ASTM G81-97a(2007)

(Test Method)Standard Test Method for Jaw Crusher Gouging Abrasion Test

Standard Test Method for Jaw Crusher Gouging Abrasion Test

SIGNIFICANCE AND USE

A number of types of jaw crushers have been used for laboratory abrasion tests, see Refs (1-5)4 and a limited amount of data has been published (6-10). With emphasis on the crusher described in Section 6, this test method ranks materials and also indicates differences in wear life for that type of abrasion defined as gouging abrasion, as is found in crushing equipment and in many mining and earthmoving applications. This test method is considered useful for research and development purposes, but not to specify universal wear ratios, since the wear ranking and severity of wear may change dramatically with a change of the characteristics (chemistry, shape, angularity, etc.) of the crushed material or type of machinery.

SCOPE

1.1 This test method covers a laboratory procedure to determine the relative gouging abrasion resistance of materials. Materials homogeneous in structure and properties are the most appropriate test materials; however, surface-treated and composite materials can also be tested. The test involves a small laboratory jaw crusher that crushes presized hard rock materials, such as a hard morainal gravel, or some other crushable substance.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (See 8.1 on Safety Precautions.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G81 − 97a(Reapproved 2007)

Standard Test Method for

Jaw Crusher Gouging Abrasion Test

ThisstandardisissuedunderthefixeddesignationG81;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Hardness, Superficial Hardness, Knoop Hardness, and

Scleroscope Hardness

1.1 This test method covers a laboratory procedure to

E350Test Methods for Chemical Analysis of Carbon Steel,

determinetherelativegougingabrasionresistanceofmaterials.

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and

Materialshomogeneousinstructureandpropertiesarethemost

Wrought Iron

appropriate test materials; however, surface-treated and com-

E691Practice for Conducting an Interlaboratory Study to

posite materials can also be tested. The test involves a small

Determine the Precision of a Test Method

laboratory jaw crusher that crushes presized hard rock

G40Terminology Relating to Wear and Erosion

materials, such as a hard morainal gravel, or some other

crushable substance.

3. Terminology

1.2 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

3.1.1 gouging abrasion—severe form of abrasive wear in

responsibility of the user of this standard to establish appro-

which the force between an abrading body and the wearing

priate safety and health practices and determine the applica-

surface is sufficiently large that a macroscopic gouge, groove,

bility of regulatory limitations prior to use. (See 8.1 on Safety

deep scratch, or indentation can be produced in a single

Precautions.)

contact.

2. Referenced Documents

3.1.2 The definitions of some other related terms may be

found in Terminology G40.

2.1 ASTM Standards:

3.2 Definitions of Terms Specific to This Standard:

A128/A128MSpecification for Steel Castings, Austenitic

3.2.1 cheek plates—wear liners that protect the sides of the

Manganese

crusher adjacent to the movable and stationary jaws.

A514/A514M Specification for High-Yield-Strength,

Quenched and Tempered Alloy Steel Plate, Suitable for

3.2.2 movable jaw—part of the crusher that moves against

Welding

the material being crushed.

A517/A517MSpecificationforPressureVesselPlates,Alloy

3.2.3 reference plate—jawplatemadeofamaterialuniform

Steel, High-Strength, Quenched and Tempered

in microstructure and hardness and not varying significantly

E10Test Method for Brinell Hardness of Metallic Materials

from one piece to another; such a plate will give highly

E18Test Methods for Rockwell Hardness of Metallic Ma-

reproducible results, to which other materials to be tested may

terials

be compared.

E30TestMethodsforChemicalAnalysisofSteel,CastIron,

3 3.2.4 stationary jaw—part of the crusher that does not

Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

articulate, but is directly opposite the movable jaw and is in

E140Hardness Conversion Tables for Metals Relationship

direct crushing contact.

Among Brinell Hardness, Vickers Hardness, Rockwell

3.2.5 test plate—jaw plate made of a material for which the

gouging abrasion resistance is to be measured.

This test method is under the jurisdiction of ASTM Committee G02 on Wear

3.2.6 toggle plate—plate that holds the bottom edge of the

and Erosion and is the direct responsibility of Subcommittee G02.30 on Abrasive

movable jaw relative to the stationary jaw.

Wear.

Current edition approved July 1, 2007. Published September 2007. Originally

´1

approved in 1983. Last previous edition approved in 2002 as G81–97a(2002) .

4. Summary of Test Method

DOI: 10.1520/G0081-97AR07.

4.1 A small laboratory jaw crusher with a feed opening of

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

about 100 by 150 mm (4 by 6 in.) is modified to accept an

Standards volume information, refer to the standard’s Document Summary page on

easily machined identical pair of reference wear plates and a

the ASTM website.

pairofsimilartestwearplates.Onetestplateandonereference

The last approved version of this historical standard is referenced on

www.astm.org. plate are attached to the stationary jaw frame of the crusher,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G81 − 97a (2007)

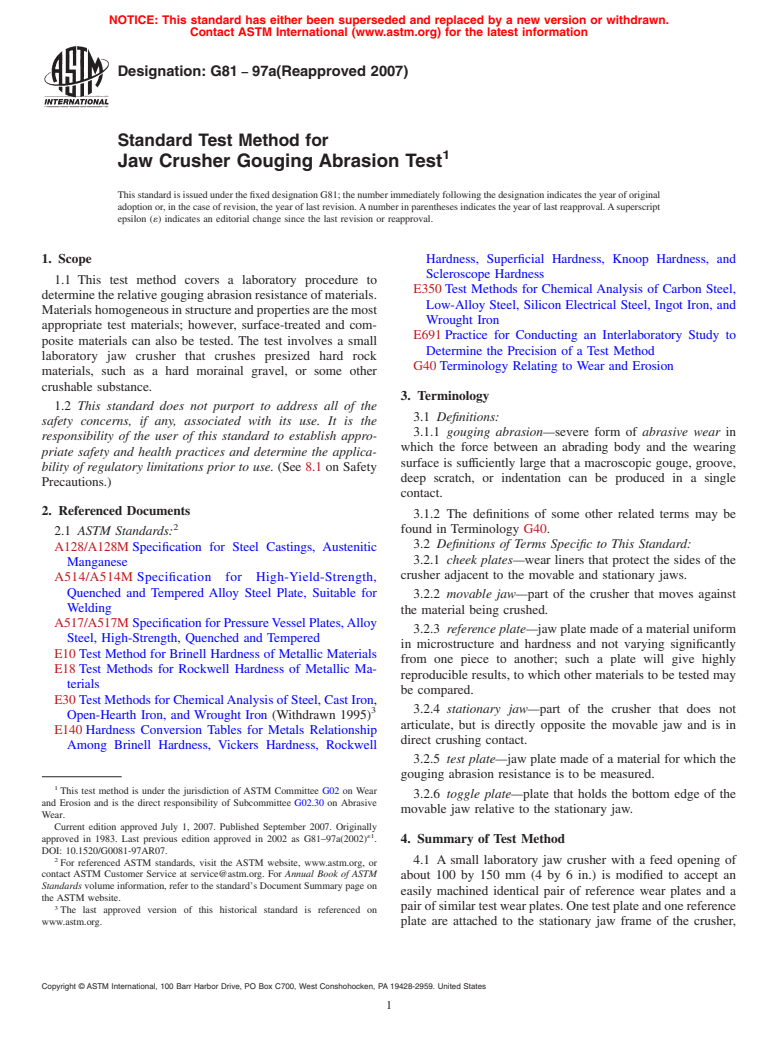

FIG. 1 Typical Jaw Crusher Construction and Layout of the Test Plates

and the other test and reference plate are attached to the testandreferenceplatesareusedthetotalamountofrockmust

movable jaw frame, such that a reference plate and a test plate be increased to 1800 kg (4000 lb) or more.

oppose one another. The minimum jaw opening is set at

5. Significance and Use

3.2mm (0.125 in.), and a 225-kg (500-lb) load of prescreened

material of suitable hardness is run through the crusher. The 5.1 A number of types of jaw crushers have been used for

minimum opening is then reset to 3.2 mm (0.125 in.) and laboratory abrasion tests, see Refs (1-5) and a limited amount

another 225 kg (500 lb) of rock is crushed. This is repeated of data has been published (6-10). With emphasis on the

until a minimum of 900 kg (2000 lb) of rock is crushed. The crusherdescribedinSection6,thistestmethodranksmaterials

precleaned and weighed test plates are then recleaned and and also indicates differences in wear life for that type of

weighed,andthemassloss(ingrams)isrecorded.Thevolume abrasion defined as gouging abrasion, as is found in crushing

loss may be calculated from the mass loss and the known equipment and in many mining and earthmoving applications.

densities of the test materials, or it may be measured for This test method is considered useful for research and devel-

nonmonolithicmaterials.Awearratioisdevelopedbydividing opmentpurposes,butnottospecifyuniversalwearratios,since

the volume loss of the test plate by the volume loss of the thewearrankingandseverityofwearmaychangedramatically

with a change of the characteristics (chemistry, shape, angu-

reference plate. This is done separately for the stationary and

the movable plates. The two wear ratios are then averaged for larity, etc.) of the crushed material or type of machinery.

a final test wear ratio. The smaller the decimal figure for the

wear ratio the better the wear resistance of the test plate 4

The boldface numbers in parentheses refer to a list of references at the end of

compared to the reference plate. When highly wear resistant

this standard.

G81 − 97a (2007)

6. Apparatus 6.8 A method of weighing 225 kg (500 lb) of rock and the

container should be available.

6.1 Ajaw crusher with an approximate feed opening of 100

by 150 mm (4 by 6 in.) is used. This should have a single 6.9 Abalance of sufficient capacity to weigh the test plates

movable jaw and be of very rugged construction (see Fig. 1). is necessary. The sensitivity should be at least 60.1 g.

6.2 The jaw crusher should be capable of accepting two

7. Materials

identical wear plates on the stationary jaw frame and two wear

plates of the same design on the movable jaw frame. Plate

7.1 Reference Plates:

locatingdevicesshouldbeattachedtoholdtheplatestightlyin 7.1.1 Reference plates can be made of any readily available

position. The plate-bottom locating device shall ensure repro-

material that gives wear behavior consistent with Section 9.

ducible positioning of the bottom of each test plate for each 7.1.2 The most common reference wear plate materials are

test. The crusher shaft bearings should be roller or needle

Specification A514/A514M, Grade B steel plate, or Specifica-

bearings to hold consistent tolerances. Spacers may be affixed tion A517/A517M, Grade B plate, quenched and tempered. It

totheshafttopreventthemovableheadfromchangingthegap is suggested that an effort be made to select a plate as close as

on the sides of the jaws. The toggle plate should be easily

possible (68 HB maximum) to 269 HB hardness (see Test

removed for rebuilding. The machine should have easily Methods E10 or E18 and Hardness Conversion Tables E140).

replaceable wear liners for the toggle plate holders.

Alarge plate should be purchased and cut into pieces suitable

to machine into individual plates. The direction of rolling

6.3 Amotor of higher power than a standard crusher motor

should be in the direction of rock flow through the crusher.

may be necessary, since the flat wear plate design takes more

Each new batch should be compared with the previous batch.

powertocrushtherock.A5.2-kW(7-hp)motorhasbeenfound

to be satisfactory for this test method.

NOTE 1—The exact hardness of the reference wear plate material is not

critical, but most published data are based upon experiments utilizing

6.4 Important Tolerances:

reference wear plates quite close to 269 HB.

6.4.1 Toggle Plate Length, +0 to −1.5 mm (+0 to −0.062

7.1.3 Cast manganese steel reference plates can also be

in.).

used. Specification A128/A128M, GradeAis a consistent cast

6.4.2 Wear Liners in Toggle Plate Holders,+0to−0.75mm

productandworkswellasareferencematerialfortestingmore

(+0 to −0.031 in.).

wearresistantmaterials.Theplatesshouldbecastoversizeand

6.4.3 Side to Side Movement of Movable Frame, 60.75mm

then heat treated.Anarrow carbon range of 1.15% 6 0.02%

(60.031 in.).

is recommended, rather than a specific hardness (see Test

6.4.4 Wear Groove in Cheek Plates, no deeper than 6 mm

Methods E30 and E350).

(0.250 in.).

7.1.4 Any material can be used as a reference material if it

6.4.5 Shaft Movement Relative to Crusher Frame, less than

provides results consistent with Section 9, and if later batches

0.25 mm (0.010 in.).

also reproduce original values. Any secondary reference ma-

6.4.6 Movable Jaw Frame Movement Relative to Shaft, less

terial can be referenced or calibrated by running it against the

than 0.25 mm (0.010 in.).

primaryreferencematerialtofindbywhatpercentagethewear

6.4.7 Difference in Toe-to-Toe Spacing, no more than 0.25

differs from the primary reference material.

mm (0.010 in.) across the width of the crusher exit.

7.2 Rock:

6.5 A frame should be made to support the crusher. The

7.2.1 The rock to be crushed should be a hard, tough,

framework must include a hopper above the crusher that will

precrushed material sized to be between 25 mm (1 in.) and 50

holdaminimumof225kg(500lb)ofrockatonetime.Below

mm (2 in.). A hard morainal rock with the following compo-

the hopper a lever-actuated control gate and a chute should be

sition is given as an example (proportions are not critical):

attachedtodelivertherockintothecrusheropening.Belowthe

18% quartz and quartzite, 28% basalt, 20% granite and

crusheraremovableboxmaybeinstalledthatwillhold225kg

gneiss, and 34% limestone and shale.

(500 lb) minimum of crushed rock.This box should have a lid

7.2.2 However, the rock composition and hardness are not

with an opening just below the crusher exit.

criticaltothetest.Forexample,taconitehasbeenused,leading

6.6 An evacuation blower should be installed on the frame

to a large increase in plate wear rate compared to the morainal

to pull dust out of the crushing area and the receiving box and

rock, but with no more than an 8% variation in the wear ratio

move it to an acceptable collection or dump area.Aprotective

measured on the samples tested.

magnetic grate should be installed at the top of the hopper to

collect any tramp iron or steel in the rock.

8. Precautions

6.7 One or more dump boxes are recommended that will

8.1 Safety Precautions:

hold225kg(500lb)ofrock.Thisisforweighingtherockand

8.1.1 All belts and flywheels should have metal guards to

transporting it to the hopper above the crusher.

meet OSHA standards.

8.1.2 A safe means of manual operation of the machine

A Massco laboratory jaw crusher from Mine and Smelter, P.O. Box 16067,

should be provided.

Denver, CO 80216 has been successfully modified for this test. If you are aware of

8.1.3 Theon/offswitchshouldhaveakey-operatedlockout.

alternative suppliers, please provide this information to ASTM International

8.1.4 The fill chute should fit well enough so that all rock is

Headquarters.Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. directed to the crushing chamber.

G81 − 97a (2007)

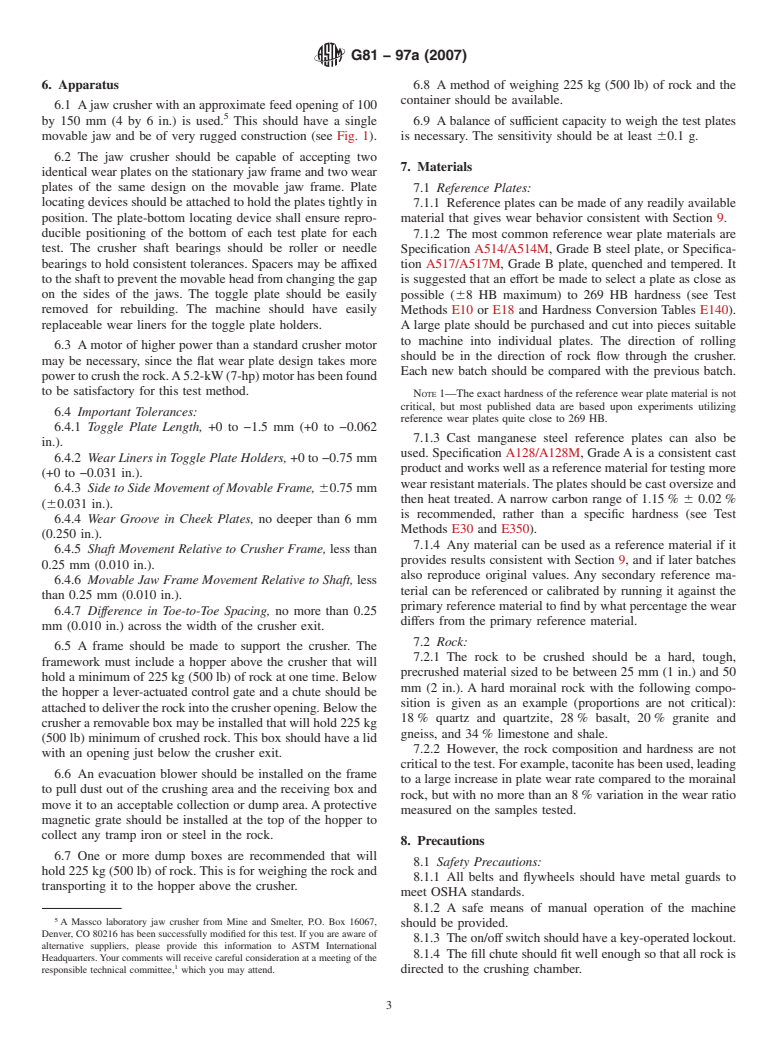

FIG. 2 Example Test Plate Dimensions for Modified Mine and Smelter 100 by 150 mm (4 by 6 in.) Jaw Crusher

8.1.5 Aproperladdershouldbefixedtothestructuresothat 8.2.8 Tolerancesmustbedevelopedforeachcrusherdesign,

theoperatorcanclimbuptopicktrampironfromthemagnetic so as to ensure a constant operation. Fig. 2 includes tolerances

grate in the hopper and to perform various inspections. for a test specimen design that fits the modified laboratory jaw

crusher noted in 6.1.

8.2 Technical Precautions:

8.2.9 Tolerancesmustbemaintainedtokeeptheside-to-side

8.2.1 The wear test plates must be identified as to test

rock flow and crushing even in the crusher. The tolerances are

location, and this identification must be retained through final

given in 6.4.

weighing.

8.2.10 For morainal gravel, the test rock can be slightly

8.2.2 Close tolerances, as noted in Fig. 2, must be kept,

damp but not dripping wet at time of testing. Holding inside a

especially on the toe end of the test plates. This must be

building for 86.4 ks (24 h) prior to test should be adequate if

controlled carefully to achieve a consistent opening and,

thewaterisallowedtodrainawayfromtherock.Formaterials

therefore, a consistent rock flow across the test specimen.

other than morainal gravel, the effects of moisture have not

8.2.3 All decarburized metal should be machined from the

been studied.

test surface and edges prior to testing (see Fig. 2).

8.2.11 Observe the crushed rock size when the testing

8.2.4 Any heat-affected zone from torch cutting should be

facility is first put into operation. If the final crushed rock size

removed from the test plates.

gets noticeably larger as machine use continues, then the

8.2.5 Samplesfortestingshouldbeselectedfromauniform

machine tolerances and calibration should be checked.

material lot using accepted statistical practice.

8.2.6 If heat treatment is required, the test specimen blank

9. Calibration and Standardization

should be heat treated prior to machining to size. The heat

treatmentmustbeidenticalforbothtestplatesthatconstitutea

9.1 Calibration:

single test.

9.1.1 The test is calibrated by running three full tests using

8.2.7 The test specimen should be finished to final size by

new plates for each test. All plates are of the same reference

grinding. Steps sho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.