ASTM B393-99

(Specification)Standard Specification for Niobium and Niobium Alloy Strip, Sheet, and Plate

Standard Specification for Niobium and Niobium Alloy Strip, Sheet, and Plate

SCOPE

1.1 This specification covers four grades of wrought niobium and niobium alloy strip, sheet, and plate as follows: Note-Committee B-10 has adopted "niobium" as the designation for Element No. 41, formerly named "columbium."

1.1.1 R04200-Type 1 -Reactor grade unalloyed niobium,

1.1.2 R04210-Type 2 -Commercial grade unalloyed niobium,

1.1.3 R04251-Type 3 -Reactor grade niobium alloy containing 1% zirconium, and

1.1.4 R04261-Type 4 -Commercial grade niobium alloy containing 1% zirconium.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test methods portion of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 393 – 99

Standard Specification for

Niobium and Niobium Alloy Strip, Sheet, and Plate

This standard is issued under the fixed designation B 393; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 plate—a flat product 6 in. (152.4 mm) or more in

width and greater than ⁄16in. (4.76 mm) in thickness.

1.1 This specification covers four grades of wrought nio-

3.1.3 sheet—a flat product 6 in. (152.4 mm) or more in

bium and niobium alloy strip, sheet, and plate as follows:

width and from 0.005 in. (0.13 mm) to ⁄16 in. (4.76 mm) in

NOTE 1—Committee B-10 has adopted “niobium” as the designation

thickness.

for Element No. 41, formerly named “columbium.”

3.1.4 strip—a flat product, which may be supplied in coil,

1.1.1 R04200-Type 1— Reactor grade unalloyed niobium,

less than 6 in. (152.4 mm) in width and from 0.005 in. (0.13

1.1.2 R04210-Type 2— Commercial grade unalloyed nio-

mm) to ⁄16 in. (4.76 mm) in thickness.

bium,

4. Ordering Information

1.1.3 R04251-Type 3— Reactor grade niobium alloy con-

taining 1 % zirconium, and

4.1 Orders for materials under this specification shall in-

1.1.4 R04261-Type 4— Commercial grade niobium alloy

clude the following information as applicable:

containing 1 % zirconium.

4.1.1 Type and grade (Section 1),

1.2 The values stated in inch-pound units are to be regarded

4.1.2 ASTM designation and year of issue,

as the standard. The values given in parentheses are for

4.1.3 Method of manufacture (Section 5),

information only.

4.1.4 Temper designation (Section 8),

1.3 The following precautionary caveat pertains only to the

4.1.5 Quantity in weight, number of pieces, and dimensions,

test methods portion of this specification. This standard does

4.1.6 Chemistry (Section 6),

not purport to address all of the safety concerns, if any,

4.1.7 Mechanical properties (Section 7),

associated with its use. It is the responsibility of the user of this

4.1.8 Quality and finish (Section 10),

standard to establish appropriate safety and health practices

4.1.9 Sampling (Section 11),

and determine the applicability of regulatory limitations prior

4.1.10 Marking (Section 18),

to use.

4.1.11 Packaging (Section 19),

4.1.12 Required reports (Section 17),

2. Referenced Documents

4.1.13 Disposition of rejected material (Section 16), and

2.1 ASTM Standards:

4.1.14 Additions to the specification and supplementary

B 391 Specification for Niobium and Niobium Alloy In-

requirements, as required.

gots

5. Materials and Manufacture

E 8 Test Methods for Tension Testing of Metallic Materials

E 29 Practice for Using Significant Digits in Test Data to

5.1 Material covered by this specification shall be made

Determine Conformance with Specifications

from ingots that conform to Specification B 391 and that are

produced by vacuum or plasma arc melting, vacuum electron-

3. Terminology

beam melting, or a combination of these three methods.

3.1 Definitions of Terms Specific to This Standard:

5.2 The various niobium mill products covered by this

3.1.1 lot—a lot shall consist of all material produced from

specification are formed with the conventional extrusion,

the same ingot at one time, with the same cross section,

forging, swaging, rolling, and drawing equipment normally

processed with the same nominal metallurgical parameters and

available in metal working plants.

heat treated at the same conditions.

6. Chemical Requirements

6.1 The niobium and niobium alloy ingots and billets for

This specification is under the jurisdiction of ASTM Committee B-10 on conversion to finished products covered by this specification

Reactive and Refractory Metals and Alloysand is the direct responsibility of

shall conform to the requirements for chemical composition

Subcommittee B10.03on Niobium and Tantalum.

and hardness as prescribed in Table 1 and Table 2.

Current edition approved Dec. 10, 1999. Published January 2000.

6.2 The manufacturer’s ingot analysis shall be considered

Annual Book of ASTM Standards, Vol 02.04.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 393

A

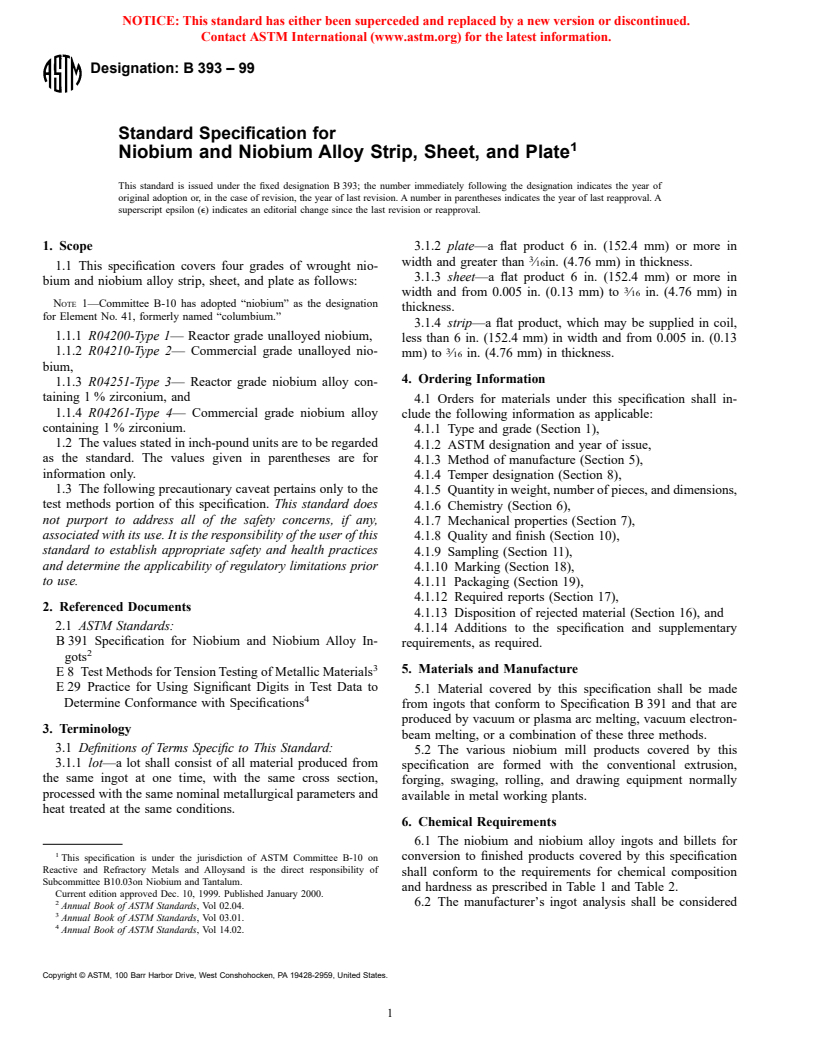

TABLE 1 Chemical Requirements TABLE 4 Mechanical Properties for Material, Annealed

Condition (90 % Minimum Recrystallized)

Type 1 Type 2 Type 3 Type 4

(Reactor (Commercial (Reactor (Commercial

Elongation in 1-in. (25.4-

Ultimate Tensile Yield Strength

Grade Grade Grade Grade

mm) gage length, min, %

Grade Strength, min, (0.2 % offset),

Element Unalloyed Unalloyed Niobium- Niobium-

0.010 or Less Than

psi (MPa) min, psi (MPa)

Niobium) Niobium) 1% 1%

Greater 0.010

R04200 R04210 Zirconium) Zirconium)

Types 1 and 2 18 000 (125) 10 500 (73) 20 15

R04251 R04261

Types 3 and 4 28 000 (195) 18 000 (125) 20 15

A

Max Weight % (Except Where Otherwise Specified)

Refer to Section 14 for conditions of mechanical tests.

Each ingot:

Carbon 0.01 0.01 0.01 0.01

that is, at least 90 % recrystallized.

Nitrogen 0.01 0.01 0.01 0.01

8.2 Other temper designations, such as cold-worked temper

Oxygen 0.015 0.025 0.015 0.025

or stress-relieved temper, can be specified as agreed upon

Hydrogen 0.0015 0.0015 0.0015 0.0015

Zirconium 0.02 0.02 0.8 to 1.2 0.8 to 1.2

between the purchaser and the manufacturer at the time of

(range) (range)

purchase.

Tantalum 0.1 0.3 0.1 0.5

Iron 0.005 0.01 0.005 0.01

9. Permissible Variations in Dimensions and Weight

Silicon 0.005 0.005 0.005 0.005

Tungsten 0.03 0.05 0.03 0.05

9.1 Tolerances for thickness, width, and length for flat-

Nickel 0.005 0.005 0.005 0.005

rolled products covered by this specification shall be as

Molybdenum 0.010 0.020 0.010 0.050

Hafnium 0.02 0.02 0.02 0.02 prescribed in Table 5.

Titanium 0.02 0.03 0.02 0.03

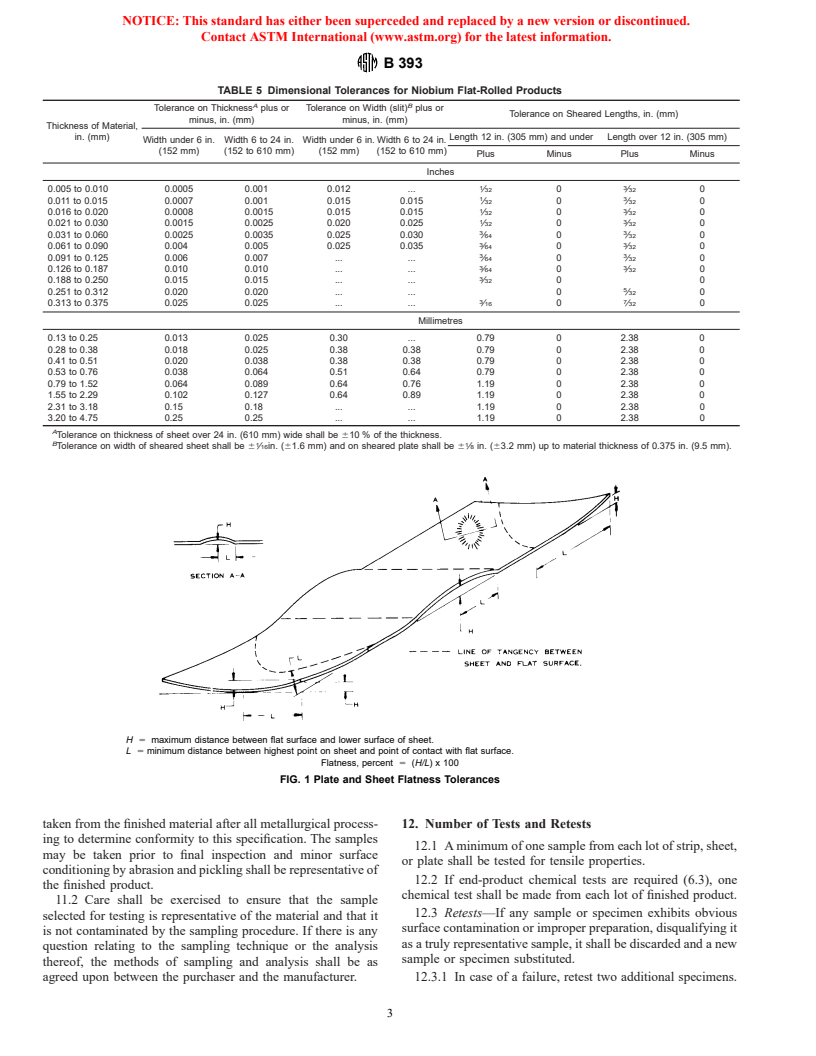

9.2 Flatness tolerance for sheet and plate products supplied

When specified:

under this specification shall be a maximum of 6 % as

Boron 2 ppm . 2 ppm .

Aluminum 0.002 0.005 0.002 0.005

determined by the following equation (see Fig. 1):

Beryllium 0.005 . 0.005 .

Flatness, % 5 ~H/L! 3 100

Chromium 0.002 . 0.002 .

Cobalt 0.002 . 0.002 . (1)

where:

H 5 maximum vertical distance between a flat reference

TABLE 2 Brinell Hardness

and the lower surface of the sheet, and

L 5 minimum horizontal distance between the highest

Type 1 Type 2 Type 3 Type 4

Maximum average 90 125 125 135

point on a sheet and the point of contact with a flat

Maximum per individual impression 105 150 140 150

reference surface. (Fig. 1 is included to illustrate the

method for taking measurements for calculation of

sheet flatness. However, a value of H less than ⁄32 in.

the chemical analysis for products supplied under this specifi-

(0.070 mm) shall not be cause for rejection.)

cation, except for interstitials as specified in 6.3.

9.3 Quantity or Weight—For orders requiring up to 100 lb

6.3 When requested by the purchaser at the time of pur-

(45.4 kg) of finished product, the manufacturer may overship

chase, the manufacturer shall furnish a report certifying the

by 20 %. When the order is for quantities up to 1000 lb (453.6

values of the interstitial elements (C, O, N, H) as prescribed in

kg), the manufacturer may overship by 10 %. The permissible

Table 3 for each lot of material supplied.

overshipment shall be negotiated for orders larger than this

7. Mechanical Requirements

quantity.

7.1 The annealed materials supplied under this specification

10. Quality and Finish

shall conform to the requirements for mechanical properties as

10.1 Finished niobium and niobium alloy strip, sheet, and

specified in Table 4.

plate shall be free of injurious internal and external imperfec-

8. Temper Designations

tions of a nature that will interfere with the purpose for which

it was intended. Material may be finished as rolled, as cleaned,

8.1 Unless otherwise stated, the materials supplied under

or as ground. If shipped as hot-worked, cold-worked, cleaned,

these specifications shall be in the fully annealed condition,

or ground, the manufacturer shall be permitted to remove

TABLE 3 Additional Chemical Requirements for Finished

minor surface imperfections, if such removal does not reduce

Product (When Specified by Purchaser)

the dimensions below the minimum permitted by the tolerances

Type 2 Type 3 Type 4

specified in Table 5.

Type 1

(Commercial (Reactor (Commercial

(Reactor Grade 10.2 The finished strip, sheet, or plate shall be visibly free of

Grade Grade Grade

Element Unalloyed

oxide, grease, oil, residual lubricants, and other extraneous

Unalloyed Niobium—1 % Niobium—1 %

Niobium)

Niobium) Zirconium) Zirconium)

materials.

R04200

R04210 R04251 R04261

10.3 Methods of testing for these defects and standards of

Max Weight %

acceptability shall be as agreed upon between the manufacturer

Oxygen 0.0250 0.0400 0.0250 0.0400

and the purchaser.

Carbon 0.0100 0.0150 0.0100 0.0150

Nitrogen 0.0100 0.0100 0.0100 0.0100

11. Sampling

Hydrogen 0.0015 0.0015 0.0015 0.0015

11.1 Samples fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.