ASTM D1816-97

(Test Method)Standard Test Method for Dielectric Breakdown Voltage of Insulating Oils of Petroleum Origin Using VDE Electrodes

Standard Test Method for Dielectric Breakdown Voltage of Insulating Oils of Petroleum Origin Using VDE Electrodes

SCOPE

1.1 This test method covers the determination of the dielectric breakdown voltage of insulating oils of petroleum origin. This test method is applicable to liquid petroleum oils commonly used in cables, transformers, oil circuit breakers, and similar apparatus as an insulating and cooling medium. The suitability of this test method for testing oils having viscosities of more than 19 cSt (mm /s) (100 SUS) at 40°C (104°F) has not been determined.

1.2 This test method is more sensitive to the deleterious effects of moisture in solution than is Test Method D877, especially when cellulosic fibers are present in the oil. It has been found to be especially useful in diagnostic and laboratory investigations of the dielectric breakdown strength of oil in insulating systems.

1.3 This test method is recommended for testing filtered, degassed, and dehydrated oil prior to and during the filling of power systems apparatus rated above 230 kV, and for testing samples of oil from the apparatus after filling. It is also finding increased usage for testing oils from transformers in service.

1.4 This test method is not recommended for, and should not be used for, acceptance tests on oil received from vendors in tank cars, tank trucks, or drums.

1.5 Both the metric and the alternative inch-pound units are acceptable.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1816 – 97

Standard Test Method for

Dielectric Breakdown Voltage of Insulating Oils of

Petroleum Origin Using VDE Electrodes

This standard is issued under the fixed designation D 1816; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 2864 Terminology Relating to Electrical Insulating Liq-

uids and Gases

1.1 This test method covers the determination of the dielec-

2.2 IEEE Standard:

tric breakdown voltage of insulating oils of petroleum origin.

No. 4 Techniques for High Voltage Testing

This test method is applicable to liquid petroleum oils com-

monly used in cables, transformers, oil circuit breakers, and

3. Significance and Use

similar apparatus as an insulating and cooling medium. The

3.1 The dielectric breakdown voltage of an insulating liquid

suitability of this test method for testing oils having viscosity

is of importance as a measure of the liquid’s ability to

of more than 19 cSt, (100SUS) at 40°C (104°F) has not been

withstand electric stress without failure. It serves to indicate

determined. Refer to Terminology D 2864 for definitions used

the presence of contaminating agents such as water, dirt,

in this test method.

cellulosic fibers, or conducting particles in the liquid, one or

1.2 This test method is more sensitive to the deleterious

more of which may be present in significant concentrations

effects of moisture in solution than is Test Method D 877,

when low breakdown voltages are obtained. However, a high

especially when cellulosic fibers are present in the oil. It has

dielectric breakdown voltage does not necessarily indicate the

been found to be especially useful in diagnostic and laboratory

absence of all contaminants; it may merely indicate that the

investigations of the dielectric breakdown strength of oil in

2 concentrations of contaminants that are present in the liquid

insulating systems.

between the electrodes are not large enough to deleteriously

1.3 This test method should be used for the testing of oil in

affect the average breakdown voltage of the liquid when tested

power system equipment where the oil has been filtered and

by this test method (see Appendix X1.)

vacuum filled.

1.4 Both the metric and the alternative inch-pound units are

4. Apparatus

acceptable.

4.1 Transformer— The desired test voltage may be most

1.5 This standard does not purport to address all of the

readily obtained by a step-up transformer energized from a

safety concerns, if any, associated with its use. It is the

variable low-voltage commercial power frequency source. To

responsibility of the user of this standard to establish appro-

reduce the likelihood of external flashover and to minimize

priate safety and health practices and determine the applica-

field distortion between the electrodes, a two-bushing, center-

bility of regulatory limitations prior to use.

tap-grounded transformer is recommended. Design the trans-

former and controlling element of such size that, with the test

2. Referenced Documents

specimen in the circuit, the voltage waveshape is approxi-

2.1 ASTM Standards:

mately a sinusoid with both half cycles alike, and it should

D 235 Specification for Mineral Spirits (Petroleum Spirits)

3 have a ratio of peak-to-rms value equal to the square root of

(Hydrocarbon Dry Cleaning Solvent)

two within 6 5 %. The peak to rms value may be checked by

D 877 Test Method for Dielectric Breakdown Voltage of

4 means of an oscilloscope, a spheregap, or a peak-reading

Insulating Liquids Using Disk Electrodes

voltmeter in conjunction with an rms voltmeter. Where the

D 923 Test Method for Sampling Electrical Insulating Liq-

4 wave form cannot be determined conveniently, a transformer

uids

having a rating of not less than ⁄2 kVA at the usual breakdown

voltage shall be used. Transformers of larger kVA capacity may

be used, but in no case should the short-circuit current in the

specimen circuit be outside the range from 1 to 10 mA/kV of

This test method is under the jurisdiction of ASTM Committee D-27 on

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom-

applied voltage. This limitation of current may be accom-

mittee D27.05on Electrical Tests.

plished by using a suitable external series resistor or by

Current edition approved May 10, 1997. Published January 1998. Originally

published as D 1816 – 60 T. Last previous edition D 1816 – 84a.

Supporting data is available from ASTM Headquarters. Request RR:D27-1006.

Annual Book of ASTM Standards, Vol 06.04.

Available from the Institute of Electrical and Electronic Engineers, Inc., PO

Annual Book of ASTM Standards, Vol 10.03.

Box 1331, Piscataway, NJ 08855.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 1816

employing a transformer with sufficient inherent reactance.

4.2 Circuit-Interrupting Equipment—Protect the primary of

the test transformer with an automatic circuit-breaking device

capable of opening in three cycles or less on the current

produced by breakdown of the test specimen, or up to five

cycles if the short-circuit current as described in 4.1 does not

exceed 200 mA. The current-sensing element that trips the

circuit-breaker should operate when the specimen-circuit cur-

rent is in the range from 2 to 20 mA. A prolonged flow of

current at the time of breakdown causes carbonization of the

liquid and pitting and heating of the electrodes, and thereby

increases the electrode and test cell maintenance, and time of

testing.

4.3 Voltage-Control Equipment—Raise the voltage ⁄2 kV/s

6 20 %. The rate-of-rise may be calculated from measure-

ments of the time required to raise the voltage between two

prescribed values. Voltage control may be secured by a

motor-driven variable-ratio-autotransformer. Preference should

be given to equipment having an approximate straight-line

voltage-time curve over the desired operating range. Motor

drive is preferred to manual drive because of the ease of

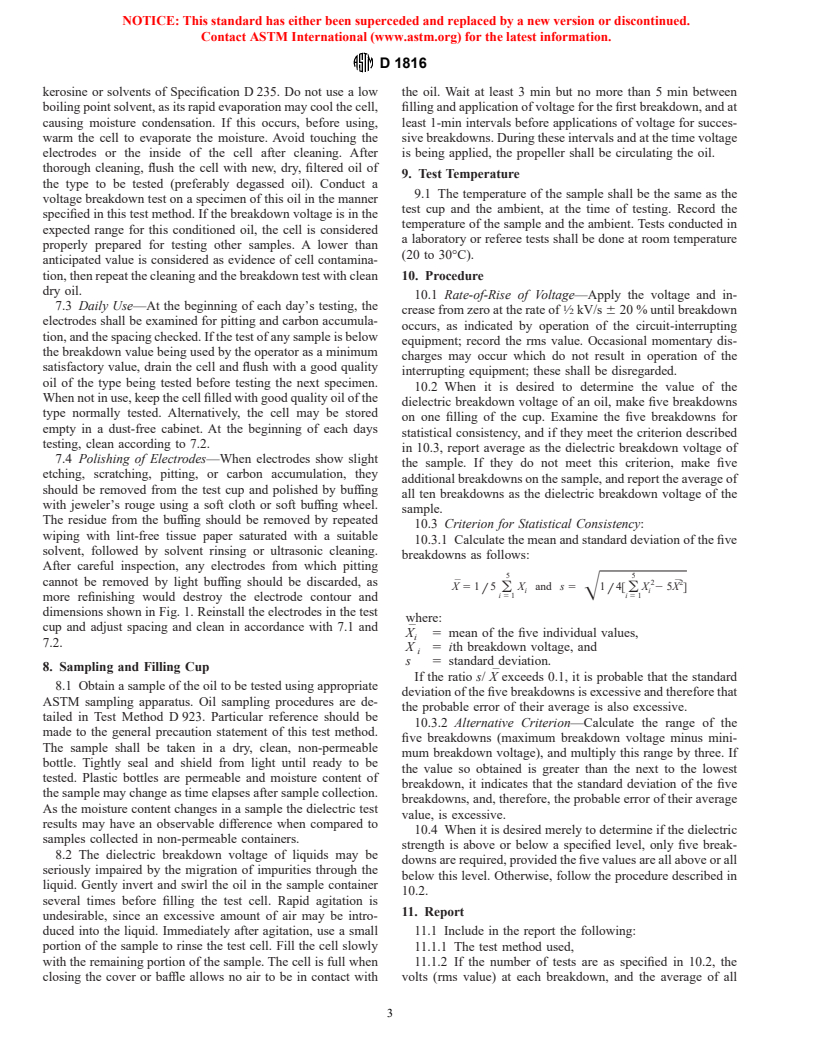

FIG. 1 VDE Electrode

maintaining a reasonably uniform rate-of-voltage rise with this

test method. When motor driven equipment is used, the speed

of 20° 6 5 %), operating at a speed between 200 and 300 rpm.

control rheostat should be calibrated in terms of rate-of-voltage

The impeller, located below the lower edge of the electrodes,

rise for the test transformer used.

rotating in such a direction that the resulting liquid flow is

4.4 Voltmeter—Measure the voltage using a method that

directed downward against the bottom of the test cell. Con-

fulfills the requirements of IEEE Standard No. 4, giving rms

struct the test cell of a material of high dielectric strength, that

values, preferably by means of:

is not soluble in or attacked by any of the cleaning or test

4.4.1 A voltmeter connected to the secondary of a separate

liquids used, and is nonabsorbent to moisture and the cleaning

potential transformer, or

and test liquids. So that the breakdown may be observed,

4.4.2 A voltmeter connected to a well-designed tertiary coil

transparent materials are desirable, but not essential. In order to

in the test transformer, or

preclude stirring air with the sample, provide the cell with a

4.4.3 A voltmeter connected to the low-voltage side of the

cover or baffle that will effectively prevent air from contacting

testing transformer if the measurement error can be maintained

the circulating liquid.

within the limit specified in 4.5.

4.5 Accuracy—The combined accuracy of the voltmeter and

7. Adjustment and Care of Electrodes and Test Cell

voltage divider circuit shall be such that measurement error

7.1 Spacing—With the electrodes firmly locked in position,

does not exceed 5 % at the rate-of-voltage rise specified in 4.3.

check the electrodes with a standard round gage for 2-mm or

5. Electrodes

0.080-in. spacing, when a voltage source of a suitable range is

available, or for 1-mm or 0.040-in. spacing when the test

5.1 The electrodes shall be polished brass spherically-

transformer voltage limit is restricted to approximately 50 kV.

capped electrodes of the VDE (Verband Deutscher Elektrotech-

Flat “go” and “no-go” gages may be substituted having

niker, Specification 0370) type having the dimensions shown

thicknesses of the specified value 60.03 mm for electrode

in Fig. 1 6 1 %, mounted with axes horizontal and coincident.

spacings of 1 or 2 mm, or thicknesses of the specified value

5.2 The test cell shall be designed to permit easy removal of

60.001 in. for spacings of 0.040 or 0.080 in. If it is necessary

the electrodes for cleaning and polishing.

to readjust the electrodes, lock the electrodes and check the

6. Test Cell

spacing. For referee tests or tests that will be used for close

6.1 Construct the test cell as a cube. A cell having a capacity comparisons, the laboratories shall agree in advance on the gap

of approximately 0.95 L, has been found to be satisfactory for spacing for the tests. Four gaps are possible 0.040 or 0.080 in.

or 1 or 2 mm. The gap agreed upon shall be measured with the

an electrode spacing of 2 mm or 0.080 in. A cell having a

capacity of approximately 0.5 L has been found to be satisfac- gage that corresponds exactly to one of the selected gap within

tory for an electrode spacing of 1 mm or 0.040 in. Mount the tolerance stated above for the gage.

electrodes rigidly from opposite sides with the gap approxi- 7.2 Cleaning—Wipe the electrodes and cell clean with dry,

mately centered. Clearance from all other sides and any part of lint-free tissue paper, or a clean dry chamois. It is important to

the stirring device is at least 12.7 mm ( ⁄2 in.). Provide the test avoid touching the electrodes or the cleaned gage with the

cell with a motor-driven two-bladed impeller measuring ap- fingers or with portions of the tissue paper or chamois that have

proximately 35 mm (1 ⁄8 in.) between the blade extremities, been in contact with the hands. After adjustment of the gap

having a pitch of approximately 40 mm or 1.57 in. (blade angle spacing, rinse the cell with a dry hydrocarbon solvent, such as

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.