ASTM A895-89(2000)

(Specification)Standard Specification for Free-Machining Stainless Steel Plate, Sheet, and Strip

Standard Specification for Free-Machining Stainless Steel Plate, Sheet, and Strip

SCOPE

1.1 This specification covers hot-finished or cold-finished plate, sheet, and strip in the more commonly used types of stainless free machining steels designed especially for optimum machinability and for general corrosion and high temperature service. Stainless and heat resisting plate, sheet, and strip other than free machining types are covered in separate specifications.

1.2 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 895 – 89 (Reapproved 2000)

Standard Specification for

Free-Machining Stainless Steel Plate, Sheet, and Strip

This standard is issued under the fixed designation A 895; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4.2 Plate, sheet, and strip may be furnished in one of the

conditions listed in Table 1.

1.1 This specification covers hot-finished or cold-finished

plate, sheet, and strip in the more commonly used types of

stainless free machining steels designed especially for opti-

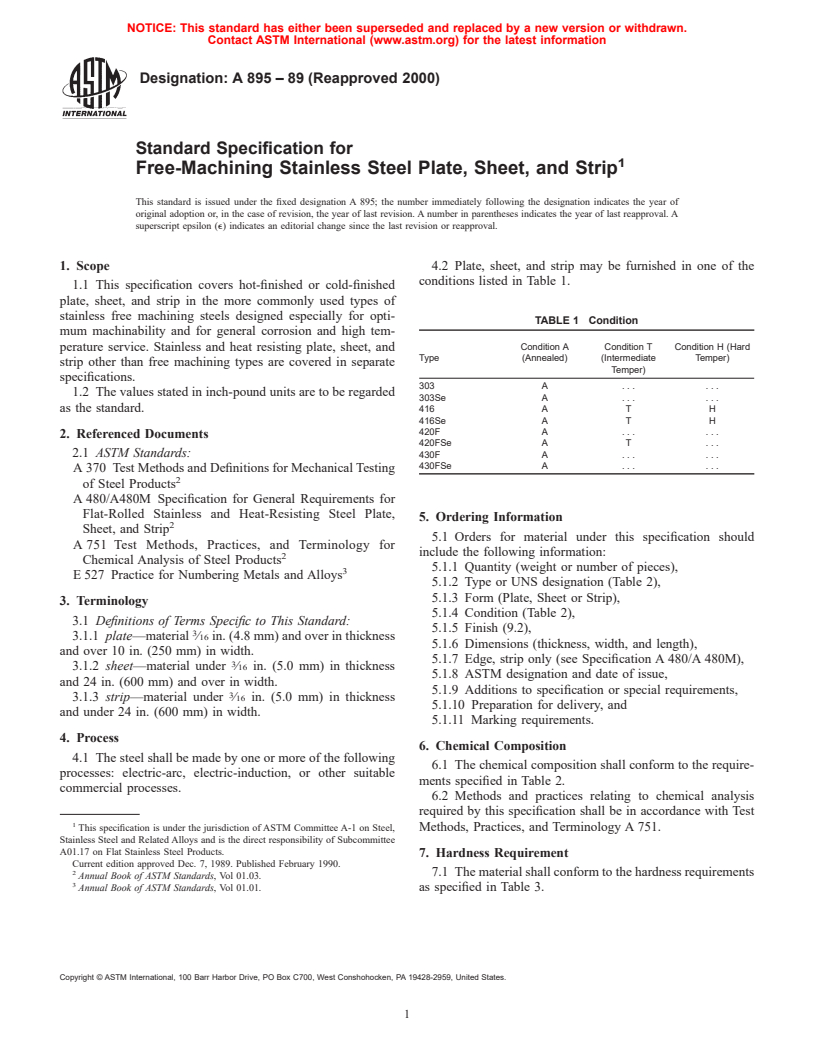

TABLE 1 Condition

mum machinability and for general corrosion and high tem-

perature service. Stainless and heat resisting plate, sheet, and Condition A Condition T Condition H (Hard

Type (Annealed) (Intermediate Temper)

strip other than free machining types are covered in separate

Temper)

specifications.

303 A . .

1.2 The values stated in inch-pound units are to be regarded

303Se A . . . . . .

as the standard.

416 A T H

416Se A T H

420F A . . . . . .

2. Referenced Documents

420FSe A T . . .

2.1 ASTM Standards:

430F A . . . . . .

430FSe A . . . . . .

A 370 Test Methods and Definitions for Mechanical Testing

of Steel Products

A 480/A480M Specification for General Requirements for

Flat-Rolled Stainless and Heat-Resisting Steel Plate,

5. Ordering Information

Sheet, and Strip

5.1 Orders for material under this specification should

A 751 Test Methods, Practices, and Terminology for

include the following information:

Chemical Analysis of Steel Products

5.1.1 Quantity (weight or number of pieces),

E 527 Practice for Numbering Metals and Alloys

5.1.2 Type or UNS designation (Table 2),

5.1.3 Form (Plate, Sheet or Strip),

3. Terminology

5.1.4 Condition (Table 2),

3.1 Definitions of Terms Specific to This Standard:

5.1.5 Finish (9.2),

3.1.1 plate—material ⁄16 in. (4.8 mm) and over in thickness

5.1.6 Dimensions (thickness, width, and length),

and over 10 in. (250 mm) in width.

5.1.7 Edge, strip only (see Specification A 480/A 480M),

3.1.2 sheet—material under ⁄16 in. (5.0 mm) in thickness

5.1.8 ASTM designation and date of issue,

and 24 in. (600 mm) and over in width.

5.1.9 Additions to specification or special requirements,

3.1.3 strip—material under ⁄16 in. (5.0 mm) in thickness

5.1.10 Preparation for delivery, and

and under 24 in. (600 mm) in width.

5.1.11 Marking requirements.

4. Process

6. Chemical Composition

4.1 The steel shall be made by one or more of the following

6.1 The chemical composition shall conform to the require-

processes: electric-arc, electric-induction, or other suitable

ments specified in Table 2.

commercial processes.

6.2 Methods and practices relating to chemical analysis

required by this specification shall be in accordance with Test

Methods, Practices, and Terminology A 751.

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.17 on Flat Stainless Steel Products.

7. Hardness Requirement

Current edition approved Dec. 7, 1989. Published February 1990.

2 7.1 The material shall conform to the hardness requirements

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.01. as specified in Table 3.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 895 – 89 (2000)

TABLE 2 Chemical Requirements

Chemical Composition, %

UNS

A

Manganese, Phosphorus,

B B

Designation

Type Carbon Sulfur Silicon, max Chromium Nickel Other Elements

max max

S30300 303 0.15 2.00 0.20 0.15 min 1.00 17.00–19.00 8.00–10.00 . . .

S30323 303Se 0.15 2.00 0.20 0.06 1.00 17.00–19.00 8.00–10.00 Se 0.15 min

S41600 416 0.15 1.25 0.06 0.15 min 1.00 12.00–14.00 . . . . . .

S41623 416Se 0.15 1.25 0.06 0.06 1.00 12.00–14.00 . . . Se 0.15 min

C C

S42020 420F 0.30–0.40 1.25 0.06 0.15 min 1.00 12.00–14.00 0.50 Cu 0.60 max

C C

S42023 420FSe 0.20–0.40 1.25 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.