ASTM G81-97a(2013)

(Test Method)Standard Test Method for Jaw Crusher Gouging Abrasion Test

Standard Test Method for Jaw Crusher Gouging Abrasion Test

SIGNIFICANCE AND USE

5.1 A number of types of jaw crushers have been used for laboratory abrasion tests, see Refs (1-5)4 and a limited amount of data has been published (6-10). With emphasis on the crusher described in Section 6, this test method ranks materials and also indicates differences in wear life for that type of abrasion defined as gouging abrasion, as is found in crushing equipment and in many mining and earthmoving applications. This test method is considered useful for research and development purposes, but not to specify universal wear ratios, since the wear ranking and severity of wear may change dramatically with a change of the characteristics (chemistry, shape, angularity, etc.) of the crushed material or type of machinery.

SCOPE

1.1 This test method covers a laboratory procedure to determine the relative gouging abrasion resistance of materials. Materials homogeneous in structure and properties are the most appropriate test materials; however, surface-treated and composite materials can also be tested. The test involves a small laboratory jaw crusher that crushes presized hard rock materials, such as a hard morainal gravel, or some other crushable substance.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (See 8.1 on Safety Precautions.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G81 − 97a (Reapproved 2013)

Standard Test Method for

1

Jaw Crusher Gouging Abrasion Test

ThisstandardisissuedunderthefixeddesignationG81;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Hardness, Superficial Hardness, Knoop Hardness, Sclero-

scope Hardness, and Leeb Hardness

1.1 This test method covers a laboratory procedure to

E350Test Methods for Chemical Analysis of Carbon Steel,

determinetherelativegougingabrasionresistanceofmaterials.

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and

Materialshomogeneousinstructureandpropertiesarethemost

Wrought Iron

appropriate test materials; however, surface-treated and com-

E691Practice for Conducting an Interlaboratory Study to

posite materials can also be tested. The test involves a small

Determine the Precision of a Test Method

laboratory jaw crusher that crushes presized hard rock

G40Terminology Relating to Wear and Erosion

materials, such as a hard morainal gravel, or some other

crushable substance.

3. Terminology

1.2 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 gouging abrasion—severe form of abrasive wear in

responsibility of the user of this standard to establish appro-

which the force between an abrading body and the wearing

priate safety and health practices and determine the applica-

surface is sufficiently large that a macroscopic gouge, groove,

bility of regulatory limitations prior to use. (See 8.1 on Safety

deep scratch, or indentation can be produced in a single

Precautions.)

contact.

2. Referenced Documents

3.1.2 The definitions of some other related terms may be

2

found in Terminology G40.

2.1 ASTM Standards:

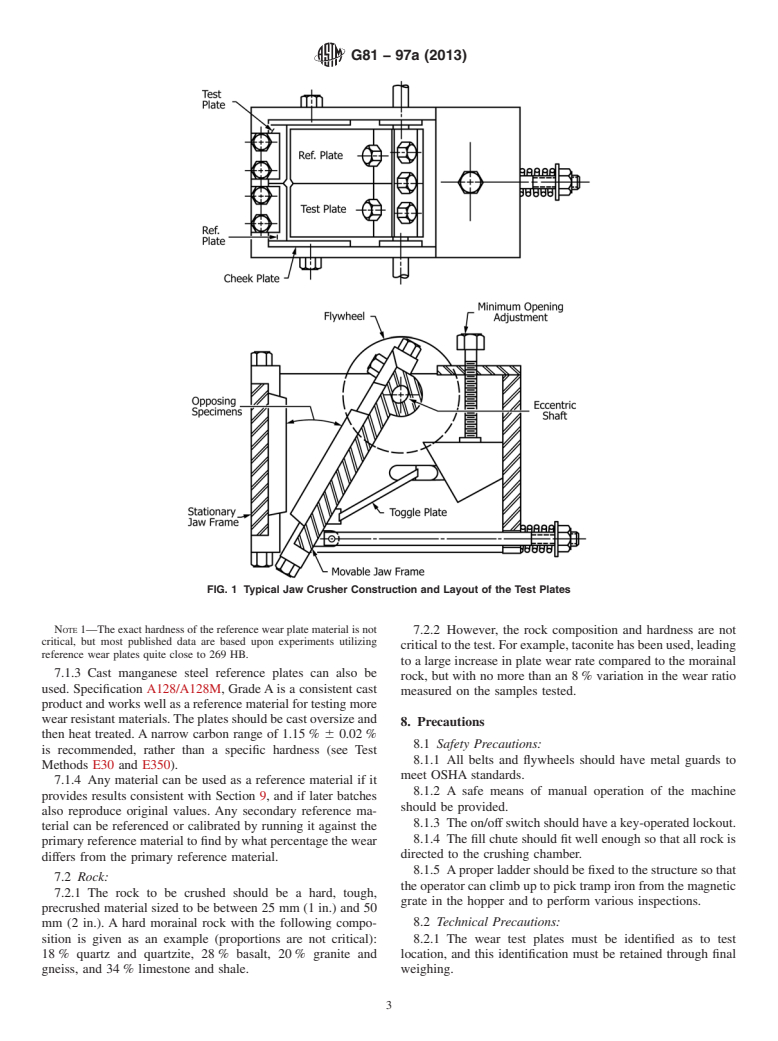

3.2 Definitions of Terms Specific to This Standard:

A128/A128MSpecification for Steel Castings, Austenitic

3.2.1 cheek plates—wear liners that protect the sides of the

Manganese

crusher adjacent to the movable and stationary jaws.

A514/A514M Specification for High-Yield-Strength,

Quenched and Tempered Alloy Steel Plate, Suitable for

3.2.2 movable jaw—part of the crusher that moves against

Welding

the material being crushed.

A517/A517MSpecificationforPressureVesselPlates,Alloy

3.2.3 reference plate—jawplatemadeofamaterialuniform

Steel, High-Strength, Quenched and Tempered

in microstructure and hardness and not varying significantly

E10Test Method for Brinell Hardness of Metallic Materials

from one piece to another; such a plate will give highly

E18Test Methods for Rockwell Hardness of Metallic Ma-

reproducible results, to which other materials to be tested may

terials

be compared.

E30TestMethodsforChemicalAnalysisofSteel,CastIron,

3 3.2.4 stationary jaw—part of the crusher that does not

Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

articulate, but is directly opposite the movable jaw and is in

E140Hardness Conversion Tables for Metals Relationship

direct crushing contact.

Among Brinell Hardness, Vickers Hardness, Rockwell

3.2.5 test plate—jaw plate made of a material for which the

gouging abrasion resistance is to be measured.

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear

3.2.6 toggle plate—plate that holds the bottom edge of the

and Erosion and is the direct responsibility of Subcommittee G02.30 on Abrasive

movable jaw relative to the stationary jaw.

Wear.

Current edition approved Nov. 15, 2013. Published November 2013. Originally

approved in 1983. Last previous edition approved in 2007 as G81–97a(2007). DOI:

4. Summary of Test Method

10.1520/G0081-97AR13.

2

4.1 A small laboratory jaw crusher with a feed opening of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

about 100 by 150 mm (4 by 6 in.) is modified to accept an

Standards volume information, refer to the standard’s Document Summary page on

easily machined identical pair of reference wear plates and a

the ASTM website.

3

pairofsimilartestwearplates.Onetestplateandonereference

The last approved version of this historical standard is referenced on

www.astm.org. plate are attached to the stationary jaw frame of the crusher,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G81 − 97a (2013)

and the other test and reference plate are attached to the removed for rebuilding. The machine should have easily

movable jaw frame, such that a reference plate and a test plate replaceable wear liners for the toggle plate holders.

oppose one another. The minimum

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.