ASTM A770/A770M-03(2007)

(Specification)Standard Specification for Through-Thickness Tension Testing of Steel Plates for Special Applications

Standard Specification for Through-Thickness Tension Testing of Steel Plates for Special Applications

ABSTRACT

This specification covers procedures and acceptance standards for the determination of reduction of area using steel plates as tension test specimen. The tension testing method shall provide a measure of the resistance of a steel plate to lamellar tearing. Alternative test specimen may be used in place of the standard test specimen. Several types of test specimen shall have specified values of plate thickness, diameter, minimum radius, and length of reduced section.

SCOPE

1.1 This specification covers the procedures and acceptance standards for the determination of reduction of area using a tension test specimen whose axis is perpendicular to the rolled surfaces of steel plates 1 in. [25 mm] and greater in thickness. The principal purpose of the testing is to provide a measure of the resistance of a steel plate to lamellar tearing. (See Appendix X1.)

1.2 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 This specification is expressed in both inch-pound and SI units. However, unless the order specifies the applicable “M” specification designation (SI units), the material shall be furnished to inch-pound units.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A770/A770M – 03 (Reapproved 2007)

Standard Specification for

Through-Thickness Tension Testing of Steel Plates for

Special Applications

This standard is issued under the fixed designationA770/A770M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Tension Tests

1.1 This specification covers the procedures and accep- 4.1 Number of Tests:

tancestandardsforthedeterminationofreductionofareausing 4.1.1 Two tests shall be required from each plate-as-rolled,

a tension test specimen whose axis is perpendicular to the except for plates subjected to heat treatment by quenching and

rolled surfaces of steel plates 1 in. [25 mm] and greater in tempering. Two tests shall be required from each quenched-

thickness. The principal purpose of the testing is to provide a and-tempered plate. The tests shall be representative of the

measure of the resistance of a steel plate to lamellar tearing. plate in its final condition.

(See Appendix X1.) 4.1.2 When plates are furnished by the manufacturer in an

1.2 The values stated in either inch-pound units or SI units unheat-treated condition and qualified by heat-treated speci-

are to be regarded as standard. Within the text, the SI units are mens (including normalized, normalized and tempered, and

shown in brackets. The values stated in each system are not quenched and tempered), two tests shall be required from each

exact equivalents; therefore, each system must be used inde- plate-as-rolled.

pendentlyoftheother.Combiningvaluesfromthetwosystems

NOTE 1—The term “plate-as-rolled’’ refers to the unit plate rolled from

may result in nonconformance with the specification.

a slab or directly from an ingot. It does not refer to the condition of the

1.3 This specification is expressed in both inch-pound and

plate.

SI units. However, unless the order specifies the applicable

4.2 LocationofTestCoupons—Takeonetestcouponateach

“M” specification designation (SI units), the material shall be

end of each plate as defined in 4.1. Take the test coupons from

furnished to inch-pound units.

the center of the plate width.

4.3 OrientationofTestSpecimens—The longitudinal axis of

2. Referenced Documents

thereducedsectionofthetestspecimensshallbeperpendicular

2.1 ASTM Standards:

to the rolled surface of the plate.

A370 Test Methods and Definitions for Mechanical Testing

4.4 Preparation of Test Specimens:

of Steel Products

4.4.1 Welded Prolongations—When required, join welded

prolongations to the surface(s) of the plate being tested. The

3. Ordering Information

joining method used shall be one which results in a minimal

3.1 The inquiry and order shall include the following, if

heat-affected zone in the portion of the plate to be tested.

required:

Shielded metal arc, friction, stud, or electron-beam welding

3.1.1 Supplementary requirements that are available to meet

methods have proven to be suitable.

end use requirements (see S1 through S5).

4.4.2 Standard Test Specimens:

3.1.2 Special requirements agreed upon between the manu-

4.4.2.1 Threetypesofstandardroundtensiontestspecimens

facturer and the purchaser.

are shown in Fig. 1 and Table 1. For Types 1 and 2 specimens,

locate the center of the length of the reduced section at the

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

approximate mid-point of the plate thickness. For Type 3

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

specimens, locate the weld fusion line of one plate surface

A01.11 on Steel Plates for Boilers and Pressure Vessels.

within ⁄4 in. [6 mm] of one end of the reduced section.

Current edition approved Nov. 1, 2007. Published March 2008. Originally

4.4.2.2 For plates from 1 in. [25 mm] to 1 ⁄4 in. [32 mm]

approved in 1980. Last previous edition approved in 2003 as A770/A770M – 03.

DOI: 10.1520/A0770_A0770M-03R07.

inclusive in thickness, use either the 0.350-in. [8.75-mm] Type

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

1 specimen or the 0.500-in. [12.5-mm] Type 2 specimen.

cation SA-770/SA-770M in Section II of that Code.

4.4.2.3 For plates over 1 ⁄4 in. to 2 in. [50 mm] inclusive in

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM thickness, use the 0.500-in. [12.5-mm] Type 2 specimen.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A770/A770M – 03 (2007)

NOTE—For Type 3 only one welded prolongation may be needed,

depending upon plate thickness.

FIG. 1 Standard Round Tension Test Specimens

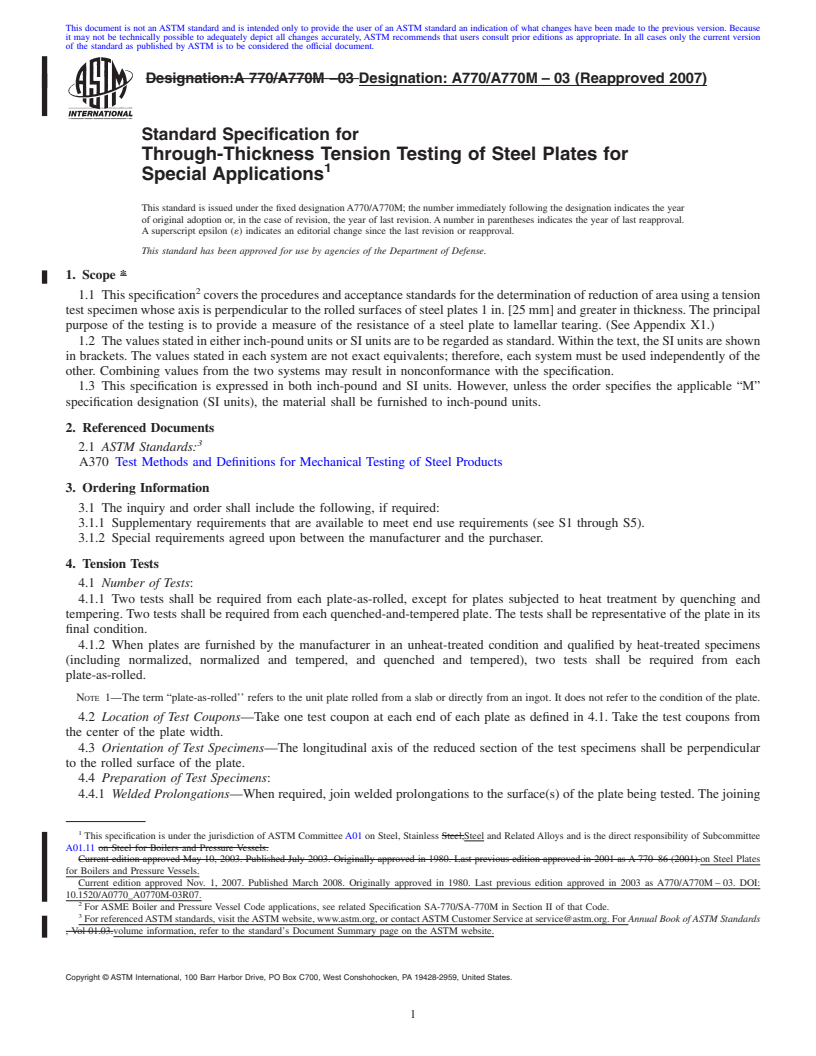

TABLE 1 Schedule of Standard Test Specimens, Inches

A

[Millimetres]

Specimen Type

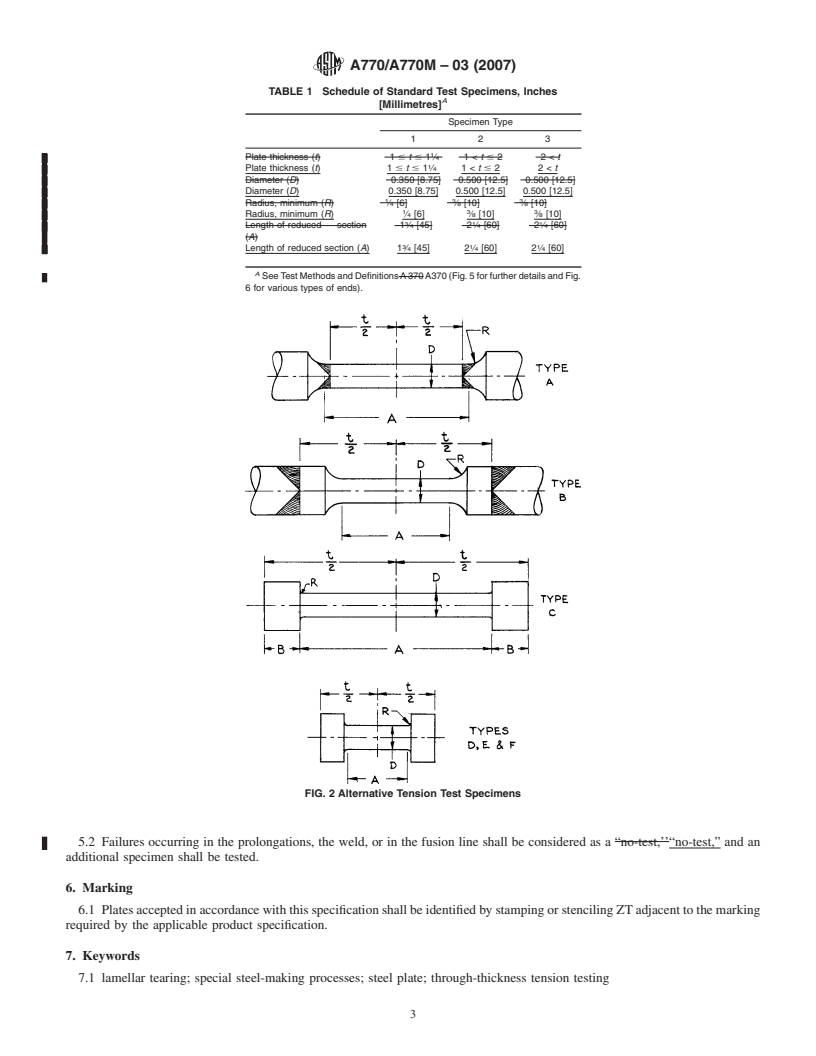

FIG. 2 Alternative Tension Test Specimens

Plate thickness (t)1# t# 1 ⁄4 1< t#22< t

Diameter (D) 0.350 [8.75] 0.500 [12.5] 0.500 [12.5]

1 3 3

Radius, minimum (R) ⁄4 [6] ⁄8 [10] ⁄8 [10]

3 1 1 used. The test specimen type to be used, Type D, Type E, or

Length of reduced section (A)1 ⁄4 [45] 2 ⁄4 [60] 2 ⁄4 [60]

Type F, is determined by the nominal plate thickness as

A

SeeTestMethodsandDefinitionsA370(Fig.5forfurtherdetailsandFig.6for

various types of ends). described inTable 2.Aseries of two or moreType F specimens

may be used to cover the full thickness of the plate. The length

of the reduced section (A), as shown in Fig. 2 and specified in

4.4.2.4 For plates greater than 2 in. [50 mm] in thickness,

Table 2, is the length of the reduced section excluding the

use the Type 3 specimen.

machined radius (R). Within the plate thickness dimension

4.4.3 Alternative Test Specimens—The alternative test

specified for each test specimen type, either the button-head

specimens in Fig. 2 and Table 2 may be used in place of the

thickness, the reduced section length, or the machined radius

standard specimens in Fig. 1 and Table 1.

may be varied. In all cases, the minimum length of the reduced

4.4.3.1 For plates over 2 in. [50 mm] in thickness,TypeAor

section must be as specified in Table 2 to maintain a minimum

TypeBspecimensmaybeused.TheTypeAspecimenprovides

length to diameter ratio (see Appendix X2.2).

a reduced section length greater than the plate thickness. The

Type B specimen provides a reduced section length of 2 ⁄4 in.

5. Acceptance Standards

[57 mm] with its center at the mid-thickness of the plate. Over

a minimum plate thickness determined by the specimen end 5.1 Each tension test shall have a minimum reduction of

configuration, no welded prolongations may be needed for the area no less than 20 %. If the reduction of area of both tests is

Type B specimen. For plates over 4 ⁄4 in. [108 mm] in less than 20 %, no retest shall be permitted. If the reduction of

thickness, the Type C specimen may be used. For plates over 6 area of one of the two tests from a plate is less than 20 %, one

in. [150 mm] in thickness, a series of two or more Type A or retest of two additional specimens taken from a location

Type C specimens with reduced sections of 4 in. [100 mm] or adjacent to the specimen that failed may be made, and both of

less may be used to cover the full thickness of the plate. The these additional specimens shall have a reduction of area of

number of tests required will depend upon the thickness of the 20 % or more.

plate being tested and the reduced section length selected. 5.2 Failures occurring in the prolongations, the weld, or in

4.4.3.2 For plates over 1 in. [25 mm] in thickness, a series the fusion line shall be considered as a “no-test,” and an

of button-head specimens shown in Fig. 2 and Table 2 may be additional specimen shall be tested.

A770/A770M – 03 (2007)

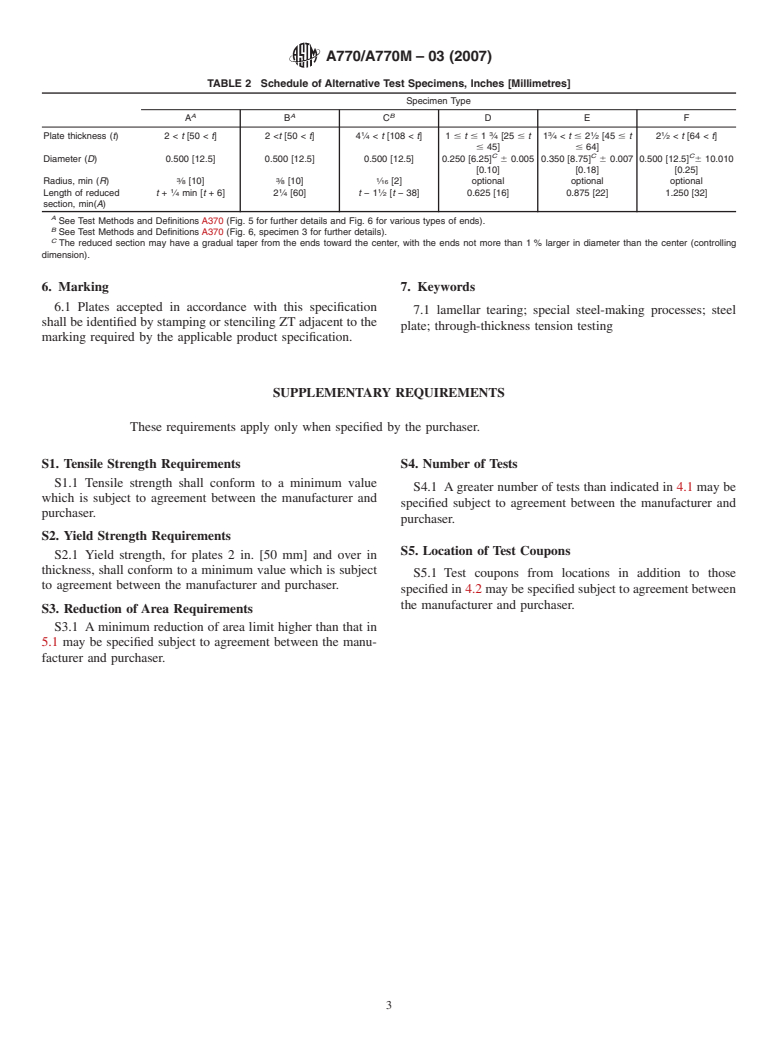

TABLE 2 Schedule of Alternative Test Specimens, Inches [Millimetres]

Specimen Type

A A B

A B C DE F

1 3 3 1 1

Plate thickness (t)2< t [50 < t]2

# 45] # 64]

C C C

Diameter (D) 0.500 [12.5] 0.500 [12.5] 0.500 [12.5] 0.250 [6.25] 6 0.005 0.350 [8.75] 6 0.007 0.500 [12.5] 6 10.010

[0.10] [0.18] [0.25]

3 3 1

Radius, min (R) ⁄8 [10] ⁄8 [10] ⁄16 [2] optional optional optional

1 1 1

Length of reduced t + ⁄4 min [t+6] 2 ⁄4 [60] t−1 ⁄2 [t − 38] 0.625 [16] 0.875 [22] 1.250 [32]

section, min(A)

A

See Test Methods and Definitions A370 (Fig. 5 for further details and Fig. 6 for various types of ends).

B

See Test Methods and Definitions A370 (Fig. 6, specimen 3 for further details).

C

The reduced section may have a gradual taper from the ends toward the center, with the ends not more than 1 % larger in diameter than the center (controlling

dimension).

6. Marking 7. Keywords

6.1 Plates accepted in accordance with this specification

7.1 lamellar tearing; special steel-making processes; steel

shall be identified by stamping or stenciling ZT adjacent to the

plate; through-thickness tension testing

marking required by the applicable product specification.

SUPPLEMENTARY REQUIREMENTS

These requirements apply only when specified by the purchaser.

S1. Tensile Str

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 770/A770M – 86(Reapproved1996) Designation: A 770/A 770M – 03

(Reapproved 2007)

Standard Specification for

Through-Thickness Tension Testing of Steel Plates for

Special Applications

This standard is issued under the fixed designationA 770/A 770M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 Thisspecification coverstheproceduresandacceptancestandardsforthedeterminationofreductionofareausingatension

test specimen whose axis is perpendicular to the rolled surfaces of steel plates 1 in. [25 mm] and greater in thickness.The principal

purpose of the testing is to provide a measure of the resistance of a steel plate to lamellar tearing. (See Appendix X1.)

1.2 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedasstandard.Withinthetext,theSIunitsareshown

in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the

other. Combining values from the two systems may result in nonconformance with the specification.

1.3 This specification is expressed in both inch-pound and SI units. However, unless the order specifies the applicable “M”

specification designation (SI units), the material shall be furnished to inch-pound units.

2. Referenced Documents

2.1 ASTM Standards:

A 370 Test Methods and Definitions for Mechanical Testing of Steel Products

3. Ordering Information

3.1 The inquiry and order shall include the following, if required:

3.1.1 Supplementary requirements that are available to meet end use requirements (see S1 through S5).

3.1.2 Special requirements agreed upon between the manufacturer and the purchaser.

4. Tension Tests

4.1 Number of Tests:

4.1.1 Two tests shall be required from each plate-as-rolled, except for plates subjected to heat treatment by quenching and

tempering. Two tests shall be required from each quenched-and-tempered plate. The tests shall be representative of the plate in its

final condition.

4.1.2 When plates are furnished by the manufacturer in an unheat-treated condition and qualified by heat-treated specimens

(including normalized, normalized and tempered, and quenched and tempered), two tests shall be required from each

plate-as-rolled.

NOTE 1—The term “plate-as-rolled’’ refers to the unit plate rolled from a slab or directly from an ingot. It does not refer to the condition of the plate.

4.2 Location of Test Coupons—Take one test coupon at each end of each plate as defined in 4.1. Take the test coupons from

the center of the plate width.

4.3 Orientation of Test Specimens— The longitudinal axis of the reduced section of the test specimens shall be perpendicular

to the rolled surface of the plate.

4.4 Preparation of Test Specimens :

4.4.1 Welded Prolongations—When required, join welded prolongations to the surface(s) of the plate being tested. The joining

method used shall be one which results in a minimal heat-affected zone in the portion of the plate to be tested. Shielded metal arc,

ThisspecificationisunderthejurisdictionofASTMCommitteeA-1A01onSteel,StainlessSteel,SteelandRelatedAlloysandisthedirectresponsibilityofSubcommittee

A01.11 on Steel Plates for Boilers and Pressure Vessels.

Current edition approved Feb. 28, 1986.Nov. 1, 2007. Published April 1986.March 2008. Originally published as A770–80.approved in 1980. Last previous edition

A770–82.approved in 2003 as A 770/A 770M – 03.

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA-770/SA-770M in Section II of that Code.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 01.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A 770/A 770M – 03 (2007)

friction, stud, or electron-beam welding methods have proven to be suitable.

4.4.2 Types of Test SpecimensStandard Test Specimens:

4.4.2.1 Three types of standard round tension test specimens are shown in Fig. 1 and Table 1. For Types 1 and 2 specimens,

locate the center of the length of the reduced section at the approximate mid-point of the plate thickness. For Type 3 specimens,

locate the weld fusion line of one plate surface within ⁄4 in. [6 mm] of one end of the reduced section.

4.4.2.2 For plates from 1 in. [25 mm] to 1 ⁄4 in. [32 mm] inclusive in thickness, use either the 0.350-in. [8.75-mm] Type 1

specimen or the 0.500-in. [12.5-mm] Type 2 specimen.

4.4.2.3 For plates over 1 ⁄4 in. to 2 in. [50 mm] inclusive in thickness, use the 0.500-in. [12.5-mm] Type 2 specimen.

4.4.2.4 For plates greater than 2 in. [50 mm] in thickness, use the Type 3 specimen.

4.4.3 Alternative Test Specimens—The alternative test specimens in Fig. 2 and Table 2 may be used in place of the standard

specimens in Fig. 1 and Table 1, subject to agreement between the manufacturer and the purchaser. .

4.4.3.1 For plates over 2 in. [50 mm] in thickness, Type A or Type B specimens may be used. The Type A specimen provides

a reduced section length greater than the plate thickness. The Type B specimen provides a reduced section length of 2 ⁄4 in. [57

mm] with its center at the mid-thickness of the plate. Over a minimum plate thickness determined by the specimen end

configuration, no welded prolongations may be needed for the Type B specimen. For plates over 4 ⁄4 in. [108 mm] in thickness,

the standard round tension test specimen Type C specimen may be used. For plates over 6 in. [150 mm] in thickness, a series of

two or more TypeAor Type C specimens with reduced sections of 4 in. [100 mm] or less may be used to cover the full thickness

of the plate. The number of tests required will depend upon the thickness of the plate being tested and the reduced section length

selected.

4.4.3.2 For plates over 1 in. [25 mm] in thickness, a series of button-head specimens shown in Fig. 2 and Table 2 may be used.

The test specimen type to be used, Type D, Type E, or Type F, is determined by the nominal plate thickness as described in Table

2.Aseries of two or moreType F specimens may be used to cover the full thickness of the plate.The length of the reduced section

(A), as shown in Fig. 2 and specified in Table 2, is the length of the reduced section excluding the machined radius ( R). Within

the plate thickness dimension specified for each test specimen type, either the button-head thickness, the reduced section length,

or the machined radius may be varied. In all cases, the minimum length of the reduced section must be as specified in Table 2 to

maintain a minimum length to diameter ratio (see Appendix X2.2).

5. Acceptance Standards

5.1 Each tension test shall have a minimum reduction of area no less than 20 %. If the reduction of area of both tests is less

than 20 %, no retest shall be permitted. If the reduction of area of one of the two tests from a plate is less than 20 %, one retest

of two additional specimens taken from a location adjacent to the specimen that failed may be made, and both of these additional

specimens shall have a reduction of area of 20 % or more.

NOTE—For Type 3 only one welded prolongation may be needed,

depending upon plate thickness.

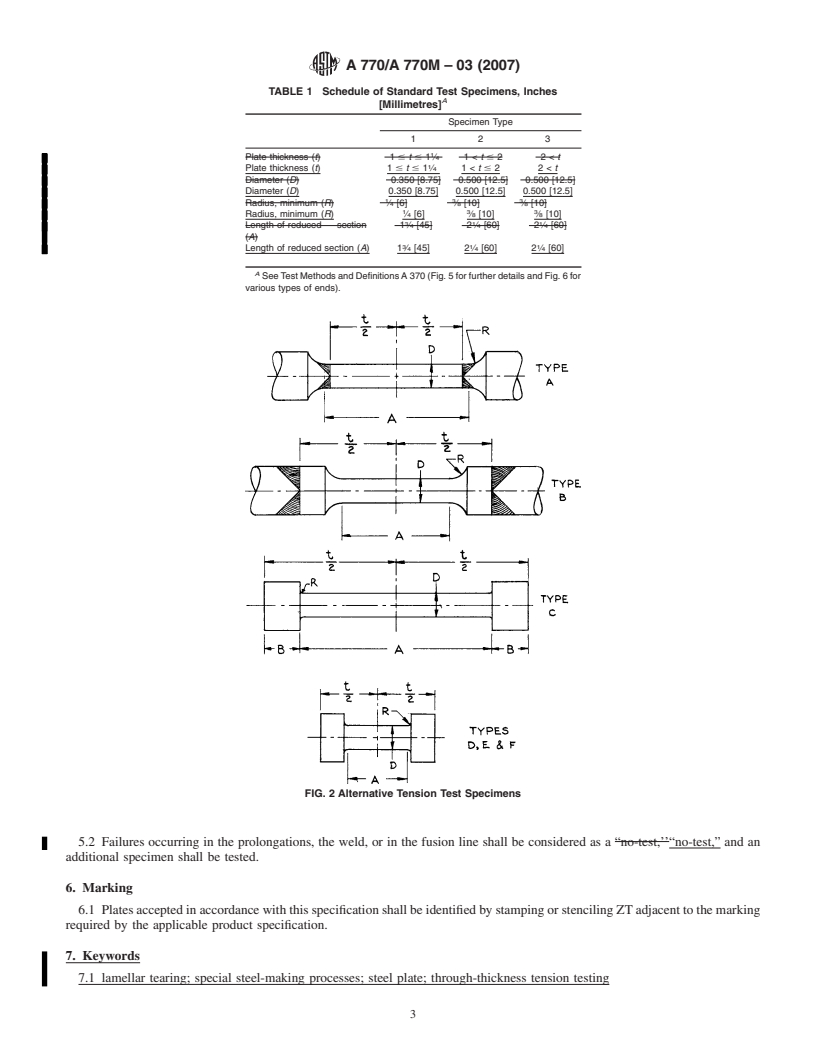

FIG. 1 Standard Round Tension Test Specimens

A 770/A 770M – 03 (2007)

TABLE 1 Schedule of Standard Test Specimens, Inches

A

[Millimetres]

Specimen Type

Plate thickness (t) 1# t# 1 ⁄4 1< t# 2 2< t

Plate thickness (t) 1# t# 1 ⁄4 1< t# 2 2< t

Diameter (D) 0.350 [8.75] 0.500 [12.5] 0.500 [12.5]

Diameter (D) 0.350 [8.75] 0.500 [12.5] 0.500 [12.5]

1 3 3

Radius, minimum (R) ⁄4 [6] ⁄8 [10] ⁄8 [10]

1 3 3

Radius, minimum (R) ⁄4 [6] ⁄8 [10] ⁄8 [10]

3 1 1

Length of reduced section 1 ⁄4 [45] 2 ⁄4 [60] 2 ⁄4 [60]

(A)

3 1 1

Length of reduced section (A) 1 ⁄4 [45] 2 ⁄4 [60] 2 ⁄4 [60]

A

SeeTestMethodsandDefinitionsA 370(Fig.5forfurtherdetailsandFig.6for

various types of ends).

FIG. 2 Alternative Tension Test Specimens

5.2 Failures occurring in the prolongations, the weld, or in the fusion line shall be considered as a “no-test,’’“no-test,” and an

additional specimen shall be tested.

6. Marking

6.1 PlatesacceptedinaccordancewiththisspecificationshallbeidentifiedbystampingorstencilingZTadjacenttothemarking

required by the applicable product specification.

7. Keywords

7.1 lamellar tearing; special steel-making processes; steel plate; through-thickness tension testing

A 770/A 770M – 03 (2007)

TABLE 2 Schedule of Alternative Test Specimens, Inches [Millimetres]

Specimen Type

A A B

A B C D E F

1 3 3 1 1

Plate thickness (t) 2< t 2

[50 < t] [50 < t] [108 < t] [25# t# 45] [45# t# 64] [64 < t]

1 3 3 1 1

Plate thickness (t) 2< t 2

[50 < t] [50 < t] [108 < t] [25# t# 45] [45# t# 64] [64 < t]

C C C

Diameter (D) 0.500 [12.5] 0.500 [12.5] 0.500 [12.5] 0.250 [6.25] 6 0.350 [8.75] 6 0.500 [12.5]

0.005 [0.10] 0.007 [0.18] 6 l0.010

[0.25]

C C C

Diameter (D) 0.500 [12.5] 0.500 [12.5] 0.500 [12.5] 0.250 [6.25] 6 0.350 [8.75] 6 0.500 [12.5]

6 l0.010

3 3 1

Radius, min (R) ⁄8 [10] ⁄8 [10] ⁄16 [10] optional optional optional

3 3 1

Radius, min (R) ⁄8 [10] ⁄8 [10] ⁄16 [10] optional optional optional

1 1 1

Length of reduced t + ⁄4 min 2 ⁄4 [60] t−1 ⁄2 0.625 [16] 0.875 [

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 770/A770M –03 Designation: A770/A770M – 03 (Reapproved 2007)

Standard Specification for

Through-Thickness Tension Testing of Steel Plates for

Special Applications

This standard is issued under the fixed designationA770/A770M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope *

1.1 Thisspecification coverstheproceduresandacceptancestandardsforthedeterminationofreductionofareausingatension

test specimen whose axis is perpendicular to the rolled surfaces of steel plates 1 in. [25 mm] and greater in thickness.The principal

purpose of the testing is to provide a measure of the resistance of a steel plate to lamellar tearing. (See Appendix X1.)

1.2 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedasstandard.Withinthetext,theSIunitsareshown

in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the

other. Combining values from the two systems may result in nonconformance with the specification.

1.3 This specification is expressed in both inch-pound and SI units. However, unless the order specifies the applicable “M”

specification designation (SI units), the material shall be furnished to inch-pound units.

2. Referenced Documents

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

3. Ordering Information

3.1 The inquiry and order shall include the following, if required:

3.1.1 Supplementary requirements that are available to meet end use requirements (see S1 through S5).

3.1.2 Special requirements agreed upon between the manufacturer and the purchaser.

4. Tension Tests

4.1 Number of Tests:

4.1.1 Two tests shall be required from each plate-as-rolled, except for plates subjected to heat treatment by quenching and

tempering. Two tests shall be required from each quenched-and-tempered plate. The tests shall be representative of the plate in its

final condition.

4.1.2 When plates are furnished by the manufacturer in an unheat-treated condition and qualified by heat-treated specimens

(including normalized, normalized and tempered, and quenched and tempered), two tests shall be required from each

plate-as-rolled.

NOTE 1—The term “plate-as-rolled’’ refers to the unit plate rolled from a slab or directly from an ingot. It does not refer to the condition of the plate.

4.2 Location of Test Coupons—Take one test coupon at each end of each plate as defined in 4.1. Take the test coupons from

the center of the plate width.

4.3 Orientation of Test Specimens—The longitudinal axis of the reduced section of the test specimens shall be perpendicular

to the rolled surface of the plate.

4.4 Preparation of Test Specimens:

4.4.1 Welded Prolongations—When required, join welded prolongations to the surface(s) of the plate being tested. The joining

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel,Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.11 on Steel for Boilers and Pressure Vessels.

Current edition approved May 10, 2003. Published July 2003. Originally approved in 1980. Last previous edition approved in 2001 as A 770–86 (2001).on Steel Plates

for Boilers and Pressure Vessels.

Current edition approved Nov. 1, 2007. Published March 2008. Originally approved in 1980. Last previous edition approved in 2003 as A770/A770M – 03. DOI:

10.1520/A0770_A0770M-03R07.

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA-770/SA-770M in Section II of that Code.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 01.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A770/A770M – 03 (2007)

method used shall be one which results in a minimal heat-affected zone in the portion of the plate to be tested. Shielded metal arc,

friction, stud, or electron-beam welding methods have proven to be suitable.

4.4.2 Standard Test Specimens:

4.4.2.1 Three types of standard round tension test specimens are shown in Fig. 1 and Table 1. For Types 1 and 2 specimens,

locate the center of the length of the reduced section at the approximate mid-point of the plate thickness. For Type 3 specimens,

locate the weld fusion line of one plate surface within ⁄4 in. [6 mm] of one end of the reduced section.

4.4.2.2 For plates from 1 in. [25 mm] to 1 ⁄4 in. [32 mm] inclusive in thickness, use either the 0.350-in. [8.75-mm] Type 1

specimen or the 0.500-in. [12.5-mm] Type 2 specimen.

4.4.2.3 For plates over 1 ⁄4 in. to 2 in. [50 mm] inclusive in thickness, use the 0.500-in. [12.5-mm] Type 2 specimen.

4.4.2.4 For plates greater than 2 in. [50 mm] in thickness, use the Type 3 specimen.

4.4.3 Alternative Test Specimens—The alternative test specimens in Fig. 2 and Table 2 may be used in place of the standard

specimens in Fig. 1 and Table 1.

4.4.3.1 For plates over 2 in. [50 mm] in thickness, Type A or Type B specimens may be used. The Type A specimen provides

a reduced section length greater than the plate thickness. The Type B specimen provides a reduced section length of 2 ⁄4 in. [57

mm] with its center at the mid-thickness of the plate. Over a minimum plate thickness determined by the specimen end

configuration, no welded prolongations may be needed for the Type B specimen. For plates over 4 ⁄4 in. [108 mm] in thickness,

theTypeCspecimenmaybeused.Forplatesover6in.[150mm]inthickness,aseriesoftwoormoreTypeAorTypeCspecimens

with reduced sections of 4 in. [100 mm] or less may be used to cover the full thickness of the plate. The number of tests required

will depend upon the thickness of the plate being tested and the reduced section length selected.

4.4.3.2 For plates over 1 in. [25 mm] in thickness, a series of button-head specimens shown in Fig. 2 and Table 2 may be used.

The test specimen type to be used, Type D, Type E, or Type F, is determined by the nominal plate thickness as described in Table

2.Aseries of two or moreType F specimens may be used to cover the full thickness of the plate.The length of the reduced section

(A), as shown in Fig. 2 and specified in Table 2, is the length of the reduced section excluding the machined radius (R). Within

the plate thickness dimension specified for each test specimen type, either the button-head thickness, the reduced section length,

or the machined radius may be varied. In all cases, the minimum length of the reduced section must be as specified in Table 2 to

maintain a minimum length to diameter ratio (see Appendix X2.2).

5. Acceptance Standards

5.1 Each tension test shall have a minimum reduction of area no less than 20 %. If the reduction of area of both tests is less

than 20 %, no retest shall be permitted. If the reduction of area of one of the two tests from a plate is less than 20 %, one retest

of two additional specimens taken from a location adjacent to the specimen that failed may be made, and both of these additional

specimens shall have a reduction of area of 20 % or more.

NOTE—For Type 3 only one welded prolongation may be needed,

depending upon plate thickness.

FIG. 1 Standard Round Tension Test Specimens

A770/A770M – 03 (2007)

TABLE 1 Schedule of Standard Test Specimens, Inches

A

[Millimetres]

Specimen Type

Plate thickness (t) 1# t# 1 ⁄4 1< t# 2 2< t

Plate thickness (t) 1# t# 1 ⁄4 1< t# 2 2< t

Diameter (D) 0.350 [8.75] 0.500 [12.5] 0.500 [12.5]

Diameter (D) 0.350 [8.75] 0.500 [12.5] 0.500 [12.5]

1 3 3

Radius, minimum (R) ⁄4 [6] ⁄8 [10] ⁄8 [10]

1 3 3

Radius, minimum (R) ⁄4 [6] ⁄8 [10] ⁄8 [10]

3 1 1

Length of reduced section 1 ⁄4 [45] 2 ⁄4 [60] 2 ⁄4 [60]

(A)

3 1 1

Length of reduced section (A) 1 ⁄4 [45] 2 ⁄4 [60] 2 ⁄4 [60]

A

SeeTestMethodsandDefinitionsA370A370(Fig.5forfurtherdetailsandFig.

6 for various types of ends).

FIG. 2 Alternative Tension Test Specimens

5.2 Failures occurring in the prolongations, the weld, or in the fusion line shall be considered as a “no-test,’’“no-test,” and an

additional specimen shall be tested.

6. Marking

6.1 PlatesacceptedinaccordancewiththisspecificationshallbeidentifiedbystampingorstencilingZTadjacenttothemarking

required by the applicable product specification.

7. Keywords

7.1 lamellar tearing; special steel-making processes; steel plate; through-thickness tension testing

A770/A770M – 03 (2007)

TABLE 2 Schedule of Alternative Test Specimens, Inches [Millimetres]

Specimen Type

A A B

A B C D E F

1 3 3 1 1

Plate thickness (t) 2< t [50 2

< t] < t] [108 < t] [25# t# 45] [45# t# 64] [64 < t]

1 3 3 1 1

Plate thickness (t) 2< t[50 < t] 2

# 45] # 64]

C C C

Diameter (D) 0.500 [12.5] 0.500 [12.5] 0.500 [12.5] 0.250 [6.25] 6 0.350 [8.75] 6 0.500 [12.5]

0.005 [0.10] 0.007 [0.18] 6 l0.010

[0.25]

C C C

Diameter (D) 0.500 [12.5] 0.500 [12.5] 0.500 [12.5] 0.250 [6.25] 6 0.005 0.350 [8.75] 6 0.007 0.500 [12.5] 6 10.010

[0.10] [0.18] [0.25]

3 3 1

Radius, min (R) ⁄8 [10] ⁄8 [10] ⁄16 [2] optional optional optional

3 3 1

Radius, min (R) ⁄8 [10] ⁄8 [10] ⁄16 [2] optional optional optional

1 1 1

Length of reduced t + ⁄4 min 2 ⁄4 [60] t−1 ⁄2 [t 0.625 [16] 0.875 [22] 1.250 [32]

section min(A) [t+6] − 38]

1 1 1

Length of reduced t + ⁄4 min [t+6] 2 ⁄4 [60] t−1 ⁄2 [t − 38] 0.625 [16] 0.875 [22] 1.250 [32]

section, min(A)

A

See Test Methods and Definitions A 370 A370 (Fig. 5 for further details and Fig. 6 for various types of ends).

B

See Test Methods and Definitions A 370 A370 (Fig. 6, specimen 3 for further details).

C

The reduced section may have a gradual taper from the ends toward the center, with the ends not more than 1 % larger in diameter than the center (controlling

dimension).

SUPPLEMENTAR

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.