ASTM E103-12

(Test Method)Standard Practice for Rapid Indentation Hardness Testing of Metallic Materials

Standard Practice for Rapid Indentation Hardness Testing of Metallic Materials

SIGNIFICANCE AND USE

This practice is used when it is desired to make Brinell type hardness tests very rapidly on a high volume of samples, as in the inspection of the output of a heat-treating furnace.

This practice requires the measurement of indentation depth and eliminates the need to measure the diameter of the indent optically as required in a Brinell hardness test.

This practice is not a standard Brinell hardness test method and does not meet the requirements of Test Method E10.

4.4 Since the test forces and method of display of the depth measurement differ between manufacturers of rapid indentation hardness testing equipment, the test results from equipment from different manufacturers are not comparable.

SCOPE

1.1 This practice covers a procedure for rapid indentation hardness testing of metallic materials.

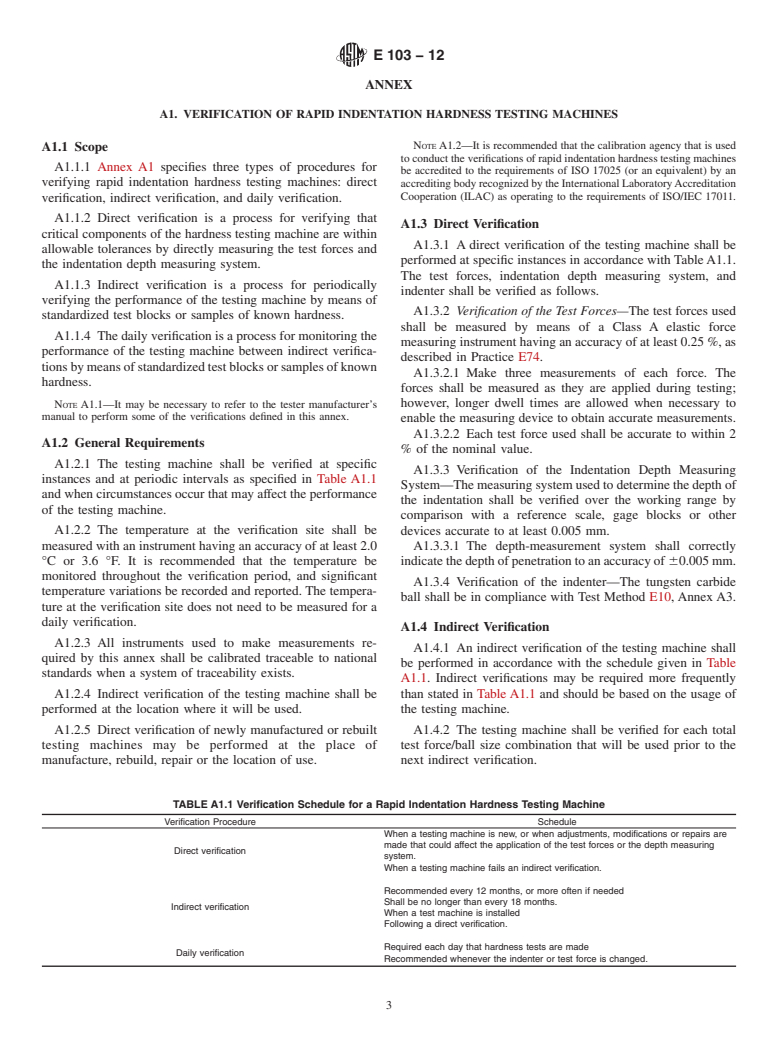

1.2 This practice includes additional requirements in Annex A1 for the direct, indirect, and daily verification of rapid indentation hardness testing machines.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 103 − 12

Standard Practice for

1

Rapid Indentation Hardness Testing of Metallic Materials

This standard is issued under the fixed designation ; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 calibration—determination of the values of the sig-

nificant parameters by comparison with values indicated by a

1.1 This practice covers a procedure for rapid indentation

reference instrument or by a set of reference standards.

hardness testing of metallic materials.

3.1.2 rapid indentation hardness test—an indentation hard-

1.2 This practice includes additional requirements in Annex

ness test using calibrated machines to force a tungsten carbide

A1 for the direct, indirect, and daily verification of rapid

ball, under specified conditions, into the surface of the material

indentation hardness testing machines.

under test and to measure the depth of the indentation. The

1.3 The values stated in SI units are to be regarded as

depth measured can be from the surface of the test specimen or

standard. No other units of measurement are included in this

from a reference position established by the application of a

standard.

preliminary test force. The depth measurement is usually

1.4 This standard does not purport to address all of the correlated to another scale or Brinell hardness number.

safety concerns, if any, associated with its use. It is the

3.1.3 verification—checking or testing to assure confor-

responsibility of the user of this standard to establish appro-

mance with the specification.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Significance and Use

4.1 This practice is used when it is desired to make Brinell

2. Referenced Documents

type hardness tests very rapidly on a high volume of samples,

2

2.1 ASTM Standards:

as in the inspection of the output of a heat-treating furnace.

E4 Practices for Force Verification of Testing Machines

4.2 This practice requires the measurement of indentation

E10 Test Method for Brinell Hardness of Metallic Materials

depth and eliminates the need to measure the diameter of the

E74 Practice of Calibration of Force-Measuring Instruments

indent optically as required in a Brinell hardness test.

for Verifying the Force Indication of Testing Machines

4.3 This practice is not a standard Brinell hardness test

3

2.2 ISO Standards:

method and does not meet the requirements of Test Method

ISO 17025 General requirements for the competence of

E10.

testing and calibration laboratories

ISO/IEC 17011 Conformity assessment -- General require- 4.4 Since the test forces and method of display of the depth

measurement differ between manufacturers of rapid indenta-

ments for accreditation bodies accrediting conformity

assessment bodies tion hardness testing equipment, the test results from equip-

ment from different manufacturers are not comparable.

3. Terminology

5. Apparatus

3.1 Definitions:

5.1 Testing Machine—Equipment for rapid indentation

hardness testing usually consists of a testing machine, which

supports the test specimen and applies an indenting force(s) to

1

This test method is under the jurisdiction of ASTM Committee E28 on

aballincontactwiththespecimen,andasystemformeasuring

Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on

Indentation Hardness Testing.

and displaying an indication of the depth of the indentation.

Current edition approved Jan. 1, 2012. Published March 2012. Originally

The test force can be applied either as a single total test force

published as E 103 – 84. Last previous edition E 103 – 84 (2002) which was

whereby the depth is measured usually from the surface of the

withdrawn in July 2011 and reinstated in January 2012. DOI: 10.1520/E0103-12.

2

test specimen or as a preliminary and total test force whereby

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the depth is measured as the increase from the preliminary to

Standards volume information, refer to the standard’s Document Summary page on

the total test force.

the ASTM website.

3

5.1.1 The testing machine shall meet the requirements of

Available from International Organization for Standardization (ISO), 1, ch. de

la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org. Annex A1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E103−12

5.1.2 The testing machine s

...

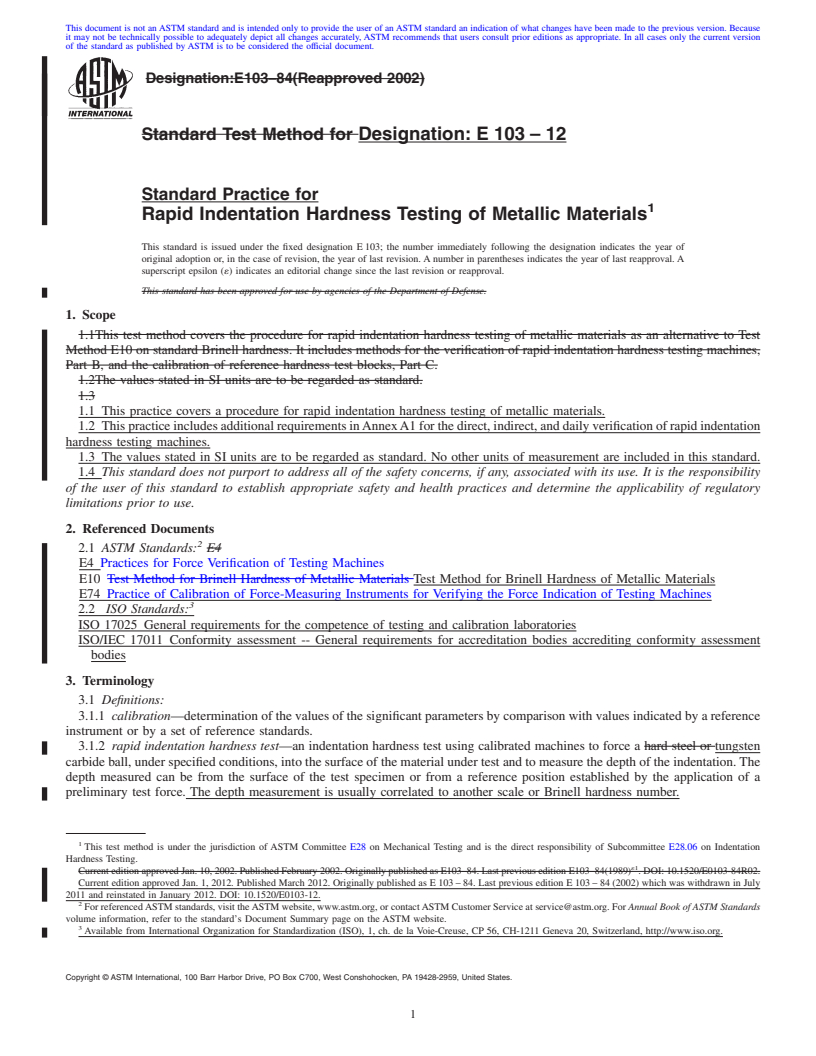

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E103–84(Reapproved 2002)

Standard Test Method for Designation: E 103 – 12

Standard Practice for

1

Rapid Indentation Hardness Testing of Metallic Materials

This standard is issued under the fixed designation E103; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

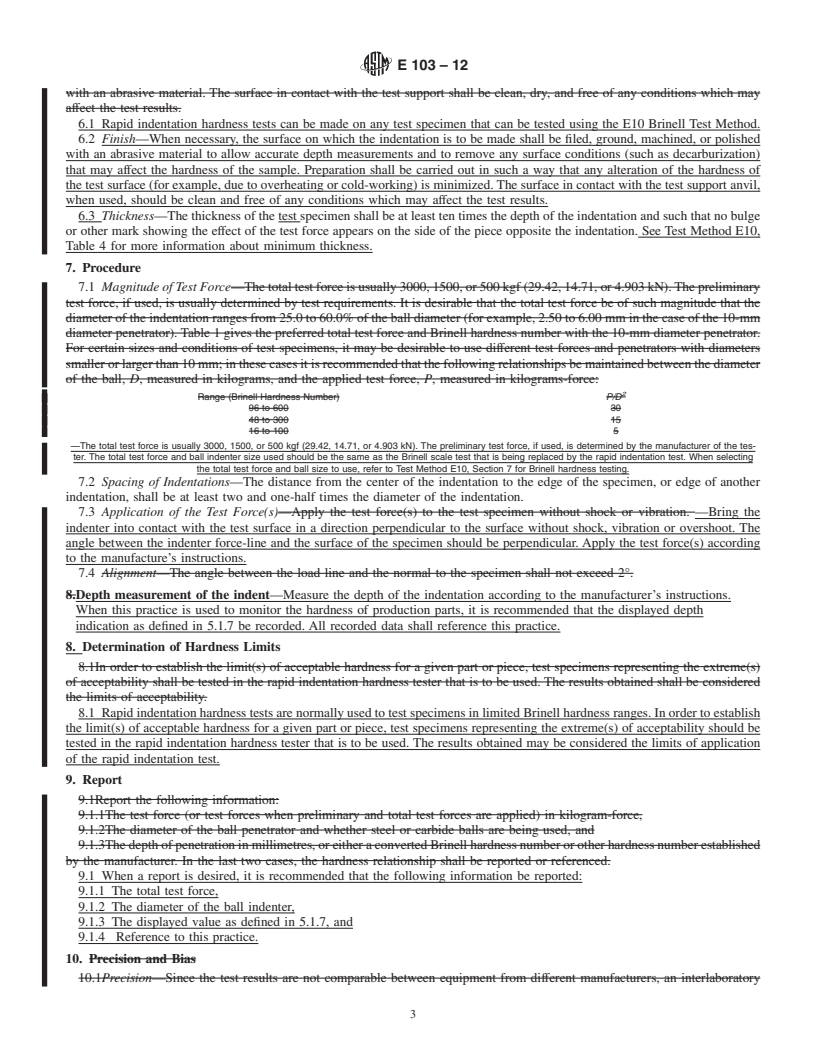

1.1This test method covers the procedure for rapid indentation hardness testing of metallic materials as an alternative to Test

Method E10 on standard Brinell hardness. It includes methods for the verification of rapid indentation hardness testing machines,

Part B, and the calibration of reference hardness test blocks, Part C.

1.2The values stated in SI units are to be regarded as standard.

1.3

1.1 This practice covers a procedure for rapid indentation hardness testing of metallic materials.

1.2 ThispracticeincludesadditionalrequirementsinAnnexA1forthedirect,indirect,anddailyverificationofrapidindentation

hardness testing machines.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards: E4

E4 Practices for Force Verification of Testing Machines

E10 Test Method for Brinell Hardness of Metallic Materials Test Method for Brinell Hardness of Metallic Materials

E74 Practice of Calibration of Force-Measuring Instruments for Verifying the Force Indication of Testing Machines

3

2.2 ISO Standards:

ISO 17025 General requirements for the competence of testing and calibration laboratories

ISO/IEC 17011 Conformity assessment -- General requirements for accreditation bodies accrediting conformity assessment

bodies

3. Terminology

3.1 Definitions:

3.1.1 calibration—determinationofthevaluesofthesignificantparametersbycomparisonwithvaluesindicatedbyareference

instrument or by a set of reference standards.

3.1.2 rapid indentation hardness test—an indentation hardness test using calibrated machines to force a hard steel or tungsten

carbideball,underspecifiedconditions,intothesurfaceofthematerialundertestandtomeasurethedepthoftheindentation.The

depth measured can be from the surface of the test specimen or from a reference position established by the application of a

preliminary test force. The depth measurement is usually correlated to another scale or Brinell hardness number.

1

This test method is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.06 on Indentation

Hardness Testing.

´1

CurrenteditionapprovedJan.10,2002.PublishedFebruary2002.OriginallypublishedasE103–84.LastpreviouseditionE103–84(1989) .DOI:10.1520/E0103-84R02.

Current edition approved Jan. 1, 2012. Published March 2012. Originally published as E103–84. Last previous edition E103–84(2002) which was withdrawn in July

2011 and reinstated in January 2012. DOI: 10.1520/E0103-12.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E103–12

3.1.3 verification—checking or testing to assure conformance with the requirements of the method. —checking or testing to

assure conformance with the specification.

4. Significance and Use

4.1This test method is used when it is desired to make hardness tests very rapidly, as in the inspection of the output of a

heat-treating furnace.

4.2This test method is not to be regarded as a standard Brinell hardness test method.

4.3Since the test forces and method of display of the depth measurement differ between manufacturers of rapid indentation

har

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.