ASTM B395-95

(Specification)Standard Specification for U-Bend Seamless Copper and Copper Alloy Heat Exchanger and Condenser Tubes

Standard Specification for U-Bend Seamless Copper and Copper Alloy Heat Exchanger and Condenser Tubes

SCOPE

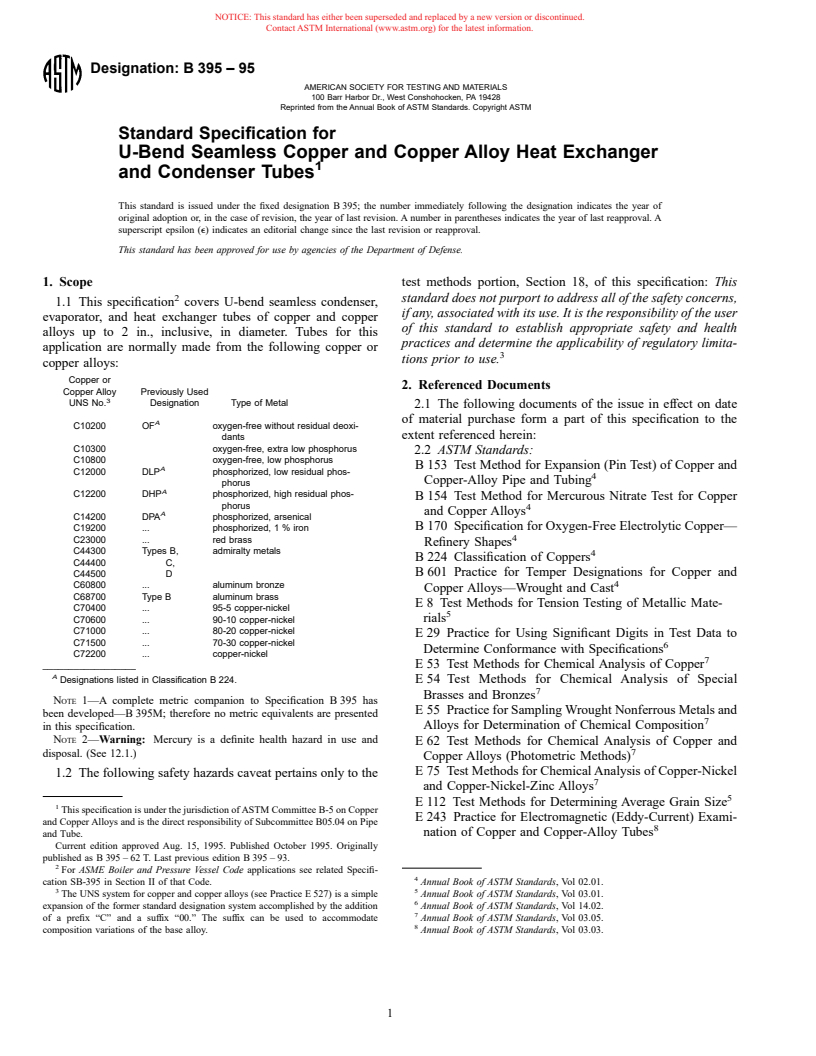

1.1 This specification covers U-bend seamless condenser, evaporator, and heat exchanger tubes of copper and copper alloys up to 2 in., inclusive, in diameter. Tubes for this application are normally made from the following copper or copper alloys: Copper or Copper Alloy Previously Used UNS No. 3 Designation Type of Metal C10200 OF A oxygen-free without residual deoxi- dants C10300 oxygen-free, extra low phosphorus C10800 oxygen-free, low phosphorus C12000 DLP A phosphorized, low residual phos- phorus C12200 DHP A phosphorized, high residual phos- phorus C14200 DPA A phosphorized, arsenical C19200 ... phosphorized, 1 % iron C23000 ... red brass C44300 Types B, admiralty metals C44400 C, C44500 D C60800 ... aluminum bronze C68700 Type B aluminum brass C70400 ... 95-5 copper-nickel C70600 ... 90-10 copper-nickel C71000 ... 80-20 copper-nickel C71500 ... 70-30 copper-nickel C72200 ... copper-nickel A Designations listed in Classification B 224.

1.2 The following safety hazards caveat pertains only to the test methods portion, Section 18, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

Designation: B 395 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

U-Bend Seamless Copper and Copper Alloy Heat Exchanger

1

and Condenser Tubes

This standard is issued under the fixed designation B 395; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope test methods portion, Section 18, of this specification: This

2

standard does not purport to address all of the safety concerns,

1.1 This specification covers U-bend seamless condenser,

if any, associated with its use. It is the responsibility of the user

evaporator, and heat exchanger tubes of copper and copper

of this standard to establish appropriate safety and health

alloys up to 2 in., inclusive, in diameter. Tubes for this

practices and determine the applicability of regulatory limita-

application are normally made from the following copper or

3

tions prior to use.

copper alloys:

Copper or

2. Referenced Documents

Copper Alloy Previously Used

3

UNS No. Designation Type of Metal

2.1 The following documents of the issue in effect on date

of material purchase form a part of this specification to the

A

C10200 OF oxygen-free without residual deoxi-

extent referenced herein:

dants

C10300 oxygen-free, extra low phosphorus

2.2 ASTM Standards:

C10800 oxygen-free, low phosphorus

B 153 Test Method for Expansion (Pin Test) of Copper and

A

C12000 DLP phosphorized, low residual phos-

4

Copper-Alloy Pipe and Tubing

phorus

A

C12200 DHP phosphorized, high residual phos-

B 154 Test Method for Mercurous Nitrate Test for Copper

phorus

4

and Copper Alloys

A

C14200 DPA phosphorized, arsenical

B 170 Specification for Oxygen-Free Electrolytic Copper—

C19200 . phosphorized, 1 % iron

4

C23000 . red brass

Refinery Shapes

C44300 Types B, admiralty metals

4

B 224 Classification of Coppers

C44400 C,

C44500 D B 601 Practice for Temper Designations for Copper and

4

C60800 . aluminum bronze

Copper Alloys—Wrought and Cast

C68700 Type B aluminum brass

E 8 Test Methods for Tension Testing of Metallic Mate-

C70400 . 95-5 copper-nickel

5

rials

C70600 . 90-10 copper-nickel

C71000 . 80-20 copper-nickel

E 29 Practice for Using Significant Digits in Test Data to

C71500 . 70-30 copper-nickel

6

Determine Conformance with Specifications

C72200 . copper-nickel

7

__________________ E 53 Test Methods for Chemical Analysis of Copper

A

Designations listed in Classification B 224. E 54 Test Methods for Chemical Analysis of Special

7

Brasses and Bronzes

NOTE 1—A complete metric companion to Specification B 395 has

E 55 Practice for Sampling Wrought Nonferrous Metals and

been developed—B 395M; therefore no metric equivalents are presented

7

Alloys for Determination of Chemical Composition

in this specification.

NOTE 2—Warning: Mercury is a definite health hazard in use and

E 62 Test Methods for Chemical Analysis of Copper and

7

disposal. (See 12.1.)

Copper Alloys (Photometric Methods)

E 75 Test Methods for Chemical Analysis of Copper-Nickel

1.2 The following safety hazards caveat pertains only to the

7

and Copper-Nickel-Zinc Alloys

5

E 112 Test Methods for Determining Average Grain Size

1

This specification is under the jurisdiction of ASTM Committee B-5 on Copper

E 243 Practice for Electromagnetic (Eddy-Current) Exami-

and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe

8

nation of Copper and Copper-Alloy Tubes

and Tube.

Current edition approved Aug. 15, 1995. Published October 1995. Originally

published as B 395 – 62 T. Last previous edition B 395 – 93.

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

4

cation SB-395 in Section II of that Code. Annual Book of ASTM Standards, Vol 02.01.

3 5

The UNS system for copper and copper alloys (see Practice E 527) is a simple Annual Book of ASTM Standards, Vol 03.01.

6

expansion of the former standard designation system accomplished by the addition Annual Book of ASTM Standards, Vol 14.02.

7

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate Annual Book of ASTM Standards, Vol 03.05.

8

composition variations of the base alloy. Annual Book of ASTM Standards, Vol 03.03.

1

---------------------- Page: 1 ----------------------

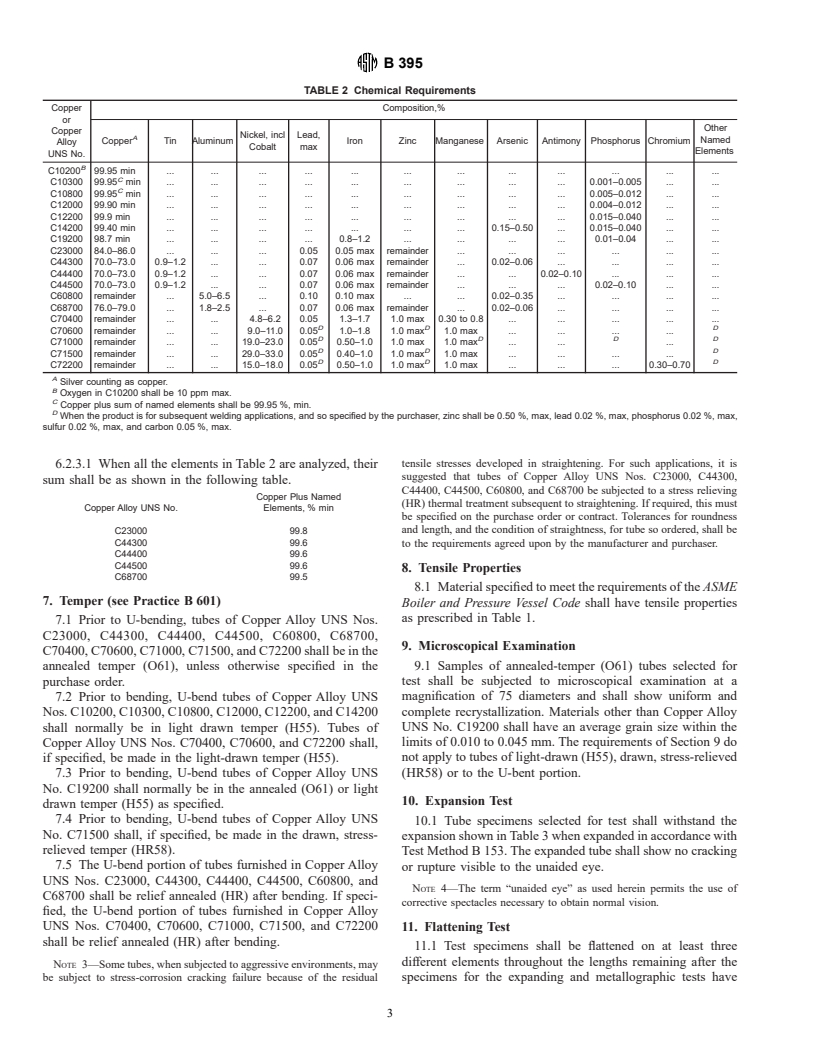

B 395

TABLE 1 Tensile Requirements

Temper Designation Tensile Yield

Elongation in

A

Copper or Copper Alloy UNS No. Strength, Strength,

2 in., min, %

B B

Standard Former

min, ksi min, ksi

C10200, C10300, C10800, C12000, C12200, C14200 H55 light drawn 36 30 .

C19200 H55 light drawn 40 35 .

C19200 O61 annealed 38 12 .

C23000 O61 annealed 40 12 .

C44300, C44400, C44500 O61 annealed 45

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.