ASTM A608/A608M-02

(Specification)Standard Specification for Centrifugally Cast Iron-Chromium-Nickel High-Alloy Tubing for Pressure Application at High Temperatures

Standard Specification for Centrifugally Cast Iron-Chromium-Nickel High-Alloy Tubing for Pressure Application at High Temperatures

SCOPE

1.1 This specification covers iron-chromium-nickel, high-alloy tubes made by the centrifugal casting process intended for use under pressure at high temperatures.

1.2 The grades of high alloys detailed in Table 1 are intended for applications requiring strength and resistance to corrosion and scaling at high temperatures.

1.3 Optional Supplementary Requirements S1 to S11 are provided; these call for additional tests to be made if desired.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of each other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 608/A 608M – 02

Standard Specification for

Centrifugally Cast Iron-Chromium-Nickel High-Alloy Tubing

1

for Pressure Application at High Temperatures

This standard is issued under the fixed designationA 608/A 608M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * E 139 Test Methods for Conducting Creep, Creep-Rupture,

5

and Stress-Rupture Tests of Metallic Materials

1.1 This specification covers iron-chromium-nickel, high-

E 142 Method for Controlling Quality of Radiographic

alloy tubes made by the centrifugal casting process intended

7

Testing

for use under pressure at high temperatures.

E 151 Practice for Tension Tests of Metallic Materials at

1.2 The grades of high alloys detailed in Table 1 are

Elevated Temperatures with Rapid Heating and Conven-

intended for applications requiring strength and resistance to

8

tional or Rapid Strain Rates

corrosion and scaling at high temperatures.

6

E 165 Test Method for Liquid Penetrant Examination

1.3 Optional Supplementary Requirements S1 to S11 are

provided; these call for additional tests to be made if desired.

3. Ordering Information

1.4 The values stated in either inch-pound units or SI units

3.1 Orders for material to this specification should include

are to be regarded separately as standard. Within the text, the

the following, as required, to describe the desired material

SI units are shown in brackets. The values stated in each

adequately:

system are not exact equivalents; therefore, each system must

3.1.1 Quantity (feet, centimetres, or number of lengths),

be used independently of each other. Combining values from

3.1.2 Name of material (centrifugally cast tubing),

the two systems may result in nonconformance with the

3.1.3 Specification number and grade (Table 1),

specification.

3.1.4 Size (outside or inside diameter and minimum wall

2. Referenced Documents thickness, see Section 8).

3.1.5 Condition (see Section9, as cast or as cast with

2.1 ASTM Standards:

machining on outside or inside surfaces, or machined; see 5.1,

A 342/A 342M Test Methods for Permeability of Feebly

2

8, and 9),

Magnetic Materials

3.1.6 Length (specific or random), (Permissible Variations

A 488/A 488M Practice for Steel Castings, Welding, Quali-

3

in Length Section of Specification A 530/A 530M),

fication of Procedures and Personnel

3.1.7 End finish (Ends Section of Specification A 530/

A 530/A 530M Specification for General Requirements for

4

A 530M),

Specialized Carbon and Alloy Steel Pipe

5 3.1.8 Optional requirements (see 8.2.3 regarding the manu-

E 8 Test Methods forTensionTesting of Metallic Materials

facturer’s wall thickness allowance for as cast tubing and

E 21 Test Methods for Elevated-Temperature Tension Tests

5 Supplementary Requirements S1 to S11),

of Metallic Materials

6

3.1.9 Test report required (see Section 13), and

E 94 Guide for Radiographic Examination

3.1.10 Special requirements to be added to the specification.

4. General Requirements

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and RelatedAlloys, and is the direct responsibility of Subcommittee 4.1 Material furnished under this specification shall con-

A01.18 on Castings.

form to the applicable requirements of the current edition of

Current edition approved Dec. 10, 2002. Published February 2003. Originally

Specification A 530/A 530M, unless otherwise provided

approved in 1970. Last previous edition approved in 1998 as A 608-91a (1998).

2

herein.

Annual Book of ASTM Standards, Vol 03.04.

3

Annual Book of ASTM Standards, Vol 01.02.

4

Annual Book of ASTM Standards, Vol 01.01.

5 7

Annual Book of ASTM Standards, Vol 03.01. Discontinued; see 1999 Annual Book of ASTM Standards, Vol 03.03.

6 8

Annual Book of ASTM Standards, Vol 03.03. Discontinued; see 1983 Annual Book of ASTM Standards, Vol 03.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

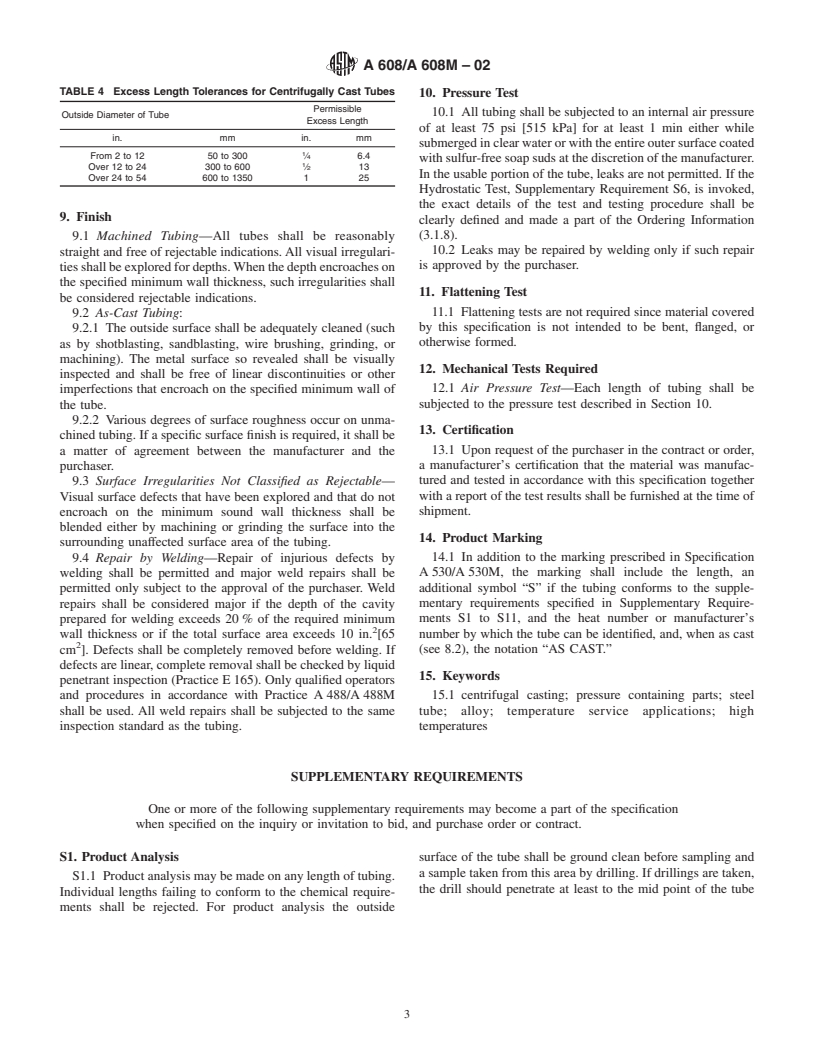

A 608/A 608M – 02

TABLE 1 Chemical Requirements

Grade Composition, %

Carbon Manganese Silicon Chromium Nickel Phosphorus Sulfur Molybdenum

HC30 0.25–0.35 0.5–1.0 0.50–2.00 26–30 4.0 max 0.04 max 0.04 max 0.50 max

HD50 0.45–0.55 1.50 max 0.50–2.00 26–30 4–7 0.04 max 0.04 max 0.50 max

HE35 0.30–0.40 1.50 max 0.50–2.00 26–30 8–11 0.04 max 0.04 max 0.50 max

HF30 0.25–0.35 1.50 max 0.50–2.00 19–23 9–12 0.04 max 0.04 max 0.50 max

HH30 0.25–0.35

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.