ASTM B122/B122M-06

(Specification)Standard Specification for Copper-Nickel-Tin Alloy, Copper-Nickel-Zinc Alloy (Nickel Silver), and Copper-Nickel Alloy Plate, Sheet, Strip, and Rolled Bar

Standard Specification for Copper-Nickel-Tin Alloy, Copper-Nickel-Zinc Alloy (Nickel Silver), and Copper-Nickel Alloy Plate, Sheet, Strip, and Rolled Bar

SCOPE

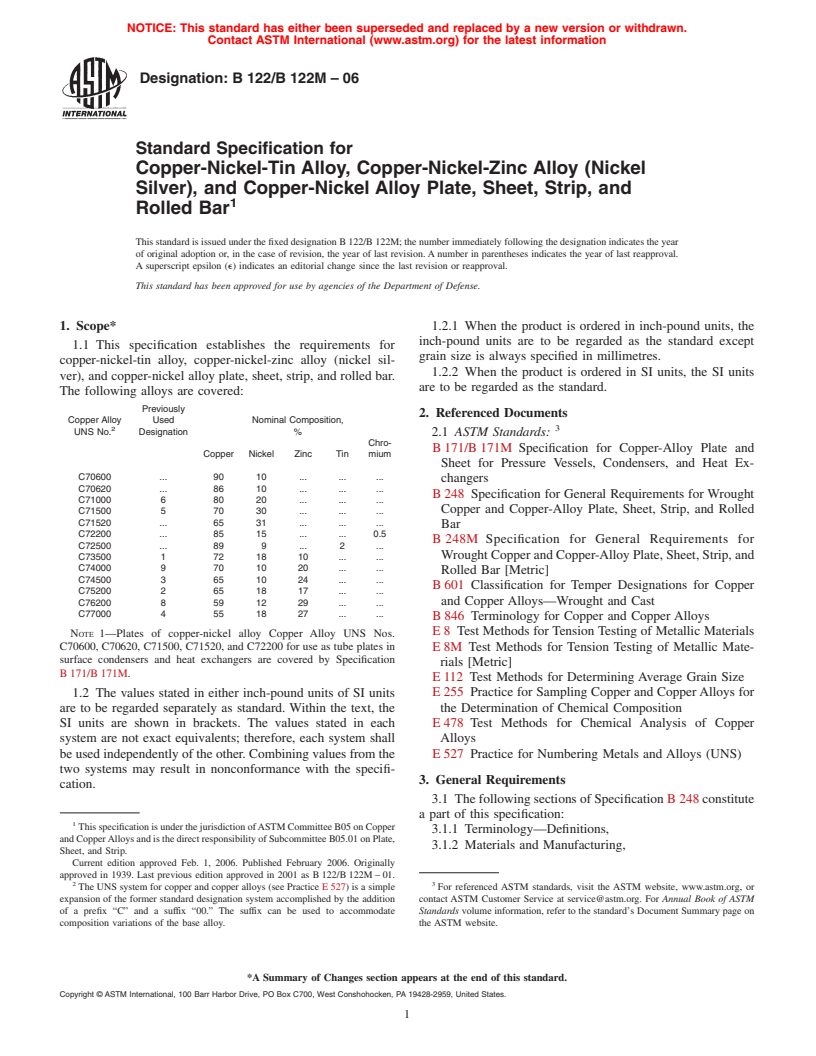

1.1 This specification establishes the requirements for copper-nickel-tin alloy, copper-nickel-zinc alloy (nickel silver), and copper-nickel alloy plate, sheet, strip, and rolled bar. The following alloys are covered:

Note 1Plates of copper-nickel alloy Copper Alloy UNS Nos. C70600, C70620, C71500, C71520, and C72200 for use as tube plates in surface condensers and heat exchangers are covered by Specification B 171/B 171M.

1.2 The values stated in either inch-pound units of SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.2.1 When the product is ordered in inch-pound units, the inch-pound units are to be regarded as the standard except grain size is always specified in millimetres.

1.2.2 When the product is ordered in SI units, the SI units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 122/B 122M – 06

Standard Specification for

Copper-Nickel-Tin Alloy, Copper-Nickel-Zinc Alloy (Nickel

Silver), and Copper-Nickel Alloy Plate, Sheet, Strip, and

1

Rolled Bar

This standard is issued under the fixed designation B 122/B 122M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 1.2.1 When the product is ordered in inch-pound units, the

inch-pound units are to be regarded as the standard except

1.1 This specification establishes the requirements for

grain size is always specified in millimetres.

copper-nickel-tin alloy, copper-nickel-zinc alloy (nickel sil-

1.2.2 When the product is ordered in SI units, the SI units

ver), and copper-nickel alloy plate, sheet, strip, and rolled bar.

are to be regarded as the standard.

The following alloys are covered:

Previously

2. Referenced Documents

Copper Alloy Used Nominal Composition,

2 3

UNS No. Designation %

2.1 ASTM Standards:

Chro-

B 171/B 171M Specification for Copper-Alloy Plate and

Copper Nickel Zinc Tin mium

Sheet for Pressure Vessels, Condensers, and Heat Ex-

C70600 . 90 10 . . .

changers

C70620 . 86 10 . . .

B 248 Specification for General Requirements for Wrought

C71000 6 80 20 . . .

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

C71500 5 70 30 . . .

C71520 . 65 31 . . .

Bar

C72200 . 85 15 . . 0.5

B 248M Specification for General Requirements for

C72500 . 89 9 . 2 .

C73500 1 72 18 10 . . Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and

C74000 9 70 10 20 . .

Rolled Bar [Metric]

C74500 3 65 10 24 . .

B 601 Classification for Temper Designations for Copper

C75200 2 65 18 17 . .

and Copper Alloys—Wrought and Cast

C76200 8 59 12 29 . .

C77000 4 55 18 27 . .

B 846 Terminology for Copper and Copper Alloys

E8 Test Methods for Tension Testing of Metallic Materials

NOTE 1—Plates of copper-nickel alloy Copper Alloy UNS Nos.

C70600, C70620, C71500, C71520, and C72200 for use as tube plates in E8M Test Methods for Tension Testing of Metallic Mate-

surface condensers and heat exchangers are covered by Specification

rials [Metric]

B 171/B 171M.

E112 Test Methods for Determining Average Grain Size

1.2 The values stated in either inch-pound units of SI units E 255 Practice for Sampling Copper and CopperAlloys for

are to be regarded separately as standard. Within the text, the the Determination of Chemical Composition

SI units are shown in brackets. The values stated in each E 478 Test Methods for Chemical Analysis of Copper

system are not exact equivalents; therefore, each system shall Alloys

be used independently of the other. Combining values from the E 527 Practice for Numbering Metals and Alloys (UNS)

two systems may result in nonconformance with the specifi-

3. General Requirements

cation.

3.1 The following sections of Specification B 248 constitute

a part of this specification:

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

3.1.1 Terminology—Definitions,

andCopperAlloysandisthedirectresponsibilityofSubcommitteeB05.01onPlate,

3.1.2 Materials and Manufacturing,

Sheet, and Strip.

Current edition approved Feb. 1, 2006. Published February 2006. Originally

approved in 1939. Last previous edition approved in 2001 as B 122/B 122M – 01.

2 3

The UNS system for copper and copper alloys (see Practice E 527) is a simple For referenced ASTM standards, visit the ASTM website, www.astm.org, or

expansion of the former standard designation system accomplished by the addition contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate Standards volume information, refer to the standard’s Document Summary page on

composition variations of the base alloy. the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

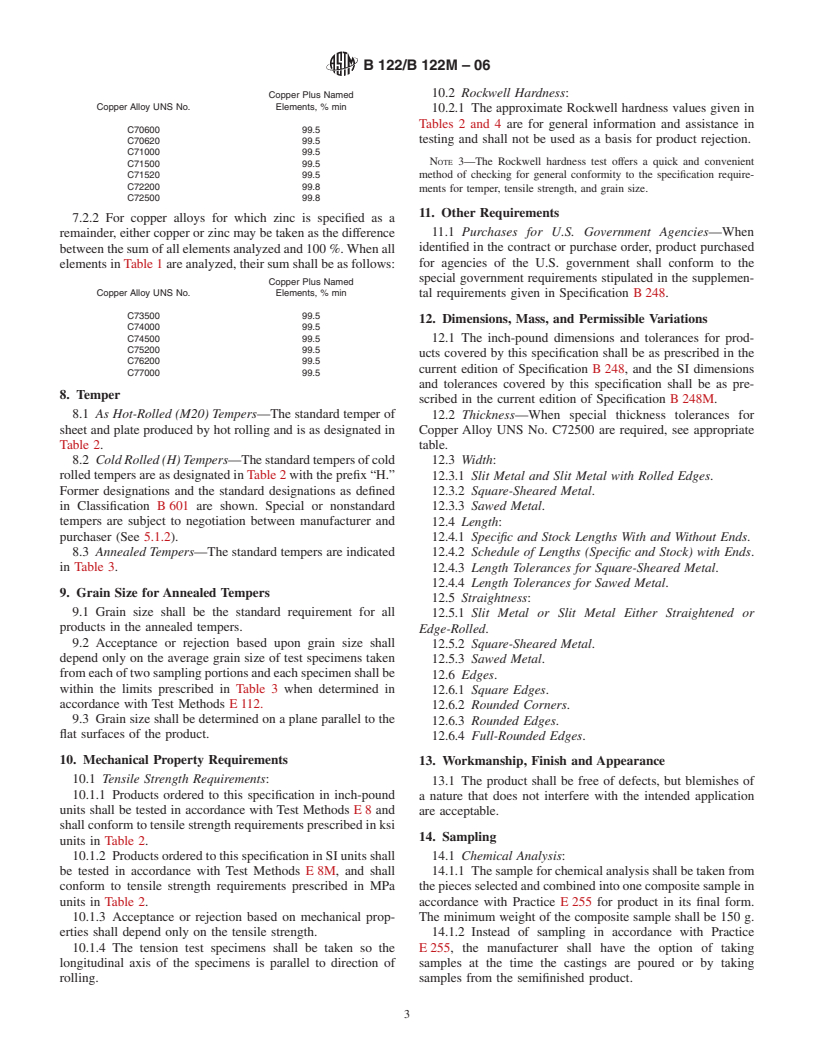

B 122/B 122M – 06

3.1.3 Workmanship, Finish, and Appearance, Requirements as defined in Specification B 248 when specified

3.1.4 Sampling—except for chemical analysis, in the contract or purchase order.

3.1.5 Number of Tests and Retests,

3.1.6 Specimen Preparation, 6. Materials and Manufacture

3.1.7 Test Methods—except for chemical analysis,

6.1 Material:

3.1.8 Significance of Numerical Limits,

6.1.1 The material of manufacture shall be a cast bar, cake,

3.1.9 Inspection,

slab, and so f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.