ASTM G164-99(2018)

(Test Method)Standard Test Method for Determination of Surface Lubrication on Flexible Webs

Standard Test Method for Determination of Surface Lubrication on Flexible Webs

SIGNIFICANCE AND USE

5.1 Many web materials do not convey satisfactorily in manufacture or work, or both, as intended in service unless their surface contains a very thin layer of lubricant in the form of a wax, particulate, thin film coating, or fluid. It is often very expensive and time consuming to use surface chemical analysis techniques to quantify the presence of these films. A simple friction test like this one performs this function.

5.2 This test has been used for over twenty years to detect the presence of lubricants on the surface of photographic films at various stages in manufacture. In this instance the surfaces are lubricated with waxes and this test reliably detects if the wax is present. It is not used to quantify the amount of wax, only if it is present. This test can be used as a quality test to make sure that a lubricant is present. Test samples are normally compared with an unlubricated reference specimen. The coefficient of friction of the test samples is compared with the coefficient of friction of the unlubricated reference specimens to determine if a lubricant is present.

SCOPE

1.1 This test method has been used since 1988 as an ANSI/ISO standard test for determination of lubrication on processed photographic films. Its purpose was to determine the presence of process-surviving lubricants on photographic films. It is the purpose of this test method to expand the applicability of this test method to other flexible webs that may need lubrication for suitable performance. This test measures the breakaway (static) coefficient of friction of a metal rider on the web by the inclined plane method. The objectives of the test is to determine if a web surface has a lubricant present or not. It is not intended to assign a friction coefficient to a material. It is not intended to rank lubricants.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G164 − 99 (Reapproved 2018)

Standard Test Method for

Determination of Surface Lubrication on Flexible Webs

This standard is issued under the fixed designation G164; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 coeffıcient of friction, µ, n, in tribology—the dimen-

sionlessratioofthefrictionforce(F)betweentwobodiestothe

1.1 This test method has been used since 1988 as an

normal force (N) pressing these bodies together.

ANSI/ISO standard test for determination of lubrication on

3.1.2 friction force, n—the resisting force tangential to the

processed photographic films. Its purpose was to determine the

interface between two bodies when, under the action of

presence of process-surviving lubricants on photographic

external force, one body moves or tends to move relative to the

films. It is the purpose of this test method to expand the

other.

applicability of this test method to other flexible webs that may

need lubrication for suitable performance. This test measures

3.1.3 lubricant, n—any substance interposed between two

the breakaway (static) coefficient of friction of a metal rider on

surfaces for the purpose of reducing the friction and wear

thewebbytheinclinedplanemethod.Theobjectivesofthetest

between them.

is to determine if a web surface has a lubricant present or not.

3.1.4 static coeffıcient of friction, n—the coefficient of

It is not intended to assign a friction coefficient to a material.

friction corresponding to the maximum friction force that must

It is not intended to rank lubricants.

be overcome to initiate macroscopic motion between two

1.2 The values stated in SI units are to be regarded as

bodies.

standard. No other units of measurement are included in this

3.1.5 triboelement, n—one of two or more solid bodies

standard.

which comprise a sliding, rolling, or abrasive contact, or a

1.3 This standard does not purport to address all of the

body subjected to impingement or cavitation.

safety concerns, if any, associated with its use. It is the

3.1.6 tribology, n—the science and technology concerned

responsibility of the user of this standard to establish appro-

with interacting surfaces in relative motion, including friction,

priate safety, health, and environmental practices and deter-

lubrication, wear, and erosion.

mine the applicability of regulatory limitations prior to use.

3.1.7 tribosystem, n—any system that contains one or more

1.4 This international standard was developed in accor-

triboelements, including all mechanical, chemical, and envi-

dance with internationally recognized principles on standard-

ronmental factors relevant to tribological behavior.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4. Summary of Test Method

mendations issued by the World Trade Organization Technical

4.1 This test method can be used to measure the friction

Barriers to Trade (TBT) Committee.

characteristics of the surfaces of a flexible web sliding against

the curved smooth surface of a paper clip.

2. Referenced Documents

4.2 This test method is conducted on a narrow strip taken

2.1 ANSI/ISO Standards:

from a web of interest. The strip is affixed to an inclined plane

ANSI/ISO 5769-1984, ANSI/NAPM IT9.4-1992 for

device with the surface of interest facing up. A paper clip is

Photography-Processed Films-Method for Determining

balanced on the web surface with the inclined plane in the

Lubrication

horizontal position. The plane is then angled upward until the

3. Terminology

rider breaks away.

3.1 Definitions:

4.3 Theangleatwhichbreakawayoccurredisrecorded.The

tangent of that angle is the friction coefficient for that tribo-

system.

This test method is under the jurisdiction of ASTM Committee G02 on Wear

and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

5. Significance and Use

CurrenteditionapprovedJune1,2018.PublishedJuly2018.Originallyapproved

in 1999. Last previous edition approved in 2013 as G164 – 99 (2013). DOI:

5.1 Many web materials do not convey satisfactorily in

10.1520/G0164-99R18.

manufacture or work, or both, as intended in service unless

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. their surface contains a very thin layer of lubricant in the form

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

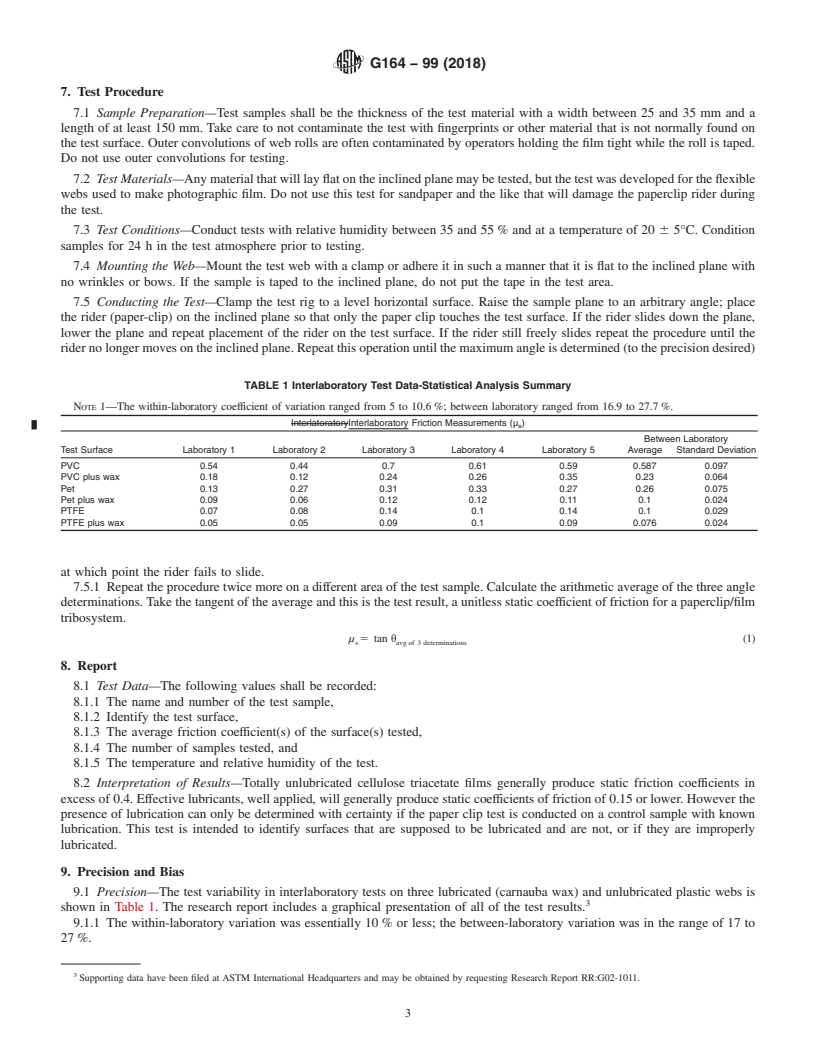

G164 − 99 (2018)

of a wax, particulate, thin film coating, or fluid. It is often very 6.2.3 It shall have a device for test material attachment or it

expensiveandtimeconsumingtousesurfacechemicalanalysis shall have sufficient room to allow attachment with two-sided

techniques to quantify the presence of these films. A simple pressure sensitive adhesive.

friction test like this one performs this function. 6.2.4 It shall be capable of being raised and lowered with

smooth uninterrupted motion and it shall have a means of

5.2 This test has been used for over twenty years to detect

clamping the plane at the angle at which rider breakaway

the presence of lubricants on the surface of photographic films

occurs.

at various stages in manufacture. In this instance the surfaces

are lubricated with waxes and this test reliably detects if the 6.3 Angle Measurement—The test metric is the angle incli-

wax is present. It is not used to quantify the amount of wax, nation of the inclined plane (θ) when rider motion occurs. This

only if it is present. This test can be used as a quality test to angle can be measured by a protractor or by calibration of a

make sure that a lubricant is present.Test samples are normally gage on the device.Asuitable device for angle measurement is

compared with an unlubricated reference specimen. The coef- an electronic level. These devices present a digital angle

ficient of friction of the test samples is compared with the readout to two places. The devices reputedly are accurate to

60.1°. The least count on the angle-measuring protractor shall

coefficient of friction of the unlubricated reference specimens

to determine if a lubricant is present. be 1°.

6. Apparatus

7. Test Procedure

6.1 Friction Slider—The rider in this friction test is a

7.1 Sample Preparation—Test samples shall be the thick-

U-shaped device with a paper clip inserted in the center. This

ness of the test material with a width between 25 and 35 mm

rider slides on the test web that is attached to the inclined

and a l

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G164 − 99 (Reapproved 2018)

Standard Test Method for

Determination of Surface Lubrication on Flexible Webs

This standard is issued under the fixed designation G164; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 coeffıcient of friction, µ, n, in tribology—the dimen-

sionless ratio of the friction force (F) between two bodies to the

1.1 This test method has been used since 1988 as an

normal force (N) pressing these bodies together.

ANSI/ISO standard test for determination of lubrication on

3.1.2 friction force, n—the resisting force tangential to the

processed photographic films. Its purpose was to determine the

interface between two bodies when, under the action of

presence of process-surviving lubricants on photographic

external force, one body moves or tends to move relative to the

films. It is the purpose of this test method to expand the

other.

applicability of this test method to other flexible webs that may

need lubrication for suitable performance. This test measures

3.1.3 lubricant, n—any substance interposed between two

the breakaway (static) coefficient of friction of a metal rider on

surfaces for the purpose of reducing the friction and wear

the web by the inclined plane method. The objectives of the test

between them.

is to determine if a web surface has a lubricant present or not.

3.1.4 static coeffıcient of friction, n—the coefficient of

It is not intended to assign a friction coefficient to a material.

friction corresponding to the maximum friction force that must

It is not intended to rank lubricants.

be overcome to initiate macroscopic motion between two

1.2 The values stated in SI units are to be regarded as

bodies.

standard. No other units of measurement are included in this

3.1.5 triboelement, n—one of two or more solid bodies

standard.

which comprise a sliding, rolling, or abrasive contact, or a

1.3 This standard does not purport to address all of the

body subjected to impingement or cavitation.

safety concerns, if any, associated with its use. It is the

3.1.6 tribology, n—the science and technology concerned

responsibility of the user of this standard to establish appro-

with interacting surfaces in relative motion, including friction,

priate safety, health, and environmental practices and deter-

lubrication, wear, and erosion.

mine the applicability of regulatory limitations prior to use.

3.1.7 tribosystem, n—any system that contains one or more

1.4 This international standard was developed in accor-

triboelements, including all mechanical, chemical, and envi-

dance with internationally recognized principles on standard-

ronmental factors relevant to tribological behavior.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4. Summary of Test Method

mendations issued by the World Trade Organization Technical

4.1 This test method can be used to measure the friction

Barriers to Trade (TBT) Committee.

characteristics of the surfaces of a flexible web sliding against

the curved smooth surface of a paper clip.

2. Referenced Documents

4.2 This test method is conducted on a narrow strip taken

2.1 ANSI/ISO Standards:

from a web of interest. The strip is affixed to an inclined plane

ANSI/ISO 5769-1984, ANSI/NAPM IT9.4-1992 for

device with the surface of interest facing up. A paper clip is

Photography-Processed Films-Method for Determining

balanced on the web surface with the inclined plane in the

Lubrication

horizontal position. The plane is then angled upward until the

3. Terminology

rider breaks away.

3.1 Definitions:

4.3 The angle at which breakaway occurred is recorded. The

tangent of that angle is the friction coefficient for that tribo-

system.

This test method is under the jurisdiction of ASTM Committee G02 on Wear

and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

5. Significance and Use

Current edition approved June 1, 2018. Published July 2018. Originally approved

in 1999. Last previous edition approved in 2013 as G164 – 99 (2013). DOI:

5.1 Many web materials do not convey satisfactorily in

10.1520/G0164-99R18.

2 manufacture or work, or both, as intended in service unless

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. their surface contains a very thin layer of lubricant in the form

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G164 − 99 (2018)

of a wax, particulate, thin film coating, or fluid. It is often very 6.2.3 It shall have a device for test material attachment or it

expensive and time consuming to use surface chemical analysis shall have sufficient room to allow attachment with two-sided

techniques to quantify the presence of these films. A simple pressure sensitive adhesive.

friction test like this one performs this function. 6.2.4 It shall be capable of being raised and lowered with

smooth uninterrupted motion and it shall have a means of

5.2 This test has been used for over twenty years to detect

clamping the plane at the angle at which rider breakaway

the presence of lubricants on the surface of photographic films

occurs.

at various stages in manufacture. In this instance the surfaces

are lubricated with waxes and this test reliably detects if the 6.3 Angle Measurement—The test metric is the angle incli-

wax is present. It is not used to quantify the amount of wax, nation of the inclined plane (θ) when rider motion occurs. This

only if it is present. This test can be used as a quality test to angle can be measured by a protractor or by calibration of a

make sure that a lubricant is present. Test samples are normally gage on the device. A suitable device for angle measurement is

compared with an unlubricated reference specimen. The coef- an electronic level. These devices present a digital angle

ficient of friction of the test samples is compared with the readout to two places. The devices reputedly are accurate to

coefficient of friction of the unlubricated reference specimens 60.1°. The least count on the angle-measuring protractor shall

to determine if a lubricant is present. be 1°.

6. Apparatus

7. Test Procedure

6.1 Friction Slider—The rider in this friction test is a

7.1 Sample Preparation—Test samples shall be the thick-

U-shaped device with a paper clip inserted in the center. This

ness of the test material with a width between 25 and 35 mm

rider slides on the test web that is attached to the inclined

and a length of at least 150 mm. Take care to not contaminate

plane. The material of con

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G164 − 99 (Reapproved 2013) G164 − 99 (Reapproved 2018)

Standard Test Method for

Determination of Surface Lubrication on Flexible Webs

This standard is issued under the fixed designation G164; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method has been used since 1988 as an ANSI/ISO standard test for determination of lubrication on processed

photographic films. Its purpose was to determine the presence of process-surviving lubricants on photographic films. It is the

purpose of this test method to expand the applicability of this test method to other flexible webs that may need lubrication for

suitable performance. This test measures the breakaway (static) coefficient of friction of a metal rider on the web by the inclined

plane method. The objectives of the test is to determine if a web surface has a lubricant present or not. It is not intended to assign

a friction coefficient to a material. It is not intended to rank lubricants.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ANSI/ISO Standards:

ANSI/ISO 5769-1984, ANSI/NAPM IT9.4-1992 for Photography-Processed Films-Method for Determining Lubrication

3. Terminology

3.1 Definitions:

3.1.1 coeffıcient of friction, μ, n, in tribology—the dimensionless ratio of the friction force (F) between two bodies to the normal

force (N) pressing these bodies together.

3.1.2 friction force, n—the resisting force tangential to the interface between two bodies when, under the action of external

force, one body moves or tends to move relative to the other.

3.1.3 lubricant, n—any substance interposed between two surfaces for the purpose of reducing the friction and wear between

them.

3.1.4 static coeffıcient of friction, n—the coefficient of friction corresponding to the maximum friction force that must be

overcome to initiate macroscopic motion between two bodies.

3.1.5 triboelement, n—one of two or more solid bodies which comprise a sliding, rolling, or abrasive contact, or a body

subjected to impingement or cavitation.

3.1.6 tribology, n—the science and technology concerned with interacting surfaces in relative motion, including friction,

lubrication, wear, and erosion.

3.1.7 tribosystem, n—any system that contains one or more triboelements, including all mechanical, chemical, and

environmental factors relevant to tribological behavior.

4. Summary of Test Method

4.1 This test method can be used to measure the friction characteristics of the surfaces of a flexible web sliding against the

curved smooth surface of a paper clip.

This test method is under the jurisdiction of ASTM Committee G02 on Wear and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

Current edition approved Nov. 15, 2013June 1, 2018. Published November 2013July 2018. Originally approved in 1999. Last previous edition approved in 20092013 as

G164–99(2009).G164 – 99 (2013). DOI: 10.1520/G0164-99R13.10.1520/G0164-99R18.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G164 − 99 (2018)

4.2 This test method is conducted on a narrow strip taken from a web of interest. The strip is affixed to an inclined plane device

with the surface of interest facing up. A paper clip is balanced on the web surface with the inclined plane in the horizontal position.

The plane is then angled upward until the rider breaks away.

4.3 The angle at which breakaway occurred is recorded. The tangent of that angle is the friction coefficient for that tribosystem.

5. Significance and Use

5.1 Many web materials do not convey satisfactorily in manufacture or work, or both, as intended in service unless their surface

contains a very thin layer of lubricant in the form of a wax, particulate, thin film coating, or fluid. It is often very expensive and

time consuming to use surface chemical analysis techniques to quantify the presence of these films. A simple friction test like this

one performs this function.

5.2 This test has been used for over twenty years to detect the presence of lubricants on the surface of photographic films at

various stages in manufacture. In this instance the surfaces are lubricated with waxes and this test reliably detects if the wax is

present. It is not used to quantify the amount of wax, only if it is present. This test can be used as a quality test to make sure that

a lubricant is present. Test samples are normally compared with an unlubricated reference specimen. The coefficient of friction of

the test samples is compared with the coefficient of friction of the unlubricated reference specimens to determine if a lubricant is

present.

6. Apparatus

6.1 Friction Slider—The rider in this friction test is a U-shaped device with a paper clip inserted in the center. This rider slides

on the test web that is attached to the inclined plane. The material of construction is not important, but the center of gravity shall

be at least 25 mm below the end of the paper clip. Acrylic sheet has been determined to be a suitable material of construction. The

paper clip must be uncoated steel and have a smooth (as opposed to serrated or dull) finish. The overall dimensions of suitable

paper clips are between 5 and 8 mm wide and between 25 and 35 mm long. The wire diameter should be in the range of 0.6 to

0.75 mm. The mass of the slider should be in the range of 50 to 100 g.

6.2 Inclined Plane—The dimensions and typical construction of the inclined plane test rig are shown in Fig. 1. The essential

requirements of the inclined plane are:

6.2.1 The surface of the inclined plane should be smooth (<0.2 μm Ra surface roughness) rigid and not deformable under test

conditions. Acrylic sheet

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.