ASTM D7234-05

(Test Method)Standard Test Method for Pull-Off Adhesion Strength of Coatings on Concrete Using Portable Pull-Off Adhesion Testers

Standard Test Method for Pull-Off Adhesion Strength of Coatings on Concrete Using Portable Pull-Off Adhesion Testers

SIGNIFICANCE AND USE

The pull-off adhesion strength and mode of failure of a coating from a concrete substrate are important performance properties that are used in specifications. This test method serves as a means for uniformly preparing and testing coated surfaces, and evaluating and reporting the results.

Variations in strength results obtained using different instruments, different substrates, or different loading fixtures with the same coating are possible. Therefore, it is recommended that the specific test instrument and loading fixture be mutually agreed upon between the interested parties.

This test method should not be used to determine surface strength of uncoated concrete. Test Method C 1583/C 1583M is suitable for that determination.

SCOPE

1.1 This test method covers procedures for evaluating the pull-off adhesion strength of a coating on concrete. The test determines the greatest perpendicular force (in tension) that a surface area can bear before a plug of material is detached. Failure will occur along the weakest plane within the system comprised of the test fixture, adhesive, coating system, and substrate, and will be exposed by the fracture surface.

1.2 This test method uses a class of apparatus known as portable pull-off adhesion testers. They are capable of applying a concentric load and counter load to a single surface so that coatings can be tested even though only one side is accessible. Measurements are limited by the strength of adhesion bonds between the loading fixture, coating system and the substrate or the cohesive strengths of the adhesive, coating layers, and substrate.

1.3 Pull-off adhesion strength measurements depend upon both material and instrumental parameters. There are different instruments used that comply with this test method. The specific instrument used should be identified when reporting results. This test is destructive and spot repairs may be necessary.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7234 − 05

StandardTest Method for

Pull-Off Adhesion Strength of Coatings on Concrete Using

Portable Pull-Off Adhesion Testers

This standard is issued under the fixed designation D7234; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers procedures for evaluating the 2.1 ASTM Standards:

pull-off adhesion strength of a coating on concrete. The test C1583 Test Method for Tensile Strength of Concrete Sur-

determines the greatest perpendicular force (in tension) that a faces and the Bond Strength or Tensile Strength of

surface area can bear before a plug of material is detached. Concrete Repair and Overlay Materials by Direct Tension

Failure will occur along the weakest plane within the system (Pull-off Method)

comprised of the test fixture, adhesive, coating system, and D16 TerminologyforPaint,RelatedCoatings,Materials,and

substrate, and will be exposed by the fracture surface. Applications

D2651 GuideforPreparationofMetalSurfacesforAdhesive

1.2 This test method uses a class of apparatus known as

2 Bonding

portable pull-off adhesion testers. They are capable of apply-

D3933 Guide for Preparation of Aluminum Surfaces for

ing a concentric load and counter load to a single surface so

Structural Adhesives Bonding (Phosphoric Acid Anodiz-

that coatings can be tested even though only one side is

ing)

accessible. Measurements are limited by the strength of adhe-

D4541 Test Method for Pull-Off Strength of Coatings Using

sion bonds between the loading fixture, coating system and the

Portable Adhesion Testers

substrate or the cohesive strengths of the adhesive, coating

E178 Practice for Dealing With Outlying Observations

layers, and substrate.

3. Terminology

1.3 Pull-off adhesion strength measurements depend upon

both material and instrumental parameters. There are different

3.1 The terms and definitions in Terminology D16 apply to

instruments used that comply with this test method. The

this test method.

specific instrument used should be identified when reporting

3.2 Definitions:

results. This test is destructive and spot repairs may be

3.2.1 adhesive, n—(with respect to this test method) adhe-

necessary.

sive refers to the material that bonds the bottom of the loading

1.4 The values stated in SI units are to be regarded as the

fixture to the top surface of the coating to be tested.

standard. The values given in parentheses are for information

3.2.2 loading fixture, n—(also referred to as dolliesorstuds)

only.

a metal structure that is flat on one end for bonding to the

1.5 This standard does not purport to address all of the

coating surface and shaped on the other end for attachment to

safety concerns, if any, associated with its use. It is the

the adhesion tester and is used to determine the pull-off

responsibility of the user of this standard to establish appro-

adhesion strength of coatings

priate safety and health practices and determine the applica-

3.2.3 portable pull-off adhesion testers, n—instruments that

bility of regulatory limitations prior to use.

are capable of applying a concentric load and counter load to

asinglesurfacesothatcoatingscanbetestedeventhoughonly

This test method is under the jurisdiction of ASTM Committee D01 on Paint

one side is accessible.

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.46 on Industrial Protective Coatingss.

Current edition approved Dec. 1, 2005. Published February 2006. DOI: 10.1520/ For referenced ASTM standards, visit the ASTM website, www.astm.org, or

D7234-05. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The term adhesion tester may be somewhat of a misnomer, but its adoption by Standards volume information, refer to the standard’s Document Summary page on

two manufacturers and at least two patents indicates continued usage. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7234 − 05

4. Summary of Test Method 6.1.5 Force Indicator and Calibration Information, for

determining the actual force delivered to the loading fixture.

4.1 The general pull-off adhesion test is performed by

The force indicator shall be verified to be within +/-5 % of the

scoring through the coating down to the surface of the concrete

force measured by a calibrated testing machine at a frequency

substrate at a diameter equal to the diameter of the loading

determined by the user, typically once a year.

fixture (dolly, stud), and securing the loading fixture normal

(perpendicular) to the surface of the coating with an adhesive. 6.2 Timer, or means of limiting the rate of stress to less than

After the adhesive is cured, a testing apparatus is attached to 0.2 MPa/s (30 psi/s) so that the maximum stress (failure) is

the loading fixture and aligned to apply tension normal to the obtained in about 5 to 30 s.

test surface. The force applied to the loading fixture is then

6.3 Solvent, or other means for cleaning the loading fixture

uniformly increased and monitored until a plug of material is

surface.

detached. When a plug of material is detached, the exposed

6.4 Fine Sandpaper,orothermeansofcleaningorpreparing

surface represents the plane of limiting strength within the

the coating that will not alter its integrity.

system.Thenatureofthefailureisqualifiedinaccordancewith

the percent of adhesive and cohesive failures, and the actual 6.5 Adhesive,forsecuringthefixturetothecoatingthatdoes

interfacesandlayersinvolved.Thepull-offadhesionstrengthis not affect the coating properties. Two-component epoxies and

computed based on the maximum indicated load, the instru-

acrylics have been found to be the most versatile.

ment calibration data, and the surface area stressed. Pull-off

6.6 Mechanical Clamps, if needed, for holding the fixture in

adhesion strength results obtained using different devices may

place while the adhesive cures.

be different because the results depend on instrumental param-

6.7 Cotton Swabs, or other means for removing excess

eters.

adhesive.

5. Significance and Use 6.8 Core Bit with Drill Press or Hand Drill, and means to

ensure that the scoring is normal to the coating for the

5.1 The pull-off adhesion strength and mode of failure of a

procedures that use a round loading fixture. The core bit inside

coating from a concrete substrate are important performance

diameter should equal the diameter of the loading fixture. If a

properties that are used in specifications. This test method

core bit with an inside diameter equal to the diameter of the

serves as a means for uniformly preparing and testing coated

loadingfixtureisnotavailable,theclosestsizeavailableshould

surfaces, and evaluating and reporting the results.

be used. The core bit or saw blades should be diamond tipped

5.2 Variations in strength results obtained using different

and, when required to minimize heat and suppress dust,

instruments, different substrates, or different loading fixtures

supplemented with water lubrication. For the test procedures

with the same coating are possible. Therefore, it is recom-

that use a square or rectangular loading fixture, a circular saw

mended that the specific test instrument and loading fixture be

is required instead of a core bit and drill. Alternately, for thin

mutually agreed upon between the interested parties.

or elastomeric coatings, a sharp knife or hole saw may be

5.3 This test method should not be used to determine sufficient to score around the loading fixture.

surface strength of uncoated concrete. Test Method C1583 is

suitable for that determination. 7. Test Preparation

7.1 Themethodforselectingthecoatingsitestobeprepared

6. Apparatus

for testing depends upon the objectives of the test and

agreements between the contracting parties. There are, how-

6.1 Adhesion Tester, including the components and accesso-

ries described in 6.1.1-6.1.5 ever,afewphysicalrestrictionsimposedbythegeneralmethod

and apparatus. The following requirements apply to all sites:

6.1.1 Loading Fixtures,havingaflatsurfaceononeendthat

7.1.1 The selected test area must be a flat surface large

can be adhered to the coating and a means of attachment to the

enoughtoaccommodatethespecifiednumberofreplicatetests.

tester on the other end. The bonding surface may be round,

The surface may have any orientation with reference to

squareorrectangular.Theroundloadingfixturesareusually50

gravitational pull. Each test site must be separated by at least

mm (2.0 in) in diameter but may range from 20 mm (0.75 in)

the distance needed to accommodate the detaching apparatus.

to 75 mm (3.0 in) in diameter.

The size of a test site is essentially that of the secured loading

6.1.2 Detaching Assembly, having a central grip for engag-

fixture. At least three replications are required in order to

ing the loading fixture.

statistically characterize the test area.

6.1.3 Base, on the detaching assembly, for uniformly press-

7.1.2 The selected test areas must also have enough perpen-

ing against the coating surface around the fixture either

dicularandradialclearancetoaccommodatetheapparatus,and

directly, or by way of an intermediate bearing ring.Ameans of

aligning the base is needed so that the resultant force is normal

to the surface.

6.1.4 Force Applicator, means of moving the grip away

The sole source of supply of the acrylics known to the committee at this time

is Versiloc 201 and 204 with accelerator, available from Lord Corp., Industrial

from the base in as smooth and continuous a manner as

Adhesive Div., 2000 W. Grandview Blvd., P.O. Box 10038, Erie, PA 16514. If you

possible so that a torsion free, co-axial (opposing pull of the

are aware of alternative suppliers, please provide this information to ASTM

grip and push of the base along the same axis) force results

International Headquarters. Your comments will receive careful consideration at a

between them. meeting of the responsible technical committee, which you may attend.

D7234 − 05

be flat enough to permit alignment. It should be noted that fixture or the surface to be tested, or both, using a method

measurementsclosetoanedgemaynotberepresentativeofthe recommended by the adhesive manufacturer. Be certain to

coating as a whole.

apply the adhesive across the entire surface. Position fixture on

the surface to be tested centered directly over the scored

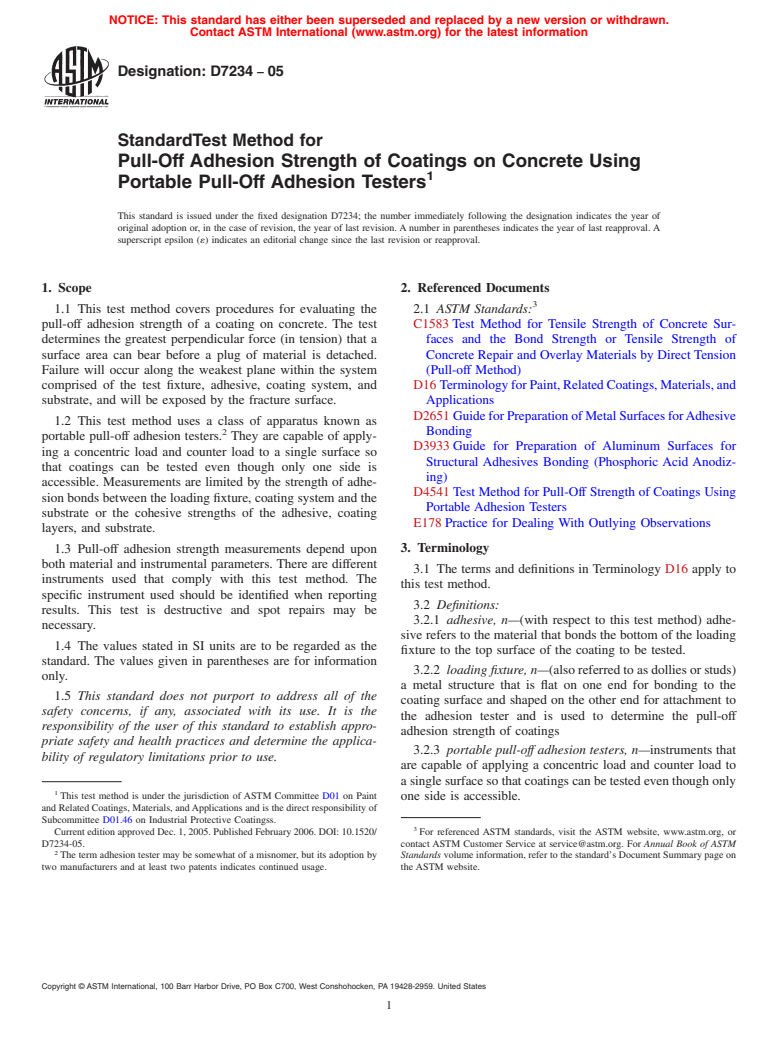

7.2 Scoring the coating down to the surface of the substrate

section with the fixture outer sides lined up with the inside

is required for all coatings thicker than 0.5 mm (20 mils) and

circumference of the scored section. Carefully remove the

for all reinforced or elastomeric coatings. While scoring is

excess adhesive from around the fixture. (Warning—

recommended for coatings thinner than 0.5 mm (20 mils), the

Movement, especially twisting, can cause tiny bubbles to

test may be performed without scoring, but the results should

coalesce into large holidays that constitute stress discontinui-

note this exception. Scoring shall be performed in a manner

ties during testing.)

that ensures the cut is made normal to the coating surface and

in a manner that does not twist or torque the test area and

NOTE 2—Adding about 1 percent of #5 glass beads to the adhesive

minimizes heat generated and edge damage or microcracks to

assists in even alignment of the test fixture to the surface.

the coating and the concrete substrate. For thick coatings it is

7.5 Basedontheadhesivemanufacturer’srecommendations

recommended to cool the coating and substrate during the

and the anticipated environmental conditions, allow enough

cutting process with water lubrication. When using a round

time for the adhesive to set up and reach the recommended

loading fixture, scoring is performed before the loading fixture

cure. During the adhesive set and early cure stage, a constant

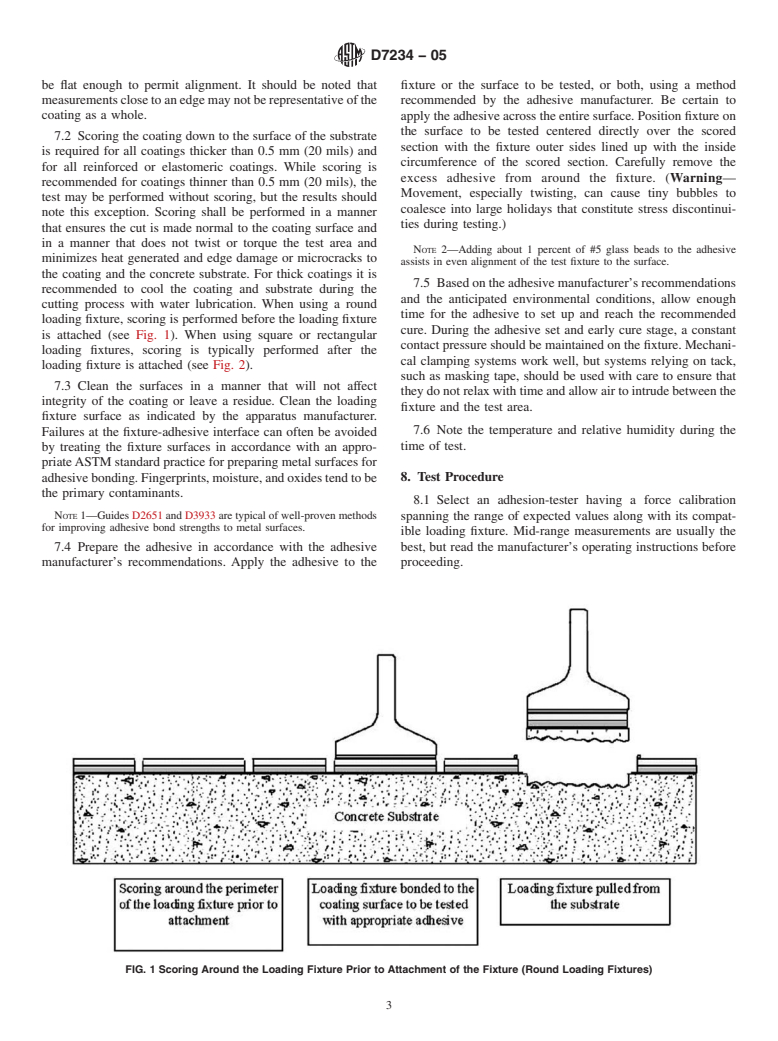

is attached (see Fig. 1). When using square or rectangular

contact pressure should be maintained on the fixture. Mechani-

loading fixtures, scoring is typically performed after the

cal clamping systems work well, but systems relying on tack,

loading fixture is attached (see Fig. 2).

such as masking tape, should be used with care to ensure that

7.3 Clean the surfaces in a manner that will not affect

theydonotrelaxwithtimeandallowairtointrudebetweenthe

integrity of the coating or leave a residue. Clean the loading

fixture and the test area.

fixture surface as indicated by the apparatus manufacturer.

7.6 Note the temperature and relative humidity during the

Failures at the fixture-adhesive interface can often be avoided

time of test.

by treating the fixture surfaces in accordance with an appro-

priateASTM standard practice for preparing metal surfaces for

adhesivebonding.Fingerprints,moisture,andoxidestendtobe 8. Test Procedure

the primary contaminants.

8.1 Select an adhesion-tester having a force calibration

NOTE 1—Guides D2651 and D3933 are typical of well-proven methods

spanning the range of expected values along with its compat-

for improving adhesive bond strengths to metal surfaces.

ible loading fixture. Mid-range measurements are usually the

7.4 Prepare the adhesive in accordance with the adhesive best, but read the manufacturer’s operating instructions before

manufacturer’s recommendations. Apply the adhesive to the proceeding.

FIG. 1 Scoring Around the Loading Fixture Prior to Attachment of the Fixture (Round Loading Fixtures)

D7234 − 05

FIG. 2 Scoring Around the Loading Fixture After Attachment of the Fixture (Square or Rectangular Fixtures)

8.2 If a bearing ring or comparable device is to be used, 9.2 Either use the calibration chart supplied by the manu-

placeitconcentricallyaroundtheloadingfixtureonthecoating facturer or compute the relative stress applied to each coating

surface. If shims are required when a bearing ring is employed, sample as follows:

place them between the tester base and bearing ring rather than

4F

X 5 (1)

on the coating surface. 2

πd

8.3 Carefully connect the central grip of the detaching

where:

assembly to the loading fixture without bumping, bending, or

X = pull-off adhesion strength achieved at failure in MPa

otherwise prestressing the sample and connect the detaching

(psi).

assembly to its control mechanism, if necessary. For nonhori-

F = Maximum force applied to the test surface at failure and

zontal surfaces, support the detaching assembly so that its

as determined in 9.1 in N(lb) ,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.