ASTM F1416-96(2003)

(Guide)Standard Guide for Selection of Time-Temperature Indicators

Standard Guide for Selection of Time-Temperature Indicators

SCOPE

1.1 This guide covers information on the selection of commercially available time-temperature indicators (TTIs) for noninvasive external package use on perishable products, such as food and pharmaceuticals. When attached to the package of a perishable product, TTIs are used to measure the combined time and temperature history of the product in order to predict the remaining shelf life of the product or to signal the end of its usable shelf life. It is the responsibility of the processor of the perishable product to determine the shelf life of a product at the appropriate temperatures and to consult with the indicator manufacturer to select the available indicator which most closely matches the quality of the product as a function of time and temperature.

Note 1—Besides time-temperature indicator, TTI is also an abbreviation for time-temperature monitor and time-temperature integrator.

1.2 Time-temperature indicators may be integrated into a Hazard Analysis and Critical Control Point (HACCP) plan. Appropriate instructions should be established for handling products for which either the indicator has signaled the end of usable shelf life or the shelf life of the product at its normal storage temperature has been reached.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1416–96 (Reapproved 2003)

Standard Guide for

Selection of Time-Temperature Indicators

This standard is issued under the fixed designation F 1416; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

ln~LIFE /LIFE !

1. Scope

1 2

E 5 3 R (1)

a

1 1

1.1 This guide covers information on the selection of

T T

1 2

commercially available time-temperature indicators (TTIs) for

noninvasive external package use on perishable products, such where LIFE and LIFE = shelf lives at temperatures T and T .

1 2 1 2

as food and pharmaceuticals. When attached to the package of

2.1.2 all-temperature time-temperature indicator—a TTI

a perishable product, TTIs are used to measure the combined

that continues to change at some rate at all temperatures.

time and temperature history of the product in order to predict

2.1.3 Arrhenius plot—a plot of the logarithm of the shelf

the remaining shelf life of the product or to signal the end of its

life of a product versus the reciprocal of temperature (1\T).

usable shelf life. It is the responsibility of the processor of the

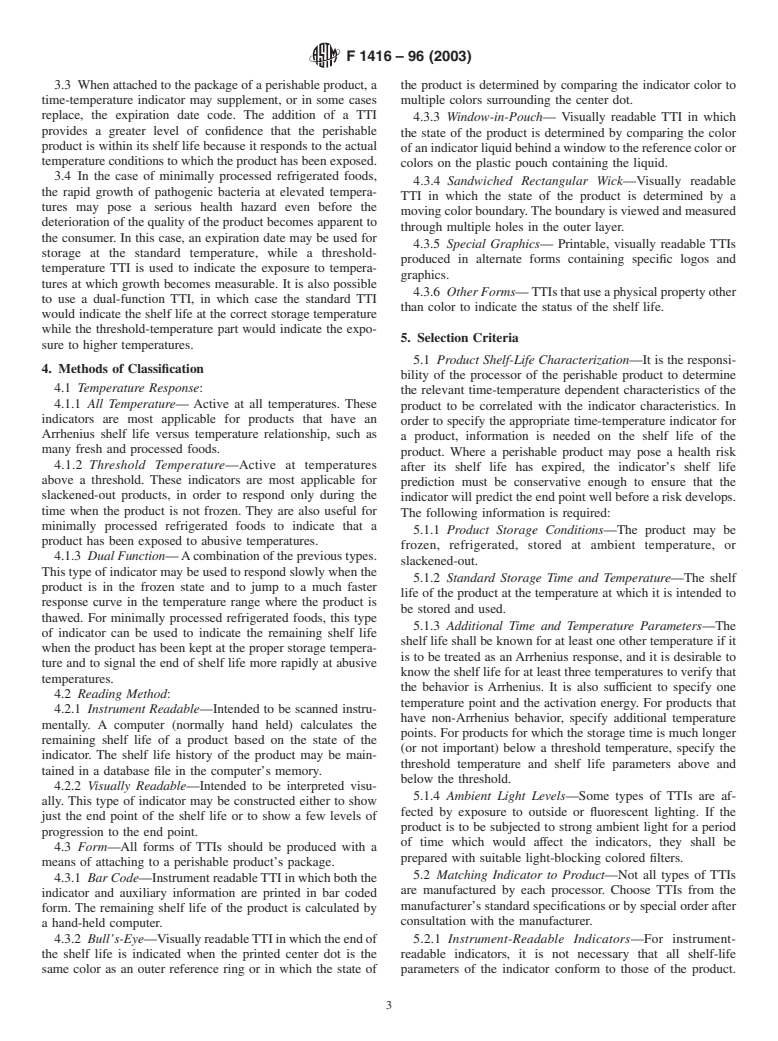

2.1.3.1 Discussion—If the shelf life of a product exhibits

perishableproducttodeterminetheshelflifeofaproductatthe

Arrhenius behavior, then anArrhenius plot of the shelf life will

appropriate temperatures and to consult with the indicator

be a straight line.The activation energy of the shelf life is equal

manufacturer to select the available indicator which most

to the slope of the line times R (see 2.1.1.1). It is more accurate

closely matches the quality of the product as a function of time

to use a regression analysis to determine the slope based on the

and temperature.

data from at least three temperatures than to use only two

points as in the previous equation. A blank Arrhenius plot is

NOTE 1—Besides time-temperature indicator, TTI is also an abbrevia-

shown in Fig. 1.The plot axes are the log of the shelf life and

tion for time-temperature monitor and time-temperature integrator.

the reciprocal of temperature. For ease of use, the Fahrenheit

1.2 Time-temperature indicators may be integrated into a

and Celsius temperatures are shown on the graph instead of the

Hazard Analysis and Critical Control Point (HACCP) plan.

inverse temperature.

Appropriate instructions should be established for handling

2.1.4 Arrhenius relationship—a relationship that describes

products for which either the indicator has signaled the end of

the dependence of the rate of a chemical reaction on tempera-

usable shelf life or the shelf life of the product at its normal

ture as follows:

storage temperature has been reached.

E

1.3 This standard does not purport to address all of the

a

k 5 A e 2 (2)

S D

RT

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

where:

priate safety and health practices and determine the applica-

k = rate constant,

bility of regulatory limitations prior to use.

A = constant with the same time units as k,

T = temperature, K (°C + 273), and

2. Terminology

R = universal gas constant.

2.1 Definitions:

When R = 0.001987 kcal/(mol · deg), the activation energy,

2.1.1 activation energy—the quantity commonly used to

E , is given in units of kcal/mol.

a

describe the dependence of the shelf life of a product (or the

When R = 0.00831 kJ/(mol · deg), the activation energy, E ,

a

rate of a reaction) on temperature, as given by the Arrhenius

is given in units of kJ/mol.

relationship.

2.1.4.1 Discussion—This relationship also describes the

2.1.1.1 Discussion—The higher the activation energy, the

dependence of the shelf life of many TTIs and perishable

more the shelf life of a product changes with temperature. If

products on the effective average temperature to which they are

the shelf life of a product is known at two temperatures, the

exposed. Since the shelf life is the time for the reaction to

activation energy is given by the following formula:

proceed to a specific extent, theArrhenius relationship for shelf

life is given by the following formula:

This guide is under the jurisdiction of ASTM Committee F02 on Flexible E

a

LIFE 5 Be (3)

S D

Barrier Materials and is the direct responsibility of Subcommittee F02.15 on

RT

Chemical/Safety Properties.

Current edition approved Feb. 10, 1996. Published April 1996. where B = constant with the same time units as LIFE.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1416–96 (2003)

2.1.9 threshold-temperature time-temperature indicator—a

TTI that only changes at temperatures above a specific thresh-

old.

2.1.10 time-temperature indicator (TTI)—a device that can

be affixed to the package of a perishable product and that

exhibits a change in a physically measurable or visually

measurable property as a combined function of both time and

temperature. For example, properties that change include color,

light reflectance, or a moving boundary between two colors.

2.1.11 time-temperature integrator—see time-temperature

indicator.

2.1.11.1 Discussion—This term emphasizes the fact that the

indicator’s response is an integration of the effects of both time

and temperature.

2.1.12 time-temperature monitor—see time-temperature in-

dicator.

2.2 Definitions of Terms Specific to This Standard:

2.2.1 activation method—the method by which an inactive

TTI is changed to an active state.

2.2.1.1 Discussion—This may include a physical activation

NOTE 1—This blank graph may be used to determine if the shelf life of

method, such as removing or breaking a barrier, or may require

a product exhibits standardArrhenius behavior.The plot axes are the log

of the shelf life and the reciprocal of temperature. Note that the X-axis of raising the temperature to the normal operating range of the

this plot is marked in Celsius degrees instead of inverse Kelvin degrees,

TTI.

so that the spacing between degrees is not uniform. For ease of use, the

2.2.2 inactive state—the state in which a TTI does not

Fahrenheit and Celsius temperatures are shown on the graph instead of the

respond to changes in temperature over time.

inverse temperature. To use, plot the shelf life of the product at

2.2.2.1 Discussion—Some types of indicators are active

temperatures for which it is known. If the shelf life follows theArrhenius

when manufactured and kept essentially inactive by storage at

relationship, the points can be connected with a straight line. The

activation energy may be calculated by the equation in 2.1.1.1. low temperatures.

FIG. 1 Blank Arrhenius Plot

2.2.3 slackened-out product—a product that is stored frozen

for an indeterminate time and then thawed (slackened out) for

the final part of its distribution and use.

2.1.5 dual function time-temperature indicator— a TTI that

3. Significance and Use

combines both all-temperature and threshold-temperature re-

sponses, overlaid in a single indicator in order to modify the

3.1 Expiration dates are often marked on the packages of

total time-temperature response.

perishable products to indicate the presumed end of their shelf

2.1.6 effective average temperature—the single constant

lives. Since the shelf lives of most perishable products are

temperature that would have the same effect on the shelf life of

temperature dependent, the expiration date is determined by

a product as the actual temperature profile has for the same

assuming the product will be kept within a prescribed tempera-

time period.

ture range for its entire life.Aproblem with this method is that

2.1.7 hazard analysis and critical control points

there is no way to determine if the shelf life of a product has

(HACCP)—a method to control food quality and safety by

been shortened by exposure to a higher temperature. A time-

identifying and controlling those processing and distribution

temperature indicator solves this problem when attached to the

steps where a food safety hazard may be prevented, eliminated,

package because it reaches its end point sooner when exposed

or reduced to acceptable levels.

to a higher temperature.

2.1.8 shelf life—the time required for various changes to a

3.2 In order to directly indicate the end of the shelf life, the

product to accumulate to the point where the product no longer

time-temperature indicator characteristics should be matched

meets predetermined criteria and is no longer considered

as closely as possible to the quality characteristics of the

suitable for its original purpose.

product. When kept at the standard storage temperature for the

2.1.8.1 Discussion—In some cases, such as where patho- product, the indicator should reach its end point at the same

genic microbial growth is involved, there may be a serious time as the product’s shelf life. In addition, to determine the

health risk in using a product past its shelf life. In such cases, accuracy of the match at other temperatures, the change of

the shelf life to be monitored should be conservative enough so shelf life with temperature should be known for both the

that its expiration is signaled well before a health concern product and the indicator. The Arrhenius relationship is a

develops. It may be desirable to indicate even short occur- common and convenient method of describing the change of

rences of undesirably high temperatures. Other changes may shelf life with temperature. In cases where it is not applicable,

also occur, such as in col

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.