ASTM C217/C217M-15a

(Test Method)Standard Test Method for Weather Resistance of Slate

Standard Test Method for Weather Resistance of Slate

SIGNIFICANCE AND USE

4.1 This test method is useful in indicating the differences in weather resistance between various slates. This test method also provides one element in the comparison of slates.

SCOPE

1.1 This test method covers two procedures for weather resistance of slate in all outdoor installations by determining the depth of softening by shear/scratch tester or by hand scraping.

Note 1: The test is based on the fact that slates containing pyrite, calcite, and carbon undergo a chemical weathering which results in the conversion of the calcite particles to gypsum. The swelling action that results causes disintegration of the slate. The extent of this action on various slates in the test has been found to correlate with the durability of the materials in actual weathering.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C217/C217M − 15a

Standard Test Method for

1

Weather Resistance of Slate

This standard is issued under the fixed designation C217/C217M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

4.1 Thistestmethodisusefulinindicatingthedifferencesin

1.1 This test method covers two procedures for weather

weather resistance between various slates. This test method

resistance of slate in all outdoor installations by determining

also provides one element in the comparison of slates.

the depth of softening by shear/scratch tester or by hand

scraping.

5. Apparatus

NOTE 1—The test is based on the fact that slates containing pyrite,

5.1 Either one of the following shall be used:

calcite, and carbon undergo a chemical weathering which results in the

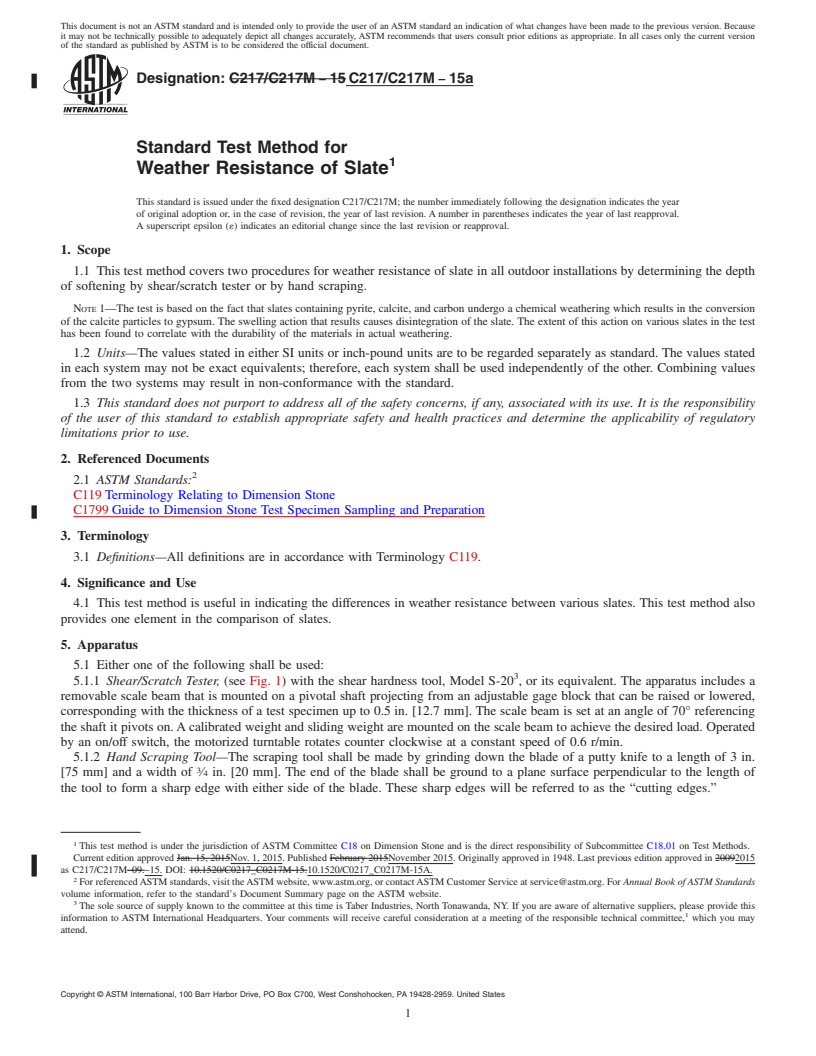

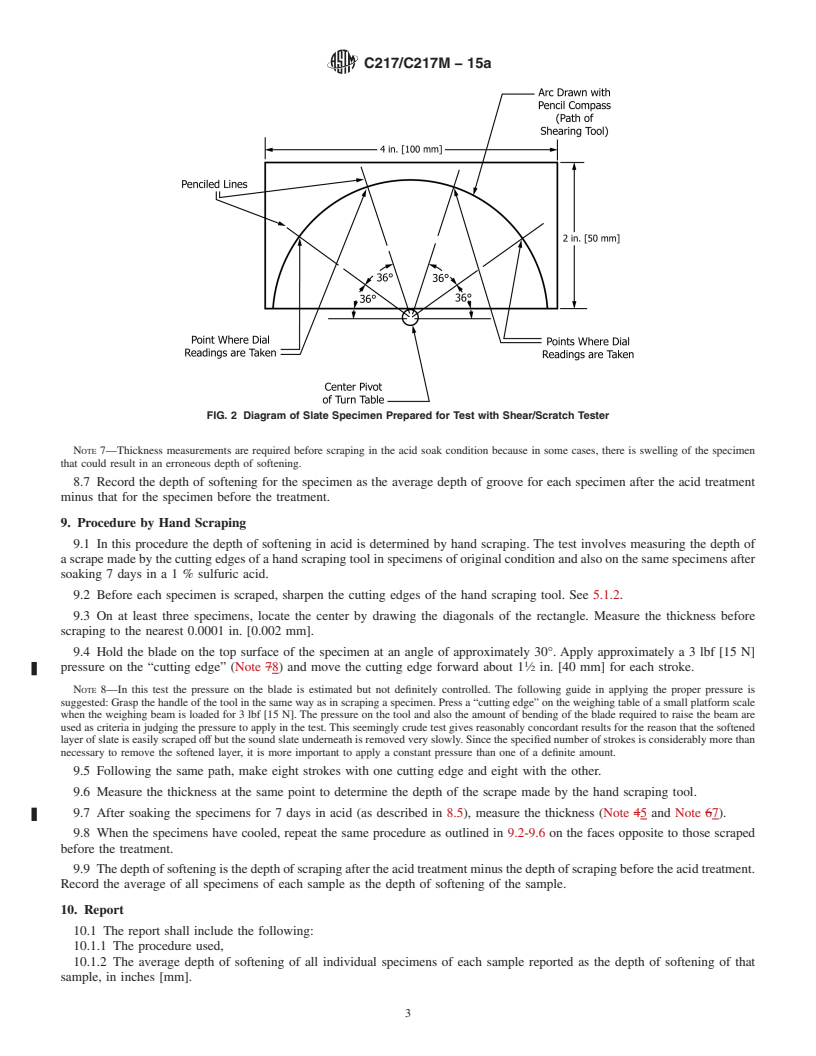

5.1.1 Shear/Scratch Tester, (see Fig. 1) with the shear

conversion of the calcite particles to gypsum. The swelling action that

3

hardness tool, Model S-20 , or its equivalent. The apparatus

results causes disintegration of the slate. The extent of this action on

various slates in the test has been found to correlate with the durability of includes a removable scale beam that is mounted on a pivotal

the materials in actual weathering.

shaft projecting from an adjustable gage block that can be

raised or lowered, corresponding with the thickness of a test

1.2 Units—The values stated in either SI units or inch-

specimen up to 0.5 in. [12.7 mm]. The scale beam is set at an

pound units are to be regarded separately as standard. The

angle of 70° referencing the shaft it pivots on. A calibrated

values stated in each system may not be exact equivalents;

weight and sliding weight are mounted on the scale beam to

therefore,eachsystemshallbeusedindependentlyoftheother.

achieve the desired load. Operated by an on/off switch, the

Combining values from the two systems may result in non-

motorized turntable rotates counter clockwise at a constant

conformance with the standard.

speed of 0.6 r/min.

1.3 This standard does not purport to address all of the

5.1.2 Hand Scraping Tool—The scraping tool shall be made

safety concerns, if any, associated with its use. It is the

by grinding down the blade of a putty knife to a length of 3 in.

responsibility of the user of this standard to establish appro-

3

[75 mm] and a width of ⁄4 in. [20 mm]. The end of the blade

priate safety and health practices and determine the applica-

shall be ground to a plane surface perpendicular to the length

bility of regulatory limitations prior to use.

of the tool to form a sharp edge with either side of the blade.

These sharp edges will be referred to as the “cutting edges.”

2. Referenced Documents

6. Sampling

2

2.1 ASTM Standards:

6.1 The samples shall be selected by the purchaser or his

C119 Terminology Relating to Dimension Stone

authorized representative so as to be truly representative of the

C1799 Guide to Dimension Stone Test Specimen Sampling

consignment under consideration. Six shingles of roofing from

and Preparation

each carload or fraction thereof or similar quantities from other

kinds of slate shall constitute a sample.

3. Terminology

NOTE 2—Six shingles 10 in. [250 mm] or more in length and of any

3.1 Definitions—All definitions are in accordance with Ter-

standard width are sufficient for this test.

minology C119.

NOTE 3—Refer to Guide C1799 for additional information on selecting,

preparing, and conditioning test specimens.

7. Test Specimens

1

This test method is under the jurisdiction of ASTM Committee C18 on

Dimension Stone and is the direct responsibility of Subcommittee C18.01 on Test 7.1 Prepare at least three specimens, each 2 by 4 in. [50 by

Methods.

100 mm] measured along the cleavage faces, for determining

Current edition approved Nov. 1, 2015. Published November 2015. Originally

approved in 1948. Last previous edition approved in 2015 as C217/C217M–15.

3

DOI: 10.1520/C0217_C0217M-15A. The sole source of supply known to the committee at this time is Taber

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Industries, North Tonawanda, NY. If you are aware of alternative suppliers, please

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM provide this information to ASTM International Headquarters. Your comments will

1

Standards volume information, refer to the standard’s Document Summary page on receive careful consideration at a meeting of the responsible technical committee,

the ASTM website. which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C217/C217M − 15 C217/C217M − 15a

Standard Test Method for

1

Weather Resistance of Slate

This standard is issued under the fixed designation C217/C217M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers two procedures for weather resistance of slate in all outdoor installations by determining the depth

of softening by shear/scratch tester or by hand scraping.

NOTE 1—The test is based on the fact that slates containing pyrite, calcite, and carbon undergo a chemical weathering which results in the conversion

of the calcite particles to gypsum. The swelling action that results causes disintegration of the slate. The extent of this action on various slates in the test

has been found to correlate with the durability of the materials in actual weathering.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C119 Terminology Relating to Dimension Stone

C1799 Guide to Dimension Stone Test Specimen Sampling and Preparation

3. Terminology

3.1 Definitions—All definitions are in accordance with Terminology C119.

4. Significance and Use

4.1 This test method is useful in indicating the differences in weather resistance between various slates. This test method also

provides one element in the comparison of slates.

5. Apparatus

5.1 Either one of the following shall be used:

3

5.1.1 Shear/Scratch Tester, (see Fig. 1) with the shear hardness tool, Model S-20 , or its equivalent. The apparatus includes a

removable scale beam that is mounted on a pivotal shaft projecting from an adjustable gage block that can be raised or lowered,

corresponding with the thickness of a test specimen up to 0.5 in. [12.7 mm]. The scale beam is set at an angle of 70° referencing

the shaft it pivots on. A calibrated weight and sliding weight are mounted on the scale beam to achieve the desired load. Operated

by an on/off switch, the motorized turntable rotates counter clockwise at a constant speed of 0.6 r/min.

5.1.2 Hand Scraping Tool—The scraping tool shall be made by grinding down the blade of a putty knife to a length of 3 in.

3

[75 mm] and a width of ⁄4 in. [20 mm]. The end of the blade shall be ground to a plane surface perpendicular to the length of

the tool to form a sharp edge with either side of the blade. These sharp edges will be referred to as the “cutting edges.”

1

This test method is under the jurisdiction of ASTM Committee C18 on Dimension Stone and is the direct responsibility of Subcommittee C18.01 on Test Methods.

Current edition approved Jan. 15, 2015Nov. 1, 2015. Published February 2015November 2015. Originally approved in 1948. Last previous edition approved in 20092015

as C217/C217M–09.–15. DOI: 10.1520/C0217_C0217M-15.10.1520/C0217_C0217M-15A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The sole source of supply known to the committee at this time is Taber Industries, North Tonawanda, NY. If you are aware of alternative suppliers, please provide this

1

information to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may

attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C217/C217M − 15a

FIG. 1 Shear/Scratch Tester

6. Sampling

6.1 The samples shall be selected by the purchaser or his authorized representative so as to be truly representative of the

consignment under consideration. Six

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.