ASTM A1091/A1091M-21

(Specification)Standard Specification for Steel Castings, Creep-Strength Enhanced Ferritic Alloy, for Pressure-Containing Parts, Suitable for High-Temperature Service

Standard Specification for Steel Castings, Creep-Strength Enhanced Ferritic Alloy, for Pressure-Containing Parts, Suitable for High-Temperature Service

ABSTRACT

This specification covers general requirements for creep-strength enhanced alloy steel castings for valves, flanges, fittings, and other pressure-containing parts intended primarily for high-temperature service. However, the castings are not restricted to such applications, and may be used for other applications for which the attributes of the material, as defined by this specification, are suitable. The specification includes one grade of martensitic alloy steel, Grade C91, which is provided in two classes, differentiated by the type of heat treatment after weld repairs.

This specification also prescribes the general conditions for delivery, including those for investment castings, as well as the requirements for ordering information; materials and manufacture (heat-treatment and machining); chemical composition; testing of mechanical properties (tensile testing and hardness testing); quality of castings; rework, weld repair, and retreatment; and certification and marking of castings.

SCOPE

1.1 This specification covers creep-strength enhanced alloy steel castings for valves, flanges, fittings, and other pressure-containing parts intended primarily for high-temperature service (see Note 1). However, they are not restricted to such applications and the castings may be used for other applications for which the attributes of the material, as defined by this specification, are suitable.

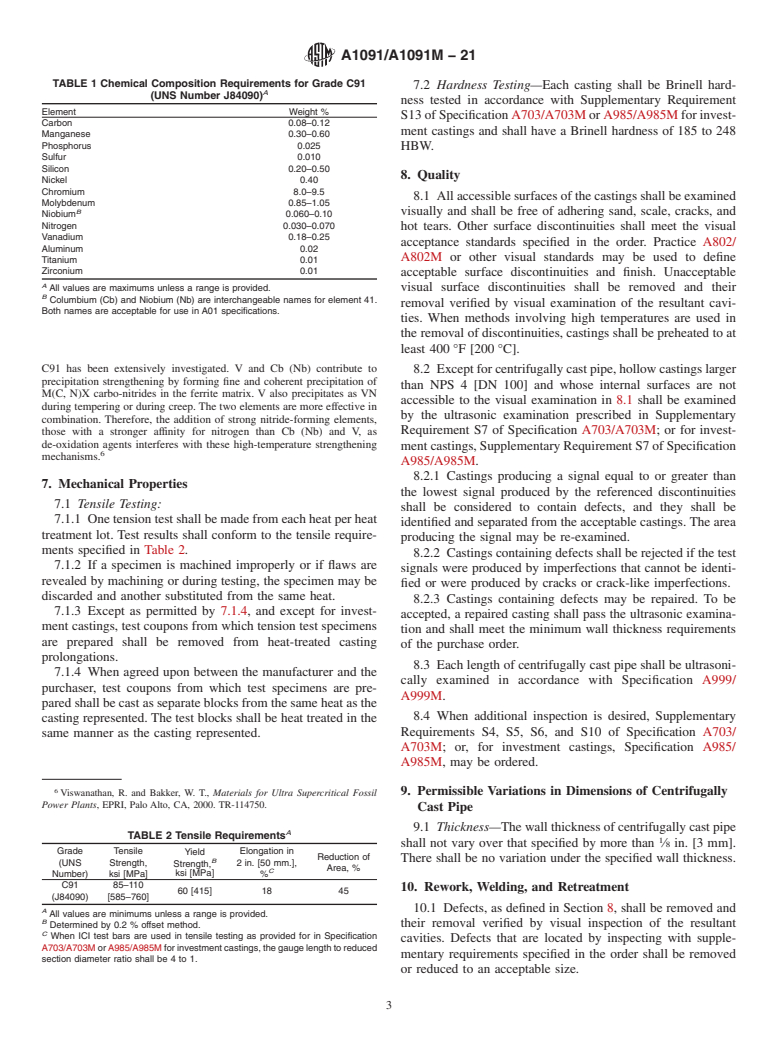

1.2 One grade of martensitic alloy steel, Grade C91 (UNS Number J84090), is covered (see Note 2). It is provided in two classes, differentiated by the type of heat treatment after welding. This and similar steels are characterized by a predominantly tempered martensitic or tempered Bainitic microstructure that is stabilized by the precipitation of temper-resistant particles at various precipitate nucleation sites in the microstructure. Such steels are designed to have creep-rupture strengths significantly superior to those of alloys of nominally similar compositions, but in which the precipitates or nucleation sites are absent. Since this crucial difference cannot be revealed by room-temperature mechanical property tests, these alloys require tighter controls on manufacturing and processing.

Note 1: The grades covered by this specification represent materials that are generally suitable for assembly with other castings or wrought steel parts by fusion welding. It is not intended to imply that these grades possess equal degrees of weldability; therefore, it is the responsibility of the purchaser to establish a suitable welding technique. Since these grades possess varying degrees of suitability for high-temperature service, it is also the responsibility of the purchaser to determine which grade shall be furnished, due consideration being given to the requirements of the applicable construction codes.

Note 2: The committee formulating this specification has included one grade of material that is considered to represent a type of ferritic alloy steel suitable for valves, flanges, fittings, and other pressure-containing parts. Additional alloy steels will be considered for inclusion in this specification by the committee as the need becomes apparent.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A1091/A1091M −21

Standard Specification for

Steel Castings, Creep-Strength Enhanced Ferritic Alloy, for

Pressure-Containing Parts, Suitable for High-Temperature

1

Service

This standard is issued under the fixed designation A1091/A1091M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

1.1 This specification covers creep-strength enhanced alloy

each system may not be exact equivalents; therefore, each

steel castings for valves, flanges, fittings, and other pressure-

system shall be used independently of the other. Combining

containing parts intended primarily for high-temperature ser-

values from the two systems may result in nonconformance

vice (see Note 1). However, they are not restricted to such

with the standard.

applications and the castings may be used for other applica-

1.4 This international standard was developed in accor-

tions for which the attributes of the material, as defined by this

dance with internationally recognized principles on standard-

specification, are suitable.

ization established in the Decision on Principles for the

1.2 One grade of martensitic alloy steel, Grade C91 (UNS

Development of International Standards, Guides and Recom-

Number J84090), is covered (see Note 2). It is provided in two

mendations issued by the World Trade Organization Technical

classes, differentiated by the type of heat treatment after

Barriers to Trade (TBT) Committee.

welding. This and similar steels are characterized by a pre-

dominantly tempered martensitic or tempered Bainitic micro-

2. Referenced Documents

structure that is stabilized by the precipitation of temper-

2

2.1 ASTM Standards:

resistant particles at various precipitate nucleation sites in the

A703/A703M Specification for Steel Castings, General

microstructure. Such steels are designed to have creep-rupture

Requirements, for Pressure-Containing Parts

strengths significantly superior to those of alloys of nominally

A802/A802M Practice for Steel Castings, Surface Accep-

similar compositions, but in which the precipitates or nucle-

tance Standards, Visual Examination

ation sites are absent. Since this crucial difference cannot be

A985/A985M Specification for Steel Investment Castings

revealed by room-temperature mechanical property tests, these

General Requirements, for Pressure-Containing Parts

alloys require tighter controls on manufacturing and process-

A999/A999M Specification for General Requirements for

ing.

Alloy and Stainless Steel Pipe

NOTE 1—The grades covered by this specification represent materials

3

that are generally suitable for assembly with other castings or wrought

2.2 ANSI Standard:

steel parts by fusion welding. It is not intended to imply that these grades

ANSI B46.1 Surface Texture

possess equal degrees of weldability; therefore, it is the responsibility of

4

2.3 ASME Boiler and Pressure Vessel Code:

the purchaser to establish a suitable welding technique. Since these grades

ASME Boiler and Pressure Vessel Code Section I

possess varying degrees of suitability for high-temperature service, it is

also the responsibility of the purchaser to determine which grade shall be

ASME Boiler and Pressure Vessel Code Section III

furnished, due consideration being given to the requirements of the

ASME Boiler and Pressure Vessel Code Section IV

applicable construction codes.

ASME Boiler and Pressure Vessel Code Section VIII

NOTE2—Thecommitteeformulatingthisspecificationhasincludedone

ASME Boiler and Pressure Vessel Code Section IX

grade of material that is considered to represent a type of ferritic alloy

ASME Boiler and Pressure Vessel Code Section XII

steel suitable for valves, flanges, fittings, and other pressure-containing

parts. Additional alloy steels will be considered for inclusion in this

specification by the committee as the need becomes apparent.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel, the ASTM website.

3

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

A01.18 on Ca

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: A1091/A1091M − 16 A1091/A1091M − 21

Standard Specification for

Steel Castings, Creep-Strength Enhanced Ferritic Alloy, for

Pressure-Containing Parts, Suitable for High Temperature

1

High-Temperature Service

This standard is issued under the fixed designation A1091/A1091M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Table 3 was editorially corrected in April 2017.

1. Scope Scope*

1.1 This specification covers creep-strength enhanced alloy steel castings for valves, flanges, fittings, and other pressure-

containing parts intended primarily for high-temperature service (see Note 1). However, they are not restricted to such

applications,applications and the castings may be used for other applications for which the attributes of the material, as defined

by this specification, are suitable.

1.2 One grade of martensitic alloy steel, Grade C91, C91 (UNS Number J84090), is covered (see Note 2). It is provided in two

classes, differentiated by the type of heat treatment after weld repairs. welding. This and similar steels are characterized by a

predominantly tempered martensitic or tempered Bainitic microstructure that is stabilized by the precipitation of temper-resistant

particles at various precipitate nucleation sites in the microstructure. Such steels are designed to have creep-rupture strengths

significantly superior to those of alloys of nominally similar compositions, but in which the precipitates or nucleation sites are

absent. Since this crucial difference cannot be revealed by room-temperature mechanical property tests, these alloys require tighter

controls on manufacturing and processing.

NOTE 1—The grades covered by this specification represent materials that are generally suitable for assembly with other castings or wrought steel parts

by fusion welding. It is not intended to imply that these grades possess equal degrees of weldability; therefore, it is the responsibility of the purchaser

to establish a suitable welding technique. Since these grades possess varying degrees of suitability for high-temperature service, it is also the responsibility

of the purchaser to determine which grade shall be furnished, due consideration being given to the requirements of the applicable construction codes.

NOTE 2—The committee formulating this specification has included one grade of material that is considered to represent a type of ferritic alloy steel

suitable for valves, flanges, fittings, and other pressure-containing parts. Additional alloy steels will be considered for inclusion in this specification by

the committee as the need becomes apparent.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformancenonconformance with the standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.18

on Castings.

Current edition approved May 1, 2016May 1, 2021. Published May 2016June 2021. Originally approved in 2016. Last previous edition approved in 2016 as

A1091/A1091M – 16. DOI: 10.1520/A1091_A1091M-16E01.10.1520/A1091_A1091M-21.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A1091/A1091M − 21

2. Referenced Documents

2

2.1 ASTM Standards:

A335/A335M Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service

A703/A703M Specification for Steel Castings, General Requirements, for Pressure-Containing Parts

A802/A802M Practice for Steel Castings, Surface Acceptance Standards, Visual Examination

A985/A985M Specification for Steel Investment Castin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.