ASTM D2995-99(2009)

(Practice)Standard Practice for Estimating Application Rate of Bituminous Distributors

Standard Practice for Estimating Application Rate of Bituminous Distributors

SIGNIFICANCE AND USE

The amount of bituminous material applied to a pavement surface using a bituminous distributor can be estimated using the described procedure.

SCOPE

1.1 This practice covers the determination of transverse and longitudinal application rate of asphalt distributors in gallons per square yard (or litres per square metre).

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values given in inch-pound units are to be regarded as the standard. The SI values given in parentheses are for information purposes only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2995 − 99(Reapproved 2009)

Standard Practice for

Estimating Application Rate of Bituminous Distributors

This standard is issued under the fixed designation D2995; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Apparatus

1.1 This practice covers the determination of transverse and 4.1 Test Methods A and B:

longitudinal application rate of asphalt distributors in gallons 4.1.1 Balance, sensitive to 0.1 g.

per square yard (or litres per square metre). 4.1.2 Weighing Box or Balance Shield, to protect balance

from wind when the balance is in use at the project site (see

1.2 This standard does not purport to address all of the

Fig. 1).

safety concerns, if any, associated with its use. It is the

4.1.3 Balance Table and Work Table, for weighing.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.2 Test Method B:

bility of regulatory limitations prior to use.

4.2.1 EllipticalContainers,measuringapproximately3.5in.

1.3 The values given in inch-pound units are to be regarded

(88.9 mm) along the short axis and 9 in. (228.6 mm) along the

as the standard. The SI values given in parentheses are for

long axis of the ellipse and 8 in. (203.2 mm) in height, capable

information purposes only.

of an internal volume of approximately 1 gal.

4.2.2 Rubber Bands, capable of a snug fit when stretched

2. Summary of Practice

around the elliptical containers.

2.1 Test Method A:

4.2.3 Stopwatch, capable of recording to the nearest 0.1 s.

2.1.1 Pre-weighed calibration pads are placed on the surface

5. Materials

of the roadway in front of the distributor to be calibrated. The

asphaltdistributortobecalibratedisdrivenoverthecalibration

5.1 Test Method A:

2 2

pads while spraying asphalt. The calibration pads are removed

5.1.1 Geotextile Pads, weighing a minimum of 8 oz/yd

from the roadway and reweighed. The weight of asphalt

and measuring 12 in. (304.8 mm) by 12 in. (304.8 mm).

applied to the pads is determined by subtraction and the rate of

5.1.2 Aluminized Duct Tape, measuring 2 in. (50.8 mm)

application is calculated.

wide and 6 in. (152.4 mm) long.

5.1.3 Butcher Paper #50, measuring 30 in. (762 mm) by

2.2 Test Method B:

950 ft, for temporary protection of geotextile pads during

2.2.1 Containers are placed under each nozzle of a bitumi-

calibration.

nous distributor and bituminous material is sprayed into the

containers for a known period of time. The volume of

5.2 Test Method B:

bituminous material sprayed after this period is calculated. The

5.2.1 Plastic Bags, capable of fitting inside the elliptical

transverse uniformity of bituminous material sprayed on the

cans but of sufficiently larger dimension to allow folding over

pavement is obtained from this calculation and the distribution

the edge of the elliptical containers once placed inside.

of bituminous material applied longitudinally on the pavement

is calculated as a function of the distributor velocity. 6. Procedure (Transverse Application Rate)

6.1 Test Method A:

3. Significance and Use

6.1.1 Select enough of the geotextile fabric pads so that

3.1 The amount of bituminous material applied to a pave-

when placed end-to-end on the roadway a continuous strip is

ment surface using a bituminous distributor can be estimated

created across the width of the roadway to be sprayed with

using the described procedure.

asphalt.

This practice is under the jurisdiction of ASTM Committee D04 on Road and

Paving Materials and is the direct responsibility of Subcommittee D04.24 on Non-woven, needle punched, heat fused on one side geotextiles by Phillips

Bituminous Surface Treatments. Fibers, Monsanto, and Amoco have been found to be suitable materials for this

CurrenteditionapprovedJune1,2009.PublishedJuly2009.Originallyapproved purpose.

in 1971. Last previous edition approved in 2004 as D2995 – 04. DOI: 10.1520/ Butcher paper from Baumann Paper Co., Baumann Rd., Lexington, KY has

D2995-99R09. been found to be suitable for this purpose.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

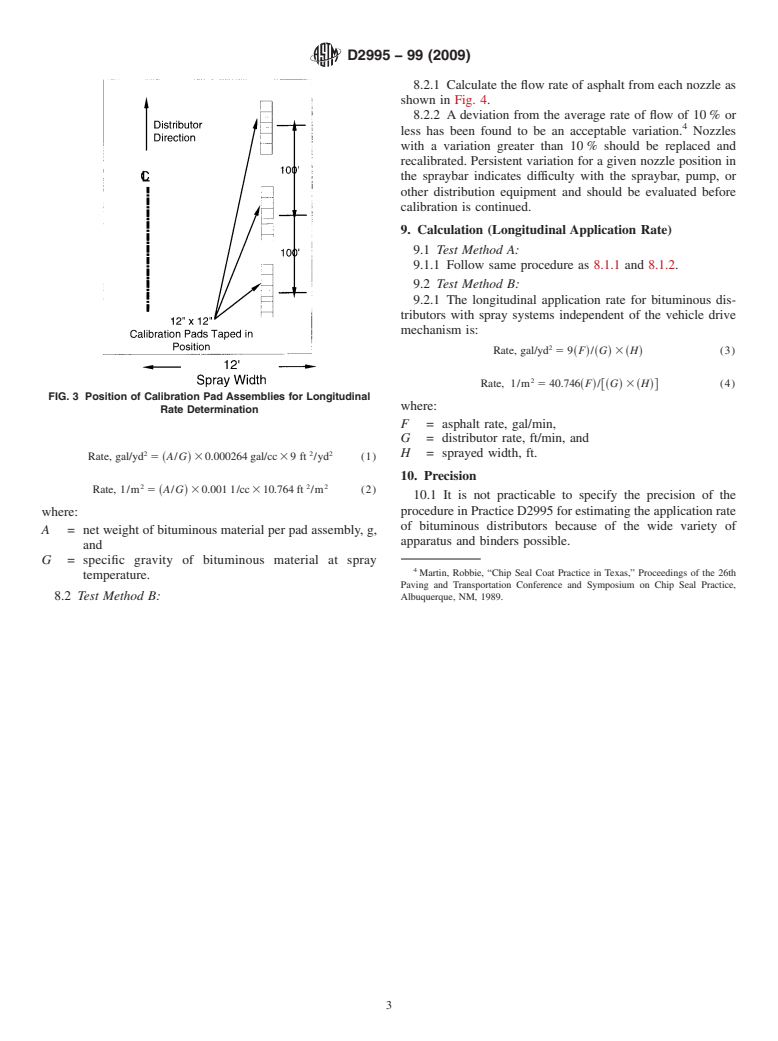

D2995 − 99 (2009)

FIG. 2 Position of Calibration Pad Assemblies for Transverse

Rate Determination

pre-weighed can assembly. Start the stopwatch the instant the

FIG. 1 Weighing Box and Balance

asphalt begins to fill the can assembly.

6.2.5 Stop the flow of asphalt to the spraybar when the can

assembly is approximately ⁄4 full. Stop the stopwatch the

6.1.2 Create a loop with the duct tape with the adhesive side

instant the asphalt stops flowing into the can assembly.

facing out. Place two loops of duct tape on one edge of each of

6.2.6 Record the weight of each can assembly in the proper

the geotextile fabric pads.

space on the report form.

6.1.3 Obtain the weight of the pad and tape assembly to the

6.2.7 Record the time elapsed between the beginning and

nearest 0.1 g.

end of the flow of asphalt to the can assembly.

6.1.4 Place the pad assembly with the tape facing down on

the roadway so the taped edge is facing the distributor. Apply

7. Procedure (Longitudinal Application Rate)

pressure to the taped pad to secure it to the roadway. Continue

7.1 Test Method A:

this operation for the remaining pads for the entire width

7.1.1 Prepare the calibration pads and tape assemblies as

desired for calibration.

described in 6.1.2 thro

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.