ASTM G184-06

(Practice)Standard Practice for Evaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using Rotating Cage

Standard Practice for Evaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using Rotating Cage

SIGNIFICANCE AND USE

Selection of corrosion inhibitor for oil field and refinery applications involves qualification of corrosion inhibitors in the laboratory (see Guide G 170). Field conditions should be simulated in the laboratory in a fast and cost-effective manner (1).3

Oil field corrosion inhibitors should provide protection over a range of flow conditions from stagnant to that found during typical production conditions. Not all inhibitors are equally effective over this range of conditions so it is important for a proper evaluation of inhibitors to test the inhibitors using a range of flow conditions.

The RC test system is relatively inexpensive and uses simple flat specimens that allow replicates to be run with each setup. (2-13).

In this practice, a general procedure is presented to obtain reproducible results using RC to simulate the effects of different types of coupon materials, inhibitor concentrations, oil, gas and brine compositions, temperature, pressure, and flow. Oil field fluids may often contain sand; however, this practice does not cover erosive effects that occur when sand is present.

SCOPE

1.1 This practice covers a generally accepted procedure to use the rotating cage (RC) for evaluating corrosion inhibitors for oil field and refinery applications.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G184 −06

StandardPractice for

Evaluating and Qualifying Oil Field and Refinery Corrosion

Inhibitors Using Rotating Cage

This standard is issued under the fixed designation G184; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D4410 Terminology for Fluvial Sediment

1.1 This practice covers a generally accepted procedure to

3. Terminology

use the rotating cage (RC) for evaluating corrosion inhibitors

for oil field and refinery applications. 3.1 The terminology used throughout shall be in accordance

with Terminologies G15 and D4410 and Guide G170.

1.2 The values stated in SI units are to be regarded as

standard. The values given in parentheses are for information

4. Summary of Practice

only.

4.1 This practice provides a method of evaluating corrosion

1.3 This standard does not purport to address all of the

inhibitor efficiency in a RC apparatus. The method uses a

safety concerns, if any, associated with its use. It is the

well-defined rotating specimen setup and mass loss measure-

responsibility of the user of this standard to establish appro-

ments to determine corrosion rates in a laboratory apparatus.

priate safety and health practices and determine the applica-

Measurements are made at a number of rotation rates to

bility of regulatory limitations prior to use.

evaluate the inhibitor performance under increasingly severe

hydrodynamic conditions.

2. Referenced Documents

2.1 ASTM Standards:

5. Significance and Use

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

5.1 Selection of corrosion inhibitor for oil field and refinery

sion Test Specimens

applicationsinvolvesqualificationofcorrosioninhibitorsinthe

G15 Terminology Relating to Corrosion and CorrosionTest-

laboratory (see Guide G170). Field conditions should be

ing (Withdrawn 2010)

simulated in the laboratory in a fast and cost-effective manner

G16 Guide for Applying Statistics to Analysis of Corrosion

(1).

Data

G31 PracticeforLaboratoryImmersionCorrosionTestingof

5.2 Oil field corrosion inhibitors should provide protection

Metals

over a range of flow conditions from stagnant to that found

G46 Guide for Examination and Evaluation of Pitting Cor-

during typical production conditions. Not all inhibitors are

rosion

equallyeffectiveoverthisrangeofconditionssoitisimportant

G111 Guide for Corrosion Tests in High Temperature or

for a proper evaluation of inhibitors to test the inhibitors using

High Pressure Environment, or Both

a range of flow conditions.

G170 Guide for Evaluating and Qualifying Oilfield and

5.3 The RC test system is relatively inexpensive and uses

Refinery Corrosion Inhibitors in the Laboratory

simple flat specimens that allow replicates to be run with each

D1141 Practice for the Preparation of Substitute Ocean

setup. (2-13).

Water

5.4 In this practice, a general procedure is presented to

obtain reproducible results using RC to simulate the effects of

different types of coupon materials, inhibitor concentrations,

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion

of Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory

oil, gas and brine compositions, temperature, pressure, and

Corrosion Tests.

flow. Oil field fluids may often contain sand; however, this

Current edition approved Jan. 15, 2006. Published February 2006. DOI:

practice does not cover erosive effects that occur when sand is

10.1520/G0184-06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or present.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on The boldface numbers in parentheses refer to the list of references at the end of

www.astm.org. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G184−06

6. Apparatus

6.1 Fig. 1 shows the schematic diagram of the RC system.

An apparatus of suitable size (usually 7500 mL) is used,

consisting of inlet and outlet ports, thermowell, temperature-

regulating device, a heating device (mantle, hot plate, or bath),

and a specimen support system.

6.1.1 The vessel (typically 150-mm diameter) is manufac-

tured from an inert material. Cast acrylic and polytetrafluoro-

ethylene (PTFE) have been used.

6.1.2 A PTFE base is fitted at the bottom of the container.

At the center of the base, a hole is drilled into which the lower

end of a stirring rod is placed. This arrangement stabilizes the

stirrer and the coupons.

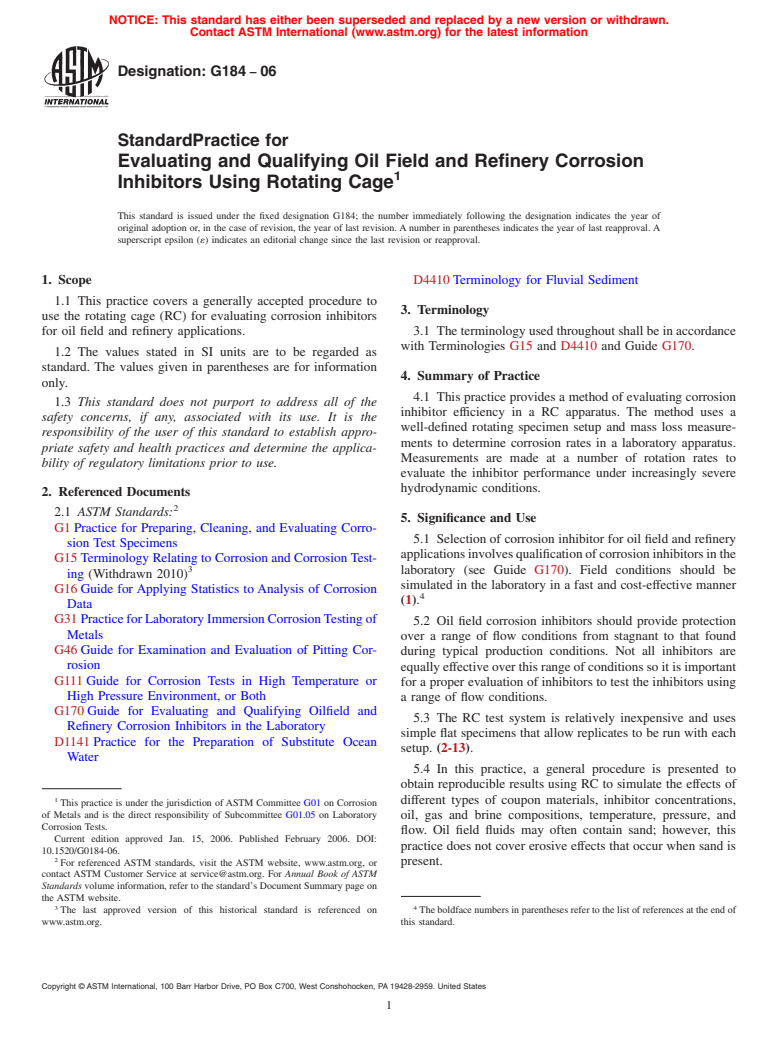

6.1.3 Typically, eight coupons (each of 75-mm length,

19-mm width, and 3-mm thickness, and a surface area of about

34.14 cm ) are supported between two PTFE disks (of 80-mm

diameter) mounted 75 mm apart on the stirring rod (Fig. 2).

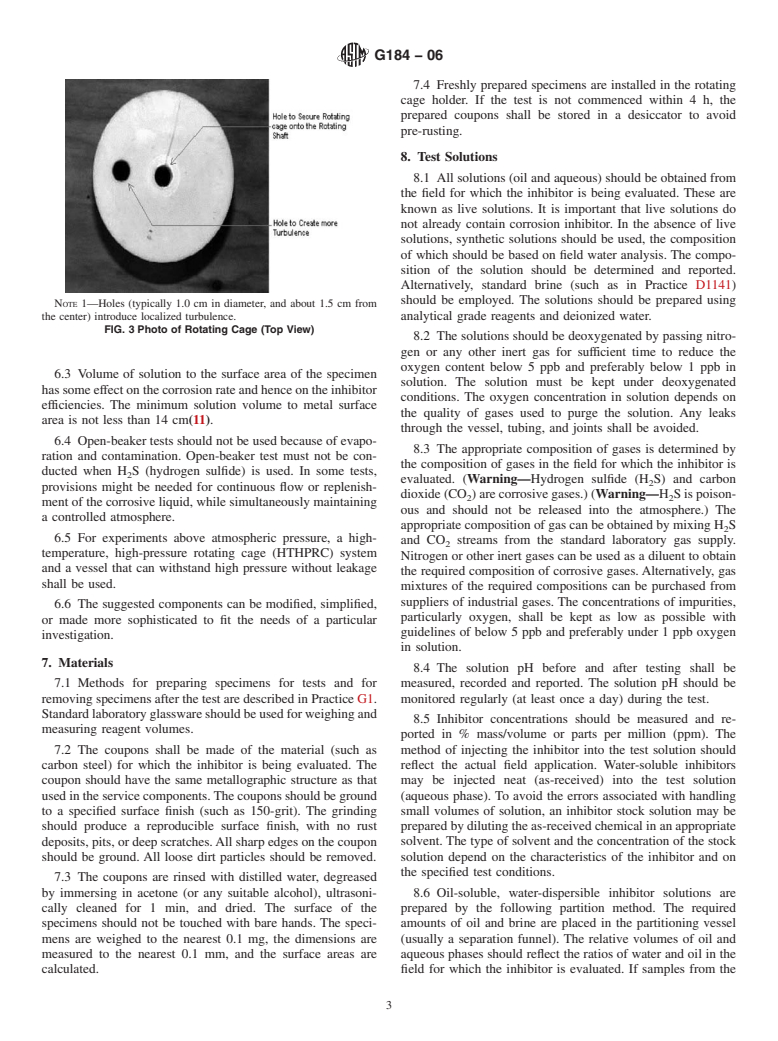

Holes (10-mm diameter) about 15 mm away from the center

are drilled in the top and bottom PTFE plates of the cage to

increase the turbulence on the inside surface of the coupon

(Fig. 3). This experimental setup can be used at temperatures

up to 70°C and rotation speeds up to 1000 rpm.

NOTE 1—Gaps (typically 0.85 6 0.01 cm) between the coupons

introduce localized turbulence.

6.2 The flow pattern varies, depending on the rotation

FIG. 2Photo of Rotating Cage Containing Coupons

speed, the volume of the container, and the fluids. The flow

patterns are described in Guide G170.

FIG. 1Schematic Diagram of Rotating Cage

G184−06

7.4 Freshly prepared specimens are installed in the rotating

cage holder. If the test is not commenced within 4 h, the

prepared coupons shall be stored in a desiccator to avoid

pre-rusting.

8. Test Solutions

8.1 All solutions (oil and aqueous) should be obtained from

the field for which the inhibitor is being evaluated. These are

known as live solutions. It is important that live solutions do

not already contain corrosion inhibitor. In the absence of live

solutions, synthetic solutions should be used, the composition

of which should be based on field water analysis. The compo-

sition of the solution should be determined and reported.

Alternatively, standard brine (such as in Practice D1141)

should be employed. The solutions should be prepared using

NOTE 1—Holes (typically 1.0 cm in diameter, and about 1.5 cm from

the center) introduce localized turbulence. analytical grade reagents and deionized water.

FIG. 3Photo of Rotating Cage (Top View)

8.2 The solutions should be deoxygenated by passing nitro-

gen or any other inert gas for sufficient time to reduce the

oxygen content below 5 ppb and preferably below 1 ppb in

6.3 Volume of solution to the surface area of the specimen

solution. The solution must be kept under deoxygenated

hassomeeffectonthecorrosionrateandhenceontheinhibitor

conditions. The oxygen concentration in solution depends on

efficiencies. The minimum solution volume to metal surface

the quality of gases used to purge the solution. Any leaks

area is not less than 14 cm(11).

through the vessel, tubing, and joints shall be avoided.

6.4 Open-beaker tests should not be used because of evapo-

8.3 The appropriate composition of gases is determined by

ration and contamination. Open-beaker test must not be con-

the composition of gases in the field for which the inhibitor is

ducted when H S (hydrogen sulfide) is used. In some tests,

evaluated. (Warning—Hydrogen sulfide (H S) and carbon

provisions might be needed for continuous flow or replenish-

dioxide(CO )arecorrosivegases.)(Warning—H Sispoison-

2 2

ment of the corrosive liquid, while simultaneously maintaining

ous and should not be released into the atmosphere.) The

a controlled atmosphere.

appropriate composition of gas can be obtained by mixing H S

6.5 For experiments above atmospheric pressure, a high-

and CO streams from the standard laboratory gas supply.

temperature, high-pressure rotating cage (HTHPRC) system

Nitrogen or other inert gases can be used as a diluent to obtain

and a vessel that can withstand high pressure without leakage

the required composition of corrosive gases.Alternatively, gas

shall be used.

mixtures of the required compositions can be purchased from

suppliers of industrial gases. The concentrations of impurities,

6.6 The suggested components can be modified, simplified,

particularly oxygen, shall be kept as low as possible with

or made more sophisticated to fit the needs of a particular

guidelines of below 5 ppb and preferably under 1 ppb oxygen

investigation.

in solution.

7. Materials

8.4 The solution pH before and after testing shall be

7.1 Methods for preparing specimens for tests and for measured, recorded and reported. The solution pH should be

removing specimens after the test are described in Practice G1. monitored regularly (at least once a day) during the test.

Standardlaboratoryglasswareshouldbeusedforweighingand

8.5 Inhibitor concentrations should be measured and re-

measuring reagent volumes.

ported in % mass/volume or parts per million (ppm). The

7.2 The coupons shall be made of the material (such as method of injecting the inhibitor into the test solution should

carbon steel) for which the inhibitor is being evaluated. The reflect the actual field application. Water-soluble inhibitors

coupon should have the same metallographic structure as that may be injected neat (as-received) into the test solution

usedintheservicecomponents.Thecouponsshouldbeground (aqueous phase). To avoid the errors associated with handling

to a specified surface finish (such as 150-grit). The grinding small volumes of solution, an inhibitor stock solution may be

should produce a reproducible surface finish, with no rust preparedbydilutingtheas-receivedchemicalinanappropriate

deposits, pits, or deep scratches.All sharp edges on the coupon solvent. The type of solvent and the concentration of the stock

should be ground. All loose dirt particles should be removed. solution depend on the characteristics of the inhibitor and on

the specified test conditions.

7.3 The coupons are rinsed with distilled water, degreased

by immersing in acetone (or any suitable alcohol), ultrasoni- 8.6 Oil-soluble, water-dispersible inhibitor solutions are

cally cleaned for 1 min, and dried. The surface of the prepared by the following partition method. The required

specimens should not be touched with bare hands. The speci- amounts of oil and brine are placed in the partitioning vessel

mens are weighed to the nearest 0.1 mg, the dimensions are (usually a separation funnel). The relative volumes of oil and

measured to the nearest 0.1 mm, and the surface areas are aqueous phases should reflect the ratios of water and oil in the

calculated. field for which the inhibitor is evaluated. If samples from the

G184−06

field are not available, heptane, kerosine, or any suitable 9.10 The additional gas inlet on top of the vessel should

hydrocarbon may be used. The corrosion inhibitor is added to allow keeping the gas mixture blanket on top of the solution,

the oil phase. The vessel is vigorously shaken for 1 min to mix which is required when the experiment is planned for a longer

bothphasesthoroughly,andthephasesareallowedtoseparate. duration, for example, more than 24 h. Keep the gas flow rate

Heating to the temperature of the field helps in the separation. to a minimum. Take care that the gas does not entrain with the

The aqueous phase is removed and used as test solution. solution.

8.7 Oil-soluble inhibitors (usually as batch inhibitors) are

9.11 Use the speed controller to preset the rotation speed

dissolved in the oil phase to form an inhibited oil-phase. The

and to start the motor. The rotation speed usually stabilizes, as

coupons are exposed to this solution for a certain amount of

displayed by the tachometer, within 30 s. Alternatively the

time (usually 30 min). The coupons are then removed and

rotation speed can be set prior to pumping the solution into the

introduced into the experimental vessel.

vessel.

9. Experimental Procedure for Atmospheric Pressure

9.12 Terminate the experiment (typically after 24 h), and

Experiments

determine the corrosion rate from the amount of metal loss

(afterpropercleaningasdescribedinPracticeG1)asdescribed

9.1 A detailed procedure to determine corrosion rates from

in Practice G31. Examine and evaluate the samples for pitting

mass loss is described in Practice G31.

corrosion as in Guide G46. Calculate the average, standard

9.2 Solutions are usually prepared in a separate container

deviation, and coefficient of variation of the coupons corrosion

called the preparation vessel, pre-saturated with the required

rate for each run using the method presented in Guide G16.If

gas mixture, and preheated to the required temperature. (Pre-

pitting corrosion is observed, then the general corrosion rate

treatment described in Sections 8.4, 8.5, and 8.6 is usually

determined from mass loss could be invalid.

carried out in the preparation vessel.) Transfer solutions from

9.13 Determine inhibitor efficiency at each rotation speed

the preparation vessel to the experimental vessel (described in

and at each inhibitor concentration using the following equa-

Section6)underpositivenitrogenorotherinertgaspressureto

tion:

minimize air contamination during the transfer operation.

C.R 2 C.R

@ # @ #

9.3 Depending on the size of the experimental vessel,

No.inhibitor Inhibitor3100

Inhibitor Efficiency,% 5 (1)

@C.R#

heating unit (mantle, bath, or wrapper around the vessel),

No Inhibitor

difference between room, and experimental temperatures, a

where:

range of temperature may occur within the vessel.Take care to

[C.R] = the corrosion rate in absence of inhibitor,

No.inhibitor

avoid or minimize the temperature differentials. Heat the test

and

vessels slowly (usually at a rate of 0.1°C/s) to avoid overheat-

[C.R] = the corrosion rate in the presence of

inhibitor

ing. The exact protocol depends on the controller, the size and

inhibitor.

output of the heater, and parameters such as vessel size,

amount of liquid, thermal conductivity of liquid, and agitation.

10. Experimental Procedure for High-Temperature,

Maintain the test temperature within 2°C of the specified

High-Pressure Experiments

temperature.

10.1 Ageneralproceduretocarryoutcorrosionexperiments

9.4 Insert pre-weighed coupons (pretreated as necessary,

at elevated pressure and temperature is described in Guide

such as with batch inhibitors), thermometer, and pH probes (as

G11

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.