ASTM B302-00

(Specification)Standard Specification for Threadless Copper Pipe, Standard Sizes

Standard Specification for Threadless Copper Pipe, Standard Sizes

SCOPE

1.1 This specification establishes requirements for threadless, seamless, deoxidized copper pipe (TP) in straight lengths, in all nominal or standard pipe sizes, for piping systems that are assembled with brazed-joint pipe fittings. The pipe shall be produced from either of coppers UNS Nos. C10300 or C12200.

1.2 The values stated in inch-pound units are the standard. The values given in parentheses are provided for information only.

1.3 The following safety hazard caveat pertains only to the test methods described Section 16 of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to its use.

General Information

Relations

Standards Content (Sample)

Designation: B 302 – 00

Standard Specification for

Threadless Copper Pipe, Standard Sizes

This standard is issued under the fixed designation B 302; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * E 255 Practice for Sampling Copper and CopperAlloys for

Determination of Chemical Composition

1.1 This specification establishes requirements for thread-

less, seamless, deoxidized copper pipe (TP) in straight lengths,

3. Terminology

in all nominal or standard pipe sizes, for piping systems that

3.1 Definitions—Refer toTerminology B 846 for definitions

are assembled with brazed-joint pipe fittings. The pipe shall be

of terms related to copper and copper alloys.

producedfromeitherofcoppersUNSNos.C10300orC12200.

3.2 Definitions of Terms Specific to This Standard:

1.2 The values stated in inch-pound units are the standard.

3.2.1 threadless pipe (TP)—seamless tube conforming to

The values given in parentheses are provided for information

the particular dimensions commercially known as “Threadless

only.

Pipe (TP).”

1.3 The following safety hazard caveat pertains only to the

test methods described Section 16 of this specification: This

4. Ordering Information

standard does not purport to address all of the safety concerns,

4.1 Ordersforproductsunderthisspecificationshallinclude

if any, associated with its use. It is the responsibility of the user

the following information:

of this standard to establish appropriate safety and health

4.1.1 ASTM designation and year of issue,

practices and determine the applicability of regulatory limita-

4.1.2 Copper UNS No. designation,

tions prior to its use.

4.1.3 Nominal or standard size (Table 1), and

4.1.4 Total length, total weight, or number of pieces of each

2. Referenced Documents

size.

2.1 ASTM Standards:

4.2 The following options are available and are to be

B 601 Practice for Temper Designations for Copper and

specifiedinthecontractorpurchaseorderatthetimeofplacing

Copper Alloys—Wrought and Cast

2 of the order:

B 846 Terminology for Copper and Copper Alloys

3 4.2.1 Tension test (Section 8),

E 8 Test Methods forTensionTesting of Metallic Materials

4.2.2 Hydrostatic test (10.2),

E 18 Test Methods for Rockwell Hardness and Rockwell

3 4.2.3 Pneumatic test (10.3),

Superficial Hardness of Metallic Materials

4.2.4 Heat identification or traceability requirements,

E 29 Practice for Using Significant Digits in Test Data to

4 4.2.5 Certification (Section 20), and

Determine Conformance with Specifications

5 4.2.6 Mill test report (Section 21).

E 53 Methods for Chemical Analysis of Copper

E 62 Test Methods for Chemical Analysis of Copper and

5. Materials and Manufacture

Copper Alloys (Photometric Methods)

5.1 Material—The material of manufacture shall be cast

E 243 Practice for Electromagnetic (Eddy-Current) Exami-

billets, bars, or tubes of copper UNS No. C10300 or C12200

nation of Copper and Copper-Alloy Tubes

and shall be of such quality and soundness as to be suitable for

processing into finished lengths of pipe to meet the properties

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper prescribed herein.

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

5.2 Manufacture:

and Tube.

5.2.1 The pipe shall be manufactured by such hot extrusion

Current edition approved Sept. 10, 2000. Published November 2000. Originally

or piercing and subsequent cold working as to produce a

published as B 302 – 55T. Last previous edition B 302 – 98.

Annual Book of ASTM Standards, Vol 02.01.

uniform, seamless wrought structure in the finished product.

Annual Book of ASTM Standards, Vol 03.01.

5.2.2 The product shall be cold worked to the finished size

Annual Book of ASTM Standards, Vol 14.02.

5 so as to meet the temper properties specified.

Annual Book of ASTM Standards, Vol 03.05.

Annual Book of ASTM Standards, Vol 03.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 302

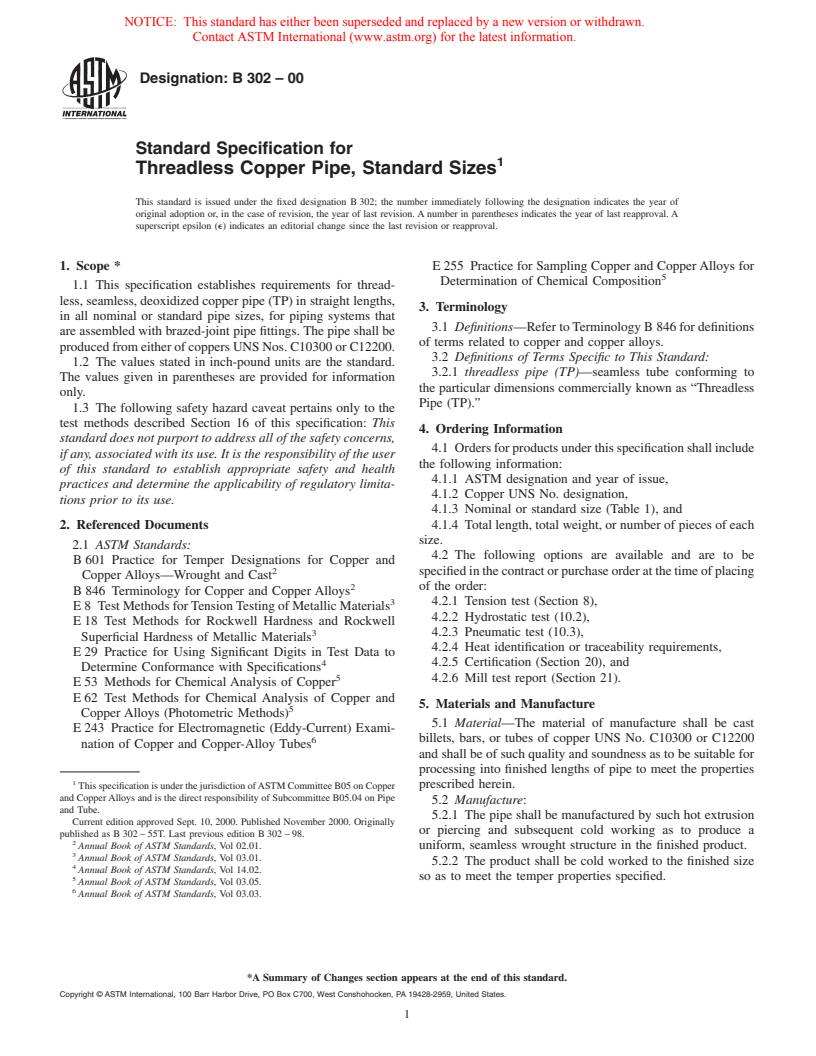

TABLE 1 Dimensions and Weights and Tolerance in Diameter and Wall Thickness for Copper Threadless Pipe (TP) Sizes

Tolerances, in. (mm)

Cross-Sectional

Nominal or Standard Outside Diameter, Inside Diameter, Wall Thickness, Theoretical Weight,

Area of Bore,

Average Outside Wall Thickness Plus

Pipe Size, in. in. (mm) in. (mm), in. (mm) lb/ft (kg/m)

2 2

in. (cm ) A

Diameter, All Minus and Minus

⁄4 0.540(13.7) 0.410(10.4) 0.065(1.65) 0.132(0.852) 0.376(0.559) 0.004(0.10) 0.0035(0.089)

⁄8 0.675(17.1) 0.545(13.8) 0.065(1.65) 0.233(1.50) 0.483(0.719) 0.004(0.10) 0.004(0.10)

⁄2 0.840(21.3) 0.710(18.0) 0.065(1.65) 0.396(2.55) 0.613(0.912) 0.005(0.13) 0.004(0.10)

⁄4 1.050(26.7) 0.920(23.4) 0.065(1.65) 0.665(4.29) 0.780(1.16) 0.005(0.13) 0.004(0.10)

1 1.315(33.4) 1.185(30.1) 0.065(1.65) 1.10(7.10) 0.989(1.47) 0.005(0.13) 0.004(0.10)

1 ⁄4 1.660(42.2) 1.530(38.9) 0.065(1.65) 1.84(11.9) 1.26(1.87) 0.006(0.15) 0.004(0.10)

1 ⁄2 1.900(48.3) 1.770(45.0) 0.065(1.65) 2.46(15.9) 1.45(2.16) 0.006(0.15) 0.004(0.10)

2 2.375(60.3) 2.245(57.0) 0.065(1.65) 3.96(25.5) 1.83(2.72) 0.007(0.18) 0.006(0.15)

2 ⁄2 2.875(73.0) 2.745(69.7) 0.065(1.65) 5.92(38.2) 2.22(3.30) 0.007(0.18) 0.006(0.15)

3 3.500(88.9) 3.334(84.7) 0.083(2.11) 8.73(56.3) 3.45(5.13) 0.008(0.20) 0.007(0.18)

3 ⁄2 4.000(102) 3.810(96.8) 0.095(2.41) 11.4(73.5) 4.52(6.73) 0.008(0.20) 0.007(0.18)

4 4.500(114) 4.286(109) 0.107(2.72) 14.4(92.9) 5.72(8.51) 0.010(0.25) 0.009(0.23)

5 5.562(141) 5.298(135) 0.132(3.40) 22.0(142) 8.73(13.0) 0.012(0.30) 0.010(0.25)

6 6.625(168) 6.309(160) 0.158(4.01) 31.3(202) 12.4(18.5) 0.014(0.36) 0.010(0.25)

8 8.625(219) 8.215(209) 0.205(5.21) 53.0(342) 21.0(31.2) 0.018(0.46) 0.014(0.36)

10 10.750(273) 10.238(260) 0.256(6.50) 82.3(531) 32.7(48.7) 0.018(0.46) 0.016(0.41)

12 12.750(324) 12.124(308) 0.313(7.95) 115(742) 47.4(70.5) 0.018(0.46) 0.020(0.51)

A

The average outside diameter of a tube is the average of the maximum and minimum outside diameters, as determined at any one cross section of the tube.

6. Chemical Composition nification of 75 diameters. When copper UNS No. C12200 is

supplied, microscopical examination for cuprous oxide is not

6.1 The product shall conform to the chemical composition

required.

requirements specified in Table 2 for the copper UNS number

designation specified in the ordering information.

10. Nondestructive Test Requirements

6.2 These composition limits do not preclude the presence

of other elements. Limits for unnamed elements shall be

10.1 Electromagnetic (Eddy-Current) Test:

established and analysis required by agreement between the

10.1.1 Each tube up to and including 2 ⁄2-in. nominal pipe

manufacture or supplier and purchaser.

size shall be subjected to an eddy-current test. Testing shall

follow the procedures of Practice E 243 and 15.2.

7. Temper

10.1.1.1 The provisions for the determination of “end-

7.1 The product shall be furnished in the H58 (drawn effect” in Practice E 243 shall not apply.

general purpose) temper as defined in Practice B 601. 10.1.1.2 Hydrostatic Test Alternative—As an alternative to

the eddy-current test for tubes of diameters above 1.25 in. (32

8. Mechanical Properties

mm), the manufacturer shall perform the hydrostatic test to the

requirements of 10.2.

8.1 Tensile Strength:

10.1.2 The tested tubes, which do not actuate the signaling

8.1.1 Product in all sizes and coppers shall have a minimum

device of the testing unit, shall be considered as conforming to

tensile strength of 36 ksi (250 MPa) when tested in accordance

the requirements of the test.

with Test Methods E 8.

10.1.3 Either notch depth or drilled hole standards shall be

8.1.2 The tension test need not be performed except when

used.

specified by the purchaser in the ordering information at the

10.1.3.1 Notchdepthstandardsshallbe10 %ofthenominal

time of placing of the order.

wall thickness.

8.2 Rockwell Hardness—Product in all sizes and coppers

10.1.3.2 The sizes of drilled hole standards shall be deter-

shall have a minimum Rockwell F hardness of 55 when tested

mined in accordance with Table X1.2 of Practice E 243.

in accordance with Test Methods E 18.

10.2 Hydrostatic Test:

9. Microscopical Examination 10.2.1 When specified in the contract or purchase order, or

as an alternative to the eddy-current test for tubes above 1.25

9.1 The pipe shall be made from copper free from cuprous

in. (32 mm) in diameter (see 10.1.1.2), each tube shall stand,

oxide, as determined by microscopical examination at a mag-

without showing evidence of leakage, an internal hydrostatic

pressure sufficient to produce a fiber stress of 6000 psi (41

TABLE 2 Chemical Requirements

MPa) as determined by the following equation for thin hollow

cylinders under tension:

Composition, %

Copper UNS No.

Copper (Incl Silver), min Phosphorus

A P 5 2St/~D 2 0.8t! (1)

C10300 99.95 0.001 to 0.005

C12200 99.9 0.015 to 0.040

where:

A

Copper + silver + phosphorus.

B 302

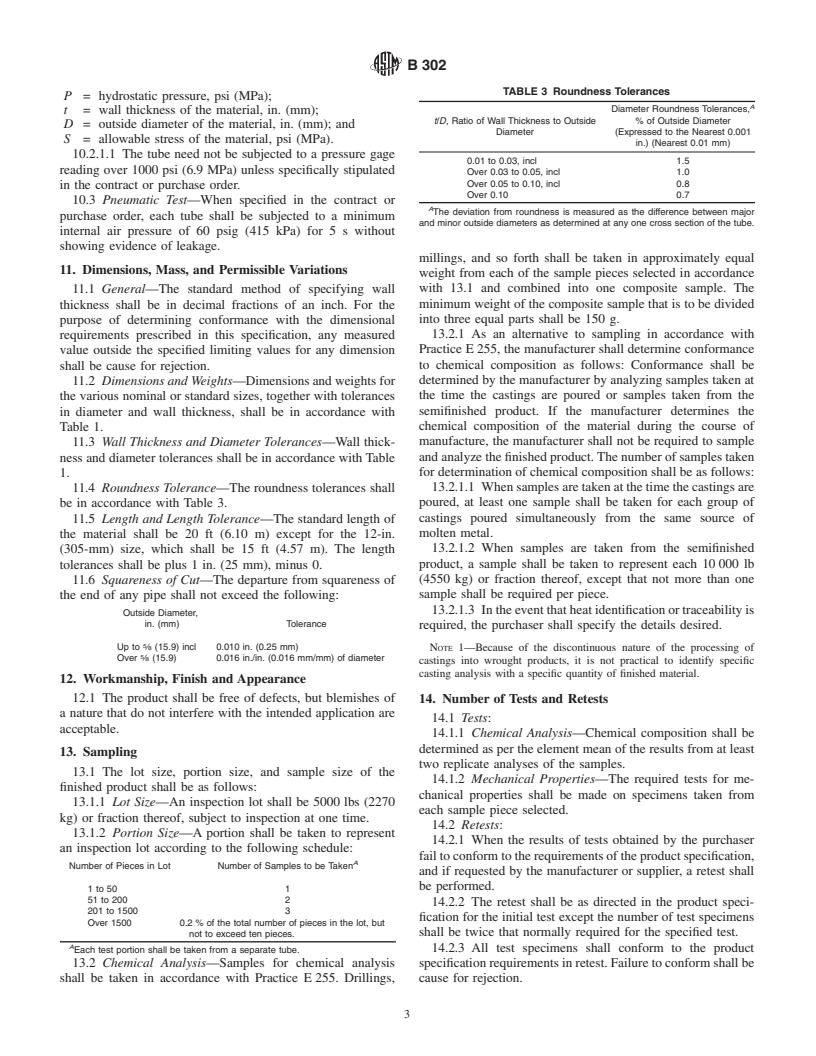

TABLE 3 Roundness Tolerances

P = hydrostatic pressure, psi (MPa);

A

Diameter Roundness Tolerances,

t = wall thickness of the material, in. (mm);

t/D, Ratio of Wall Thickness to Outside % of Outside Diameter

D = outside diameter of the material, in. (mm); and

Diameter (Expressed to the Nearest 0.001

S = allowable stress of the material, psi (MPa).

in.) (Nearest 0.01 mm)

10.2.1.1 The tube need not be subjected to a pressure gage

0.01 to 0.03, incl 1.5

reading over 1000 psi (6.9 MPa) unless specifically stipulated

Over 0.03 to 0.05, incl 1.0

Over 0.05 to 0.10, incl 0.8

in the contract or purchase order.

Over 0.10 0.7

10.3 Pneumatic Test—When specified in the contract or

A

The deviation from roundness is measured as the difference between major

purchase order, each tube shall be subjected to a minimum

and minor outside diameters as determined at any one cross section of the tube.

internal air pressure of 60 psig (415 kPa) for 5 s without

showing evidence of leakage.

millings, and so forth shall be taken in approximately equal

11. Dimensions, Mass, and Permissible Variations

weight from each of the sample pieces selected in accordance

11.1 General—The standard method of specifying wall with 13.1 and combined into one composite sample. The

minimum weight of the composite sample that is to be divided

thickness shall be in decimal fractions of an inch. For the

purpose of determining conformance with the dimensional into three equal parts shall be 150 g.

13.2.1 As an alternative to sampling in accordance with

requirements prescribed in this specification, any measured

value outside the specified limiting values for any dimension Practice E 255, the manufacturer shall determine conformance

to chemical composition as follows: Conformance shall be

shall be cause for rejection.

11.2 Dimensions and Weights—Dimensions and weights for determined by the manufacturer by analyzing samples taken at

the time the castings are poured or samples taken from the

the various nominal or standard sizes, together with tolerances

in diameter and wall thickness, shall be in accordance with semifinished product. If the manufacturer determines the

chemical composition of the material during the course of

Table 1.

manufacture, the manufacturer shall not be required to sample

11.3 Wall Thickness and Diameter Tolerances—Wall thick-

and analyze the finished product.The number of samples taken

ness and diameter tolerances shall be in accordance with Table

for determination of chemical composition shall be as follows:

1.

13.2.1.1 When samples are taken at the time the castings are

11.4 Roundness Tolerance—The roundness tolerances shall

poured, at least one sample shall be taken for each group of

be in accordance with Table 3.

castings poured simultaneously from the same source of

11.5 Length and Length Tolerance—The standard length of

molten metal.

the material shall be 20 ft (6.10 m) except for the 12-in.

(305-mm) size, which shall be 15 ft (4.57 m). The length 13.2.1.2 When samples are taken from the semifinished

product, a sample shall be taken to represent each 10 000 lb

tolerances shall be plus 1 in. (25 mm), minus 0.

11.6 Squareness of Cut—The departure from squareness of (4550 kg) or fraction thereof, except that not more than one

sample shall be required per piece.

the end of any pipe shall not exceed the following:

13.2.1.3 Intheeventthatheatidentificationortraceabilityis

Outside Diameter,

in. (mm) Tolerance

required, the purchaser shall specify the details desired.

Up to ⁄8 (15.9) incl 0.010 in. (0.25 mm)

NOTE 1—Because of the discontinuous nature of the processing of

Over ⁄8 (15.9) 0.016 in./in. (0.016 mm/mm) of diameter

castings into wrought products, it is not practical to identify specific

casting analysis with a specific quantity of finished material.

12. Workmanship, Finish and Appearance

12.1 The product shall be free of defects, but blemishes of

14. Number of Tests and Retests

a nature that do not interfere with the intended application are

14.1 Tests:

acceptable.

14.1.1 Chemical Analysis—Chemical composition shall be

determined as per the element mean of the results from at least

13. Sampling

two replicate analyses of the samples.

13.1 The lot size, portion size, and sample size of the

14.1.2 Mechanical Properties—The required tests for me-

finished product shall be as follows:

chanical properties shall be made on specimens taken from

13.1.1 Lot Size—An inspection lot shall be 5000 lbs (2270

each sample piece selected.

kg) or fraction thereof, subject to inspection at one time.

14.2 Retests:

13.1.2 Portion Size—A portion shall be taken to represent

14.2.1 When the results of tests obtained by the purchaser

an inspection lot according to the following schedule:

failtoconformtotherequirementsoftheproductspecification,

A

Number of Pieces in Lot Number of Samples to be Taken

and if requested by the manufacturer or supplier, a retest shall

be performed.

1to50 1

51 to 200 2

14.2.2 The retest shall be as directed in the product speci-

201 to 1500 3

fication for the initial test except the number of test specimens

Over 1500 0.2 % of the total number of pieces in the lot, but

not to exceed ten pieces. shall be twice that normally required for the specified test.

A

14.2.3 All test specimens shall conform to the product

Each test portion shall be taken from a separate tube.

13.2 Chemical Analysis—Samples for chemical analysis specification requirements in retest. Failure to conform shall be

shall be taken in accordance with Practice E 255. Drillings, cause for rejection.

B 302

15. Specimen Preparation requirements of this test. If reexamined or retested, tubes wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.