ASTM A999/A999M-11

(Specification)Standard Specification for General Requirements for Alloy and Stainless Steel Pipe

Standard Specification for General Requirements for Alloy and Stainless Steel Pipe

SCOPE

1.1 This specification covers a group of general requirements that, unless otherwise specified in an individual specification, shall apply to the ASTM product specifications noted below.

1.2 In the case of conflict between a requirement of a product specification and a requirement of this specification, the product specification shall prevail. In the case of conflict between a requirement of the product specification or a requirement of this specification and a more stringent requirement of the purchase order, the purchase order shall prevail.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A999/A999M – 11

Standard Specification for

1

General Requirements for Alloy and Stainless Steel Pipe

This standard is issued under the fixed designationA999/A999M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* SI units are shown in brackets. The values stated in each

2

system may not be exact equivalents; therefore, each system

1.1 This specification covers a group of general require-

shall be used independently of the other. Combining values

ments that, unless otherwise specified in an individual speci-

from the two systems may result in non-conformance with the

fication, shall apply to the ASTM product specifications noted

standard. The inch-pound units apply unless the “M” designa-

below.

tion (SI) of the product specification is specified in the order.

1.2 In the case of conflict between a requirement of a

product specification and a requirement of this specification,

NOTE 1—The dimensionless designator NPS (nominal pipe size) is

the product specification shall prevail. In the case of conflict

used in this standard for such traditional terms as “nominal diameter,”

“size,” “ nominal bore,” and “nominal size.”

between a requirement of the product specification or a

requirement of this specification and a more stringent require-

1.4 The following precautionary statement pertains only to

ment of the purchase order, the purchase order shall prevail.

the test method portion, Section 22, of this specification: This

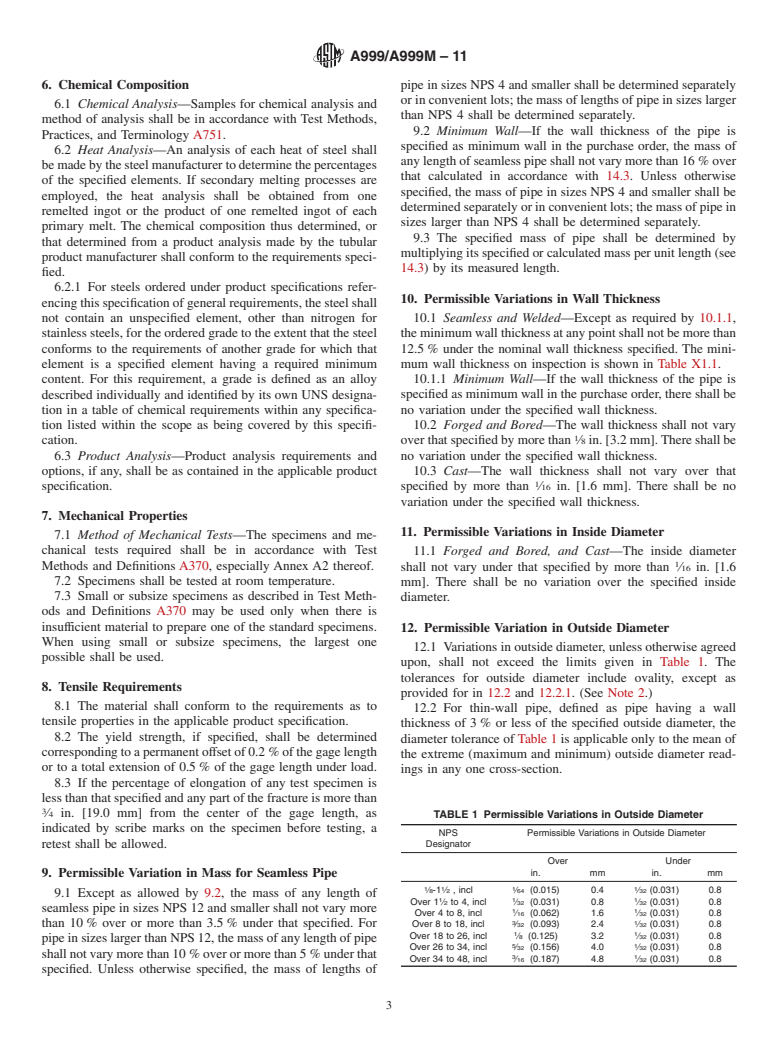

Title of Specification ASTM Desig-

standard does not purport to address all of the safety concerns,

3

nation

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

Seamless and Welded Austenitic Stainless Steel Pipes A312/A312M

Seamless and Welded Steel Pipe for Low-Temperature A333/A333M

practices and determine the applicability of regulatory limita-

Service

tions prior to use.

Seamless Ferritic Alloy-Steel Pipe for High Temperature A335/A335M

Service

2. Referenced Documents

Electric-Fusion-Welded Austenitic Chromium-Nickel Alloy A358/A358M

Steel Pipe for High-Temperature Service

4

2.1 ASTM Standards:

Carbon and Ferritic Alloy Steel Forged and Bored Pipe for A369/A369M

A312/A312M Specification for Seamless, Welded, and

High-Temperature Service

Seamless Austenitic Steel Pipe for Use With High A376/A376M

Heavily Cold Worked Austenitic Stainless Steel Pipes

Temperature Central-Station Service

A333/A333M Specification for Seamless and Welded Steel

Welded Large Diameter Austenitic Steel Pipe for Corrosive A409/A409M

Pipe for Low-Temperature Service

or High-Temperature Service

Welded, Unannealed Austenitic Stainless Steel Tubular A778

A335/A335M Specification for Seamless Ferritic Alloy-

Products

Steel Pipe for High-Temperature Service

Seamless and Welded Ferritic/Austenitic A790/A790M

Stainless Steel Pipe A358/A358M Specification for Electric-Fusion-Welded

Single- or Double-Welded Austenitic Stainless Steel Pipe A813/A813M

Austenitic Chromium-Nickel Stainless Steel Pipe for

Cold-Worked Welded Austenitic Stainless Steel Pipe A814/A814M

High-Temperature Service and General Applications

Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric A928/A928M

Fusion Welded with Addition of Filler Metal A369/A369M Specification for Carbon and Ferritic Alloy

Spray-Formed Seamless Austenitic Stainless Steel Pipe A943/A943M

Steel Forged and Bored Pipe for High-Temperature Ser-

Spray-Formed Seamless Ferritic/Austenitic Stainless Steel A949/A949M

vice

Pipe

Austenitic Chromium-Nickel-Silicon Alloy Steel Seamless A954 A370 Test Methods and Definitions for Mechanical Testing

and Welded Pipe

of Steel Products

A376/A376M Specification for Seamless Austenitic Steel

1.3 The values stated in either SI units or inch-pound units

Pipe for High-Temperature Central-Station Service

are to be regarded separately as standard. Within the text, the

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.10 on Stainless and Alloy Steel Tubular Products.

Current edition approved May 15, 2011. Published June 2011. Originally

approved in 1998. Last previous edition approved in 2009 as A999/

´1

A999M – 04a(2009) . DOI: 10.1520/A0999_A0999M-11.

2 4

For ASME Boiler and Pressure Vessel Code applications see related Specifi- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

cation SA 999 in Section II of that Code. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

These designations refer to the latest

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:A999/A999M–04a (Reapproved 2009) Designation: A999/A999M – 11

Standard Specification for

1

General Requirements for Alloy and Stainless Steel Pipe

This standard is issued under the fixed designationA999/A999M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Table X1.1 editorially corrected in October, 2009.

1. Scope*

2

1.1 This specification covers a group of general requirements that, unless otherwise specified in an individual specification,

shall apply to the ASTM product specifications noted below.

1.2 In the case of conflict between a requirement of a product specification and a requirement of this specification, the product

specification shall prevail. In the case of conflict between a requirement of the product specification or a requirement of this

specification and a more stringent requirement of the purchase order, the purchase order shall prevail.

Title of Specification ASTM Desig-

3

nation

Seamless and Welded Austenitic Stainless Steel Pipes A312/A312M

Seamless and Welded Steel Pipe for Low-Temperature A333/A333M

Service

Seamless Ferritic Alloy-Steel Pipe for High Temperature A335/A335M

Service

Electric-Fusion-Welded Austenitic Chromium-Nickel Alloy A358/A358M

Steel Pipe for High-Temperature Service

Carbon and Ferritic Alloy Steel Forged and Bored Pipe for A369/A369M

High-Temperature Service

Seamless Austenitic Steel Pipe for Use With High A376/A376M

Temperature Central-Station Service

Welded Large Diameter Austenitic Steel Pipe for Corrosive A409/A409M

or High-Temperature Service

Welded, Unannealed Austenitic Stainless Steel Tubular A778

Products

Seamless and Welded Ferritic/Austenitic A790/A790M

Stainless Steel Pipe

Single- or Double-Welded Austenitic Stainless Steel Pipe A813/A813M

Cold-Worked Welded Austenitic Stainless Steel Pipe A814/A814M

Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric A928/A928M

Fusion Welded with Addition of Filler Metal

Spray-Formed Seamless Austenitic Stainless Steel Pipe A943/A943M

Spray-Formed Seamless Ferritic/Austenitic Stainless Steel A949/A949M

Pipe

Austenitic Chromium-Nickel-Silicon Alloy Steel Seamless A954

and Welded Pipe

1.3 The values stated in either inch-poundSI units or SIinch-pound units are to be regarded separately as standard. Within the

text, the SI units are shown in brackets. The values stated in each system aremay not be exact equivalents; therefore, each system

is to shall be used independently of the other without combining other. Combining values from the two systems may result in any

way. non-conformance with the standard. The inch-pound units apply unless the “M” designation (SI) of the product specification

is specified in the order.

NOTE 1—The dimensionless designator NPS (nominal pipe size) is used in this standard for such traditional terms as “nominal diameter,” “size,” “

nominal bore,” and “nominal size.”

1.4 The following precautionary statement pertains only to the test method portion, Section 22, of this specification: This

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.10

on Stainless and Alloy Steel Tubular Products.

Current edition approved Oct. 1, 2009. Published February 2010. Originally approved in 1998. Last previous edition approved in 2004 as A999/A999M–04a. DOI:

10.1520/A0999_A0999M-04AR09E01.

´1

Current edition approved May 15, 2011. Published June 2011. Originally approved in 1998. Last previous edition approved in 2009 asA999/A999M – 04a(2009) . DOI:

10.1520/A0999_A0999M-11.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SA 999 in Section II of that Code.

3

These designations refer to the latest issue of the respective specifications. See Annual Book of ASTM Standards, Vol 01.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A999/A999M – 11

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regul

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A999/A999M–04a (Reapproved 2009) Designation: A999/A999M – 11

Standard Specification for

1

General Requirements for Alloy and Stainless Steel Pipe

This standard is issued under the fixed designationA999/A999M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

2

1.1 This specification covers a group of general requirements that, unless otherwise specified in an individual specification,

shall apply to the ASTM product specifications noted below.

1.2 In the case of conflict between a requirement of a product specification and a requirement of this specification, the product

specification shall prevail. In the case of conflict between a requirement of the product specification or a requirement of this

specification and a more stringent requirement of the purchase order, the purchase order shall prevail.

Title of Specification ASTM Desig-

3

nation

Seamless and Welded Austenitic Stainless Steel Pipes A312/A312M

Seamless and Welded Steel Pipe for Low-Temperature A333/A333M

Service

Seamless Ferritic Alloy-Steel Pipe for High Temperature A335/A335M

Service

Electric-Fusion-Welded Austenitic Chromium-Nickel Alloy A358/A358M

Steel Pipe for High-Temperature Service

Carbon and Ferritic Alloy Steel Forged and Bored Pipe for A369/A369M

High-Temperature Service

Seamless Austenitic Steel Pipe for Use With High A376/A376M

Temperature Central-Station Service

Welded Large Diameter Austenitic Steel Pipe for Corrosive A409/A409M

or High-Temperature Service

Welded, Unannealed Austenitic Stainless Steel Tubular A778

Products

Seamless and Welded Ferritic/Austenitic A790/A790M

Stainless Steel Pipe

Single- or Double-Welded Austenitic Stainless Steel Pipe A813/A813M

Cold-Worked Welded Austenitic Stainless Steel Pipe A814/A814M

Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric A928/A928M

Fusion Welded with Addition of Filler Metal

Spray-Formed Seamless Austenitic Stainless Steel Pipe A943/A943M

Spray-Formed Seamless Ferritic/Austenitic Stainless Steel A949/A949M

Pipe

Austenitic Chromium-Nickel-Silicon Alloy Steel Seamless A954

and Welded Pipe

1.3 The values stated in either inch-poundSI units or SIinch-pound units are to be regarded separately as standard. Within the

text, the SI units are shown in brackets. The values stated in each system aremay not be exact equivalents; therefore, each system

is to shall be used independently of the other without combining other. Combining values from the two systems may result in any

way. non-conformance with the standard. The inch-pound units apply unless the “M” designation (SI) of the product specification

is specified in the order.

NOTE 1—The dimensionless designator NPS (nominal pipe size) is used in this standard for such traditional terms as “nominal diameter,” “size,” “

nominal bore,” and “nominal size.”

1.4 The following precautionary statement pertains only to the test method portion, Section 22, of this specification: This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.10

on Stainless and Alloy Steel Tubular Products.

Current edition approved Oct. 1, 2009. Published February 2010. Originally approved in 1998. Last previous edition approved in 2004 as A999/A999M–04a. DOI:

10.1520/A0999_A0999M-04aR09.

´1

Current edition approved May 15, 2011. Published June 2011. Originally approved in 1998. Last previous edition approved in 2009 asA999/A999M – 04a(2009) . DOI:

10.1520/A0999_A0999M-11.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SA 999 in Section II of that Code.

3

These designations refer to the latest issue of the respective specifications. See Annual Book of ASTM Standards, Vol 01.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A999/A999M – 11

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

4

2.1 ASTM

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.