ASTM D6443-04(2010)

(Test Method)Test Method for Determination of Calcium, Chlorine, Copper, Magnesium, Phosphorus, Sulfur, and Zinc in Unused Lubricating Oils and Additives by Wavelength Dispersive X-ray Fluorescence Spectrometry (Mathematical Correction Procedure)

Test Method for Determination of Calcium, Chlorine, Copper, Magnesium, Phosphorus, Sulfur, and Zinc in Unused Lubricating Oils and Additives by Wavelength Dispersive X-ray Fluorescence Spectrometry (Mathematical Correction Procedure)

SIGNIFICANCE AND USE

Lubricating oils can be formulated with additives, which can act as detergents, anti-oxidants, anti-wear agents, and so forth. Some additives can contain one or more of calcium, copper, magnesium, phosphorus, sulfur, and zinc. This test method can be used to determine if the oils, additives, and additive packages meet specification with respect to content of these elements.

This test method can also be used to determine if lubricating oils, additives, and additive packages meet specification with respect to chlorine concentration. In this context, specification can refer to contamination.

This test method is not intended for use on samples that contain some component that significantly interferes with the analysis of the elements specified in the scope.

This test method can complement other test methods for lube oils and additives, including Test Methods D4628, D4927, D4951, and D5185.

SCOPE

1.1 This test method covers the determination of calcium, chlorine, copper, magnesium, phosphorus, sulfur, and zinc in unused lubricating oils, additives, and additive packages by wavelength dispersive X-ray fluorescence spectrometry. Matrix effects are handled with mathematical corrections.

1.2 For each element, the upper limit of the concentration range covered by this test method is defined by the highest concentration listed in Table 1. Samples containing higher concentrations can be analyzed following dilution.

1.3 For each element, the lower limit of the concentration range covered by this test method can be estimated by the limit of detection (LOD) (see also 40 CFR 136 Appendix B) or limit of quantification (LOQ), both of which can be estimated from Sr, the repeatability standard deviation. LOD and LOQ values, determined from results obtained in the interlaboratory study on precision, are listed in Table 2.

1.3.1 LOD and LOQ are not intrinsic constants of this test method. LOD and LOQ depend upon the precision attainable by a laboratory when using this test method.

1.4 This test method uses regression software to determine calibration parameters, which can include influence coefficients (that is, interelement effect coefficients) (Guide E1361), herein referenced as alphas. Alphas can also be determined from theory using relevant software.

1.5 Setup of this test method is intended for persons trained in the practice of X-ray spectrometry. Following setup, this test method can be used routinely.

1.6 The values stated in either SI units or angstrom units are to be regarded separately as standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6443 − 04(Reapproved 2010)

Standard Test Method for

Determination of Calcium, Chlorine, Copper, Magnesium,

Phosphorus, Sulfur, and Zinc in Unused Lubricating Oils

and Additives by Wavelength Dispersive X-ray Fluorescence

Spectrometry (Mathematical Correction Procedure)

This standard is issued under the fixed designation D6443; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of calcium,

responsibility of the user of this standard to establish appro-

chlorine, copper, magnesium, phosphorus, sulfur, and zinc in

priate safety and health practices and determine the applica-

unused lubricating oils, additives, and additive packages by

bility of regulatory limitations prior to use.

wavelength dispersive X-ray fluorescence spectrometry. Ma-

trix effects are handled with mathematical corrections.

2. Referenced Documents

1.2 For each element, the upper limit of the concentration

2.1 ASTM Standards:

range covered by this test method is defined by the highest

D1552 Test Method for Sulfur in Petroleum Products (High-

concentration listed in Table 1. Samples containing higher

Temperature Method)

concentrations can be analyzed following dilution.

D4057 Practice for Manual Sampling of Petroleum and

1.3 For each element, the lower limit of the concentration

Petroleum Products

range covered by this test method can be estimated by the limit

D4177 Practice for Automatic Sampling of Petroleum and

of detection (LOD) (see also 40 CFR 136 Appendix B) or

Petroleum Products

limit of quantification (LOQ), both of which can be estimated

D4307 Practice for Preparation of Liquid Blends for Use as

from S , the repeatability standard deviation. LOD and LOQ

Analytical Standards

r

values, determined from results obtained in the interlaboratory

D4628 Test Method for Analysis of Barium, Calcium,

study on precision, are listed in Table 2.

Magnesium, and Zinc in Unused Lubricating Oils by

1.3.1 LOD and LOQ are not intrinsic constants of this test

Atomic Absorption Spectrometry

method. LOD and LOQ depend upon the precision attainable

D4927 Test Methods for Elemental Analysis of Lubricant

by a laboratory when using this test method.

and Additive Components—Barium, Calcium,

Phosphorus, Sulfur, and Zinc by Wavelength-Dispersive

1.4 This test method uses regression software to determine

X-Ray Fluorescence Spectroscopy

calibration parameters, which can include influence coeffi-

D4951 Test Method for Determination ofAdditive Elements

cients (that is, interelement effect coefficients) (Guide E1361),

in Lubricating Oils by Inductively Coupled Plasma

herein referenced as alphas. Alphas can also be determined

Atomic Emission Spectrometry

from theory using relevant software.

D5185 TestMethodforDeterminationofAdditiveElements,

1.5 Setup of this test method is intended for persons trained

Wear Metals, and Contaminants in Used Lubricating Oils

inthepracticeofX-rayspectrometry.Followingsetup,thistest

and Determination of Selected Elements in Base Oils by

method can be used routinely.

Inductively Coupled Plasma Atomic Emission Spectrom-

1.6 The values stated in either SI units or angstrom units are

etry (ICP-AES)

to be regarded separately as standard. D6299 Practice for Applying Statistical Quality Assurance

and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

E29 Practice for Using Significant Digits in Test Data to

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

D02.03 on Elemental Analysis.

Current edition approved May 1, 2010. Published May 2010. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1999. Last previous edition approved in 2004 as D6443–04. DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/D6443-04R10. Standards volume information, refer to the standard’s Document Summary page on

Analytical Chemistry, Vol 55, pp. 2210-2218. the ASTM website.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D6443 − 04 (2010)

TABLE 1 Calibration Standard Compositions, Concentrations in

method can be used to determine if the oils, additives, and

Mass %

additive packages meet specification with respect to content of

Std. No. Ca Cl Cu Mg P S Zn

these elements.

1 0.02 0.02 0.01 0.20 0.25 1.00 0.02

4.2 This test method can also be used to determine if

2 0.02 0.02 0.05 0.20 0.02 0.02 0.25

3 0.02 0.20 0.01 0.05 0.25 0.02 0.25

lubricating oils, additives, and additive packages meet specifi-

4 0.02 0.20 0.05 0.05 0.02 1.00 0.02

cation with respect to chlorine concentration. In this context,

5 0.40 0.02 0.01 0.05 0.02 1.00 0.25

specification can refer to contamination.

6 0.40 0.02 0.05 0.05 0.25 0.02 0.02

7 0.40 0.20 0.01 0.20 0.02 0.02 0.02

4.3 This test method is not intended for use on samples that

8 0.40 0.20 0.05 0.20 0.25 1.00 0.25

9 0.20 0.10 0.03 0.10 0.10 0.50 0.10 contain some component that significantly interferes with the

10 0 0 0 000 0

analysis of the elements specified in the scope.

4.4 This test method can complement other test methods for

lubeoilsandadditives,includingTestMethodsD4628,D4927,

TABLE 2 Estimated LOD and LOQ, Units are Mass %

D4951, and D5185.

Ca Cl Cu Mg P Zn

LOD 0.0002 0.0004 0.0002 0.0039 0.0006 0.0002

LOQ 0.0008 0.0015 0.0007 0.0130 0.0020 0.0007

5. Interferences

5.1 The additive elements can affect the magnitudes of the

measured intensities for each analyte. In general, the

Determine Conformance with Specifications X-radiation emitted by each analyte can be absorbed by the

E1361 Guide for Correction of Interelement Effects in other elements.Also, the X-radiation emitted by an analyte can

X-Ray Spectrometric Analysis be enhanced by some other component. The magnitudes of the

absorption and enhancement effects can be significant. How-

2.2 Government Standard:

ever,implementationofaccuratelydeterminedalphasintheset

40 CFR, 136 Appendix B, Definition and Procedure for the

of calibration parameters can satisfactorily correct for absorp-

Determination of the Method Detection Limit—Revision

tion and enhancement effects, thereby making this test method

1.11, pp. 265-267

quantitative.

3. Summary of Test Method

5.2 Molybdenum lines can spectrally overlap lines of mag-

3.1 The X-ray fluorescence spectrometer is initially cali-

nesium, phosphorus, sulfur, and chlorine. Lead lines can

brated by the following procedure. For each element, the slope

spectrally overlap sulfur. Thus, this test method cannot be

and intercept of the calibration curve are determined by

applied if molybdenum or lead are present at significant

regressing concentration data and intensities measured on a set

concentrations and if accurate overlap corrections cannot be

of physical standards. Empirical alphas can also be determined made.

by regression when the appropriate set of physical standards is

5.3 When a large d-spacing diffraction structure containing

used for calibration.Theoretical alphas, calculated with special

silicon is used as the analyzing crystal, corrections for the

software, can also be used. In addition, a combination of

fluorescence of silicon may be needed. Calcium X rays from

theoretical and empirical alphas can be used.

sample specimens cause silicon to fluoresce. This silicon

3.2 AsampleisplacedintheX-raybeam,andtheintensities

radiation contributes to fluctuations in the background for

of the appropriate fluorescence lines are measured. A similar

magnesium measurements. If the effect is significant, this

measurement is made at a wavelength offset from each

interference may be treated as a line overlap due to calcium.

fluorescence line in order to obtain a background correction.

Enhancement or absorption of the X-ray fluorescence of an

6. Apparatus

analyte by an interfering element in the sample can occur, and

6.1 X-ray Spectrometer,equippedfordetectionofsoftX-ray

these effects can be handled in the data reduction by imple-

radiation in the range from 1 to 10 angstroms. For optimum

mentation of alphas. Concentrations of the analytes are deter-

sensitivity, the spectrometer is equipped with the following:

mined by comparison of net signals against calibration curves,

6.1.1 X-ray Tube Source, with chromium, rhodium, or

which include influence coefficients (that is, alphas) calculated

scandium target. Scandium can be advantageous for sensitivity

from theory, empirical data, or a combination of theory and

enhancement of the low atomic number analytes. Other targets

empirical data.

may also be employed. Avoid spectral interferences from tube

lines on the analyte lines.

4. Significance and Use

6.1.2 Helium, purgeable optical path.

4.1 Lubricatingoilscanbeformulatedwithadditives,which

6.1.3 Interchangeable Analyzer Crystals, germanium,

can act as detergents, anti-oxidants, anti-wear agents, and so

lithiumfluoride(LiF ),graphite,pentaerythritol(PE),ora50

forth. Some additives can contain one or more of calcium,

angstrom diffraction structure, or a combination thereof. Other

copper, magnesium, phosphorus, sulfur, and zinc. This test

suitable crystals can be used.

6.1.4 Pulse-Height Analyzer.

6.1.5 Detector, gas flow proportional, or tandem gas flow

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401. proportional and scintillation counter.

D6443 − 04 (2010)

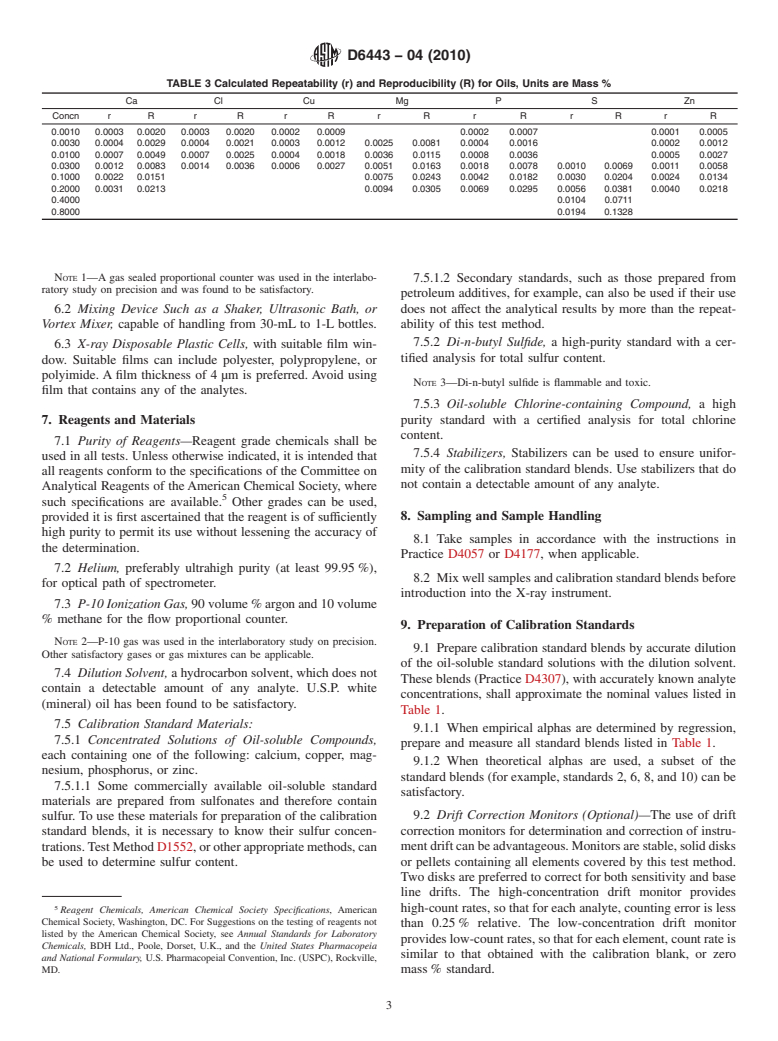

TABLE 3 Calculated Repeatability (r) and Reproducibility (R) for Oils, Units are Mass %

Ca Cl Cu Mg P S Zn

Concn r R r R r R r R r R r R r R

0.0010 0.0003 0.0020 0.0003 0.0020 0.0002 0.0009 0.0002 0.0007 0.0001 0.0005

0.0030 0.0004 0.0029 0.0004 0.0021 0.0003 0.0012 0.0025 0.0081 0.0004 0.0016 0.0002 0.0012

0.0100 0.0007 0.0049 0.0007 0.0025 0.0004 0.0018 0.0036 0.0115 0.0008 0.0036 0.0005 0.0027

0.0300 0.0012 0.0083 0.0014 0.0036 0.0006 0.0027 0.0051 0.0163 0.0018 0.0078 0.0010 0.0069 0.0011 0.0058

0.1000 0.0022 0.0151 0.0075 0.0243 0.0042 0.0182 0.0030 0.0204 0.0024 0.0134

0.2000 0.0031 0.0213 0.0094 0.0305 0.0069 0.0295 0.0056 0.0381 0.0040 0.0218

0.4000 0.0104 0.0711

0.8000 0.0194 0.1328

NOTE 1—A gas sealed proportional counter was used in the interlabo-

7.5.1.2 Secondary standards, such as those prepared from

ratory study on precision and was found to be satisfactory.

petroleum additives, for example, can also be used if their use

6.2 Mixing Device Such as a Shaker, Ultrasonic Bath, or does not affect the analytical results by more than the repeat-

Vortex Mixer, capable of handling from 30-mL to 1-L bottles. ability of this test method.

7.5.2 Di-n-butyl Sulfide, a high-purity standard with a cer-

6.3 X-ray Disposable Plastic Cells, with suitable film win-

tified analysis for total sulfur content.

dow. Suitable films can include polyester, polypropylene, or

polyimide. A film thickness of 4 µm is preferred. Avoid using

NOTE 3—Di-n-butyl sulfide is flammable and toxic.

film that contains any of the analytes.

7.5.3 Oil-soluble Chlorine-containing Compound, a high

7. Reagents and Materials purity standard with a certified analysis for total chlorine

content.

7.1 Purity of Reagents—Reagent grade chemicals shall be

7.5.4 Stabilizers, Stabilizers can be used to ensure unifor-

used in all tests. Unless otherwise indicated, it is intended that

mity of the calibration standard blends. Use stabilizers that do

all reagents conform to the specifications of the Committee on

not contain a detectable amount of any analyte.

Analytical Reagents of theAmerican Chemical Society, where

such specifications are available. Other grades can be used,

8. Sampling and Sample Handling

provided it is first ascertained that the reagent is of sufficiently

high purity to permit its use without lessening the accuracy of

8.1 Take samples in accordance with the instructions in

the determination.

Practice D4057 or D4177, when applicable.

7.2 Helium, preferably ultrahigh purity (at least 99.95 %),

8.2 Mixwellsamplesandcalibrationstandardblendsbefore

for optical path of spectrometer.

introduction into the X-ray instrument.

7.3 P-10 Ionization Gas,90volume%argonand10volume

% methane for the flow proportional counter.

9. Preparation of Calibration Standards

NOTE 2—P-10 gas was used in the interlaboratory study on precision.

9.1 Prepare calibration standard blends by accurate dilution

Other satisfactory gases or gas mixtures can be applicable.

of the oil-soluble standard solutions with the dilution solvent.

7.4 Dilution Solvent, a hydrocarbon solvent, which does not

These blends (Practice D4307), with accurately known analyte

contain a detectable amount of any analyte. U.S.P. white

concentrations, shall approximate the nominal values listed in

(mineral) oil has been found to be satisfactory.

Table 1.

7.5 Calibration Standard Materials:

9.1.1 When empirical alphas are determined by regression,

7.5.1 Concentrated Solutions of Oil-soluble Compounds,

prepare and measure all standard blends listed in Table 1.

each containing one of the following: calcium, copper, mag-

9.1.2 When theoretical alphas are used, a subset of the

nesium, phosphorus, or zinc.

standard blends (for example, standards 2, 6, 8, and 10) can be

7.5.1.1 Some commercially available oil-soluble standard

satisfactory.

materials are prepared from sulfonates and therefore contain

sulfur. To use these materials for preparation of the calibration 9.2 Drift Correction Monitors (Optional)—The use of drift

correction monitors for determination and correction of instru-

standard blends, it is necessary to know their sulfur concen-

trations.TestMethodD1552,orotherappropriatemethods,can mentdriftcanbeadvantageous.Monitorsarestable,soliddisks

or pellets containing all elements covered by this test method.

be used to determine sulfur content.

Two disks are preferred to correct for both sensitivity and base

line drifts. The high-concentration drift monitor provides

high-count rates, so that for each analyte, counting error is less

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

than 0.25 % relative. The low-concentration drift monitor

listed by the American Chemical Society, see Annual Standards for Laboratory

provideslow-countrates,sothatforeachelement,countr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.