ASTM A131/A131M-94

(Specification)Standard Specification for Structural Steel for Ships

Standard Specification for Structural Steel for Ships

SCOPE

1.1 This specification covers structural steel shapes, plates, bars, and rivets intended primarily for use in ship construction.

1.2 Material under this specification is available in the following categories:

1.2.1 Ordinary Strength—Grades A, B, D, DS, CS, and E with a specified minimum yield point of 34 ksi [235 MPa], and

1.2.2 Higher Strength— Grades AH, DH, and EH with specified minimum yield points of either 46 ksi [315 MPa], 51 ksi [350 MPa], or 57 ksi [390 MPa].

1.3 Shapes and bars are normally available as Grades A, AH32, or AH36. Other grades may be furnished by agreement between the purchaser and the manufacturer.

1.4 When the steel is to be welded, it is presupposed that a welding procedure suitable for the grade of steel and intended use or service will be utilized. See Appendix X3 of Specification A6/A6M for information on weldability.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as the standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 131/A131M – 94

Standard Specification for

Structural Steel for Ships

This standard is issued under the fixed designation A 131/A131M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope describe adequately the desired material:

3.1.1 Quantity (weight or number of pieces),

1.1 This specification covers structural steel shapes, plates,

3.1.2 Name of material (ordinary strength or higher

bars, and rivets intended primarily for use in ship construction.

strength, carbon steel shapes, plates, bars, or rivets),

1.2 Material under this specification is available in the

3.1.3 ASTM specification designation, grade, and year of

following categories:

issue,

1.2.1 Ordinary Strength—Grades A, B, D, DS, CS, and E

3.1.4 Cold flanging when applicable,

with a specified minimum yield point of 34 ksi [235 MPa], and

3.1.5 Dimensions,

1.2.2 Higher Strength—Grades AH, DH, and EH with

3.1.6 Condition (hot rolled or hot rolled and normalized),

specified minimum yield points of either 46 ksi [315 MPa], 51

and

ksi [350 MPa], or 57 ksi [390 MPa].

3.1.7 Supplementary requirements, if any.

1.3 Shapes and bars are normally available as Grades A,

AH32, or AH36. Other grades may be furnished by agreement

4. Manufacture

between the purchaser and the manufacturer.

4.1 Melting Process:

1.4 When the steel is to be welded, it is presupposed that a

4.1.1 The steel may be made by any of the following

welding procedure suitable for the grade of steel and intended

processes: open-hearth, basic-oxygen, electric-furnace,

use or service will be utilized. See Appendix X3 of Specifica-

vacuum arc remelt (VAR), or electroslag remelt (ESR).

tion A 6/A 6M for information on weldability.

4.1.2 Except for Grade A steel up to and including ⁄2 in.

1.5 The values stated in either inch-pound units or SI units

[12.5 mm] in thickness, rimming-type steels shall not be

are to be regarded separately as the standard. Within the text,

applied.

the SI units are shown in brackets. The values stated in each

4.1.3 Grades AH32 and AH36 shapes through 426 lb/ft, and

system are not exact equivalents; therefore, each system must

plates up to 0.5 in. [12.5 mm] in thickness may be semi-killed,

be used independently of the other. Combining values from the

in which case the 0.10 % minimum silicon does not apply.

two systems may result in nonconformance with this specifi-

4.1.4 Except as permitted in 4.1.4.1, Grades D, DS, CS, E,

cation.

AH40, DH32, DH36, DH40, EH32, EH36, and EH40 shall be

2. Referenced Documents made using a fine grain practice. For ordinary strength grades,

aluminum shall be used to obtain grain refinement. For high

2.1 ASTM Standards:

strength grades, aluminum, vanadium, or columbium (nio-

A 6/A6M Specification for General Requirements for

bium) may be used for grain refinement.

Rolled Structural Steel Bars, Plates, Shapes, and Sheet

4.1.4.1 Grade D material 1 ⁄8 in. [35 mm] and under in

Piling

thickness, at the option of the manufacturer, may be semi-

A 370 Test Methods and Definitions for Mechanical Testing

killed and exempt from the fine austenitic grain size require-

of Steel Products

ment of 7.1, but such material shall be subject to the toughness

E 112 Test Methods for Determining the Average Grain

requirement of 8.2.1.

Size

5. Heat Treatment

3. Ordering Information

5.1 Plates in all thicknesses ordered to Grades CS and E

3.1 Inquiries, orders, contracts, etc., for material to this

shall be normalized. Plates over 1 ⁄8 in. [35 mm] in thickness

specification should include the following information to

ordered to Grade D shall be normalized. When Grade D steel

is furnished semi-killed, it shall be normalized over 1 in. [25

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

mm] in thickness. Upon agreement between the purchaser and

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.02 on Structural Steel for Bridges, Buildings, Rolling Stock, and Ships. the manufacturer, control rolling of Grade D steel may be

Current edition approved June 15, 1994. Published August 1994. Originally

substituted for normalizing, in which case impact tests are

published as A 131 – 31 T. Last previous edition A 131/A 131M – 93b.

required for each 25 tons [25 Mg] of material in the heat.

Annual Book of ASTM Standards, Vol 01.04.

5.2 Plates in all thicknesses ordered to Grades EH32 and

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 131/A131M

EH36 shall be normalized. Plates in all thicknesses ordered to acid-soluble aluminum content of 0.010 %, or minimum total

Grade EH40 shall be normalized or quenched and tempered. aluminum content of 0.015%.

Grades AH32, AH36, AH40, DH32, DH36, and DH40 shall be

8. Mechanical Requirements

normalized when so specified in Table 1. Upon agreement

8.1 Tension Tests:

between the purchaser and the manufacturer, control rolling of

8.1.1 Except as specified in the following paragraphs the

Grade DH may be substituted for normalizing, in which case

material as represented by the test specimens shall conform to

impact tests are required on each plate.

the tensile requirements prescribed in Table 3.

5.3 In the case of shapes, the thicknesses referred to are

8.1.1.1 Unless a specific orientation is called for on the

those of the flange.

purchase order, tension test specimens may be taken parallel or

6. Chemical Requirements

transverse to the final direction of rolling at the option of the

steel manufacturer.

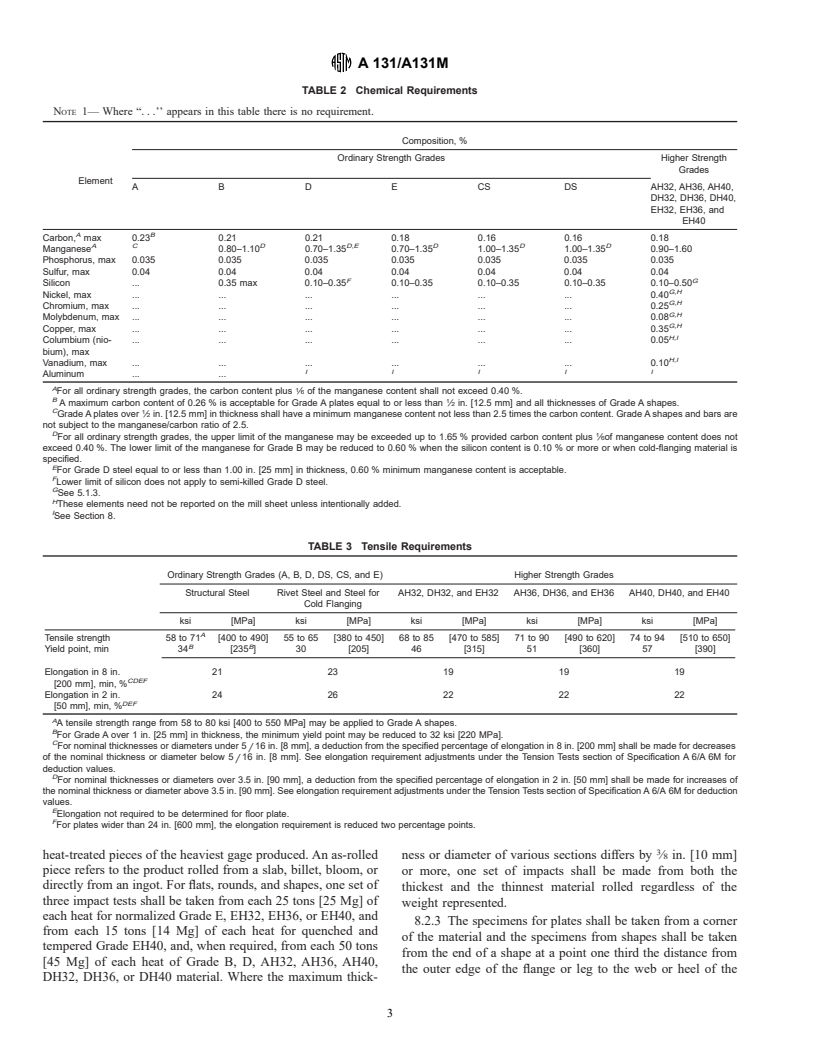

6.1 The heat analysis shall conform to the requirements for

2 2

8.1.1.2 Shapes less than 1 in. [645 mm ] in cross section,

chemical composition prescribed in Table 2.

and bars, other than flats, less than ⁄2in. [12.5 mm] in thickness

6.1.1 The steel shall conform on product analysis to the

or diameter need not be subjected to tension tests by the

requirements prescribed in Table 2, subject to the product

manufacturer.

analysis tolerances in Specification A 6/A 6M, except as speci-

8.1.1.3 The elongation requirement of Table 3 does not

fied in 6.1.2.

apply to material ordered as floor plates with a raised pattern.

6.1.2 Product analysis is not required for bar-size shapes or

However, for floor plates over ⁄2in. [12.5 mm] in thickness,

flat bars ⁄2 in. [12.5 mm] and under in thickness.

test specimens shall be bent cold with the raised pattern on the

6.1.3 When tension tests are waived in accordance

inside of the specimen through an angle of 180° without

with8.1.1.2, chemistry consistent with the mechanical proper-

cracking when subjected to a bend test in which the inside

ties desired must be applied.

diameter is three times plate thickness. Sampling for bend

7. Metallurgical Structure

testing shall be as specified for the tension tests in 8.1.2.

8.1.2 One tension test shall be made from each of two

7.1 Fine grain practice for ordinary strength grades shall be

different plates, shapes, or bars from each heat of structural

met using aluminum. For higher strength grades, aluminum,

steel and steel for cold flanging unless the finished material

vanadium, or columbium may be used as grain refining

from a heat is less than 50 tons [45 Mg], when one tension test

elements.

will be sufficient. If, however, material from one heat differs ⁄8

7.2 Except as modified by 7.2.1, grain size shall be deter-

in. [10 mm] or more in thickness or diameter, one tension test

mined on each heat by the McQuaid-Ehn test of Methods

shall be made from both the thickest and the thinnest material

E 112. The grain size so determined shall be No. 5 or finer in

rolled, regardless of the weight represented.

70 % of the area examined.

8.1.3 Two tension tests shall be made from each heat of rivet

7.2.1 As an alternative to the McQuaid-Ehn test, a fine grain

steel.

practice requirement may be met by a minimum acid-soluble

8.1.4 For Grade EH40, one tension test shall be made on

aluminum content of 0.015 % or minimum total aluminum

each plate as quenched and tempered.

content of 0.020 % for each heat.

8.2 Toughness Tests (material 2 in. [50 mm] and less in

7.2.2 For Grades AH40, DH32, DH36, DH40, EH32, EH36,

thickness):

and EH40 the fine grain practice requirement may also be met

8.2.1 Except as permitted in 8.2.1.1, Charpy V-notch tests

as follows:

shall be made on Grade B material over 1 in. [25 mm] in

7.2.2.1 Minimum columbium (niobium) content of 0.020 %

thickness and on material of Grades D, E, AH32, AH36, DH32,

or minimum vanadium content of 0.050 % for each heat, or

DH36, DH40, EH32, EH36, and EH40. The test results shall

7.2.2.2 When vanadium and aluminum are used in combi-

conform to the requirements of Table 4.

nation, minimum vanadium content of 0.030 % and minimum

8.2.1.1 Toughness tests are not required: ( a) on Grade D

normalized material made fully killed and having a fine

TABLE 1 Heat Treatment Requirements for Higher Strength

A

austenitic grain size, (b) on Grades AH32 and AH36 when

Grades (32, 36, and 40)

normalized, or when 0.5 in. [12.5 mm] or less in thickness

Aluminum-treated steels: when treated with vanadium or columbium (niobium) or 1 ⁄8 in.

AH32 or AH36 Normalizing not required up to and including 2 in. [50 mm] in

[35 mm] or less in thickness when treated with aluminum, and

thickness

(c) on Grades DH32 and DH36 material when normalized.

AH40 Normalizing required over 0.50 in. [12.5 mm]

DH32 or DH36 Normalizing required over 1.0 in. [25 mm] 8.2.2 For plate material, when required, one set of three

DH40, EH32, or EH36 Normalized

impact specimens shall be made from the thickest material in

EH40 Normalized or Quenched and Tempered

each 50 tons [45 Mg] of each heat of Grades B, D, AH32,

Columbium (niobium) or vanadium-treated steels:

AH32 or AH36 Normalizing not required up to and including 2 in. [50 mm] in AH36, AH40, DH32, DH36, and DH40 steels and from each

thickness

rolled product of Grades E, EH32, EH36, and EH40 steels.

AH40, DH32, or DH36 Normalizing required over 0.50 in. [12.5 mm]

When heat testing is called for, a set of three specimens shall

DH40, EH32, or EH36 Normalized

EH40 Normalized or Quenched and Tempered be tested for each 50 tons [45 Mg] of the same type of product

A produced on the same mill from each heat of steel. The set of

When columbium (niobium) or vanadium is used in combination with alumi-

num, heat treatment requirements for columbium or vanadium apply. impact specimens shall be taken from different as-rolled or

A 131/A131M

TABLE 2 Chemical Requirements

NOTE 1— Where “. . .’’ appears in this table there is no requirement.

Composition, %

Ordinary Strength Grades Higher Strength

Grades

Element

A B D E CS DS AH32, AH36, AH40,

DH32, DH36, DH40,

EH32, EH36, and

EH40

A B

Carbon, max 0.23 0.21 0.21 0.18 0.16 0.16 0.18

AC D D,E D D D

Manganese 0.80–1.10 0.70–1.35 0.70–1.35 1.00–1.35 1.00–1.35 0.90–1.60

Phosphorus, max 0.035 0.035 0.035 0.035 0.035 0.035 0.035

Sulfur, max 0.04 0.04 0.04 0.04 0.04 0.04 0.04

F G

Silicon . 0.35 max 0.10–0.35 0.10–0.35 0.10–0.35 0.10–0.35 0.10–0.50

G,H

Nickel, max . . . . . . 0.40

G,H

Chromium, max . . . . . . 0.25

G,H

Molybdenum, max . . . . . . 0.08

G,H

Copper, max . . . . . . 0.35

H,I

Columbium (nio- . . . . . . 0.05

bium), max

H,I

Vanadium, max . . . . . . 0.10

IIIII

Aluminum . .

A 1

For all ordinary strength grades, the carbon content plus ⁄6 of the manganese content shall not exceed 0.40 %.

B

A maximum carbon content of 0.26 % is acceptable for Grade A plates equal to or less than ⁄2 in. [12.5 mm] and all thicknesses of Grade A shapes.

C

Grade A plates over ⁄2 in. [12.5 mm] in thickness shall have a minimum manganese content not less than 2.5 times the carbon content. Grade A shapes and bars are

not subject to the manganese/carbon ratio of 2.5.

D

For all ordinary strength grades, the upper limit of the manganese may be exceeded up to 1.65 % provided carbon content plus ⁄6of manganese content does not

exceed 0.40 %. The lower limit of the manganese for Grade B may be reduced to 0.60 % when the silicon content is 0.10 % or more or when cold-flanging material is

specified.

E

For Grade D steel equal to or less than 1.00 in. [25 mm] in thickness, 0.60 % minimum manganese content is acceptable.

F

Lower limit of silicon does not apply to semi-killed Grade D steel.

G

See 5.1.3.

H

These elements need not be reported on the mill sheet unless intentionally added.

I

See Section 8.

TABLE 3 Tensile Requirements

Ordinary Strength Grades (A, B, D, DS, CS, and E) Higher Strength Grades

Structural Steel Rivet Steel and Steel for AH32, DH32, and EH32 AH36, DH36, and EH36 AH40, DH40, and EH40

Cold Flanging

ksi [MPa] ksi [MPa] ksi [MPa] ksi [MPa] ksi [MPa]

A

Tensile strength 58 to 71 [400 to 490] 55 to 65 [380 to 450] 68 to 85 [470 to 585] 71 to 90 [490 to 620] 74 to 94 [510 to 650]

B B

Yield point, min 34 [235 ] 30 [205] 46 [315] 51 [360] 57 [390]

Elongation in 8 in. 21 23 19 19 19

CDEF

[200 mm], min, %

Elongation in 2 in. 24 26 22 22 22

DEF

[50 mm], min, %

A

A tensile strength range from 58 to 80 ksi [400 to 550 MPa] may be applied to Grade A shapes.

B

For Grade A over 1 in. [25 mm] in thickness, the minimum yield point may be reduced to 32 ksi [220 MPa].

C

For nominal thicknesses or diameters under 5 16 in. [8 mm], a deduction from the specified percentage of elongation in 8 in. [200 mm] shall be made for decreases

/

of the nominal thickness or diameter below 5 16 in. [8 mm]. See elongation requirement adjustments under the Tension Tests section of Specification A 6/A 6M for

/

deduction values.

D

For nominal thicknesses or diameters over 3.5 in. [90 mm], a deduction from the specified percentage of elongation in 2 in. [50 mm] shall be made for increases of

the nominal thickness or diameter above 3.5 in. [90 mm]. See elongation requirement adjustments under the Tension Tests section of Specification A 6/A 6M for deduction

values.

E

Elongation not required to be determined for floor plate.

F

For plates wider than 24 in. [600 mm], the elongation requirement is reduced two percentage points.

heat-treated pieces of the heaviest gage produced. An as-rolled ness or diameter of various sections differs by ⁄8 in. [10 mm]

piece refers to the product rolled from a slab, billet, bloom, or or more, one set of impacts shall be made from both the

directly from an ingot. For flats, rounds, and shapes, one set of

thickest and the thinnest mate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.