ASTM D4286-08(2015)

(Practice)Standard Practice for Determining Coating Contractor Qualifications for Nuclear Powered Electric Generation Facilities

Standard Practice for Determining Coating Contractor Qualifications for Nuclear Powered Electric Generation Facilities

ABSTRACT

This practice provides a criteria guide and procedural method to assist utility owners, architects, engineers, constructors, and other selection agencies in determining the overall qualifications of a coating contractor to execute coating work for the primary containment and other safety-related facilities of light-water nuclear power plants. The qualification criteria and requirements address the essential basic capability of a contractor to execute nuclear coating work. The evaluation procedures contained herein are designed to be adaptive to detailed final qualification processes. Variation or simplification of the practice is appropriate for non safety-related areas of nuclear power plants, fossil fueled facilities, and other industrial projects. The nine evaluation categories, which detail the specific data to be provided by the contractor as essential to determining qualification status, are as follows: (1) personnel employed; (2) work experience; (3)equipment inventory; (4) quality assurance/control; (5) training and supervisory program; (6) safety program; (7) production/cost control report; (8) financial capability; and (9) current and projected performance capability. In addition, a tenth untitled category has been provided on the evaluation work for inclusion of other information pertinent to a specific project.

SCOPE

1.1 This practice provides a criteria guide and procedural method to assist utility owners, architects, engineers, constructors, and other selection agencies in determining the overall qualifications of a coating contractor to execute coating work for the primary containment and other safety-related facilities of light-water nuclear power plants.

1.2 The qualification criteria and requirements address the essential basic capability of a contractor to execute nuclear coating work. Obviously, the specific capability to execute those requirements unique to a given project must also be carefully considered. The evaluation procedure contained in this practice is designed to be adaptive to this detailed final qualification process. Variation or simplification of the practice is appropriate for non safety-related areas of nuclear power plants, fossil fueled facilities, and other industrial projects.

1.3 The overall capability of a contractor to successfully execute the varied and complex requirements of nuclear coating work is dependent upon competency in a variety of essential categories.

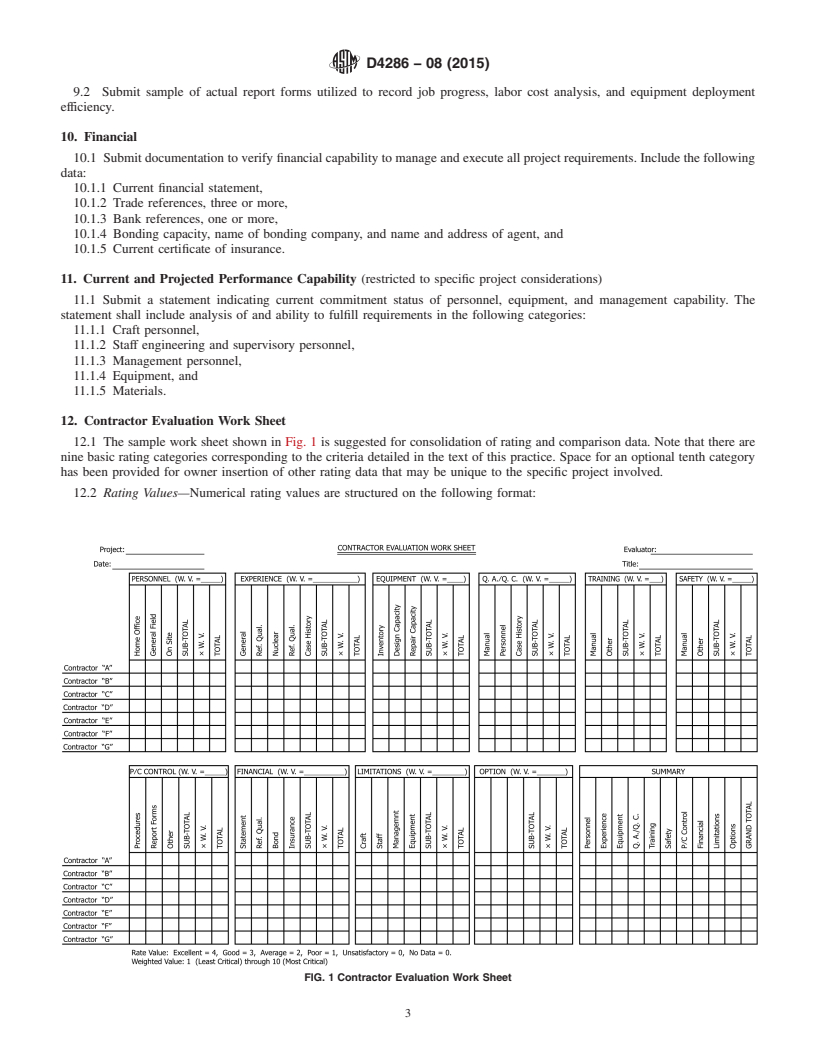

1.4 The nine evaluation categories described in Sections 3 – 12 detail the specific data to be provided by the contractor as essential to determining qualification status. In addition, a tenth untitled category has been provided on the evaluation work described in Section 12 for inclusion of other information pertinent to a specific project.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4286 −08 (Reapproved 2015)

Standard Practice for

Determining Coating Contractor Qualifications for Nuclear

1

Powered Electric Generation Facilities

This standard is issued under the fixed designation D4286; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This practice provides a criteria guide and procedural 2.1 ASTM Standards:

D3843 Practice for Quality Assurance for Protective Coat-

method to assist utility owners, architects, engineers,

constructors, and other selection agencies in determining the ings Applied to Nuclear Facilities

D4537 Guide for Establishing Procedures to Qualify and

overall qualifications of a coating contractor to execute coating

work for the primary containment and other safety-related Certify Personnel Performing Coating and Lining Work

Inspection in Nuclear Facilities

facilities of light-water nuclear power plants.

3

2.2 American National Standards:

1.2 The qualification criteria and requirements address the

N 45.2.6 Qualifications of Inspection, Examination, and

essential basic capability of a contractor to execute nuclear

Testing Personnel for Nuclear Power Plants

coating work. Obviously, the specific capability to execute

NQA-1 Quality Assurance Requirements for Nuclear Facil-

those requirements unique to a given project must also be

ity Applications

carefully considered. The evaluation procedure contained in

2.3 Other Standard:

this practice is designed to be adaptive to this detailed final

10 CFR 50Appendix B Nuclear RegulatoryAgency, Quality

qualification process.Variation or simplification of the practice

4

Assurance Criteria for Nuclear Power Plants

is appropriate for non safety-related areas of nuclear power

plants, fossil fueled facilities, and other industrial projects.

3. Personnel

1.3 The overall capability of a contractor to successfully 3.1 Home Offıce Management and Staff—Resumes of the

execute the varied and complex requirements of nuclear

following types of personnel including educational

coating work is dependent upon competency in a variety of

background, duration and degree of involvement in industrial

essential categories.

coating operations, qualifications, registrations, certifications,

and specific experience in nuclear coating work.

1.4 The nine evaluation categories described in Sections3–

3.1.1 Principals and General Management.

12 detail the specific data to be provided by the contractor as

3.1.2 Engineering Manager.

essentialtodeterminingqualificationstatus.Inaddition,atenth

3.1.3 Project Engineers—List specific nuclear coating work

untitled category has been provided on the evaluation work

project involvement.

described in Section 12 for inclusion of other information

3.1.4 QA/QC Manager—List specific qualification/

pertinent to a specific project.

certificationcredentialsperANSIN45.2.6,orGuideD4537,or

1.5 This standard does not purport to address all of the

NQA-1.

safety concerns, if any, associated with its use. It is the

3.2 General Field or Shop Supervision—Resumes to in-

responsibility of the user of this standard to establish appro-

clude specific nuclear coatings work experience.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This practice is under the jurisdiction of ASTM Committee D33 on Protective the ASTM website.

3

Coating and Lining Work for Power Generation Facilities and is the direct Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

responsibility of Subcommittee D33.05 on Application and Surface Preparation. 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Current edition approved Dec. 1, 2015. Published January 2016. Originally AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

approved in 1984. Last previous edition approved in 2008 as D4286 – 08. DOI: 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

10.1520/D4286-08R15. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4286−08 (2015)

3.3 On-Site or In-Shop Project Supervision: 6.2.2 LEVEL II Inspector, and

3.3.1 Total number of personnel qualified for nuclear coat- 6.2.3 LEVEL I Inspector.

ings work, including specific work history.

7. Traini

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4286 − 08 D4286 − 08 (Reapproved 2015)

Standard Practice for

Determining Coating Contractor Qualifications for Nuclear

1

Powered Electric Generation Facilities

This standard is issued under the fixed designation D4286; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice provides a criteria guide and procedural method to assist utility owners, architects, engineers, constructors, and

other selection agencies in determining the overall qualifications of a coating contractor to execute coating work for the primary

containment and other safety-related facilities of light-water nuclear power plants.

1.2 The qualification criteria and requirements address the essential basic capability of a contractor to execute nuclear coating

work. Obviously, the specific capability to execute those requirements unique to a given project must also be carefully considered.

The evaluation procedure contained in this practice is designed to be adaptive to this detailed final qualification process. Variation

or simplification of the practice is appropriate for non safety-related areas of nuclear power plants, fossil fueled facilities, and other

industrial projects.

1.3 The overall capability of a contractor to successfully execute the varied and complex requirements of nuclear coating work

is dependent upon competency in a variety of essential categories.

1.4 The nine evaluation categories described in Sections 3 – 12 detail the specific data to be provided by the contractor as

essential to determining qualification status. In addition, a tenth untitled category has been provided on the evaluation work

described in Section 12 for inclusion of other information pertinent to a specific project.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D3843 Practice for Quality Assurance for Protective Coatings Applied to Nuclear Facilities

D4537 Guide for Establishing Procedures to Qualify and Certify Personnel Performing Coating and Lining Work Inspection in

Nuclear Facilities

3

2.2 American National Standards:

N 45.2.6 Qualifications of Inspection, Examination, and Testing Personnel for Nuclear Power Plants

NQA-1 Quality Assurance Requirements for Nuclear Facility Applications

2.3 Other Standard:

4

10 CFR 50 Appendix B Nuclear Regulatory Agency, Quality Assurance Criteria for Nuclear Power Plants

3. Personnel

3.1 Home Offıce Management and Staff—Resumes of the following types of personnel including educational background,

duration and degree of involvement in industrial coating operations, qualifications, registrations, certifications, and specific

experience in nuclear coating work.

1

This practice is under the jurisdiction of ASTM Committee D33 on Protective Coating and Lining Work for Power Generation Facilities and is the direct responsibility

of Subcommittee D33.05 on Application and Surface Preparation.

Current edition approved Jan. 1, 2008Dec. 1, 2015. Published January 2008January 2016. Originally approved in 1984. Last previous edition approved in 19992008 as

D4286 – 90 (1999).D4286 – 08. DOI: 10.1520/D4286-08.10.1520/D4286-08R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4286 − 08 (2015)

3.1.1 Principals and General Management.

3.1.2 Engineering Manager.

3.1.3 Project Engineers—List specific nuclear coating work project involvement.

3.1.4 QA/QC Manager—List specific qualification/cer

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.