ASTM F2706-08

(Test Method)Standard Test Methods for Occipital-Cervical and Occipital-Cervical-Thoracic Spinal Implant Constructs in a Vertebrectomy Model

Standard Test Methods for Occipital-Cervical and Occipital-Cervical-Thoracic Spinal Implant Constructs in a Vertebrectomy Model

SIGNIFICANCE AND USE

Occipital-cervical and occipital-cervical-thoracic spinal implants are generally composed of several components which, when connected together, form either an occipital-cervical spinal implant assembly or an occipital-cervical-thoracic spinal implant assembly. Occipital-cervical and occipital-cervical-thoracic spinal implant assemblies are designed to provide some stability to the spine during the process of arthrodesis. These test methods outline standard materials and methods for the evaluation of different spinal implant assemblies to facilitate comparisons between different designs.

These test methods are used to quantify the static and dynamic mechanical characteristics of different designs of occipital-cervical and occipital-cervical-thoracic spinal implant assemblies. The mechanical tests are conducted in vitro using simplified load schemes and do not attempt to mimic the complex loads of the occipital-cervical and occipital-cervical-thoracic spine.

The loads applied to the spinal implant assemblies in vivo will, in general, differ from the loading configurations used in these test methods. The results obtained here cannot be used directly to predict in vivo performance. The results can be used to compare different component designs in terms of the relative mechanical parameters.

Fatigue testing in a simulated body fluid or saline may cause fretting, corrosion, or lubricate the interconnections and thereby affect the relative performance of tested devices. This test should be initially performed dry (ambient room conditions) for consistency. The effect of the environment may be significant. Repeating all or part of these test methods in simulated body fluid, saline (9 g NaCl per 1000 mL water), a saline drip, water, or a lubricant should be considered. The maximum recommended frequency for this type of cyclic testing should be 5 Hz.

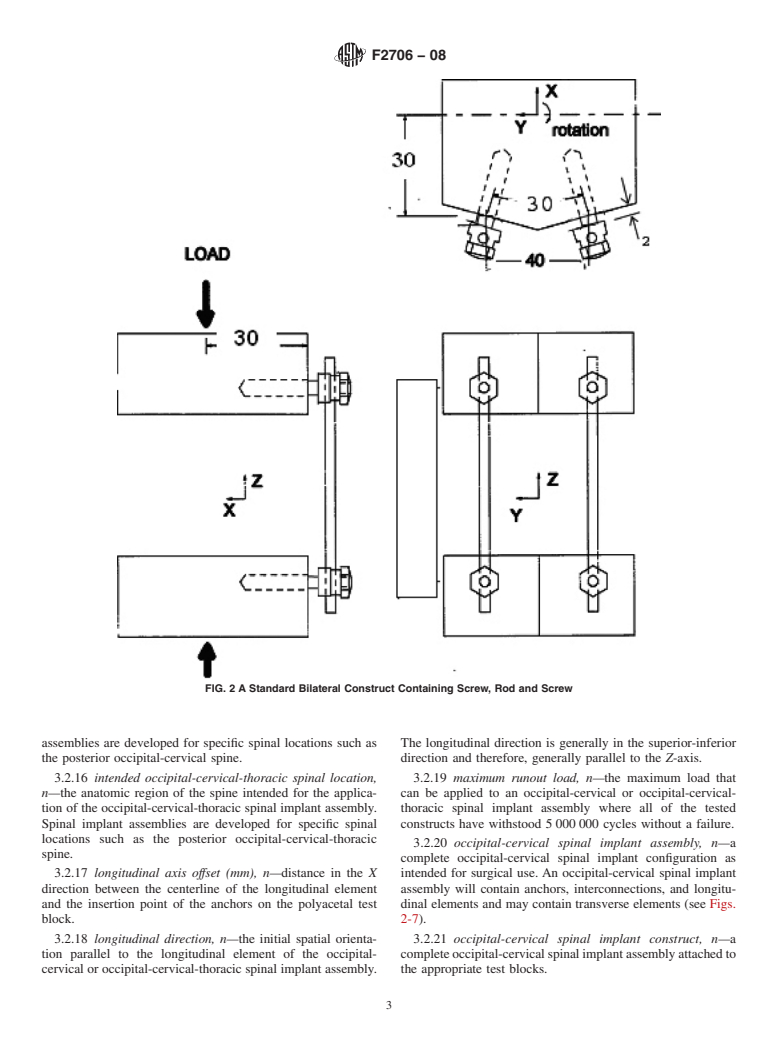

The location of the longitudinal elements is determined by the intended in vivo location of the anchors. The perpendicul...

SCOPE

1.1 These test methods cover the materials and methods for the static and fatigue testing of occipital-cervical and occipital-cervical-thoracic spinal implant assemblies in a vertebrectomy model. The test materials for most combinations of occipital-cervical and occipital-cervical-thoracic spinal implant components can be specific depending on the intended location and intended method of attachment.

1.2 These test methods are intended to provide a basis for the mechanical comparison among past, present, and future occipital-cervical and occipital-cervical-thoracic spinal implant assemblies. They allow comparison of occipital-cervical and occipital-cervical-thoracic spinal implant constructs with different methods of application to the spine. These test methods are not intended to define levels of performance, since sufficient knowledge is not available to predict the consequences of the use of a particular device.

1.3 These test methods set out guidelines for load types and methods of applying loads. Methods for three static load types and two fatigue tests for the comparative evaluation of occipital-cervical and occipital-cervical-thoracic spinal implant assemblies are defined.

1.4 These test methods establish guidelines for measuring displacements, determining the yield load, and evaluating the stiffness and strength of occipital-cervical or occipital-cervical-thoracic spinal implant assemblies.

1.5 It may not be possible to test some occipital-cervical and some occipital-cervical-thoracic spinal constructs in all test configurations.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of reg...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2706 − 08

StandardTest Methods for

Occipital-Cervical and Occipital-Cervical-Thoracic Spinal

1

Implant Constructs in a Vertebrectomy Model

This standard is issued under the fixed designation F2706; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 These test methods cover the materials and methods for

thestaticandfatiguetestingofoccipital-cervicalandoccipital-

2. Referenced Documents

cervical-thoracic spinal implant assemblies in a vertebrectomy

2

model. The test materials for most combinations of occipital-

2.1 ASTM Standards:

cervical and occipital-cervical-thoracic spinal implant compo-

E4Practices for Force Verification of Testing Machines

nents can be specific depending on the intended location and

E6Terminology Relating to Methods of Mechanical Testing

intended method of attachment.

E739PracticeforStatisticalAnalysisofLinearorLinearized

Stress-Life (S-N) and Strain-Life (´-N) Fatigue Data

1.2 These test methods are intended to provide a basis for

the mechanical comparison among past, present, and future E1823TerminologyRelatingtoFatigueandFractureTesting

F1582Terminology Relating to Spinal Implants

occipital-cervical and occipital-cervical-thoracic spinal im-

plant assemblies. They allow comparison of occipital-cervical F1717Test Methods for Spinal Implant Constructs in a

Vertebrectomy Model

and occipital-cervical-thoracic spinal implant constructs with

different methods of application to the spine. These test F2077TestMethodsForIntervertebralBodyFusionDevices

methodsarenotintendedtodefinelevelsofperformance,since

sufficient knowledge is not available to predict the conse- 3. Terminology

quences of the use of a particular device.

3.1 Definitions—For definitions of terms relating to these

1.3 These test methods set out guidelines for load types and

test methods, see Terminologies E6, F1582, and E1823.

methods of applying loads. Methods for three static load types

3.2 Definitions of Terms Specific to This Standard:

and two fatigue tests for the comparative evaluation of

3.2.1 active length of the longitudinal element, n—the

occipital-cervical and occipital-cervical-thoracic spinal im-

straight line distance between the centers of rotation of the test

plant assemblies are defined.

blocks.

1.4 These test methods establish guidelines for measuring

3.2.2 block moment arm, n—the perpendicular to the ap-

displacements, determining the yield load, and evaluating the

pliedloadbetweentheinsertionpointofananchorandtheaxis

stiffnessandstrengthofoccipital-cervicaloroccipital-cervical-

of the hinge pin.

thoracic spinal implant assemblies.

1.5 Itmaynotbepossibletotestsomeoccipital-cervicaland 3.2.3 compressive or tensile bending stiffness (N/mm),

some occipital-cervical-thoracic spinal constructs in all test n—the compressive or tensile bending yield force divided by

configurations. elastic displacement (see the initial slope of line BC in Fig. 1).

1.6 The values stated in SI units are to be regarded as

3.2.4 compressive or tensile bending ultimate load (N),

standard. No other units of measurement are included in this

n—the maximum compressive or tensile force in the X-Z plane

standard.

applied to an occipital-cervical or occipital-cervical-thoracic

spinalimplantassembly(seetheforceatPointEinFig.1).The

1.7 This standard does not purport to address all of the

ultimate load should be a function of the device and not of the

safety concerns, if any, associated with its use. It is the

load cell or testing machine.

responsibility of the user of this standard to establish appro-

1

These test methods are under the jurisdiction of ASTM Committee F04 on

2

Medical and Surgical Materials and Devices and are the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee F04.25 on Spinal Devices. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Aug. 1, 2008. Published September 2008. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2706-08. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2706 − 08

FIG. 1 Typical Load Displacement Curve or Torque Angulation Curve

3.2.5 compressive or tensile bending yield load (N), n—the occipital-cervical-thoracic spinal implant assembly ineffective

compressive or tensile bending f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.