ASTM D6790/D6790M-16

(Test Method)Standard Test Method for Determining Poisson's Ratio of Honeycomb Cores

Standard Test Method for Determining Poisson's Ratio of Honeycomb Cores

SIGNIFICANCE AND USE

5.1 Certain sandwich panel analyses require the Poisson's ratio of the honeycomb core. It is not possible to measure the honeycomb's Poisson's ratio by conventional methods.

5.2 This test method provides a standard method of determining the Poisson’s ratio of honeycomb core materials for design properties, material specifications, research and development applications, and quality assurance.

5.3 Factors that influence the Poisson’s ratio of honeycomb core materials and shall therefore be reported include the following: core material, methods of material fabrication, core geometry, core thickness, core thickness uniformity, cell wall thickness, specimen geometry, specimen preparation, and specimen conditioning.

SCOPE

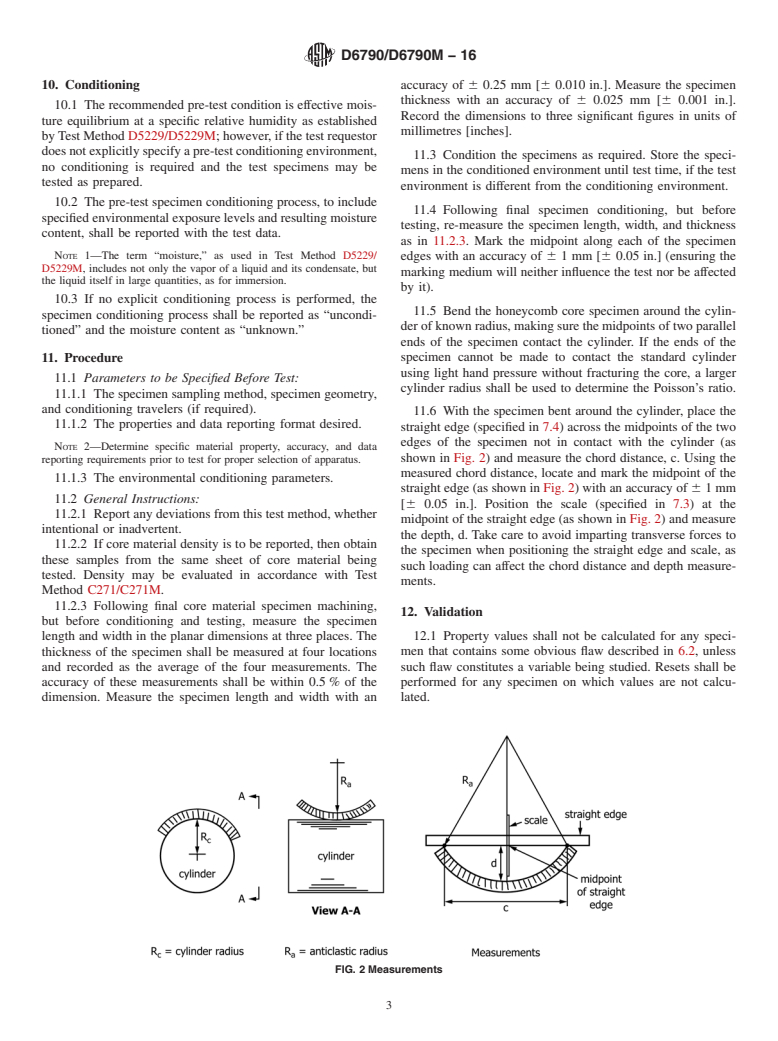

1.1 This test method covers the determination of the sandwich honeycomb core Poisson's ratio from the anticlastic curvature radii, see Fig. 1.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6790/D6790M − 16

Standard Test Method for

1

Determining Poisson’s Ratio of Honeycomb Cores

This standard is issued under the fixed designation D6790/D6790M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of the sand- 3.1 Definitions—Terminology D3878 defines terms relating

wich honeycomb core Poisson’s ratio from the anticlastic to high-modulus fibers and their composites, as well as terms

curvature radii, see Fig. 1.

relating to sandwich constructions. Terminology D883 defines

termsrelatingtoplastics.TerminologyE456andPracticeE177

1.2 The values stated in either SI units or inch-pound units

define terms relating to statistics. In the event of a conflict

are to be regarded separately as standard. The values stated in

between terms, Terminology D3878 shall have precedence

each system may not be exact equivalents; therefore, each

over the other terminologies.

system shall be used independently of the other. Combining

values from the two systems may result in non-conformance 3.2 Symbols: c = chord measurement

with the standard.

CV = coefficient of variation statistic of a sample population

1.2.1 Within the text, the inch-pound units are shown in for a given property (in percent)

brackets.

d = depth measurement

R = anticlastic curvature radius

a

1.3 This standard does not purport to address all of the

R = cylinder radius

safety concerns, if any, associated with its use. It is the c

S = standard deviation statistic of a sample population for

responsibility of the user of this standard to establish appro- n-1

a given property

priate safety and health practices and determine the applica-

x = test result for an individual specimen from the sample

bility of regulatory limitations prior to use. 1

population for a given property

x¯ = mean or average (estimate of mean) of a sample popu-

2. Referenced Documents

lation for a given property

2

2.1 ASTM Standards:

v = Poisson’s ratio

C271/C271M Test Method for Density of Sandwich Core

Materials

4. Summary of Test Method

D883 Terminology Relating to Plastics

D3878 Terminology for Composite Materials 4.1 This test method determines the Poisson’s ratio of

sandwich honeycomb core by bending the core around a

D5229/D5229M Test Method for MoistureAbsorption Prop-

erties and Equilibrium Conditioning of Polymer Matrix cylinder and taking measurements of the anticlastic curvature

that occurs.

Composite Materials

E122 Practice for Calculating Sample Size to Estimate,With

Specified Precision, the Average for a Characteristic of a 5. Significance and Use

Lot or Process

5.1 Certain sandwich panel analyses require the Poisson’s

E177 Practice for Use of the Terms Precision and Bias in

ratio of the honeycomb core. It is not possible to measure the

ASTM Test Methods

honeycomb’s Poisson’s ratio by conventional methods.

E456 Terminology Relating to Quality and Statistics

5.2 This test method provides a standard method of deter-

mining the Poisson’s ratio of honeycomb core materials for

design properties, material specifications, research and devel-

1

This test method is under the jurisdiction of ASTM Committee D30 on

opment applications, and quality assurance.

Composite Materials and is the direct responsibility of Subcommittee D30.09 on

Sandwich Construction.

5.3 Factors that influence the Poisson’s ratio of honeycomb

Current edition approved April 1, 2016. Published April 2016. Originally

core materials and shall therefore be reported include the

approved in 2002. Last previous edition approved in 2014 as D6790 - 14. DOI:

10.1520/D6790_D6790M-16.

following: core material, methods of material fabrication, core

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

geometry, core thickness, core thickness uniformity, cell wall

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

thickness, specimen geometry, specimen preparation, and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. specimen conditioning.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6790/D6790M − 16

within 0.5 % of the sample length, width and thickness. For

typical specimen geometries, an instrument with an accuracy

of 60.025 mm [60.001 in.] is desirable for thickness

measurement, whereas an instrument with an accuracy of

60.25 mm [60.01 in.] is desirable for length and width

measurement.

7.2 Cylinders—Acylinder shall be utili

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6790/D6790M − 14 D6790/D6790M − 16

Standard Test Method for

1

Determining Poisson’s Ratio of Honeycomb Cores

This standard is issued under the fixed designation D6790/D6790M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the sandwich honeycomb core Poisson’s ratio from the anticlastic curvature

radii, see Fig. 1.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.2.1 Within the text, the inch-pound units are shown in brackets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C271/C271M Test Method for Density of Sandwich Core Materials

3

C274 Terminology of Structural Sandwich Constructions (Withdrawn 2016)

D883 Terminology Relating to Plastics

D3878 Terminology for Composite Materials

D5229/D5229M Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite

Materials

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

3

E1309 Guide for Identification of Fiber-Reinforced Polymer-Matrix Composite Materials in Databases (Withdrawn 2015)

3

E1434 Guide for Recording Mechanical Test Data of Fiber-Reinforced Composite Materials in Databases (Withdrawn 2015)

3. Terminology

3.1 Definitions—Terminology D3878 defines terms relating to high-modulus fibers and their composites.

Terminologycomposites, as C274 defineswell as terms relating to structural sandwich constructions. Terminology D883 defines

terms relating to plastics. Terminology E456 and Practice E177 define terms relating to statistics. In the event of a conflict between

terms, Terminology D3878 shall have precedence over the other terminologies.

3.2 Symbols: c = chord measurement

CV = coefficient of variation statistic of a sample population for a given property (in percent)

d = depth measurement

R = anticlastic curvature radius

a

R = cylinder radius

c

S = standard deviation statistic of a sample population for a given property

n-1

1

This test method is under the jurisdiction of ASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.09 on Sandwich

Construction.

Current edition approved May 1, 2014April 1, 2016. Published June 2014April 2016. Originally approved in 2002. Last previous edition approved in 20072014 as

D6790 - 02D6790 - 14.(2007). DOI: 10.1520/D6790_D6790M-14.10.1520/D6790_D6790M-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6790/D6790M − 16

FIG. 1 Anticlastic Curvature

x = test result for an individual specimen from the sample population for a given property

1

x¯ = mean or average (estimate of mean) of a sample population for a given property

v = Poisson’s ratio

4. Summary of Test Method

4.1 This test method determines the Poisson’s ratio of sandwich honeycomb core by bending the core around a cylinder and

taking measurements of the anticlastic curvature that occurs.

5. Significance and Use

5.1 Certain sandwich panel analyses require the Poisson’s ratio of the honeycomb core. It is not possible to measure the

honeycomb’s Poisson’s ratio by conventional methods.

5.2 This test method provides a standard method of determining the Poisson’s ratio of honeycomb core materials for design

properties, mat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.