ASTM B124/B124M-06

(Specification)Standard Specification for Copper and Copper Alloy Forging Rod, Bar, and Shapes

Standard Specification for Copper and Copper Alloy Forging Rod, Bar, and Shapes

SCOPE

1.1 This specification establishes the requirements for copper and copper alloy rod, bar, and shapes intended for hot forging. The following coppers and copper alloys are involved: Copper UNS Nos.Copper Alloy UNS Nos.C11000C36500C14500C37000C14700C37700C46400C48200C48500C61900C62300C63000C63200C64200C64210C65500C67500C67600C69300C70620C71520C77400 Note 1

Additional information about forging practice and forgings produced from these alloys is given in and in Specification B 283.

1.2 Units—Values stated in either inch-pound units or in SI units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 124/B 124M – 06

Standard Specification for

1

Copper and Copper Alloy Forging Rod, Bar, and Shapes

This standard is issued under the fixed designation B 124/B 124M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification establishes the requirements for cop-

per and copper alloy rod, bar, and shapes intended for hot B 249/B 249M Specification for General Requirements for

forging.The following coppers and copper alloys are involved: Wrought Copper and Copper-Alloy Rod, Bar, Shapes and

Forgings

B 283 SpecificationforCopperandCopper-AlloyDieForg-

Copper UNS Nos. Copper Alloy UNS Nos.

ings (Hot-Pressed)

C11000 C36500

E54 Test Methods for Chemical Analysis of Special

C14500 C37000

3

Brasses and Bronzes

C14700 C37700

C46400

E62 Test Methods for Chemical Analysis of Copper and

C48200

Copper Alloys (Photometric Methods)

C48500

E75 Test Methods for ChemicalAnalysis of Copper-Nickel

C61900

C62300

and Copper-Nickel-Zinc Alloys

C63000

E76 Test Methods for ChemicalAnalysis of Nickel-Copper

C63200

3

C64200 Alloys

C64210

E 121 Test Methods for Chemical Analysis of Copper-

C65500

Tellurium Alloys

C67500

C67600 E 478 Test Methods for Chemical Analysis of Copper

C69300

Alloys

C70620

2.2 ISO Standard:

C71520

C77400 No.3110,Part2(TC26Ref.No.N 670 E/F) Determination

ofAluminum Content: FlameAtomicAbsorption Spectro-

4

metric Method

NOTE 1—Additional information about forging practice and forgings

produced from these alloys is given in Appendix X1 and in Specification

3. General Requirements

B 283.

3.1 The following sections of Specification B 249/B 249M,

1.2 Units—Values stated in either inch-pound units or in SI

as applicable, constitute a part of this specification:

units are to be regarded separately as the standard. Within the

3.1.1 Terminology,

text, the SI units are shown in brackets. The values stated in

3.1.2 Material and Manufacture,

each system are not exact equivalents; therefore, each system

3.1.3 Workmanship, Finish, and Appearance,

shall be used independently of the other. Combining values

3.1.4 Sampling,

from the two systems may result in non-conformance with the

3.1.5 Number of Tests and Retests,

standard.

3.1.6 Specimen Preparation,

1.3 This standard does not purport to address all of the

3.1.7 Test Methods,

safety concerns, if any, associated with its use. It is the

3.1.8 Significance of Numerical Limits,

responsibility of the user of this standard to establish appro-

3.1.9 Inspection,

priate safety and health practices and determine the applica-

bility of regulatory requirements prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper Standards volume information, refer to the standard’s Document Summary page on

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod, the ASTM website.

3

Bar, Wire, Shapes and Forgings. Withdrawn.

4

Current edition approved Feb. 1, 2006. Published February 2006. Originally Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

approved in 1939. Last previous edition approved in 2004 as B 124/B 124M – 04. 4th Floor, New York, NY 10036.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 124/B 124M – 06

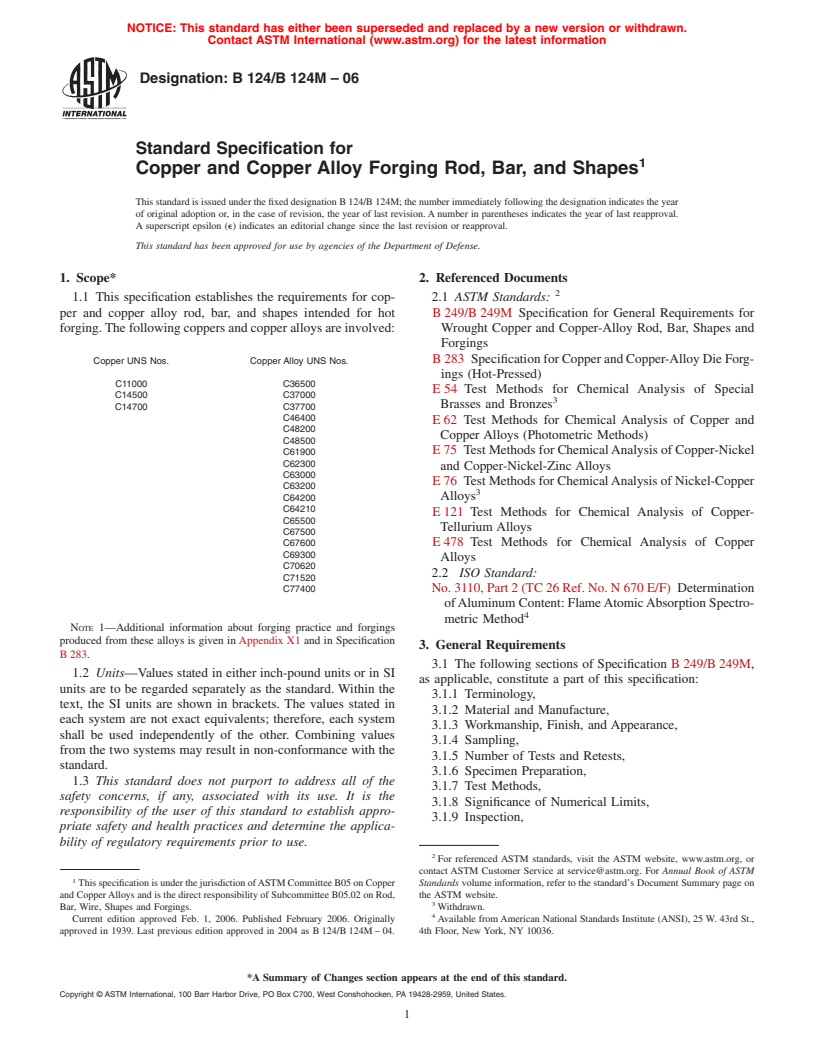

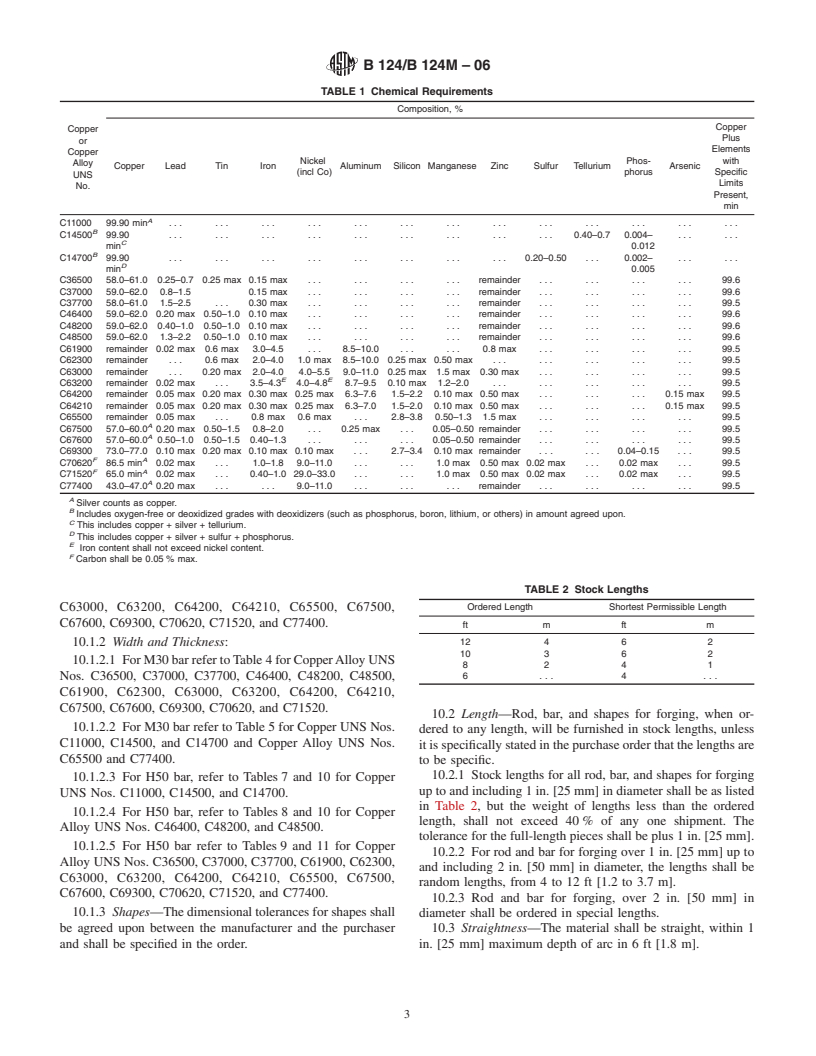

3.1.10 Rejection and Rehearing, 6. Chemical Composition

3.1.11 Certification,

6.1 The material shall conform to the chemical composition

3.1.12 Mill Test Reports, requirements in Table 1 for the copper or copper alloy UNS

3.1.13 Packaging and Package Marking, and No. designation specified in the ordering information.

6.1.1 These composition limits do not preclude the presence

3.1.14 Supplementary Requirements.

ofotherelements.Byagreementbetweenthemanufacturerand

3.2 In addition, when a section with a title identical to that

the purchaser, limits may be established and analysis required

referenced in 3.1, appears in this specification, it contains

for unnamed elements.

additional requirements that supplement those appearing in

6.2 For alloys in which either copper or zinc is listed as

Specification B 249/B 249M.

“remainder,” copper or zinc is the difference between the sum

of results of all elements determined and 10

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.