ASTM E103-84(2002)

(Test Method)Standard Test Method for Rapid Indentation Hardness Testing of Metallic Materials (Withdrawn 2011)

Standard Test Method for Rapid Indentation Hardness Testing of Metallic Materials (Withdrawn 2011)

SIGNIFICANCE AND USE

This test method is used when it is desired to make hardness tests very rapidly, as in the inspection of the output of a heat-treating furnace.

This test method is not to be regarded as a standard Brinell hardness test method.

Since the test forces and method of display of the depth measurement differ between manufacturers of rapid indentation hardness testing equipment, the test results from equipment from different manufacturers are not comparable. A. GENERAL DESCRIPTION AND TEST PROCEDURE Top

SCOPE

1.1 This test method covers the procedure for rapid indentation hardness testing of metallic materials as an alternative to Test Method E 10 on standard Brinell hardness. It includes methods for the verification of rapid indentation hardness testing machines, Part B, and the calibration of reference hardness test blocks, Part C.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the procedure for rapid indentation hardness testing of metallic materials as an alternative to Test Method E10 on standard Brinell hardness. It includes methods for the verification of rapid indentation hardness testing machines, Part B, and the calibration of reference hardness test blocks, Part C.

Formerly under the jurisdiction of Committee E28 on Mechanical Testing, this test method was withdrawn in July 2011 in accordance with section 10.6.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E103–84(Reapproved 2002)

Standard Test Method for

Rapid Indentation Hardness Testing of Metallic Materials

This standard is issued under the fixed designation E103; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.3 verification—checking or testing to assure confor-

mance with the requirements of the method.

1.1 This test method covers the procedure for rapid inden-

tationhardnesstestingofmetallicmaterialsasanalternativeto

4. Significance and Use

Test Method E10 on standard Brinell hardness. It includes

4.1 This test method is used when it is desired to make

methods for the verification of rapid indentation hardness

hardnesstestsveryrapidly,asintheinspectionoftheoutputof

testing machines, Part B, and the calibration of reference

a heat-treating furnace.

hardness test blocks, Part C.

4.2 This test method is not to be regarded as a standard

1.2 The values stated in SI units are to be regarded as

Brinell hardness test method.

standard.

4.3 Since the test forces and method of display of the depth

1.3 This standard does not purport to address all of the

measurement differ between manufacturers of rapid indenta-

safety concerns, if any, associated with its use. It is the

tion hardness testing equipment, the test results from equip-

responsibility of the user of this standard to establish appro-

ment from different manufacturers are not comparable.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

A. GENERAL DESCRIPTION AND TEST

PROCEDURE

2. Referenced Documents

2.1 ASTM Standards:

5. Apparatus

E4 Practices for Force Verification of Testing Machines

5.1 Testing Machine—Equipment for rapid indentation

E10 TestMethodforBrinellHardnessofMetallicMaterials

hardness testing is used essentially to measure hardness by

determining the depth of indentation of a penetrator into the

3. Terminology

specimen. The test force can be applied either as a single total

3.1 Definitions:

test force whereby the depth is measured usually from the

3.1.1 calibration—determination of the values of the sig-

surface of the test specimen or as a preliminary and total test

nificant parameters by comparison with values indicated by a

force whereby the depth is measured as the increase from the

reference instrument or by a set of reference standards.

preliminary to the total test force. The magnitude of the

3.1.2 rapid indentation hardness test—an indentation hard-

indenting test force or test forces is determined by agreement.

ness test using calibrated machines to force a hard steel or

The design and construction of the testing machine shall be

carbide ball, under specified conditions, into the surface of the

such that no rotational or lateral movement of the indenter or

materialundertestandtomeasurethedepthoftheindentation.

test specimen occurs while the test force is being applied or

The depth measured can be from the surface of the test

removed.

specimen or from a reference position established by the

5.2 Penetrator:

application of a preliminary test force.

5.2.1 The standard ball penetrator shall be 10 mm in

diameter. Other values of ball penetrator may be used as

provided in 7.1.

This test method is under the jurisdiction of ASTM Committee E28 on

Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on

5.2.2 The balls used shall be free of surface imperfections

Indentation Hardness Testing.

and conform to the requirements prescribed in 13.1.2.

Current edition approved Jan. 10, 2002. Published February 2002. Originally

´1 5.3 Mechanism for Measuring the Depth of the

published as E103–84. Last previous edition E103–84(1989) . DOI: 10.1520/

E0103-84R02. Indentation—The depth of the indentation is determined by a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

measuring device that shall conform to the requirements

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

prescribed in 13.1.3.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

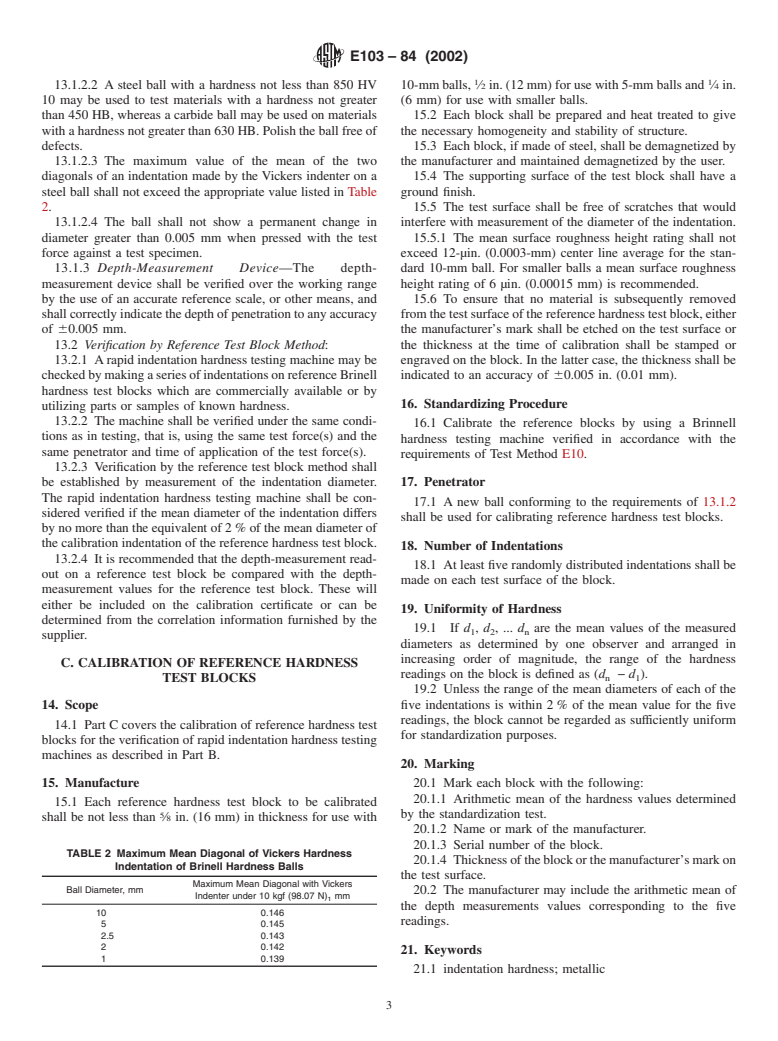

E103–84 (2002)

5.4 When diameters of indentations are measured to ascer- 9. Report

tain the accuracy of hardness values of test specimens or of

9.1 Report the following information:

reference hardness test blocks, the measuring microscope shall

9.1.1 The test force (or test forces when preliminary and

complywith3.3ofTestMethodE10andcomparablevaluesas

total test forces are applied) in kilogram-force,

determined from Table1 of Test Method E10.

9.1.2 The diameter of the ball penetrator and whether steel

or carbide balls are being used, and

6. Test Specimens

9.1.3 The depth of penetration in millimetres, or either a

6.1 Finish—When necessary, the surface on which the

converted Brinell hardness number or other hardness number

indentation is to be made shall be filed, ground, machined, or

established by the manufacturer. In the last two cases, the

polished with an abrasive material.The surface in contact with

hardness relationship shall be reported or referenced.

the test support shall be clean, dry, and free of any conditions

which may affect the test results. 10. Precision and Bias

6.2 Thickness—The thickness of the specimen shall be at

10.1 Precision—Since the test results are not comparable

least ten times the depth of the indentation and such that no

betweenequipmentfromdifferentmanufacturers,aninterlabo-

bulgeorothermarkshowingtheeffectofthetestforceappears

ratorycomparisontestprogramisnotappropriate.Therefore,a

on the side of the piece opposite the indentation.

precision statement cannot be determined for this test method.

10.2 Bias—There is no basis for defining the bias for this

7. Procedure

test method.

7.1 Magnitude of Test Force—The total test force is usually

3000, 1500, or 500 kgf (29.42, 14.71, or 4.903 kN). The

B. VERIFICATION OF RAPID INDENTATION

preliminary test force, if used, is usually determined by test HARDNESS TESTING MACHINES

requirements. It is desirable that the total test force be of such

11. Scope

magnitude that the diameter of the indentation ranges from

25.0 to 60.0% of the ball diameter (for example, 2.50 to 6.00 11.1 Part B covers two procedures for the verification of

mm in the case of the 10-mm diameter penetrator). Table 1 rapid indentation hardness testing machines. These are as

givesthepreferredtotaltestforceandBrinellhardnessnumber follows:

11.1.1 Separate verification of test force application, pen-

with the 10-mm diameter penetrator. For certain sizes and

conditions of test specimens, it may be desirable to use etrator, and depth-measuring device.

11.1.2 Verification by reference test block method.

different test forces and penetrators with diameters smaller or

larger than 10 mm; in these cases it is recommended that the 11.2 New or rebuilt machines shall be checked by the

separate verification method.

following relationships be maintained between the diameter of

the ball, D, measured in kilograms, and the applied test force, 11.3 Machines in use in production testing may be checked

by either method.

P, measured in kilograms-force:

Range (Brinell Hardness Number) P/D

12. General Requirements

96 to 600 30

48 to 300 15

12.1 Before a rapid indentation hardness testing machine is

16 to 100 5

verified, examine the machine to ensure the following:

7.2 Spacing of Indentations—The distance from the center

12.1.1 Set up the machine properly.

of the indentation to the edge of the specimen, or edge of

12.1.2 Mounttheballholder,withanewball,intheplunger.

anotherindentation,shallbeatleasttwoandone-halftimesthe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.