ASTM D6725-04(2010)

(Practice)Standard Practice for Direct Push Installation of Prepacked Screen Monitoring Wells in Unconsolidated Aquifers

Standard Practice for Direct Push Installation of Prepacked Screen Monitoring Wells in Unconsolidated Aquifers

SIGNIFICANCE AND USE

This practice is intended to provide the user with information on the appropriate methods and procedures for installing prepacked screen monitoring wells by direct push methods. The monitoring wells may be used to obtain representative water quality samples for aqueous phase contaminants or other analytes of interest, either organic or inorganic (Kram et al. 2000, McCall 2000, McCall et al. 1997). The monitoring wells may also be used to obtain information on the potentiometric surface of the local aquifer and properties of the formation such as hydraulic conductivity or transmissivity.

Use of direct push methods to install monitoring wells can significantly reduce the amount of potentially hazardous drill cuttings generated during well installation at contaminated sites. This may significantly reduce cost of an environmental site investigation and groundwater monitoring program. Minimizing generation of hazardous waste also reduces the exposure hazards to site workers, local residents, and the environment.

Direct push methods for monitoring well installation are limited to use in unconsolidated formations such as alluvial/stream sediments, glacial deposits, and beach type sediments. Direct push methods are generally successful at penetrating clays, silts, sands and some gravel. Deposits such as soils with thick caliche layers, or glacial tills with large cobbles or boulders may be difficult or impossible to penetrate to the desired depth. Direct push methods are not designed for penetration of consolidated bedrock such as limestone, granite or gneiss.

SCOPE

1.1 This practice is based on recognized methods by which direct push monitoring wells may be designed and installed for the purpose of detecting the presence or absence of a contaminant, and collecting representative groundwater quality data. The design standards and installation procedures herein are applicable to both detection and assessment monitoring programs for facilities.

1.2 The recommended monitoring well design, as presented in this practice, is based on the assumption that the objective of the program is to obtain representative groundwater information and water quality samples from aquifers. Monitoring wells constructed following this practice should produce relatively turbidity-free samples for granular aquifer materials ranging from gravels to silty sand. Strata having grain sizes smaller than the recommended design for the smallest diameter filter pack materials should be monitored by alternative monitoring well designs which are not addressed in this practice.

1.3 Direct push procedures are not applicable for monitoring well installation under all geologic and soil conditions (for example, installation in bedrock). Other rotary drilling procedures are available for penetration of these consolidated materials for well construction purposes (Guide D5092). Additionally, under some geologic conditions it may be appropriate to install monitoring wells without a filter pack (EPA 1991). Guide D6724 may be referred to for additional information on these and other methods for the direct push installation of groundwater monitoring wells.

1.4 The values stated in inch-pound units are to be regarded as standard. The values in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 This practice offers a set of instructions for performing one or more specific operations. This document cannot replace education or experience and should be used in conjunction with professional judgement. Not all aspects of this practice may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adeq...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6725 − 04(Reapproved 2010)

Standard Practice for

Direct Push Installation of Prepacked Screen Monitoring

Wells in Unconsolidated Aquifers

This standard is issued under the fixed designation D6725; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 This practice offers a set of instructions for performing

one or more specific operations. This document cannot replace

1.1 This practice is based on recognized methods by which

education or experience and should be used in conjunction

directpushmonitoringwellsmaybedesignedandinstalledfor

with professional judgement. Not all aspects of this practice

the purpose of detecting the presence or absence of a

may be applicable in all circumstances. This ASTM standard is

contaminant,andcollectingrepresentativegroundwaterquality

not intended to represent or replace the standard of care by

data. The design standards and installation procedures herein

which the adequacy of a given professional service must be

are applicable to both detection and assessment monitoring

judged, nor should this document be applied without consid-

programs for facilities.

eration of the project’s many unique aspects. The word

1.2 Therecommendedmonitoringwelldesign,aspresented

“Standard” in the title of this document means only that the

inthispractice,isbasedontheassumptionthattheobjectiveof

document has been approved through the ASTM consensus

the program is to obtain representative groundwater informa-

process.

tionandwaterqualitysamplesfromaquifers.Monitoringwells

constructed following this practice should produce relatively 2. Referenced Documents

turbidity-free samples for granular aquifer materials ranging 2

2.1 ASTM Standards:

from gravels to silty sand. Strata having grain sizes smaller

D1452PracticeforSoilExplorationandSamplingbyAuger

than the recommended design for the smallest diameter filter

Borings

pack materials should be monitored by alternative monitoring

D1587Practice for Thin-Walled Tube Sampling of Soils for

well designs which are not addressed in this practice.

Geotechnical Purposes

1.3 Direct push procedures are not applicable for monitor- D2488Practice for Description and Identification of Soils

ing well installation under all geologic and soil conditions (for

(Visual-Manual Procedure)

example, installation in bedrock). Other rotary drilling proce-

D3694Practices for Preparation of Sample Containers and

dures are available for penetration of these consolidated for Preservation of Organic Constituents

materials for well construction purposes (Guide D5092).

D4043Guide for Selection of Aquifer Test Method in

Additionally,undersomegeologicconditionsitmaybeappro- Determining Hydraulic Properties by Well Techniques

priate to install monitoring wells without a filter pack (EPA

D4044Test Method for (Field Procedure) for Instantaneous

1991). Guide D6724 may be referred to for additional infor- Change in Head (Slug) Tests for Determining Hydraulic

mation on these and other methods for the direct push

Properties of Aquifers

installation of groundwater monitoring wells. D4104Test Method (Analytical Procedure) for Determining

Transmissivity of Nonleaky Confined Aquifers by Over-

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

damped Well Response to Instantaneous Change in Head

asstandard.Thevaluesinparenthesesareforinformationonly.

(Slug Tests)

1.5 This standard does not purport to address all of the

D4448GuideforSamplingGround-WaterMonitoringWells

safety concerns, if any, associated with its use. It is the

D4700Guide for Soil Sampling from the Vadose Zone

responsibility of the user of this standard to establish appro-

D5088Practice for Decontamination of Field Equipment

priate safety and health practices and determine the applica-

Used at Waste Sites

bility of regulatory limitations prior to use.

D5092Practice for Design and Installation of Groundwater

Monitoring Wells

This practice is under the jurisdiction of ASTM Committee D18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.21 on Groundwater and

Vadose Zone Investigations. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2010. Published September 2010. Originally contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

approved in 2001. Last previous edition approved in 2004 as D6725–04. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D6725-04R10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6725 − 04 (2010)

D5314Guide for Soil Gas Monitoring in the Vadose Zone that retains filter media in place against the inner screen. The

D5521Guide for Development of Groundwater Monitoring filter media is usually composed of graded silica sand.

Wells in Granular Aquifers

3.2.2 tremie pipe or tube—a pipe or tube that is used to

D5778Test Method for Electronic Friction Cone and Piezo-

transport filter pack materials and/or annular sealant materials

cone Penetration Testing of Soils

from the ground surface into the borehole annulus or between

D5781Guide for Use of Dual-Wall Reverse-Circulation

casings and casings or riser pipe of a monitoring well.

DrillingforGeoenvironmentalExplorationandtheInstal-

4. Summary of Practice

lation of Subsurface Water-Quality Monitoring Devices

D5782Guide for Use of Direct Air-Rotary Drilling for

4.1 This practice provides information for installing a pre-

Geoenvironmental Exploration and the Installation of

packed screen monitoring well using direct push techniques.

Subsurface Water-Quality Monitoring Devices

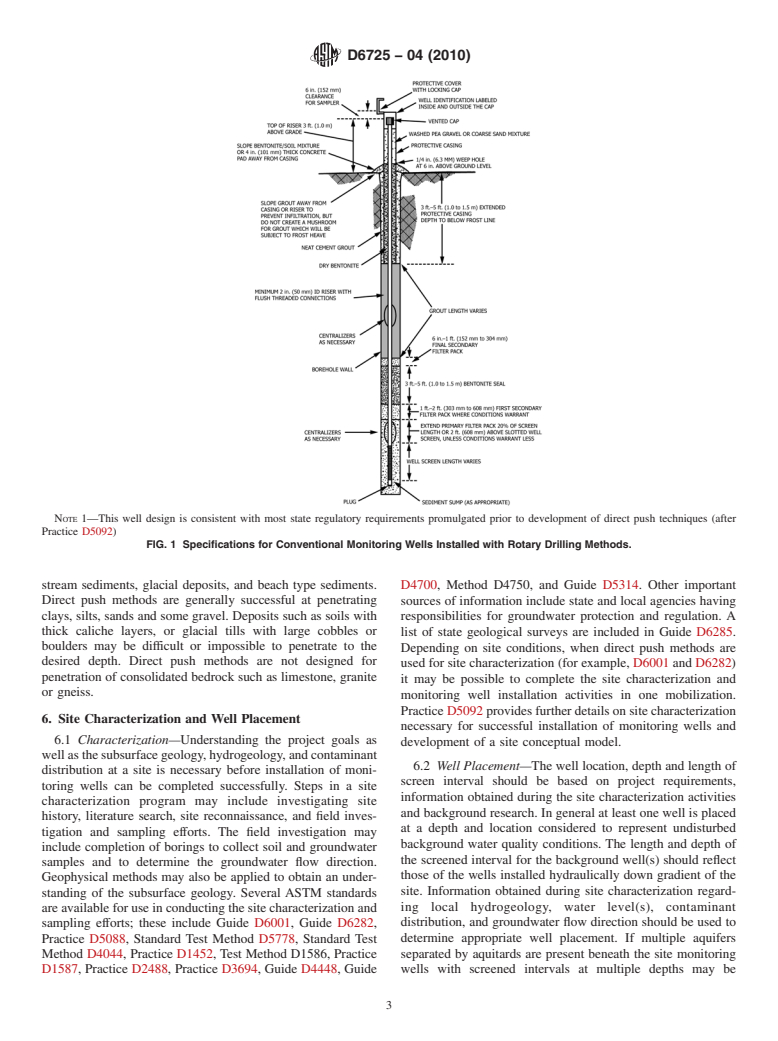

When constructed following this Standard Practice the direct

D5783Guide for Use of Direct Rotary Drilling with Water- pushinstalledmonitoringwellscanmeetmoststateregulations

Based Drilling Fluid for Geoenvironmental Exploration

and federal guidelines (EPA 1986, 1991, 1992) for well

and the Installation of SubsurfaceWater-Quality Monitor- construction (Fig. 1) and protection of the aquifer and ground-

ing Devices

water resources.

D5784Guide for Use of Hollow-StemAugers for Geoenvi-

4.2 Initially the outer casing (or probe rod) is advanced to

ronmental Exploration and the Installation of Subsurface

depth using direct push methods. The monitoring well is

Water-Quality Monitoring Devices

constructed inside the casing with prepacked well screens and

D5785Test Method for (Analytical Procedure) for Deter-

riser pipe. The casing is retracted to set the well at the desired

mining Transmissivity of Confined NonleakyAquifers by

depth in the formation. Bottom up tremie installation of the

Underdamped Well Response to Instantaneous Change in

annularsealandgroutisconductedthroughtheoutercasingas

Head (Slug Test)

it is retracted. This grouting method is required to obtain the

D5786Practice for (Field Procedure) for Constant Draw-

highest integrity well construction. Commonly available types

down Tests in Flowing Wells for Determining Hydraulic

ofabovegroundorflushmountwellprotectionareinstalledto

Properties of Aquifer Systems

physically protect the well and prevent tampering. The small

D5787Practice for Monitoring Well Protection

diameter wells may be developed using bailers, peristalic

D5881Test Method for (Analytical Procedure) Determining

pumps, bladder pumps or an inertial check valve system. The

Transmissivity of Confined Nonleaky Aquifers by Criti-

inertial check valve and tubing system is especially effective

cally Damped Well Response to Instantaneous Change in

when used for development in medium to coarse-grained

Head (Slug)

aquifers. This development method simultaneously surges and

D5912Test Method for (Analytical Procedure) Determining

purges fines from the screen interval. Slug testing of the wells

Hydraulic Conductivity of an Unconfined Aquifer by

can be conducted to determine local aquifer properties and

Overdamped Well Response to Instantaneous Change in

verify that development has been successful. Low flow and

Head (Slug) (Withdrawn 2013)

othersamplingtechniquesmaybeusedtoobtainrepresentative

D6001Guide for Direct-Push Groundwater Sampling for

waterqualitysamples.Clearandaccuratedocumentationofthe

Environmental Site Characterization

well construction is required.

D6282Guide for Direct Push Soil Sampling for Environ-

5. Significance and Use

mental Site Characterizations

D6285Guide for Locating Abandoned Wells

5.1 This practice is intended to provide the user with

D6634Guide for Selection of Purging and Sampling De-

information on the appropriate methods and procedures for

vices for Groundwater Monitoring Wells

installing prepacked screen monitoring wells by direct push

D6724Guide for Installation of Direct Push Groundwater

methods. The monitoring wells may be used to obtain repre-

Monitoring Wells

sentative water quality samples for aqueous phase contami-

D6771Practice for Low-Flow Purging and Sampling for

nants or other analytes of interest, either organic or inorganic

Wells and Devices Used for Ground-Water Quality Inves-

(Kram et al. 2000, McCall 2000, McCall et al. 1997). The

tigations (Withdrawn 2011)

monitoringwellsmayalsobeusedtoobtaininformationonthe

potentiometricsurfaceofthelocalaquiferandpropertiesofthe

3. Terminology

formation such as hydraulic conductivity or transmissivity.

3.1 Definitions—Refer to Terminology D653 for definitions

5.2 Use of direct push methods to install monitoring wells

of terminology.

can significantly reduce the amount of potentially hazardous

3.2 Definitions of Terms Specific to This Standard:

drillcuttingsgeneratedduringwellinstallationatcontaminated

3.2.1 prepacked screen—a manufactured well screen that is

sites. This may significantly reduce cost of an environmental

assembled with a slotted inner casing and an external filter

site investigation and groundwater monitoring program. Mini-

media support. The external filter media support may be

mizing generation of hazardous waste also reduces the expo-

constructedofastainlesssteelwiremeshscreenorslottedPVC

sure hazards to site workers, local residents, and the environ-

ment.

5.3 Directpushmethodsformonitoringwellinstallationare

The last approved version of this historical standard is referenced on

www.astm.org. limited to use in unconsolidated formations such as alluvial/

D6725 − 04 (2010)

NOTE 1—This well design is consistent with most state regulatory requirements promulgated prior to development of direct push techniques (after

Practice D5092)

FIG. 1 Specifications for Conventional Monitoring Wells Installed with Rotary Drilling Methods.

stream sediments, glacial deposits, and beach type sediments. D4700, Method D4750, and Guide D5314. Other important

Direct push methods are generally successful at penetrating

sources of information include state and local agencies having

clays, silts, sands and some gravel. Deposits such as soils with responsibilities for groundwater protection and regulation. A

thick caliche layers, or glacial tills with large cobbles or

list of state geological surveys are included in Guide D6285.

boulders may be difficult or impossible to penetrate to the

Depending on site conditions, when direct push methods are

desired depth. Direct push methods are not designed for

usedforsitecharacterization(forexample,D6001andD6282)

penetration of consolidated bedrock such as limestone, granite

it may be possible to complete the site characterization and

or gneiss.

monitoring well installation activities in one mobilization.

PracticeD5092providesfurtherdetailsonsitecharacterization

6. Site Characterization and Well Placement

necessary for successful installation of monitoring wells and

6.1 Characterization—Understanding the project goals as

development of a site conceptual model.

wellasthesubsurfacegeology,hydrogeology,andcontaminant

6.2 Well Placement—The well location, depth and length of

distribution at a site is necessary before installation of moni-

screen interval should be based on project requirements,

toring wells can be completed successfully. Steps in a site

information obtained during the site characterization activities

characterization program may include investigating site

and background research. In general at least one well is placed

history, literature search, site reconnaissance, and field inves-

at a depth and location considered to represent undisturbed

tigation and sampling efforts. The field investigation may

background water quality conditions. The length and depth of

include completion of borings to collect soil and groundwater

the screened interval for the background well(s) should reflect

samples and to determine the groundwater flow direction.

those of the wells installed hydraulically down gradient of the

Geophysical methods may also be applied to obtain an under-

site. Information obtained during site characterization regard-

standing of the subsurface geology. Several ASTM standards

ing local hydrogeology, water level(s), contaminant

areavailableforuseinconductingthesitecharacterizationand

distribution, and groundwater flow direction should be used to

sampling efforts; these include Guide D6001, Guide D6282,

Practice D5088, Standard Test Method D5778, Standard Test determine appropriate well placement. If multiple aquifers

separated by aquitards are present beneath the site monitoring

Method D4044, Practice D1452,Test Method D1586, Practice

D1587, Practice D2488, Practice D3694, Guide D4448, Guide wells with screened intervals at multiple depths may be

D6725 − 04 (2010)

required at each location. The purpose for installation should 7.2 Water—In general, little water is used in the construc-

be considered in selecting the locations of the monitoring tion of direct push installed prepacked screen wells other than

wells. Purposes may include detection monitoring, long term

in preparation of annular seal and grout mixtures. However,

monitoring, or data collection to determine the presence,

there are situations that may require addition of water to the

extent,andconcentrationsofpotentialcontaminants.Guidance

well or borehole during installation. One of the most common

on selection of well locations, screen lengths and intervals are

situations that may require addition of water is under drilling

found m several references, some of which are: EPA 1986,

conditions where formation blow-in may occur. Under these

1991,1992,1998,Nielsen1991,Fetter1994,andUSGS1997.

conditions(mostoften

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.