1875 (4.763)

couples in accordance with the sampling procedures specified

0.2500 (6.35)

in this section and with inspection requirements stated herein

and in referenced specifications. Acceptance of the sample

inspection results does not relieve the thermocouple manufac-

5.1.2 Thermocouple Wires—Thermocouple wires referred turer of the responsibility that all thermocouples shall conform

to in this specification shall be Type K with standard initial to all requirements of this specification and the latest issue of

calibration tolerance to be used to replace limits of error. the referenced specifications.

6.1.1 Acceptance of thermocouples manufactured in accor-

NOTE 1—The purchaser may specify an alternative type of thermo-

dance with this specification requires the satisfactory comple-

couple wire as designated in Specification E 230E 230 by indicating this

tionofthegeneraltestsspecifiedforallthermocouplesandtwo

deviation in the ordering documents.

additional tests on selected sample thermocouples.

5.1.3 Insulation—The insulating material shall be either

6.1.2 Select a sample thermocouple at random from each“

magnesia (MgO) or alumina (Al O ) and shall comply with

2 3

lot” of thermocouples.A“lot” of thermocouples is defined as a

the following requirements as to composition:

group of 15 thermocouples or fraction thereof, manufactured

5.1.3.1 The magnesia shall be electrically fused with a 99.4

from the same materials in the same production run. Use a

percent minimum content of magnesia and with a maximum

section of the sample thermocouple for the tests required in 6.7

content of boron plus cadmium of 30 ppm. All impurities

and 6.10.2. For the test in 6.10.2, fabricate a measuring

includingboronandcadmiumshallbelessthan6000ppm.The

junction of the same class as that in the original “lot.”

sulfur content shall be less than 50 ppm and the carbon content

Inspection and testing of this measuring junction, such as that

less than 300 ppm.

in 6.3, is not required.

5.1.3.2 Thealuminashallbealphaaluminawithaminimum

6.2 Insulation Resistance—The electrical resistance be-

contentof99.5 %alumina.Themaximumboronpluscadmium

tween conducting wires and between each conducting wire and

content shall be 30 ppm. Sulfur shall not exceed 50 ppm while

the sheath shall be in accordance withTable 2, with the applied

carbonshallnotexceed300ppm.Allimpuritiesinthealumina,

voltage specified (both direct and reversed polarity) before

including the boron and cadmium, shall be no more than 5000

closures on both Class 1 and Class 2 thermocouples for a

ppm.

thermocouple length not exceeding 50 ft (15 m). This section

5.1.3.3 A certified analysis of the composition of the insu-

also applies to completed Class 1 thermocouples in the respect

lating material as supplied to the thermocouple manufacturer

thatthepurchasermayselectasamplethermocouplefromeach

shall be furnished to the purchaser. The thermocouple manu-

lot and remove the measuring junction to perform the test and

facturer shall be responsible for maintaining the purity within

exercise due caution to prevent moisture pickup. If the ther-

the specified limits in the finished product.

mocouple fails this test, reject the“ lot” of thermocouples. This

5.1.4 Welding Rod—Filler rod material used for welding on

section also applies to completed Class 2 thermocouples with

the sheath or thermocouple closures shall comply with the

respect to the insulation resistance between wires and sheath;

requirements of AWS Specification A 59 for the tubing mate-

in this case the purchaser may accept or reject thermocouples

rial specified on the ordering documents.

individually.

5.2 Processing:

6.3 Radiographic Inspection:

5.2.1 Cleanliness—The surface of the completed thermo-

6.3.1 Examine a length of the fabricated thermocouple

couples at the time of delivery shall be free of residues

extending a minimum of 4 in. (102 mm) from the measuring

containing nuclear poisons, such as boron and cadmium

junction, including the weld closure, by radiography to deter-

compounds, or foreign substances, such as chlorine com-

mine that the dimensions are in conformance with Table 1 and

pounds, strong acids, bases, oils, greases, or dust that could

that any defects do not exceed the requirements in 6.3.1.1 and

become the source of corrosion or chemistry changes in a

6.3.1.2:

primary coolant or heat-transfer medium. The use of com-

pounds containing halogens is prohibited for final cleaning. 6.3.1.1 Cracks, voids, or inclusions in the sheath wall

Alcohol, or methyl isobutyl ketone may be used unless greater than 15 % of the sheath wall thickness, or 0.002 in.

otherwise specified. (0.05 mm), whichever is greater,

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

ϵ1

E 235 – 88 (1996)

6.3.1.2 Cracks, voids, inclusions, discontinuities, or local dance with Methods E 3E3. The sheath material at the

reductionoftheconductors,insulation,orsheathdiameterinor mounted specimen shall not contain evidence of cracks or

near the thermal junction greater than 0.002 in. (0.05 mm). localized wall thinning when longitudinally sectioned and

6.3.2 Radiograph the thermocouple in two directions 90° examinedbynormalmetallographicpracticeatamagnification

of 200 to 5003 in accordance with Methods E 2E2.

apart and perpendicular to the thermocouple axi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.