ASTM G203-10(2016)

(Guide)Standard Guide for Determining Friction Energy Dissipation in Reciprocating Tribosystems

Standard Guide for Determining Friction Energy Dissipation in Reciprocating Tribosystems

SIGNIFICANCE AND USE

5.1 Many sliding systems exhibit intermittent high friction force excursions compared to competing tribosystems. However, where friction forces or friction coefficients are averaged, the test data may show that the two systems have the same friction characteristics, when in fact they were not the same; there was a friction “problem” in the one with the periodic aberrations. The FED takes into account all friction forces that occur in the test increment. It is all of the friction energy that the couple dissipated in the designated test duration. It captures the friction profile of a system in a single number that can be used to screen candidate couples for friction characteristics.

5.2 If the friction energy used in a reciprocating tribosystem is of concern this metric along with the friction recording, average coefficient of friction, and standard deviation of the force readings, produces the most meaningful data. It is a metric of the energy loss in a tribosystem.

SCOPE

1.1 This guide covers and is intended for use in interpreting the friction forces recorded in reciprocating tribosystems. The guide applies to any reciprocating tribosystem, whether it is a wear or fretting test or an actual machine or device.

1.2 The energy dissipation guide was developed in analyzing friction results in the Test Method G133 reciprocating ball-on-flat test, but it applies to other ASTM or ISO reciprocating tests. This technique is frequently used to record the friction response in fretting tribosystems.

1.3 Specimen material may play some role in the results if the materials under test display viscoelastic behavior. This guide as written is for metals, plastics, and ceramics that do not display viscoelastic behavior. It also applies to lubricated and non-lubricated contacts.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G203 − 10 (Reapproved 2016)

Standard Guide for

Determining Friction Energy Dissipation in Reciprocating

1

Tribosystems

This standard is issued under the fixed designation G203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Friction Measurements

1.1 This guide covers and is intended for use in interpreting

3. Terminology

the friction forces recorded in reciprocating tribosystems. The

guide applies to any reciprocating tribosystem, whether it is a

3.1 Definitions:

wear or fretting test or an actual machine or device.

3.1.1 coeffıcient of friction, n—in tribology, the dimension-

less ratio of the friction force (F) between two bodies to the

1.2 The energy dissipation guide was developed in analyz-

normal force (N) pressing these bodies together. G40

ing friction results in the Test Method G133 reciprocating

ball-on-flat test, but it applies to other ASTM or ISO recipro-

3.1.2 fretting—small amplitude oscillatory motion, usually

cating tests. This technique is frequently used to record the

tangential between two solid surfaces in contact. G40

friction response in fretting tribosystems.

3.2 Definitions of Terms Specific to This Standard:

1.3 Specimen material may play some role in the results if

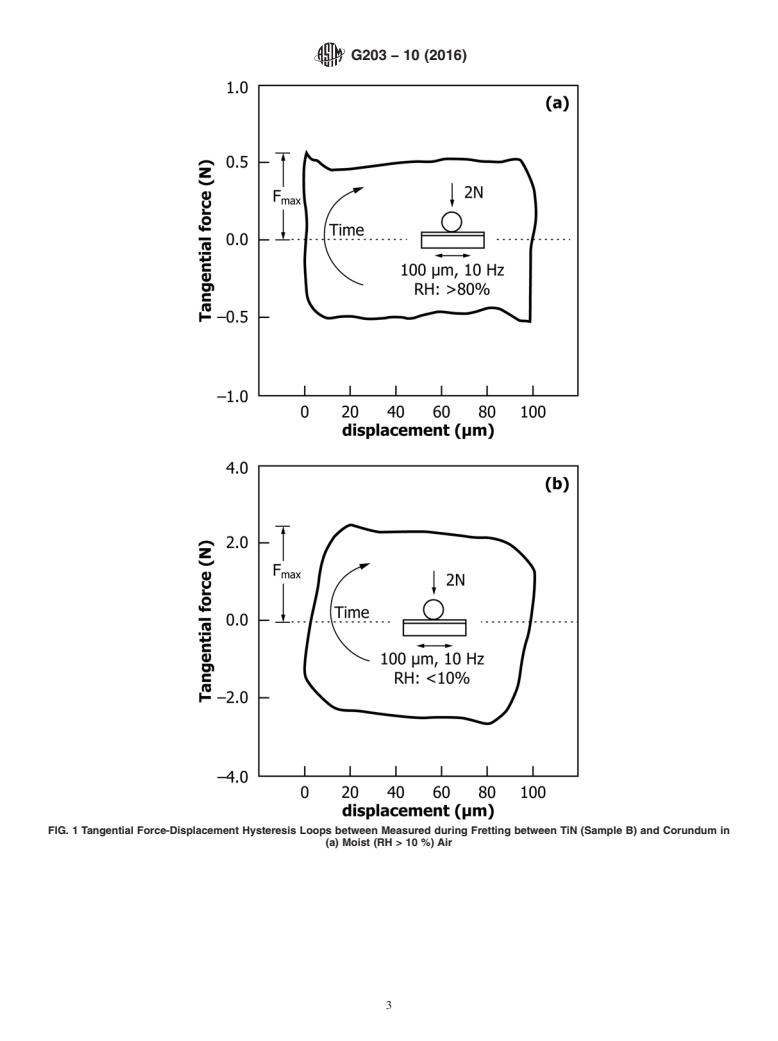

3.2.1 friction envelope—when making friction energy loss

the materials under test display viscoelastic behavior. This

measurements, the graphic representation of the cyclic friction

guide as written is for metals, plastics, and ceramics that do not

force versus time history of a tribosystem in which the

display viscoelastic behavior. It also applies to lubricated and

boundaries surrounding these variations in time produces a

non-lubricated contacts.

shape with a measurable area.

1.4 The values stated in SI units are to be regarded as

3.2.2 reciprocating tribosystem—sliding system where the

standard. No other units of measurement are included in this

direction of motion of the moving member periodically re-

standard.

verses (for example, piston in a cylinder).

1.5 This standard does not purport to address all of the

3.3 Acronyms:

safety concerns, if any, associated with its use. It is the

3.3.1 DAS, n—data acquisition system.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.3.2 FED, n—frictionenergydissipated.Theworkrequired

bility of regulatory limitations prior to use.

to overcome the resistance to motion encountered in sliding

one solid on another expressed in energy units (joules).

2. Referenced Documents

3.3.3 RFED, n—relative friction energy dissipated. The

2

2.1 ASTM Standards:

work required to overcome the resistance to motion encoun-

G40 Terminology Relating to Wear and Erosion

teredinslidingonesolidonanothersolidexpressedinarbitrary

G115 Guide for Measuring and Reporting Friction Coeffi-

units for comparison studies on candidate tribocouples.

cients

G133 Test Method for Linearly Reciprocating Ball-on-Flat

4. Summary of Guide

Sliding Wear

G163 Guide for Digital Data Acquisition in Wear and

4.1 Frictional effects can be a concern in many tribosystems

soitiscommontomonitorfrictionforceinlaboratorytestsand

even field evaluations of machines. There are many ways of

1

This guide is under the jurisdiction of ASTM Committee G02 on Wear and

reporting the recorded friction forces: friction force (see Guide

Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

G115), average friction force for a test, average coefficient of

Current edition approved July 1, 2016. Published July 2016. Originally approved

friction, static and kinetic coefficient of friction, coefficient of

in 2010. Last previous edition approved in 2010 as G203 – 10. DOI:10.1520/

G0203–10R16.

friction at periodic time intervals, etc. This guide presents a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

methodology to convert friction forces monitored throughout a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

test cycle into a test metric called friction energy dissipated

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. (FED).Forwithin-labteststhemetricis relative friction energy

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G203 − 10 (2016)

dissipated (RFED). Both of these terms represent an integra- 8. Procedure

tion of the area within the force/tangential displacement output

8.1 Two options are descri

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G203 − 10 G203 − 10 (Reapproved 2016)

Standard Guide for

Determining Friction Energy Dissipation in Reciprocating

1

Tribosystems

This standard is issued under the fixed designation G203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers and is intended for use in interpreting the friction forces recorded in reciprocating tribosystems. The guide

applies to any reciprocating tribosystem, whether it is a wear or fretting test or an actual machine or device.

1.2 The energy dissipation guide was developed in analyzing friction results in the Test Method G133 reciprocating ball-on-flat

test, but it applies to other ASTM or ISO reciprocating tests. This technique is frequently used to record the friction response in

fretting tribosystems.

1.3 Specimen material may play some role in the results if the materials under test display viscoelastic behavior. This guide as

written is for metals, plastics, and ceramics that do not display viscoelastic behavior. It also applies to lubricated and non-lubricated

contacts.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

G40 Terminology Relating to Wear and Erosion

G115 Guide for Measuring and Reporting Friction Coefficients

G133 Test Method for Linearly Reciprocating Ball-on-Flat Sliding Wear

G163 Guide for Digital Data Acquisition in Wear and Friction Measurements

3. Terminology

3.1 Definitions:

3.1.1 coeffıcient of friction, n—in tribology, the dimensionless ratio of the friction force (F) between two bodies to the normal

force (N) pressing these bodies together. G40

3.1.2 fretting—small amplitude oscillatory motion, usually tangential between two solid surfaces in contact. G40

3.2 Definitions of Terms Specific to This Standard:

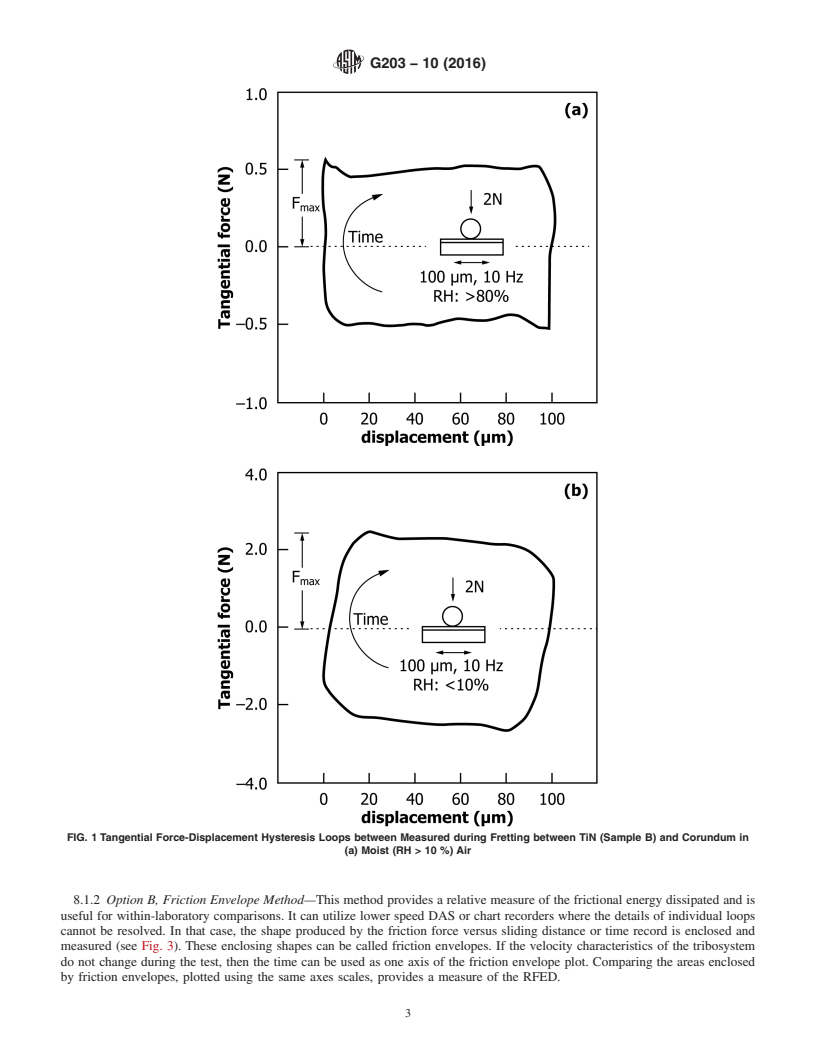

3.2.1 friction envelope—when making friction energy loss measurements, the graphic representation of the cyclic friction force

versus time history of a tribosystem in which the boundaries surrounding these variations in time produces a shape with a

measurable area.

3.2.2 reciprocating tribosystem—sliding system where the direction of motion of the moving member periodically reverses (for

example, piston in a cylinder).

3.3 Acronyms:

3.3.1 DAS, n—data acquisition system.

1

This guide is under the jurisdiction of ASTM Committee G02 on Wear and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

Current edition approved April 1, 2010July 1, 2016. Published May 2010July 2016. DOI:10.1520/G0203–10.Originally approved in 2010. Last previous edition approved

in 2010 as G203 – 10. DOI:10.1520/G0203–10R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G203 − 10 (2016)

3.3.2 FED, n—friction energy dissipated. The work required to overcome the resistance to motion encountered in sliding one

solid on another expressed in energy units (joules).

3.3.3 RFED, n—relative friction energy dissipated. The work required to overcome the resistance to motion encountered in

sliding one solid on another solid expressed in arbitrary units for comparison studies on candidate tribocouples.

4. Summary of Guide

4.1 Frictional effects can be a concern in many tribosystems so it is common to monitor friction force in laboratory tests and

even field evaluations of machines. There are many ways of reporting the recorded friction forces: friction force (see Guide G115),

average friction force for a test, average coefficient of friction, static and kinetic coefficient of friction, coefficient of friction at

periodic time intervals, etc. This guide presents a methodology

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.