ASTM E2562-07

(Test Method)Standard Test Method for Quantification of Pseudomonas aeruginosa Biofilm Grown with High Shear and Continuous Flow using CDC Biofilm Reactor

Standard Test Method for Quantification of <i>Pseudomonas aeruginosa</i> Biofilm Grown with High Shear and Continuous Flow using CDC Biofilm Reactor

SIGNIFICANCE AND USE

Bacteria that exist in biofilm are phenotypically different from suspended cells of the same genotype. Research has shown that biofilm bacteria are more difficult to kill than suspended bacteria (5). Laboratory biofilms are engineered in growth reactors designed to produce a specific biofilm type. Altering system parameters will correspondingly result in a change in the biofilm. For example, research has shown that biofilm grown under high shear is more difficult to kill than biofilm grown under low shear (6). The purpose of this test method is to direct a user in the laboratory study of a Pseudomonas aeruginosa biofilm by clearly defining each system parameter. This test method will enable an investigator to grow, sample, and analyze a Pseudomonas aeruginosa biofilm grown under high shear. The biofilm generated in the CDC biofilm reactor is also suitable for efficacy testing. After the 48 h growth phase is complete, the user may add the treatment in situ or harvest the coupons and treat them individually.

SCOPE

1.1 This test method specifies the operational parameters required to grow a repeatable Pseudomonas aeruginosa biofilm under high shear (1). The resulting biofilm is representative of generalized situations where biofilm exists under high shear rather than representative of one particular environment.

1.2 This test method uses the Centers for Disease Control and Prevention (CDC) biofilm reactor. The CDC biofilm reactor is a continuously stirred flow reactor with high wall shear. Although it was originally designed to model a potable water system for the evaluation of Legionella pneumophila (2), the reactor is versatile and may also be used for growing and/or characterizing biofilm of varying species (3 and 4).

1.3 This test method describes how to sample and analyze biofilm for viable cells. Biofilm population density is recorded as log colony forming units per surface area.

1.4 Basic microbiology training is required to perform this test method.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation: E2562 – 07

Standard Test Method for

Quantification of Pseudomonas aeruginosa Biofilm Grown

with High Shear and Continuous Flow using CDC Biofilm

Reactor

This standard is issued under the fixed designation E2562; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Standards:

Method 9050 C.1a Buffered Dilution Water Preparation

1.1 This test method specifies the operational parameters

requiredtogrowarepeatablePseudomonasaeruginosabiofilm

3. Terminology

under high shear (1). The resulting biofilm is representative of

3.1 Definitions:

generalized situations where biofilm exists under high shear

3.1.1 biofilm, n—microorganisms living in a self-organized,

rather than representative of one particular environment.

cooperativecommunityattachedtosurfaces,interfaces,oreach

1.2 This test method uses the Centers for Disease Control

other, embedded in a matrix of extracellular polymeric sub-

and Prevention (CDC) biofilm reactor. The CDC biofilm

stances of microbial origin, while exhibiting an altered pheno-

reactor is a continuously stirred flow reactor with high wall

type with respect to growth rate and gene transcription.

shear. Although it was originally designed to model a potable

3.1.1.1 Discussion—Biofilms may be comprised of bacte-

watersystemfortheevaluationof Legionella pneumophila (2),

ria, fungi, algae, protozoa, viruses, or infinite combinations of

thereactorisversatileandmayalsobeusedforgrowingand/or

these microorganisms. The qualitative characteristics of a

characterizing biofilm of varying species (3 and 4).

biofilm (including, but not limited to, population density,

1.3 This test method describes how to sample and analyze

taxonomic diversity, thickness, chemical gradients, chemical

biofilm for viable cells. Biofilm population density is recorded

composition,consistency,andothermaterialsinthematrixthat

as log colony forming units per surface area.

arenotproducedbythebiofilmmicroorganisms)arecontrolled

1.4 Basic microbiology training is required to perform this

by the physicochemical environment in which it exists.

test method.

3.1.2 coupon, n—biofilm sample surface.

1.5 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

4. Summary of Test Method

only.

4.1 This test method is used for growing a repeatable

1.6 This standard does not purport to address all of the

Pseudomonas aeruginosa biofilm in a CDC biofilm reactor.

safety concerns, if any, associated with its use. It is the

The biofilm is established by operating the reactor in batch

responsibility of the user of this standard to establish appro-

mode (no flow of the nutrients) for 24 h. A steady state

priate safety and health practices and determine the applica-

population is reached while the reactor operates for an addi-

bility of regulatory limitations prior to use.

tional24hwithcontinuousflowofthenutrients.Theresidence

2. Referenced Documents time of the nutrients in the reactor is set to select for biofilm

3 growth, and is species and reactor parameter specific. During

2.1 ASTM Standards:

the entire 48 h, the biofilm is exposed to continuous fluid shear

D5465 Practice for Determining Microbial Colony Counts

from the rotation of a baffled stir bar. Controlling the rate at

from Waters Analyzed by Plating Methods

which the baffle turns determines the intensity of the shear

stress to which the coupons are exposed. At the end of the 48

h, biofilm accumulation is quantified by removing coupons

This test method is under the jurisdiction of ASTM Committee E35 on

from suspended rods, scraping the biofilm from the coupon

Pesticides and Alternative Control Agents and is the direct responsibility of

surface,disaggregatingtheclumps,anddilutingandplatingfor

Subcommittee E35.15 on Antimicrobial Agents.

Current edition approved April 1, 2007. Published May 2007. DOI: 10.1520/

viable cell enumeration.

E2562-07.

The boldface numbers in parentheses refer to a list of references at the end of

this standard.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Eaton, A.D., Clesceri, L.S., Rice, E.W., Greenberg, A.E., (Eds.) Standard

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Methods for the Examination of Water and Waste Water , 21st Edition, American

Standards volume information, refer to the standard’s Document Summary page on Public HealthAssociation,American Water WorksAssociation, Water Environment

the ASTM website. Federation, Washington D.C., 2005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

E2562 – 07

5. Significance and Use

5.1 Bacteriathatexistinbiofilmarephenotypicallydifferent

from suspended cells of the same genotype. Research has

shown that biofilm bacteria are more difficult to kill than

suspended bacteria (5). Laboratory biofilms are engineered in

growth reactors designed to produce a specific biofilm type.

Altering system parameters will correspondingly result in a

change in the biofilm. For example, research has shown that

biofilm grown under high shear is more difficult to kill than

biofilm grown under low shear (6). The purpose of this test

method is to direct a user in the laboratory study of a

Pseudomonas aeruginosa biofilm by clearly defining each

system parameter. This test method will enable an investigator

to grow, sample, and analyze a Pseudomonas aeruginosa

biofilm grown under high shear. The biofilm generated in the

CDC biofilm reactor is also suitable for efficacy testing. After

the 48 h growth phase is complete, the user may add the

treatment in situ or harvest the coupons and treat them

individually.

FIG. 1 Expanded Schematic of Reactor Top

6. Apparatus

6.1 Wooden Applicator Sticks, sterile.

6.2 Inoculating Loop.

6.18 Silicone Tubing—Two sizes of tubing: one with ID 3.1

6.3 Petri Dish, 100 by 15 mm, plastic, sterile and empty to

mm and OD 3.2 mm and the other with ID 7.9 mm and OD 9.5

put beneath rod while sampling.

mm. Both sizes must withstand sterilization.

6.4 Culture Tubes and Culture Tube Closures, any with a

6.19 Glass Flow Break—Any that will connect with tubing

volume capacity of 10 mLand a minimum diameter of 16 mm.

of ID 3.1 mm and withstands sterilization.

Recommended size is 16 by 125 mm borosilicate glass with

6.19.1 Clamp—Used to hold flow break, extension clamp

threaded opening. with 0.5 cm minimum grip size.

6.5 Pipetter—Continuously adjustable pipetter with volume 6.19.2 Clamp Stand—Height no less than 76.2 cm, used

capability of 1 mL. with clamp to suspend glass flow break vertically and stabilize

6.6 Vortex—Any vortex that will ensure proper agitation tubing above reactor.

and mixing of culture tubes. 6.20 Reactor Components.

6.7 Homogenizer—Any that can mix at 20 500 6 5000 6.20.1 Berzelius Pyrex or Kimax Tall Beaker, 1000 mL

without pour spout, 9.5 6 0.5 cm diameter. Pyrex/Kimax

r/min ina5to10mL volume.

barbed outlet spout added at 400 6 20 mL mark. Angle the

6.8 Homogenizer Probe—Any that can mix at 20 500 6

spout 30 to 45° to ensure drainage. Spout should accommodate

5000 r/min ina5to10mL volume and can withstand

flexible tubing with an ID of 8 to 11 mm.

autoclaving or other means of sterilization.

6.9 Sonicator—Any noncavitating sonicating bath that op-

NOTE 2—The rods, described in 6.20.3 and baffle (6.20.5) will displace

erates at 50 to 60 Hz.

approximately 50 mL of liquid when system is completely assembled.

6.10 Bunsen Burner, used to flame inoculating loop and Therefore,anoutletspoutatthe400mLmarkwillresultinapproximately

a 350 mL operating volume. The user is encouraged to confirm the actual

other instruments.

liquid volume in the reactor, when the rods and baffle are in place, before

6.11 Stainless Steel Hemostat Clamp, with curved tip.

use. The measured volume is used to calculate an exact pump flow rate.

6.12 Environmental Shaker, that can maintain a temperature

6.20.2 Reactor Top—See Fig. 1. Ultra-high molecular

of 35 6 2°C.

weight (UHMW) polyethylene top (10.1 cm diameter tapering

6.13 Analytical Balance, sensitive to 0.01 g.

to 8.33 cm) equipped with 3 holes accommodating 10 cm

6.14 Sterilizers—Any steam sterilizer that can produce the

pieces of stainless steel or other rigid autoclavable tubing with

conditions of sterilization is acceptable.

OD of 5 to 8 mm for media inlet, air exchange, and inoculation

6.15 Colony Counter—Any one of several types may be

port. Center hole, 1.27 cm diameter, to accommodate the glass

used, such as the Quebec, Buck, and Wolfhuegel.Ahand tally

rod used to support the baffle assembly. Eight rod holes, 1.905

for the recording of the bacterial count is recommended if

manual counting is done.

6.16 Peristaltic Pump—Pump head that can hold tubing

The sole source of supply of the apparatus (CDC Biofilm reactor) known to the

with ID 3.1 mm and OD 3.2 mm.

committee at this time is BioSurface Technologies, Corp. www.biofilms.biz. If you

6.17 Magnetic Stir Plate—Topplate10.16 310.16cm,that

are aware of alternative suppliers, please provide this information to ASTM

International Headquarters. Your comments will receive careful consideration at a

can rotate at 125 6 60 r/min.

meeting of the responsible technical committee, which you may attend. The user

NOTE 1—A digital stir plate is recommended. may also build the reactor.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

E2562 – 07

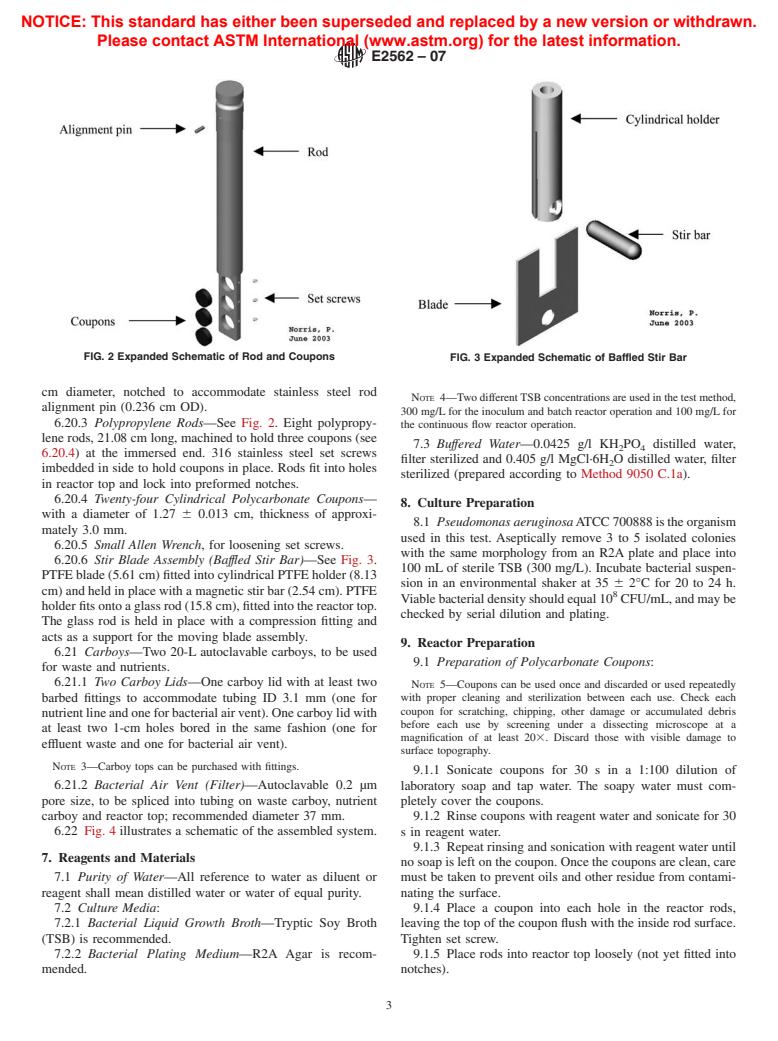

FIG. 2 Expanded Schematic of Rod and Coupons

FIG. 3 Expanded Schematic of Baffled Stir Bar

cm diameter, notched to accommodate stainless steel rod

NOTE 4—Two differentTSB concentrations are used in the test method,

alignment pin (0.236 cm OD).

300 mg/L for the inoculum and batch reactor operation and 100 mg/L for

6.20.3 Polypropylene Rods—See Fig. 2. Eight polypropy-

the continuous flow reactor operation.

lene rods, 21.08 cm long, machined to hold three coupons (see

7.3 Buffered Water—0.0425 g/l KH PO distilled water,

2 4

6.20.4) at the immersed end. 316 stainless steel set screws

filter sterilized and 0.405 g/l MgCl·6H O distilled water, filter

imbedded in side to hold coupons in place. Rods fit into holes

sterilized (prepared according to Method 9050 C.1a).

in reactor top and lock into preformed notches.

6.20.4 Twenty-four Cylindrical Polycarbonate Coupons—

8. Culture Preparation

with a diameter of 1.27 6 0.013 cm, thickness of approxi-

8.1 PseudomonasaeruginosaATCC700888istheorganism

mately 3.0 mm.

used in this test. Aseptically remove 3 to 5 isolated colonies

6.20.5 Small Allen Wrench, for loosening set screws.

with the same morphology from an R2A plate and place into

6.20.6 Stir Blade Assembly (Baffled Stir Bar)—See Fig. 3.

100 mL of sterile TSB (300 mg/L). Incubate bacterial suspen-

PTFE blade (5.61 cm) fitted into cylindrical PTFE holder (8.13

sion in an environmental shaker at 35 6 2°C for 20 to 24 h.

cm) and held in place with a magnetic stir bar (2.54 cm). PTFE

Viablebacterialdensityshouldequal10 CFU/mL,andmaybe

holderfitsontoaglassrod(15.8cm),fittedintothereactortop.

checked by serial dilution and plating.

The glass rod is held in place with a compression fitting and

acts as a support for the moving blade assembly.

9. Reactor Preparation

6.21 Carboys—Two 20-L autoclavable carboys, to be used

9.1 Preparation of Polycarbonate Coupons:

for waste and nutrients.

6.21.1 Two Carboy Lids—One carboy lid with at least two

NOTE 5—Coupons can be used once and discarded or used repeatedly

barbed fittings to accommodate tubing ID 3.1 mm (one for with proper cleaning and sterilization between each use. Check each

coupon for scratching, chipping, other damage or accumulated debris

nutrientlineandoneforbacterialairvent).Onecarboylidwith

before each use by screening under a dissecting microscope at a

at least two 1-cm holes bored in the same fashion (one for

magnification of at least 203. Discard those with visible damage to

effluent waste and one for bacterial air vent).

surface topography.

NOTE 3—Carboy tops can be purchased with fittings.

9.1.1 Sonicate coupons for 30 s in a 1:100 dilution of

6.21.2 Bacterial Air Vent (Filter)—Autoclavable 0.2 µm laboratory soap and tap water. The soapy water must com-

pore size, to be spliced into tubing on waste carboy, nutrient pletely cover the coupons.

carboy and reactor top; recommended diameter 37 mm. 9.1.2 Rinse coupons with reagent water and sonicate for 30

6.22 Fig. 4 illustrates a schematic of the assembled system. s in reagent water.

9.1.3 Repeat rinsing and sonication with reagent water until

7. Reagents and Materials

no soap is left on the coupon. Once the coupons are clean, care

7.1 Purity of Water—All reference to water as diluent or must be taken to prevent oils and other residue from contami-

reagent shall mean distilled water or water of equal purity. nating the surface.

7.2 Culture Media: 9.1.4 Place a coupon into each hole in the reactor rods,

7.2.1 Bacterial Liquid Growth Broth—Tryptic Soy Broth leaving the top of the coupon flush with the inside rod surface.

(TSB) is recommended. Tighten set screw.

7.2.2 Bacterial Plating Medium—R2A Agar is recom- 9.1.5 Place rods into reactor top loosely (not yet fitted into

mended. notches).

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

E2562 – 07

FIG. 4 Schematic of Completely Assembled Reactor System

9.2 Preparation of Reactor Top: 10.1.3 Secure the rods by setting the alignment pins into the

9.2.1 Place baffle onto glass rod suspended from the reactor notches on the reactor top.

top.

10.1.4 Inoculate the reactor with 1 mL of bacteria from the

9.2.2 Place assembled top into the reactor beaker. culturepreparedpreviously(seeSection8.1).Asepticallyinject

9.2.3 Connectthebacterialairvent(filter)byfittingthevent

the inoculum into the beaker through one of the available

to a small section of appropriately sized tubing, and attach to reactor top rigid tubes using a pipette with a sterile tip.

one of the rigid tubes on the reactor top.

10.1.5 Turn on the magnetic stir plate. The rotation speed

9.2.4 The glass flow break is spliced into the nutrient tubing

sho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.