ASTM B105-00

(Specification)Standard Specification for Hard-Drawn Copper Alloy Wires for Electric Conductors

Standard Specification for Hard-Drawn Copper Alloy Wires for Electric Conductors

SCOPE

1.1 This specification covers hard-drawn round copper alloy wires for electric conductors.

1.2 The copper alloy wires shall be made in any one of ten distinct alloys designated 8.5 to 85 in accordance with their increasing conductivities or designated by assigned UNS numbers as follows: Copper Alloy UNS Copper Alloy UNS No. No. Alloy 8.5 C65100 Alloy 40 Alloy 13 C51000 Alloy 55 C16500 Alloy 15 Alloy 74 C19600 Alloy 20 Alloy 80 C16200 Alloy 30 C50700 Alloy 85 C16200

1.3 The SI values of density and resistivity are to be regarded as standard. For all other properties the inch-pound values are to regarded as standard, and the SI values may be approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 105 – 00

Standard Specification for

Hard-Drawn Copper Alloy Wires for Electric Conductors

This standard is issued under the fixed designation B 105; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Used as Electrical Conductors

E 527 Practice for Numbering Metals and Alloys (UNS)

1.1 Thisspecificationcovershard-drawnroundcopperalloy

2.3 Other Document:

wires for electric conductors.

NBS Handbook 100—Copper Wire Tables

1.2 The copper alloy wires shall be made in any one of ten

distinct alloys designated 8.5 to 85 in accordance with their

3. Ordering Information

increasing conductivities or designated by assigned UNS

3.1 Orders for material under this specification should

numbers as follows:

include the following information:

Copper Alloy Copper Alloy

3.1.1 Quantity of each size and grade,

UNS UNS

No. No.

3.1.2 Wire size: diameter in inches or millimetres (see 9.1

and Table 1),

Alloy 8.5 C65100 Alloy 40

3.1.3 Alloy (see 1.2 and Table 1),

Alloy 13 C51000 Alloy 55 C16500

Alloy 15 Alloy 74 C19600

3.1.4 Special composition limits, if required (see 5.2),

Alloy 20 Alloy 80 C16200

3.1.5 Package size (see 14.1),

Alloy 30 C50700 Alloy 85 C16200

3.1.6 Special package marking, if required, and

NOTE 1—The UNS system for copper and copper alloys (see Practice

3.1.7 Place of inspection (see 13.1).

E 527) is a simple expansion of the former standard designation system

accomplished by the addition of a prefix “C” and a suffix “00”. The suffix

4. Material and Manufacture

can be used to accommodate composition variations of the base alloy.

4.1 The material used shall be copper alloys of such nature

1.3 The SI values of density and resistivity are to be

andcompositionastosecurebypropertreatmenttheproperties

regarded as standard. For all other properties the inch-pound

prescribed in this specification for the finished wire.

values are to regarded as standard, and the SI values may be

approximate.

5. Chemical Composition

5.1 The copper alloy wires shall conform to the require-

2. Referenced Documents

ments of Table 2 as to chemical composition. The values

2.1 The following documents of the issue in effect on the

prescribed in Table 2 cover limits of composition of the

date of material purchase form a part of this specification to the

different alloys which may be supplied (see Note 2).

extent referenced herein.

NOTE 2—It is the intention of this specification to permit under each of

2.2 ASTM Standards:

the alloys listed in 1.2 any alloy coming within the total range of analysis

B 193 Test Method for Resistivity of Electrical Conductor

specified in Section 5, provided the product conforms to the other

Materials

requirements of this specification. For purposes of information only, the

B 258 Specification for Standard Nominal Diameters and

types of alloy now commonly used for each of the several alloys are listed

Cross-SectionalAreasofAWGSizesofSolidRoundWires

below. Certain alloys that have a “commercial standing” may have been

assignedaUNSdesignation(see1.2).Thechemicalcompositionofanyof

the materials shall be within the total range specified in Section 5, but in

This specification is under the jurisdiction of the ASTM Committee B-1 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

Conductors of Copper and Copper Alloys.

Current edition approved April 10, 2000. Published June 2000. Originally Annual Book of ASTM Standards, Vol 01.01.

published as B 105 – 36 T. Last previous edition B 105 – 94. Available from the National Technical Information Service, 5285 Port Royal

Annual Book of ASTM Standards, Vol 02.03. Rd, Springfield, VA 22161.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 105

A

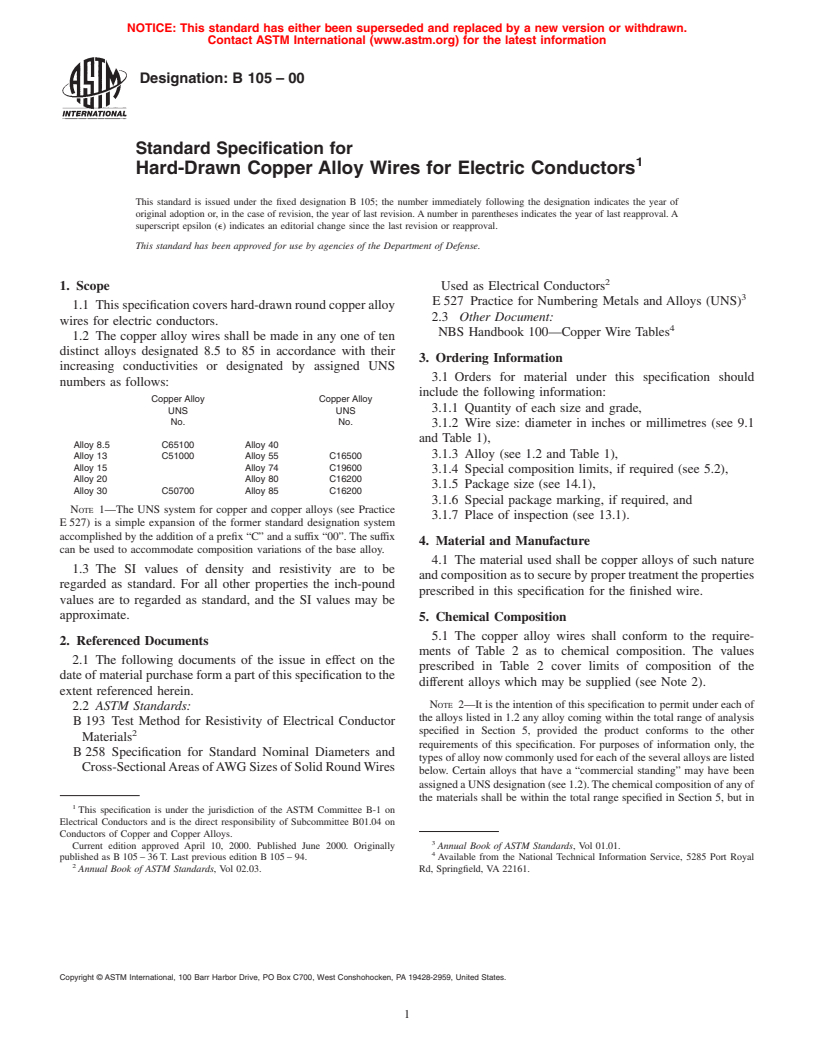

TABLE 1 Tensile Requirements

NOTE 1—Conversion factors are presented for ready adaptation to computer readout and electronic data transmission. The factors are written as a number greater than one and less than ten with

six or less decimal places. This number is followed by the letter E (for exponent), a plus or minus symbol, and two digits which indicate the power of 10 by which the number must be multiplied

to obtain the correct value. For example: 2.54E+01 5 2.54 3 10 5 25.4.

Tensile

Strength,

Elongation, min.

Diameter Area at 20°C min, % Alloy 8.5 Alloy 13 Alloy 15 and 20 Alloy 30 Alloy 40 Alloy 55 Alloy 74 Alloy 80 Alloy 85

in 10 in.

2 2

in. mm cmil in. mm (250 mm) ksi Mpa ksi Mpa ksi Mpa ksi Mpa ksi Mpa ksi Mpa ksi Mpa ksi Mpa ksi Mpa

0.2893 7.3482 83694.49 0.065733 42.4086 2.2 97.5 672.2 102.5 706.7 109.5 755.0 74.0 510.2 73.4 508.1 76.0 524.0 74.0 510.2 72.0 496.4 68.5 472.3

0.2576 6.5430 66357.76 0.052117 33.6240 2.0 103.8 715.7 108.8 750.2 114.5 789.5 80.0 551.6 74.9 516.4 77.8 536.4 75.5 520.6 73.5 506.8 69.9 481.9

0.2294 5.8268 52624.36 0.041331 26.6652 1.8 107.5 741.2 112.5 775.7 118.5 817.0 85.0 586.1 76.3 526.1 79.3 546.8 77.5 534.3 75.0 517.1 71.2 490.9

0.2043 5.1892 41738.49 0.032781 21.1492 1.6 110.2 759.8 115.2 794.3 121.3 836.3 89.0 613.6 77.7 535.7 80.9 557.8 79.0 544.7 76.4 526.8 72.5 499.9

0.1819 4.6203 33087.61 0.025987 16.7657 1.5 112.2 773.6 117.2 808.1 123.3 850.1 92.5 637.8 79.0 544.7 82.4 568.1 80.0 551.6 77.5 534.3 73.6 507.5

0.1620 4.1148 26244.00 0.020612 13.2980 1.4 114.0 786.0 119.0 820.5 125.0 861.9 94.8 653.6 80.4 554.3 84.0 579.2 81.0 558.5 78.6 541.9 74.7 515.0

0.1443 3.6652 20822.49 0.016354 10.5509 1.3 115.3 795.0 120.3 829.4 126.5 872.2 96.5 665.3 81.8 564.0 85.5 589.5 82.4 568.1 79.8 550.2 75.8 522.6

0.1285 3.2639 16512.25 0.012969 8.3669 1.3 116.6 803.9 121.6 838.4 127.9 881.8 97.9 675.0 83.2 573.6 87.0 599.8 83.5 575.7 81.0 558.5 77.0 530.9

0.1144 2.9058 13087.36 0.01027879 6.6315 1.2 117.8 812.2 122.8 846.7 129.2 890.8 99.0 682.6 84.6 583.3 88.5 610.2 84.6 583.3 82.2 566.8 78.1 538.5

0.1019 2.5883 10383.61 0.00815527 5.2615 1.2 118.9 819.8 123.9 854.3 130.3 898.4 100.1 690.2 86.0 593.0 90.0 620.5 85.5 589.5 83.4 575.0 79.2 546.1

0.0907 2.3038 8226.49 0.00646107 4.1684 1.2 119.8 826.0 124.8 860.5 131.2 904.6 101.2 697.8 87.1 600.5 91.3 629.5 86.6 597.1 84.6 583.3 80.3 553.7

0.0808 2.0523 6528.64 0.00512758 3.3081 1.1 120.6 831.5 125.6 866.0 132.0 910.1 102.2 704.6 88.2 608.1 92.6 638.5 87.7 604.7 85.7 590.9 81.4 561.2

0.0720 1.8288 5184.00 0.00407150 2.6268 1.1 121.2 835.6 126.2 870.1 132.6 914.3 103.0 710.2 89.6 617.8 93.8 646.7 88.8 612.3 86.8 598.5 82.5 568.8

0.0641 1.6281 4108.81 0.00322705 2.0820 1.1 121.7 839.1 126.7 873.6 133.2 918.4 103.7 715.0 90.4 623.3 95.0 655.0 89.8 619.2 87.8 605.4 83.4 575.0

0.0571 1.4503 3260.41 0.00256072 1.6521 1.0 122.2 842.5 127.2 877.0 133.6 921.1 104.4 719.8 91.4 630.2 96.0 661.9 90.6 624.7 88.7 611.6 84.2 580.5

0.0508 1.2903 2580.64 0.00202683 1.3076 1.0 122.5 844.6 127.5 879.1 134.0 923.9 105.2 725.3 92.1 635.0 97.0 668.8 92.0 634.3 89.5 617.1 85.0 586.1

0.0453 1.1506 2052.09 0.00161171 1.0398 1.0 122.8 846.7 127.8 881.2 134.2 925.3 105.9 730.2 93.1 641.9 98.0 675.7 92.8 639.8 90.3 622.6 85.7 590.9

0.0403 1.0236 1624.09 0.00127556 0.8229 0.9 123.0 848.1 128.0 882.5 134.5 927.4 106.6 735.0 94.0 648.1 98.6 679.8 93.5 644.7 91.0 627.4 86.4 595.7

0.0359 0.9119 1288.81 0.00101223 0.6530 0.9 123.2 849.4 128.2 883.9 134.8 929.4 107.3 739.8 94.5 651.6 99.0 682.6 94.0 648.1 91.6 631.6 87.0 599.8

0.0320 0.8128 1024.00 0.00080425 0.5189 0.9 123.5 851.5 128.5 886.0 135.0 930.8 108.0 744.8 95.0 655.0 99.5 686.0 94.5 651.6 92.2 635.7 87.6 604.0

A 2 2 2

Conversion factors: 1 in. 5 2.54E+01mm,1 kcmil 5 5.067E−01mm .1in. 5 6.452E+02mm , 1 ksi 5 6.895E+00 MPa.

B 105

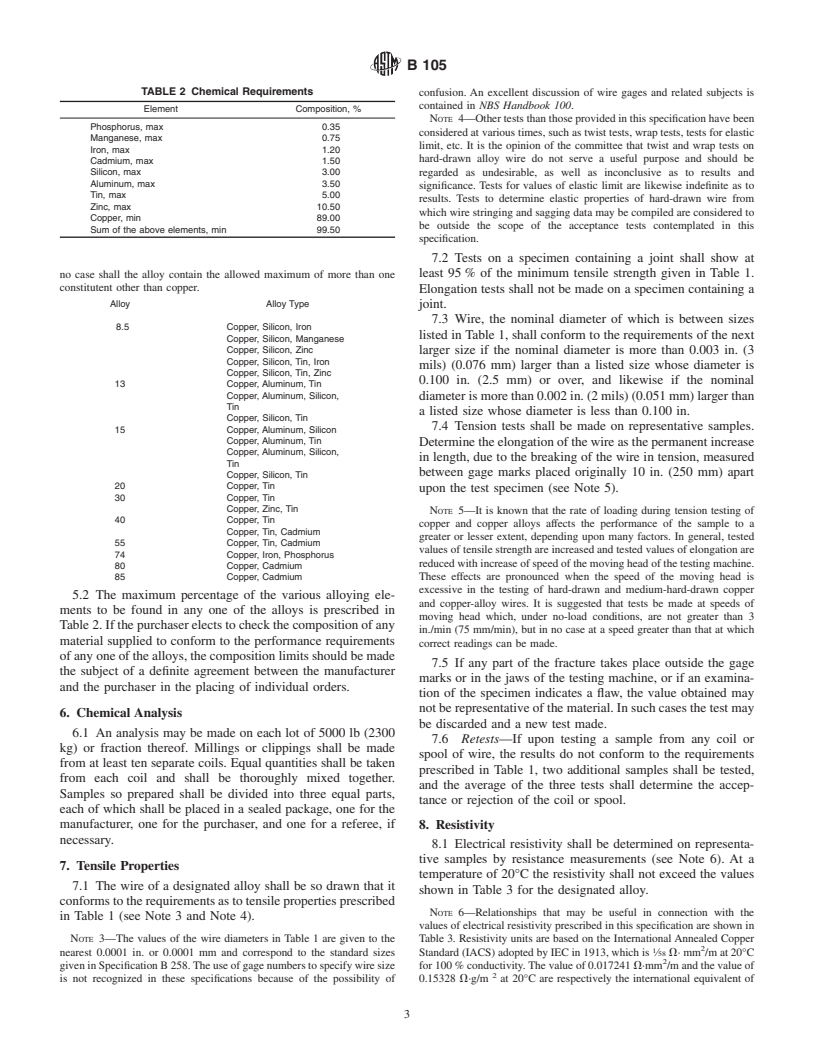

TABLE 2 Chemical Requirements confusion. An excellent discussion of wire gages and related subjects is

contained in NBS Handbook 100.

Element Composition, %

NOTE 4—Other tests than those provided in this specification have been

Phosphorus, max 0.35

considered at various times, such as twist tests, wrap tests, tests for elastic

Manganese, max 0.75

limit, etc. It is the opinion of the committee that twist and wrap tests on

Iron, max 1.20

hard-drawn alloy wire do not serve a useful purpose and should be

Cadmium, max 1.50

Silicon, max 3.00 regarded as undesirable, as well as inconclusive as to results and

Aluminum, max 3.50

significance. Tests for values of elastic limit are likewise indefinite as to

Tin, max 5.00

results. Tests to determine elastic properties of hard-drawn wire from

Zinc, max 10.50

which wire stringing and sagging data may be compiled are considered to

Copper, min 89.00

be outside the scope of the acceptance tests contemplated in this

Sum of the above elements, min 99.50

specification.

7.2 Tests on a specimen containing a joint shall show at

no case shall the alloy contain the allowed maximum of more than one least 95 % of the minimum tensile strength given in Table 1.

constitutent other than copper.

Elongation tests shall not be made on a specimen containing a

Alloy Alloy Type joint.

7.3 Wire, the nominal diameter of which is between sizes

8.5 Copper, Silicon, Iron

listed in Table 1, shall conform to the requirements of the next

Copper, Silicon, Manganese

Copper, Silicon, Zinc

l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.