ASTM B315-19

(Specification)Standard Specification for Seamless Copper Alloy Pipe and Tube

Standard Specification for Seamless Copper Alloy Pipe and Tube

ABSTRACT

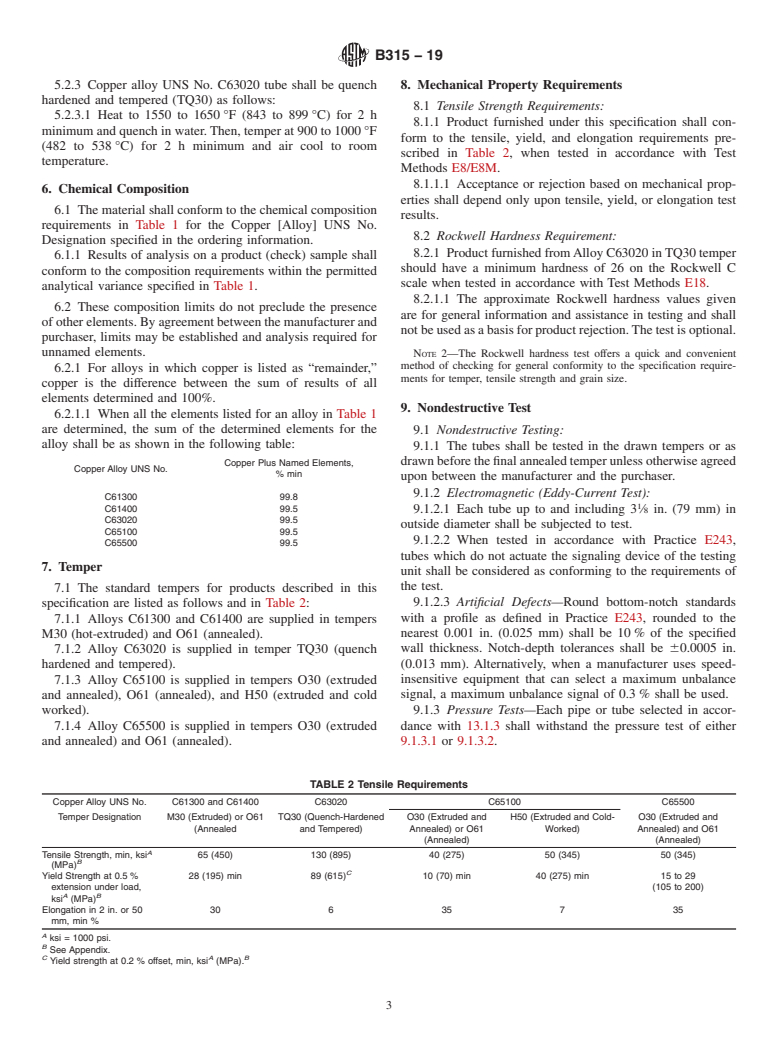

This specification establishes the requirements for seamless, copper alloy pipe and tube in nominal pipe sizes, both regular and extra-strong, and seamless tube in straight lengths for general engineering purposes. The material of manufacture shall be a cast billet, bar, or tube. The product shall be produced by hot-working or cold-working operations, or both. Unless otherwise specified, the product shall be finished by such cold working and annealing or heat treatment. Only tensile, yield, or elongation test results shall be a basis for rejection based upon mechanical properties. At least two replicate analyses for each element with a limiting value shall be conducted under chemical analysis. The test specimen shall be of the size and shape to permit testing with the available test equipment. The surface of the specimen shall be sufficiently flat and smooth to permit the accurate determination of hardness and shall be sufficiently free of scale and foreign material to permit the accurate determination of hardness. Care shall be taken to avoid changing the material's condition through either cold working or heating, or both. The product shall be free from defects, but blemishes of a nature that do not interfere with the intended application are acceptable.

SCOPE

1.1 This specification2 establishes the requirements for seamless, copper alloy pipe and tube in nominal pipe sizes, both regular and extra strong, and seamless tube in straight lengths for general engineering purposes. Pipe and tube are produced in the copper alloy UNS Numbers: C61300, C61400, C63020, C65100, and C65500.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety caveat pertains only to the test method(s) described in this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B315 −19

Standard Specification for

1

Seamless Copper Alloy Pipe and Tube

This standard is issued under the fixed designation B315; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Sheet, Strip, and Rolled Bar for General Purposes and

2

Pressure Vessels

1.1 This specification establishes the requirements for

B121/B121M Specification for Leaded Brass Plate, Sheet,

seamless, copper alloy pipe and tube in nominal pipe sizes,

Strip, and Rolled Bar

both regular and extra strong, and seamless tube in straight

B122/B122M Specification for Copper-Nickel-Tin Alloy,

lengths for general engineering purposes. Pipe and tube are

Copper-Nickel-Zinc Alloy (Nickel Silver), and Copper-

produced in the copper alloy UNS Numbers: C61300, C61400,

Nickel Alloy Plate, Sheet, Strip, and Rolled Bar

C63020, C65100, and C65500.

B152/B152M Specification for Copper Sheet, Strip, Plate,

1.2 Units—The values stated in inch-pound units are to be

and Rolled Bar

regarded as standard. The values given in parentheses are

B169/B169M Specification for Aluminum Bronze Sheet,

mathematical conversions to SI units that are provided for

Strip, and Rolled Bar

information only and are not considered standard.

B194 SpecificationforCopper-BerylliumAlloyPlate, Sheet,

1.3 The following safety caveat pertains only to the test

Strip, and Rolled Bar

method(s) described in this specification. This standard does

B422/B422M Specification for Copper-Aluminum-Silicon-

not purport to address all of the safety concerns, if any,

Cobalt Alloy, Copper-Nickel-Silicon-Magnesium Alloy,

associated with its use. It is the responsibility of the user of this

Copper-Nickel-Silicon Alloy, Copper-Nickel-Aluminum-

standard to establish appropriate safety, health, and environ-

Magnesium Alloy, and Copper-Nickel-Tin Alloy Sheet

mental practices and determine the applicability of regulatory

and Strip

limitations prior to use.

B465 SpecificationforCopper-IronAlloyPlate,Sheet,Strip,

1.4 This international standard was developed in accor-

and Rolled Bar

dance with internationally recognized principles on standard-

B534 Specification for Copper-Cobalt-Beryllium Alloy and

ization established in the Decision on Principles for the

Copper-Nickel-Beryllium Alloy Plate, Sheet, Strip, and

Development of International Standards, Guides and Recom-

Rolled Bar

mendations issued by the World Trade Organization Technical

B591 Specification for Copper-Zinc-Tin and Copper-Zinc-

Barriers to Trade (TBT) Committee.

Tin-Iron-NickelAlloys Plate, Sheet, Strip, and Rolled Bar

B592 Specification for Copper-Zinc-Aluminum-Cobalt

2. Referenced Documents

Alloy, Copper-Zinc-Tin-IronAlloy Plate, Sheet, Strip, and

3

2.1 ASTM Standards:

Rolled Bar

B36/B36M Specification for Brass Plate, Sheet, Strip, And

B740 Specification for Copper-Nickel-Tin Spinodal Alloy

Rolled Bar

Strip

B96/B96M Specification for Copper-Silicon Alloy Plate,

B747 Specification for Copper-Zirconium Alloy Sheet and

Strip

B768 Specification for Copper-Cobalt-Beryllium Alloy and

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

Copper-Nickel-Beryllium Alloy Strip and Sheet

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

B846 Terminology for Copper and Copper Alloys

and Tube.

Current edition approved April 1, 2019. Published April 2019. Originally

B888/B888M Specification for Copper Alloy Strip for Use

approved in 1957. Last previous edition approved in 2012 as B315–12. DOI:

in Manufacture of Electrical Connectors or Spring Con-

10.1520/B0315–19.

2

tacts

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

cation SB315 in Section II of that Code.

E8/E8M Test Methods for Tension Testing of Metallic Ma-

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

terials

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

E18 Test Methods for Rockwell Hardness of Metallic Ma-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. terials

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B315−19

E29 Practice for Using Significant Digits in Test Data to 4.1.4.6 When copper alloy UNS No. C63020 is ordered

Determine Conformance with Specifications under this

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B315 − 12 B315 − 19

Standard Specification for

1

Seamless Copper Alloy Pipe and Tube

This standard is issued under the fixed designation B315; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

2

1.1 This specification establishes the requirements for seamless, copper alloy pipe and tube in nominal pipe sizes, both regular

and extra strong, and seamless tube in straight lengths for general engineering purposes. Pipe and tube are produced in the copper

alloy UNS Numbers: C61300, C61400, C63020, C65100, and C65500.

NOTE 1—Inquiry should be made of the manufacturer or supplier concerning the availability of product in a specific alloy.

1.2 Units—Values The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety caveat pertains only to the test method(s) described in this specification. This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

B36/B36M Specification for Brass Plate, Sheet, Strip, And Rolled Bar

B96/B96M Specification for Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar for General Purposes and Pressure Vessels

B121/B121M Specification for Leaded Brass Plate, Sheet, Strip, and Rolled Bar

B122/B122M Specification for Copper-Nickel-Tin Alloy, Copper-Nickel-Zinc Alloy (Nickel Silver), and Copper-Nickel Alloy

Plate, Sheet, Strip, and Rolled Bar

B152/B152M Specification for Copper Sheet, Strip, Plate, and Rolled Bar

B169/B169M Specification for Aluminum Bronze Sheet, Strip, and Rolled Bar

B194 Specification for Copper-Beryllium Alloy Plate, Sheet, Strip, and Rolled Bar

B422/B422M Specification for Copper-Aluminum-Silicon-Cobalt Alloy, Copper-Nickel-Silicon-Magnesium Alloy, Copper-

Nickel-Silicon Alloy, Copper-Nickel-Aluminum-Magnesium Alloy, and Copper-Nickel-Tin Alloy Sheet and Strip

B465 Specification for Copper-Iron Alloy Plate, Sheet, Strip, and Rolled Bar

B534 Specification for Copper-Cobalt-Beryllium Alloy and Copper-Nickel-Beryllium Alloy Plate, Sheet, Strip, and Rolled Bar

B591 Specification for Copper-Zinc-Tin and Copper-Zinc-Tin-Iron-Nickel Alloys Plate, Sheet, Strip, and Rolled Bar

B592 Specification for Copper-Zinc-Aluminum-Cobalt Alloy, Copper-Zinc-Tin-Iron Alloy Plate, Sheet, Strip, and Rolled Bar

B740 Specification for Copper-Nickel-Tin Spinodal Alloy Strip

B747 Specification for Copper-Zirconium Alloy Sheet and Strip

B768 Specification for Copper-Cobalt-Beryllium Alloy and Copper-Nickel-Beryllium Alloy Strip and Sheet

B846 Terminology for Copper and Copper Alloys

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.04 on Pipe and

Tube.

Current edition approved Oct. 1, 2012April 1, 2019. Published November 2012April 2019. Originally approved in 1957. Last previous edition approved in 20062012 as

B315 – 06.B315–12. DOI: 10.1520/B0315-12.10.1520/B0315–19.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SB315 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page:

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.