ASTM E1695-20

(Test Method)Standard Test Method for Measurement of Computed Tomography (CT) System Performance

Standard Test Method for Measurement of Computed Tomography (CT) System Performance

SIGNIFICANCE AND USE

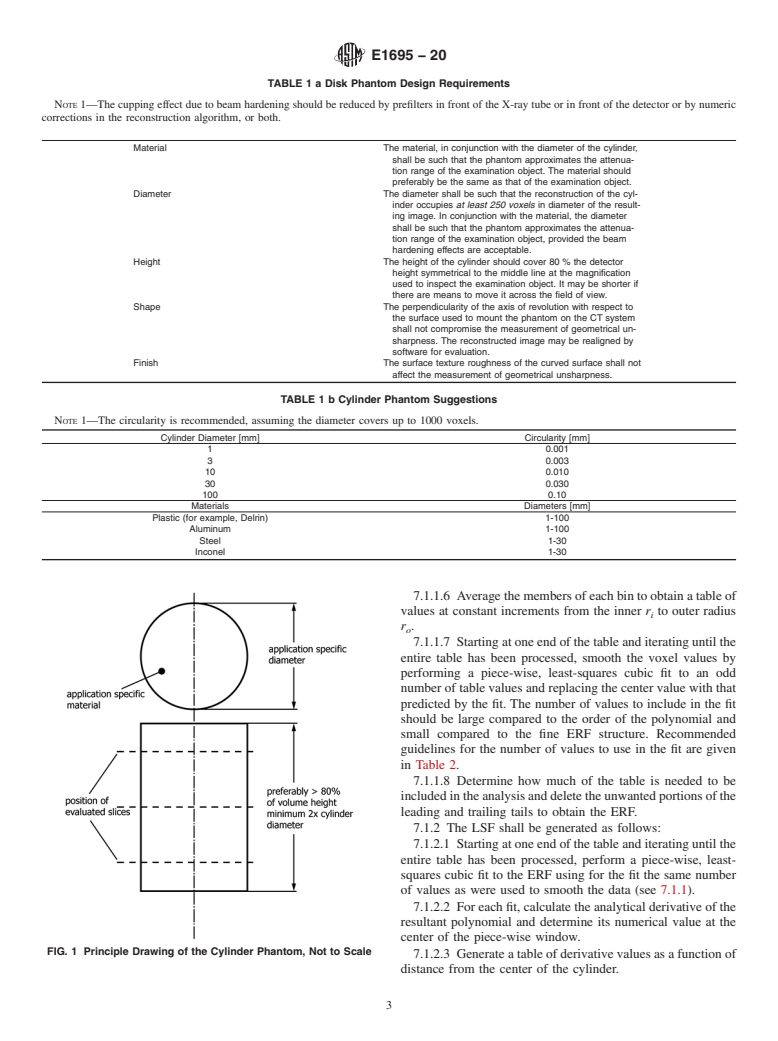

4.1 The major factors affecting the quality of a CT image are total image unsharpness (UTimage), contrast (Δµ), and random noise (σ). Geometrical and detector unsharpness limit the spatial resolution of a CT system, that is, its ability to image fine structural detail in an object. Random noise and contrast response limit the contrast sensitivity of a CT system, that is, its ability to detect the presence or absence of features in an object. Spatial resolution and contrast sensitivity may be measured in various ways. In this test method, spatial resolution is quantified in terms of the modulation transfer function (MTF), and contrast sensitivity is quantified in terms of the contrast discrimination function (CDF). The relationship between contrast sensitivity and spatial resolution describing the resolving and detecting capabilities is given by the contrast-detail-diagram (CDD metric, see also Guide E1441 and Practice E1570). This test method allows the purchaser or the provider of CT systems or services, or both, to measure and specify spatial resolution and contrast sensitivity and is a measure for system stability over time and performance acceptability.

SCOPE

1.1 This test method provides instruction for determining the spatial resolution and contrast sensitivity in X-ray and γ-ray computed tomography (CT) volumes. The determination is based on examination of the CT volume of a uniform cylinder of material. The spatial resolution measurement (Modulation Transfer Function) is derived from an image analysis of the sharpness at the edges of the reconstructed cylinder slices. The contrast sensitivity measurement (Contrast Discrimination Function) is derived from an image analysis of the contrast and the statistical noise at the center of the cylinder slices.

1.2 This test method is more quantitative and less susceptible to interpretation than alternative approaches because the required cylinder is easy to fabricate and the analysis easy to perform.

1.3 This test method is not to predict the detectability of specific object features or flaws in a specific application. This is subject of IQI and RQI standards and standard practices.

1.4 This method tests and describes overall CT system performance. Performance tests of systems components such as X-ray tubes, gamma sources, and detectors are covered by separate documents, namely Guide E1000, Practice E2737, and Practice E2002; c.f. 2.1, which should be consulted for further system analysis.

1.5 Units—The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1695 − 20

Standard Test Method for

Measurement of Computed Tomography (CT) System

1

Performance

This standard is issued under the fixed designation E1695; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This test method provides instruction for determining

ization established in the Decision on Principles for the

thespatialresolutionandcontrastsensitivityinX-rayand γ-ray

Development of International Standards, Guides and Recom-

computed tomography (CT) volumes. The determination is

mendations issued by the World Trade Organization Technical

based on examination of the CT volume of a uniform cylinder

Barriers to Trade (TBT) Committee.

of material. The spatial resolution measurement (Modulation

Transfer Function) is derived from an image analysis of the

2. Referenced Documents

sharpness at the edges of the reconstructed cylinder slices. The

2

2.1 ASTM Standards:

contrast sensitivity measurement (Contrast Discrimination

E177 Practice for Use of the Terms Precision and Bias in

Function) is derived from an image analysis of the contrast and

ASTM Test Methods

the statistical noise at the center of the cylinder slices.

E691 Practice for Conducting an Interlaboratory Study to

1.2 This test method is more quantitative and less suscep-

Determine the Precision of a Test Method

tible to interpretation than alternative approaches because the

E1000 Guide for Radioscopy

required cylinder is easy to fabricate and the analysis easy to

E1316 Terminology for Nondestructive Examinations

perform.

E1441 Guide for Computed Tomography (CT)

E1570 Practice for Fan Beam Computed Tomographic (CT)

1.3 This test method is not to predict the detectability of

Examination

specific object features or flaws in a specific application. This

E2002 Practice for Determining Total Image Unsharpness

is subject of IQI and RQI standards and standard practices.

and Basic Spatial Resolution in Radiography and Radios-

1.4 This method tests and describes overall CT system

copy

performance. Performance tests of systems components such

E2737 Practice for Digital Detector Array Performance

as X-ray tubes, gamma sources, and detectors are covered by

Evaluation and Long-Term Stability

separatedocuments,namelyGuideE1000,PracticeE2737,and

3

2.2 ISO Standard:

Practice E2002; c.f. 2.1, which should be consulted for further

15708 NDT – Radiation Methods – Computed Tomography

system analysis.

– Part 1: Terminology, Part 2: Principles, Equipment and

1.5 Units—The values stated in SI units are to be regarded

Samples, Part 3: Operation and Interpretation, Part 4:

as standard. The values given in parentheses after SI units are

Qualification

provided for information only and are not considered standard.

3. Terminology

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.1 Definitions—The definitions of terms relating to

responsibility of the user of this standard to establish appro- Gamma- and X-Radiology, which appear in Terminology

priate safety, health, and environmental practices and deter- E1316 and Guide E1441, shall apply to the terms used in this

mine the applicability of regulatory limitations prior to use. test method.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction of ASTM Committee E07 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on Standards volume information, refer to the standard’s Document Summary page on

Radiology (X and Gamma) Method. the ASTM website.

3

Current edition approved June 1, 2020. Published August 2020. Originally Available from International Organization for Standardization (ISO), ISO

approved in 1995. Last previous edition approved in 2013 as E1695 – 95(2013). Central Secretariat, BIBC II, Chemin de Blandonnet 8, CP 401, 1214 Vernier,

DOI: 10.1520/E1695-20. Geneva, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1695 − 20

3.2 Definitions of Terms Specific to This Standard: 6. Procedure of Measurement

3.2.1 examination object, n—a part or specimen being

6.1 The phantom shall be mounted on the CT system with

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1695 − 95 (Reapproved 2013) E1695 − 20

Standard Test Method for

Measurement of Computed Tomography (CT) System

1

Performance

This standard is issued under the fixed designation E1695; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method provides instruction for determining the spatial resolution and contrast sensitivity in X-ray and γ-ray

computed tomography (CT) images.volumes. The determination is based on examination of the CT imagevolume of a uniform

diskcylinder of material. The spatial resolution measurement (Modulation Transfer Function) is derived from an image analysis

of the sharpness at the edgeedges of the disk. reconstructed cylinder slices. The contrast sensitivity measurement (Contrast

Discrimination Function) is derived from an image analysis of the contrast and the statistical noise at the center of the disk.cylinder

slices.

1.2 This test method is more quantitative and less susceptible to interpretation than alternative approaches because the required

diskcylinder is easy to fabricate and the analysis is immune to cupping artifacts. This test method may not yield meaningful results

if the disk image occupies less than a significant fraction of the field of view.easy to perform.

1.3 This test method may also be used to evaluate other performance parameters. Among those characteristics of a CT system that

are detectable with this test method are: the mid-frequency enhancement of the reconstruction kernel, the presence (or absence)

of detector crosstalk, the undersampling of views, and the clipping of unphysical (that is, negative) CT numbers (see Air Force

Technical Report WL-TR-94-4021is not to predict the detectability of specific object features or flaws in a specific application. This

). It is highly likely that other characteristics as well can be detected with this test method.is subject of IQI and RQI standards and

standard practices.

1.4 This method tests and describes overall CT system performance. Performance tests of systems components such as X-ray

tubes, gamma sources, and detectors are covered by separate documents, namely Guide E1000, Practice E2737, and Practice

E2002; c.f. 2.1, which should be consulted for further system analysis.

1.5 Units—The values stated in SI units are to be regarded as the standard. Inch-pound standard. The values given in parentheses

after SI units are provided for information only.only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on Radiology

(X and Gamma) Method.

Current edition approved June 1, 2013June 1, 2020. Published June 2013August 2020. Originally approved in 1995. Last previous edition approved in 20062013 as

ε1

E1695 - 95E1695 – 95(2006)(2013). . DOI: 10.1520/E1695-95R13.10.1520/E1695-20.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1695 − 20

2. Referenced Documents

2

2.1 ASTM Standards:

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1000 Guide for Radioscopy

E1316 Terminology for Nondestructive Examinations

E1441 Guide for Computed Tomography (CT)

E1570 Practice for Fan Beam Computed Tomographic (CT) Examination

E2002 Practice for Determining Total Image Unsharpness and Basic Spatial Resolution in Radiography and Radioscop

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.