ASTM D5501-94(1998)e1

(Test Method)Standard Test Method for Determination of Ethanol Content of Denatured Fuel Ethanol by Gas Chromatography

Standard Test Method for Determination of Ethanol Content of Denatured Fuel Ethanol by Gas Chromatography

SCOPE

1.1 This test method covers the determination of the ethanol content of denatured fuel ethanol by gas chromatography.

1.2 Ethanol is determined from 93 to 97 mass percent and methanol is determined from 0.1 to 0.6 mass percent. Equations used to convert these individual alcohols from mass percent to volume percent are provided.

1.3 This test method does identify and quantify methanol but does not purport to identify all individual components that make up the denaturant.

1.4 Water cannot be determined by this test method and shall be measured by a procedure such as Test Method D1364 and the result used to correct the chromatographic values.

1.5 This test method is inappropriate for impurities that boil at temperatures higher than 225°C or for impurities that cause poor or no response in a flame ionization detector, such as water.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation: D 5501 – 94 (Reapproved 1998)

Standard Test Method for

Determination of Ethanol Content of Denatured Fuel Ethanol

by Gas Chromatography

This standard is issued under the fixed designation D 5501; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial corrections were made to Section 2 and 12.3 in April 1998.

1. Scope Liquids by Digital Density Meter

D 4057 Practice for Manual Sampling of Petroleum and

1.1 This test method covers the determination of the ethanol

Petroleum Products

content of denatured fuel ethanol by gas chromatography.

D 4307 Practice for Preparation of Liquid Blends for Use as

1.2 Ethanol is determined from 93 to 97 mass % and

Analytical Standards

methanol is determined from 0.1 to 0.6 mass %. Equations

D 4626 Practice for Calculation of Gas Chromatographic

used to convert these individual alcohols from mass % to

Response Factors

volume % are provided.

D 4806 Specification for Denatured Fuel Ethanol for Blend-

1.3 This test method does identify and quantify methanol

ing with Gasolines for Use as Automotive Spark-Ignition

but does not purport to identify all individual components that

Engine Fuel

make up the denaturant.

E 355 Practice for Gas Chromatography Terms and Rela-

1.4 Water cannot be determined by this test method and

tionships

shall be measured by a procedure such as Test Method D 1364

E 594 Practice for Testing Flame Ionization Detectors Used

and the result used to correct the chromatographic values.

in Gas Chromatography

1.5 This test method is inappropriate for impurities that boil

E 1064 Test Method for Water in Organic Liquids by

at temperatures higher than 225°C or for impurities that cause

Coulometric Karl Fischer Titration

poor or no response in a flame ionization detector, such as

water.

3. Terminology

1.6 The values stated in SI units are to be regarded as the

3.1 Definitions—This test method makes reference to many

standard. The values given in parentheses are provided for

common gas chromatographic procedures, terms, and relation-

information purposes only.

ships. Detailed definitions can be found in Practices E 355 and

1.7 This standard does not purport to address all of the

E 594.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 A representative aliquot of the fuel ethanol sample is

bility of regulatory limitations prior to use.

introduced into a gas chromatograph equipped with a methyl

silicone bonded phase fused silica capillary column. Helium

2. Referenced Documents

carrier gas transports the vaporized aliquot through the column

2.1 ASTM Standards:

where the components are separated by the chromatographic

D 1298 Test Method for Density, Relative Density (Specific

process. Components are sensed by a flame ionization detector

Gravity), or API Gravity of Crude Petroleum and Liquid

2 as they elute from the column. The detector signal is processed

Petroleum Products by Hydrometer Method

by an electronic data acquisition system. The ethanol and

D 1364 Test Method for Water in Volatile Solvents (Fischer

3 methanol components are identified by comparing their reten-

Reagent Titration Method)

tion times to the ones identified by analyzing standards under

D 4052 Test Method for Density and Relative Density of

identical conditions. The concentration of all components are

determined in mass percent area by normalization of the peak

areas.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.04.0L on Gas Chromatography Methods.

Current edition approved Aug. 15, 1994. Published October 1994. Originally

published as D 5501–94. Last previous edition D 5501–94. Annual Book of ASTM Standards, Vol 05.02.

2 5

Annual Book of ASTM Standards, Vol 05.01. Annual Book of ASTM Standards, Vol 14.01.

3 6

Annual Book of ASTM Standards, Vol 06.04. Annual Book of ASTM Standards, Vol 15.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5501

5. Significance and Use 6.4 Electronic Data Acquisition System— Any data acqui-

sition and integration device used for quantification of these

5.1 Fuel ethanol is required to be denatured with gasoline in

analyses must meet or exceed these minimum requirements:

accordance with Specification D 4806. State and federal laws

6.4.1 Capacity for at least 80 peaks/analysis,

specify the concentration of ethanol in gasoline blends. The

6.4.2 Normalized area percent calculation with response

determination of the amount of denaturant is important to

factors,

ensure the blended fuel complies with federal and state laws.

6.4.3 Identification of individual components based on re-

This test method provides a method of determining the

tention time,

percentage of ethanol (purity) of the fuel ethanol that is

6.4.4 Noise and spike rejection capability,

blended into gasoline.

6.4.5 Sampling rate for fast (<1 s) peaks,

6. Apparatus

6.4.6 Positive and negative sloping baseline correction,

6.4.7 Peak detection sensitivity compensation for narrow

6.1 Gas Chromatograph, capable of operating at the condi-

and broad peaks, and

tions listed in Table 1. A heated flash vaporizing injector

6.4.8 Non-resolved peaks separated by perpendicular drop

injector designed to provide a linear sample split injection (for

or tangential skimming as needed.

example, 200:1) is required for proper sample introduction.

Carrier gas controls shall be of adequate precision to provide

7. Reagents and Materials

reproducible column flows and split ratios in order to maintain

7.1 Purity of Reagents—Reagent grade chemicals shall be

analytical integrity. Pressure control devices and gauges shall

used in all tests. Unless otherwise indicated, it is intended that

be designed to attain the linear velocity required in the column

all reagents conform to the specifications of the Committee on

used. A hydrogen flame ionization detector with associated gas

Analytical Reagents of the American Chemical Society where

controls and electronics, designed for optimum response with

such specifications are available.

open tabular columns, is required.

7.2 Carrier Gas, helium, with a minimum purity of 99.95

6.2 Sample Introduction—Manual or automatic liquid sy-

mol %. Oxygen removal systems and gas purifiers should be

ringe sample injection to the splitting injector is employed.

used.

Devices capable of 0.1 to 0.5 μL injections are suitable. It

should be noted that inadequate splitter design, poor injection

NOTE 1—Warning: Helium, compressed gas under high pressure.

technique, and overloading the column can result in poor

7.3 Detector Gases, hydrogen, air, and nitrogen. The mini-

resolution. Avoid overloading, particularly of the ethanol peak,

mum purity of the gases used should be 99.95 % for the

and eliminate this condition during analysis.

hydrogen and nitrogen. The air should be hydrocarbon-free

6.3 Column—This test method utilizes a fused silica open

grade. Gas purifiers are recommended for the detector gases.

tubular column with non-polar methyl silicone bonded (cross-

linked) phase internal coating. Any column with equivalent or

NOTE 2—Warning: Hydrogen, extremely flammable gas under high

better chromatographic efficiency and selectivity to those pressure.

NOTE 3—Warning: Air and nitrogen, compressed gases under high

described in 6.3.1 can be used.

pressure.

6.3.1 Open tubular column with a non-polar methyl silicone

7.4 Standards for Calibration and Identification—

bonded (cross-linked) phase internal coating, either 150 m by

0.25 mm with a 1.0 μm film thickness, or 100 m by 0.25 mm Standards of all components to be analyzed are required for

establishing identification by retention time as well as calibra-

with a 0.5 film thickness is required.

tion for quantitative measurements. These materials shall be of

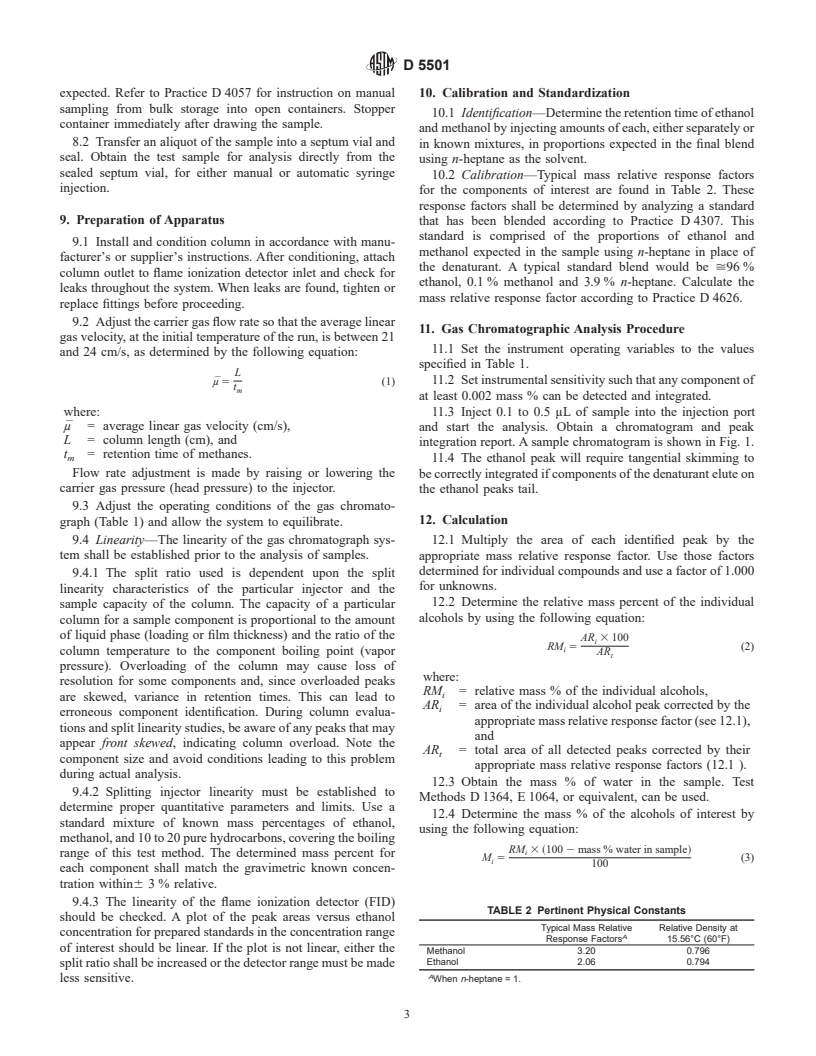

TABLE 1 Typical Operating Conditions

known purity and free of the other components to be analyzed.

Column Temperature Program 7.4.1 Ethanol (Warning—See Note 4, Note 5).

Column length 100 m 150 m

NOTE 4—Two grades of ethanol are available. Only absolute ethanol

Initial temperature 15°C 60°C

99.5 minimum percent meets the requirements of this test method.

Initial hold time 12 min 15 min

Program rate 30°C/min 30°C/min

7.4.2 Methanol (Warning—See Note 5).

Final temperature 250°C 250°C

7.4.3 Heptane (Warning—See Note 5).

Final hold time 19 min 23 min

Injector NOTE 5—Warning: These materials are flammable and may be harmful

or fatal, if ingested or inhaled.

Temperature 300°C

Split ratio 200:1

8. Sampling

Sample size 0.1 to 0.5 μL

Detector

8.1 Denatured ethanol can be sampled into an open con-

tainer since a vapor pressure of less than 21 kPa (3 psi) is

Type Flame ionization

Temperature 300°C

Fuel g

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.