ASTM C1127-01(2009)

(Guide)Standard Guide for Use of High Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane with an Integral Wearing Surface

Standard Guide for Use of High Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane with an Integral Wearing Surface

SIGNIFICANCE AND USE

This guide is divided into two sections which provide design and specification guidelines for the use of a cold liquid-applied elastomeric membrane with integral wearing surface for waterproofing building decks in building areas to be occupied by personnel, vehicles, or equipment.

The intent of Sections 5-11, Design Considerations, is to provide information and design guidelines where a waterproofing membrane with integral wearing surface is to be used. The intent of the remaining sections is to provide minimum guide specifications for the use of the purchaser and the seller in contract documents.

Where the state of the art is such that criteria for a particular condition is not as yet firmly established or has numerous variables that require consideration, reference is made to the applicable portion of Sections 5-11 that covers the particular area of concern. Section 16 describes the repair, rehabilitation, and replacement of the membrane. DESIGN CONSIDERATIONS Top

SCOPE

1.1 This guide describes the design and installation of cold liquid-applied elastomeric waterproofing membrane systems that have an integral wearing surface. The cold liquid-applied elastomeric waterproofing membrane (membrane) to which this guide refers is specified in Specification C 957.

1.2 Concrete Slab-on-Grade—Waterproofing the upper surface of a concrete slab on grade presents special problems due to the possibility of negative hydrostatic pressure causing loss of bond to the substrate. Consideration of these problems is beyond the scope of this guide. Consult the membrane manufacturer for recommendations when this situation exists.

1.3 The committee having jurisdiction for this guide is not aware of any similar ISO standard.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Note in 15.4.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1127 −01(Reapproved 2009)

Standard Guide for

Use of High Solids Content, Cold Liquid-Applied

Elastomeric Waterproofing Membrane with an Integral

Wearing Surface

This standard is issued under the fixed designation C1127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C332 Specification for Lightweight Aggregates for Insulat-

ing Concrete

1.1 This guide describes the design and installation of cold

C717 Terminology of Building Seals and Sealants

liquid-applied elastomeric waterproofing membrane systems

C755 Practice for Selection of Water Vapor Retarders for

that have an integral wearing surface. The cold liquid-applied

Thermal Insulation

elastomeric waterproofing membrane (membrane) to which

C920 Specification for Elastomeric Joint Sealants

this guide refers is specified in Specification C957.

C957 Specification for High-Solids Content, Cold Liquid-

1.2 Concrete Slab-on-Grade—Waterproofing the upper sur-

Applied Elastomeric Waterproofing Membrane With Inte-

face of a concrete slab on grade presents special problems due

gral Wearing Surface

to the possibility of negative hydrostatic pressure causing loss

C962 Standards Guide for Use of Elastomeric Joint Sealants

of bond to the substrate. Consideration of these problems is

(Withdrawn 1992)

beyond the scope of this guide. Consult the membrane manu-

C1193 Guide for Use of Joint Sealants

facturer for recommendations when this situation exists.

D653 Terminology Relating to Soil, Rock, and Contained

Fluids

1.3 The committee having jurisdiction for this guide is not

aware of any similar ISO standard. D1752 Specification for Preformed Sponge Rubber Cork

and Recycled PVC Expansion Joint Fillers for Concrete

1.4 The values stated in SI units are to be regarded as the

Paving and Structural Construction

standard. The values given in parentheses are for information

D2628 Specification for Preformed Polychloroprene Elasto-

only.

meric Joint Seals for Concrete Pavements

1.5 This standard does not purport to address all of the

2.2 U.S. Department of Commerce Standard:

safety concerns, if any, associated with its use. It is the

Product Standard PS 1-74 Construction and Industrial Ply-

responsibility of the user of this standard to establish appro- 4

wood

priate safety and health practices and determine the applica-

2.3 American Concrete Institute (ACI) Standard:

bility of regulatory limitations prior to use. For specific hazard

301-84 (1985) Specification for Structural Concrete for

statements see Note in 15.4.

Buildings

2.4 Steel Structures Painting Council (SSPC) Standards:

2. Referenced Documents

Steel Structures Painting Manual, Systems and Specifica-

2.1 ASTM Standards:

tions:

C33 Specification for Concrete Aggregates

Specification SSPC SP-2 Wire Brush Cleaning

C150 Specification for Portland Cement

Specification SSPC SP-6 Commercial Blast Cleaning

C330 Specification for Lightweight Aggregates for Struc-

2.5 American Plywood Association (APA) Standard:

tural Concrete

APA Plywood Construction Guide

This guide is under the jurisdiction of ASTM Committee D08 on Roofing and

Waterproofing and is the direct responsibility of Subcommittee D08.25 on Liquid The last approved version of this historical standard is referenced on

Applied Polymeric Materials Used for Roofing and Waterproofing Membranes that www.astm.org.

are Directly Exposed to the Weather. Available from National Institute of Standards and Technology (NIST), 100

Current edition approved Jan. 1, 2009. Published January 2009. Originally Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

approved in 1989. Last previous edition approved in 2001 as C1127 – 01. DOI: Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

10.1520/C1127-01R09. Hills, MI 48333-9094, http://www.concrete.org.

2 6

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Society for Protective Coatings (SSPC), 40 24th St., 6th Floor,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Pittsburgh, PA 15222-4656, http://www.sspc.org.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican PlywoodAssoc. (Forest Industries), P.O. Box 11700,

the ASTM website. Tacoma, WA 98411.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1127−01 (2009)

3. Terminology 4. Significance and Use

3.1 Definitions—Refer toTerminology C717 for the follow- 4.1 This guide is divided into two sections which provide

ing terms used in this guide: bond breaker; cellular; cold joint; design and specification guidelines for the use of a cold

compatibility; compound; construction joint; control joint; liquid-applied elastomeric membrane with integral wearing

creep; dry film thickness; elastomer; expansion joint; gasket; surfaceforwaterproofingbuildingdecksinbuildingareastobe

isolation joint; joint; laitance; primer; reglet; reinforced joint; occupied by personnel, vehicles, or equipment.

sealant; spalling.

4.2 The intent of Sections5–11, Design Considerations, is

3.2 Definitions of Terms Specific to This Standard:

to provide information and design guidelines where a water-

3.2.1 cold-applied—capable of being applied without heat-

proofing membrane with integral wearing surface is to be used.

ing as contrasted to hot-applied.

The intent of the remaining sections is to provide minimum

3.2.1.1 Discussion—Cold-applied products are furnished in

guide specifications for the use of the purchaser and the seller

a liquid state, whereas hot-applied products are furnished as

in contract documents.

solids that must be heated to liquefy them.

4.3 Where the state of the art is such that criteria for a

3.2.2 curing time—the period between application and the

particular condition is not as yet firmly established or has

time when the material attains its intended physical properties.

numerous variables that require consideration, reference is

made to the applicable portion of Sections5–11 that covers

3.2.3 deck—the horizontal structural substrate supporting

the particular area of concern. Section 16 describes the repair,

the plaza deck system.

rehabilitation, and replacement of the membrane.

3.2.4 deflection—the deviation of a structural element from

its original shape or plane due to physical loading, temperature

DESIGN CONSIDERATIONS

gradients, or rotation of its support.

5. General

3.2.5 finish—the exposed top surface of the plaza deck

system, or traffic or wearing surface. 5.1 Major Components, Subsystems, and Features—Design

of plaza deck waterproofing includes consideration of several

3.2.6 flashing—a generic term describing the transitional

subsystems, with their material components and interrelation-

area between the waterproofing membrane and surfaces above

ships. The specific project requirements, types of substrates

the wearing surface of the plaza; a terminal closure or barrier

exposed to weather, difference in climatic conditions to which

to prevent ingress of water into the system.

the deck is exposed, and interior environmental requirements

3.2.7 floated finish—a concrete finish provided by consoli-

of the occupied space, are major determinants in the selection

dating and leveling the concrete with only a power driven or

of components. Information needed to design the deck subsys-

hand float, or both.

tems includes temperature extremes of the inner and outer

3.2.7.1 Discussion—A floated finish is more coarse than a

surfaces, precipitation rates, solar exposure, prevailing wind

troweled finish. For specifications, see ACI Specification 301.

direction, the pattern and reflectivity of adjacent structures,

anticipated amount and intensity of vibration resulting from

3.2.8 freeze-thaw cycle—the freezing and subsequent thaw-

function or adjacent occupancies, and design live loads.

ing of a material.

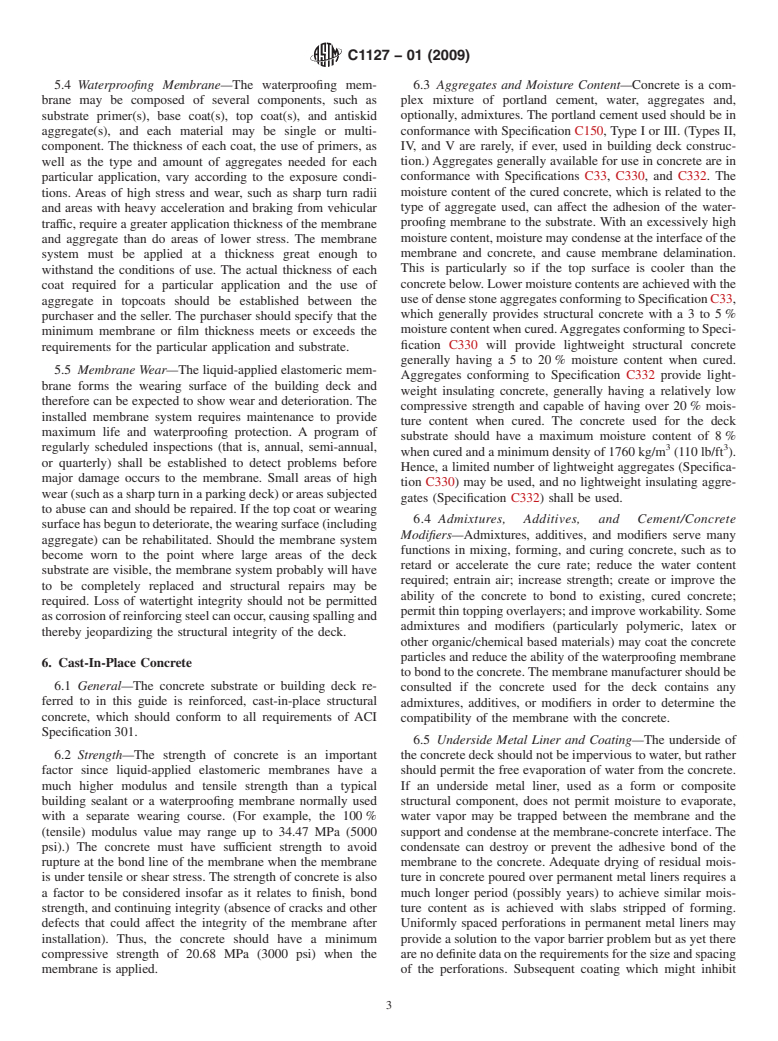

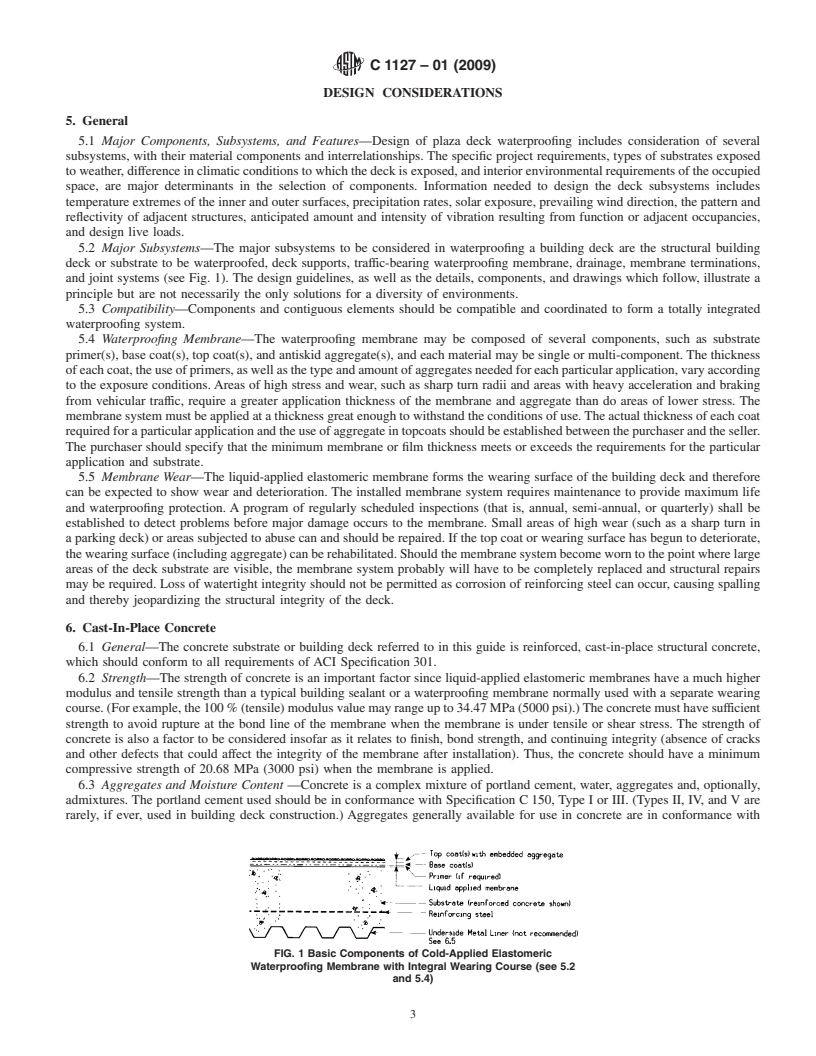

5.2 Major Subsystems—The major subsystems to be consid-

3.2.9 grout—concretecontainingnocoarseaggregate;athin

ered in waterproofing a building deck are the structural

mortar.

building deck or substrate to be waterproofed, deck supports,

3.2.10 preparatory coat—an initial coat of the liquid-

traffic-bearing waterproofing membrane, drainage, membrane

applied membrane which is applied at cracks, joints, or

terminations, and joint systems (see Fig. 1). The design

terminal points to provide reinforcement to the membrane at

guidelines, as well as the details, components, and drawings

these critical areas.

which follow, illustrate a principle but are not necessarily the

3.2.11 structural slab—a horizontal, supporting, cast-in-

only solutions for a diversity of environments.

place concrete building deck.

5.3 Compatibility—Components and contiguous elements

3.2.12 traffıc surface—a surface exposed to traffic, either

should be compatible and coordinated to form a totally

pedestrian or vehicular.

integrated waterproofing system.

3.2.13 troweled finish—a concrete finish provided by

smoothing the surface with power-driven or hand trowels, or

both, after the float finishing operation.

3.2.13.1 Discussion—Atroweled finish is smoother than the

floated finish. For specifications, see ACI Specification 301.

3.2.14 wearing surface—see traffıc surface.

3.2.15 wet-film thickness—the thickness of a liquid coating

as it is applied.

FIG. 1 Basic Components of Cold-Applied Elastomeric Water-

3.2.16 wet-film gauge—a gauge for measuring the thickness

proofing Membrane with Integral Wearing Course (see 5.2 and

of a wet film. 5.4)

C1127−01 (2009)

5.4 Waterproofing Membrane—The waterproofing mem- 6.3 Aggregates and Moisture Content—Concrete is a com-

brane may be composed of several components, such as plex mixture of portland cement, water, aggregates and,

substrate primer(s), base coat(s), top coat(s), and antiskid optionally, admixtures. The portland cement used should be in

aggregate(s), and each material may be single or multi- conformance with Specification C150, Type I or III. (Types II,

IV, and V are rarely, if ever, used in building deck construc-

component. The thickness of each coat, the use of primers, as

well as the type and amount of aggregates needed for each tion.)Aggregates generally available for use in concrete are in

conformance with Specifications C33, C330, and C332. The

particular application, vary according to the exposure condi-

tions. Areas of high stress and wear, such as sharp turn radii moisture content of the cured concrete, which is related to the

type of aggregate used, can affect the adhesion of the water-

and areas with heavy acceleration and braking from vehicular

proofing membrane to the substrate. With an excessively high

traffic, require a greater application thickness of the membrane

moisturecontent,moisturemaycondenseattheinterfaceofthe

and aggregate than do areas of lower stress. The membrane

membrane and concrete, and cause membrane delamination.

system must be applied at a thickness great enough to

This is particularly so if the top surface is cooler than the

withstand the conditions of use. The actual thickness of each

concrete below. Lower moisture contents are achieved with the

coat required for a particular application and the use of

useofdensestoneaggregatesconformingtoSpecificationC33,

aggregate in topcoats should be established between the

which generally provides structural concrete witha3to5%

purchaser and the seller. The purchaser should specify that the

moisturecontentwhencured.AggregatesconformingtoSpeci-

minimum membrane or film thickness meets or exceeds the

fication C330 will provide lightweight structural concrete

requirements for the particular application and substrate.

generally havinga5to20% moisture content when cured.

5.5 Membrane Wear—The liquid-applied elastomeric mem-

Aggregates conforming to Specification C332 provide light-

brane forms the wearing surface of the building deck and

weight insulating concrete, generally having a relatively low

therefore can be expected to show wear and deterioration. The

compressive strength and capable of having over 20 % mois-

installed membrane system requires maintenance to provide

ture content when cured. The concrete used for the deck

maximum life and waterproofing protection. A program of

substrate should have a maximum moisture content of 8 %

3 3

regularly scheduled inspections (that is, annual, semi-annual,

when cured and a minimum density of 1760 kg/m (110 lb/ft ).

or quarterly) shall be established to detect problems before

Hence, a limited number of lightweight aggregates (Specifica-

major damage occurs to the membrane. Small areas of high

tion C330) may be used, and no lightweight insulating aggre-

wear (such as a sharp turn in a parking deck) or areas subjected

gates (Specification C332) shall be used.

to abuse can and should be repaired. If the top coat or wearing

6.4 Admixtures, Additives, and Cement/Concrete

surfacehasbeguntodeteriorate,thewearingsurface(including

Modifiers—Admixtures, additives, and modifiers serve many

aggregate) can be rehabilitated. Should the membrane system

functions in mixing, forming, and curing concrete, such as to

become worn to the point where large areas of the deck

retard or accelerate the cure rate; reduce the water content

substrate are visible, the membrane system probably will have

required; entrain air; increase strength; create or improve the

to be completely replaced and structural repairs may be

ability of the concrete to bond to existing, cured concrete;

required. Loss of watertight integrity should not be permitted

permit thin topping overlayers; and improve workability. Some

ascorrosionofreinforcingsteelcanoccur,causingspallingand

admixtures and modifiers (particularly polymeric, latex or

thereby jeopardizing the structural integrity of the deck.

other organic/chemical based materials) may coat the concrete

particles and reduce the ability of the waterproofing membrane

6. Cast-In-Place Concrete

tobondtotheconcrete.Themembranemanufacturershouldbe

6.1 General—The concrete substrate or building deck re-

consulted if the concrete used for the deck contains any

ferred to in this guide is reinforced, cast-in-place structural

admixtures, additives, or modifiers in order to determine the

concrete, which should conform to all requirements of ACI

compatibility of the membrane with the concrete.

Specification 301.

6.5 Underside Metal Liner and Coating—The underside of

6.2 Strength—The strength of concrete is an important the concrete deck should not be impervious to water, but rather

fac

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1127–01 Designation: C 1127 – 01 (Reapproved 2009)

Standard Guide for

Use of High Solids Content, Cold Liquid-Applied

Elastomeric Waterproofing Membrane with an Integral

Wearing Surface

This standard is issued under the fixed designation C 1127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide describes the design and installation of cold liquid-applied elastomeric waterproofing membrane systems that

have an integral wearing surface. The cold liquid-applied elastomeric waterproofing membrane (membrane) to which this guide

refers is specified in Specification C 957.

1.2 Concrete Slab-on-Grade—Waterproofing the upper surface of a concrete slab on grade presents special problems due to the

possibility of negative hydrostatic pressure causing loss of bond to the substrate. Consideration of these problems is beyond the

scope of this guide. Consult the membrane manufacturer for recommendations when this situation exists.

1.3 The committee having jurisdiction for this guide is not aware of any similar ISO standard.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements see Note in 15.4.

2. Referenced Documents

2.1 ASTM Standards:

C33 Specification for Concrete Aggregates

C 150 Specification for Portland Cement

C 330 Specification for Lightweight Aggregates for Structural Concrete

C 332 Specification for Lightweight Aggregates for Insulating Concrete

C 717 Terminology of Building Seals and Sealants

C 755 Practice for Selection of Water Vapor Retarders for Thermal Insulation

C 920 Specification for Elastomeric Joint Sealants

C 957 Specification for High-Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane With Integral

Wearing Surface

C 962 Guide for Use of Elastomeric Joint Sealants

C 1193 Guide for Use of Joint Sealants

D 653 Terminology Relating to Soil, Rock, and Contained Fluids

D 1752 Specification for Preformed Sponge Rubber Cork and Recycled PVC Expansion Joint Fillers for Concrete Paving and

Structural Construction

D 2628 Specification for Preformed Polychloroprene Elastomeric Joint Seals for Concrete Pavements

2.2 U.S. Department of Commerce Standard:

Product Standard PS 1-74 Construction and Industrial Plywood

2.3 American Concrete Institute (ACI) Standard:

This guide is under the jurisdiction ofASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.22 on Waterproofing

and Dampproofing Systems.

Current edition approved June 10, 2001. Published July 2001. Originally published as C1127–89. Last previous edition C1127–95.

Current edition approved Jan. 1, 2009. Published January 2009. Originally approved in 1989. Last previous edition approved in 2001 as C 1127 – 01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Withdrawn.

Available from National Institute of Standards and Technology, Gaithersburg, MD 20899.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1127 – 01 (2009)

301-84 (1985) Specification for Structural Concrete for Buildings

2.4 Steel Structures Painting Council (SSPC) Standards:

Steel Structures Painting Manual, Systems and Specifications:

Specification SSPC SP-2 Wire Brush Cleaning

Specification SSPC SP-6 Commercial Blast Cleaning

2.5 American Plywood Association (APA) Standard:

APA Plywood Construction Guide

3. Terminology

3.1 Definitions—Refer to Terminology C 717 for the following terms used in this guide: bond breaker; cellular; cold joint;

compatibility; compound; construction joint; control joint; creep; dry film thickness; elastomer; expansion joint; gasket; isolation

joint; joint; laitance; primer; reglet; reinforced joint; sealant; spalling.

3.2 Description of Terms Specific to This Standard:

3.2.1 cold-applied—capable of being applied without heating as contrasted to hot-applied.

3.2.1.1 Discussion—Cold-applied products are furnished in a liquid state, whereas hot-applied products are furnished as solids

that must be heated to liquefy them.

3.2.2 curing time—the period between application and the time when the material attains its intended physical properties.

3.2.3 deck—the horizontal structural substrate supporting the plaza deck system.

3.2.4 deflection—the deviation of a structural element from its original shape or plane due to physical loading, temperature

gradients, or rotation of its support.

3.2.5 finish—the exposed top surface of the plaza deck system, or traffic or wearing surface.

3.2.6 flashing—a generic term describing the transitional area between the waterproofing membrane and surfaces above the

wearing surface of the plaza; a terminal closure or barrier to prevent ingress of water into the system.

3.2.7 floated finish—a concrete finish provided by consolidating and leveling the concrete with only a power driven or hand

float, or both.

3.2.7.1 Discussion—A floated finish is more coarse than a troweled finish. For specifications, see ACI Specification 301.

3.2.8 freeze-thaw cycle—the freezing and subsequent thawing of a material.

3.2.9 grout—concrete containing no coarse aggregate; a thin mortar.

3.2.10 preparatory coat—an initial coat of the liquid-applied membrane which is applied at cracks, joints, or terminal points

to provide reinforcement to the membrane at these critical areas.

3.2.11 structural slab—a horizontal, supporting, cast-in-place concrete building deck.

3.2.12 traffıc surface—a surface exposed to traffic, either pedestrian or vehicular.

3.2.13 troweled finish—a concrete finish provided by smoothing the surface with power-driven or hand trowels, or both, after

the float finishing operation.

3.2.13.1 Discussion—A troweled finish is smoother than the floated finish. For specifications, see ACI Specification 301.

3.2.14 wearing surface—see traffıc surface.

3.2.15 wet-film thickness—the thickness of a liquid coating as it is applied.

3.2.16 wet-film gauge—a gauge for measuring the thickness of a wet film.

4. Significance and Use

4.1 This guide is divided into two sections which provide design and specification guidelines for the use of a cold liquid-applied

elastomeric membrane with integral wearing surface for waterproofing building decks in building areas to be occupied by

personnel, vehicles, or equipment.

4.2 The intent of Sections 5-11, Design Considerations, is to provide information and design guidelines where a waterproofing

membrane with integral wearing surface is to be used. The intent of the remaining sections is to provide minimum guide

specifications for the use of the purchaser and the seller in contract documents.

4.3 Where the state of the art is such that criteria for a particular condition is not as yet firmly established or has numerous

variables that require consideration, reference is made to the applicable portion of Sections 5-11 that covers the particular area of

concern. Section 16 describes the repair, rehabilitation, and replacement of the membrane.

DESIGN CONSIDERATIONS

5. General

5.1 Major Components, Subsystems, and Features—Design of plaza deck waterproofing includes consideration of several

Available from the American Concrete Institute, P.O. Box 19150, Detroit, MI48219.

Available from American Concrete Institute (ACI), P.O. Box 9094, Farmington Hills, MI 48333-9094, http://www.concrete.org.

Available from Steel Structures Painting Council, 4400 Fifth Ave., Pittsburgh, PA15213.

Available from Society for Protective Coatings (SSPC), 40 24th St., 6th Floor, Pittsburgh, PA 15222-4656, http://www.sspc.org.

Available from American Plywood Assoc. (Forest Industries), P.O. Box 11700, Tacoma, WA 98411.

C 1127 – 01 (2009)

subsystems, with their material components and interrelationships. The specific project requirements, types of substrates exposed

to weather, difference in climatic conditions to which the deck is exposed, and interior environmental requirements of the occupied

space, are major determinants in the selection of components. Information needed to design the deck subsystems includes

temperature extremes of the inner and outer surfaces, precipitation rates, solar exposure, prevailing wind direction, the pattern and

reflectivity of adjacent structures, anticipated amount and intensity of vibration resulting from function or adjacent occupancies,

and design live loads.

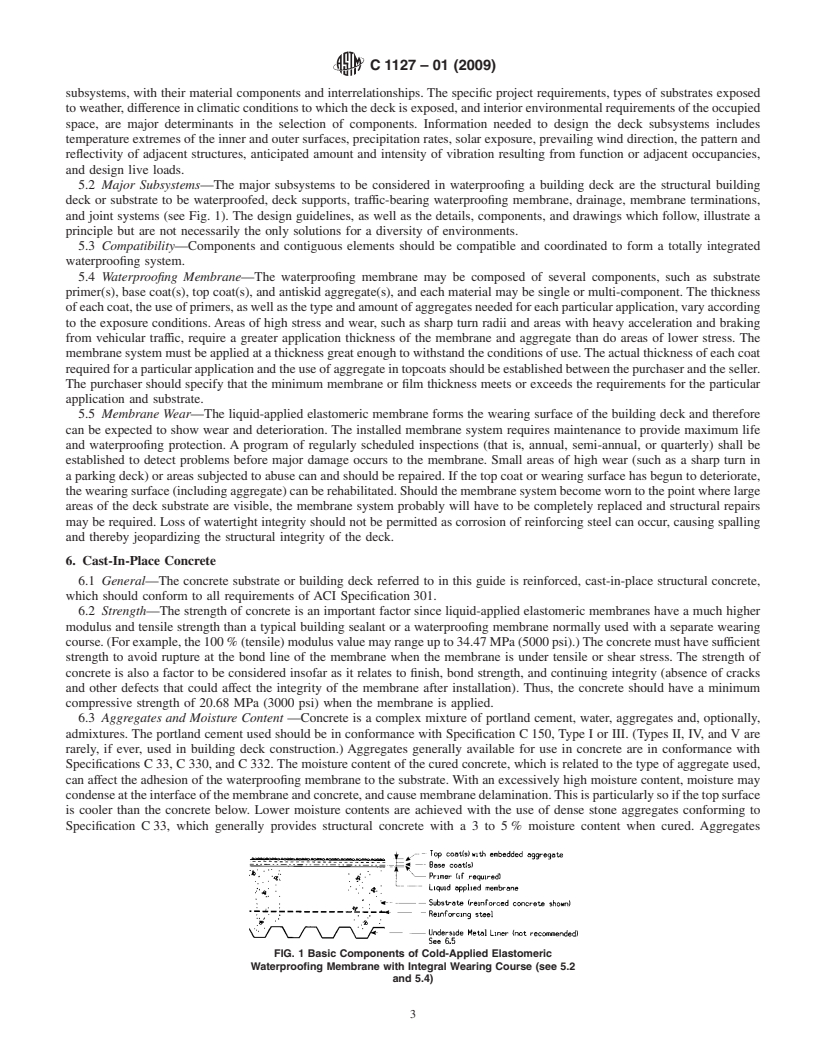

5.2 Major Subsystems—The major subsystems to be considered in waterproofing a building deck are the structural building

deck or substrate to be waterproofed, deck supports, traffic-bearing waterproofing membrane, drainage, membrane terminations,

and joint systems (see Fig. 1). The design guidelines, as well as the details, components, and drawings which follow, illustrate a

principle but are not necessarily the only solutions for a diversity of environments.

5.3 Compatibility—Components and contiguous elements should be compatible and coordinated to form a totally integrated

waterproofing system.

5.4 Waterproofing Membrane—The waterproofing membrane may be composed of several components, such as substrate

primer(s), base coat(s), top coat(s), and antiskid aggregate(s), and each material may be single or multi-component. The thickness

ofeachcoat,theuseofprimers,aswellasthetypeandamountofaggregatesneededforeachparticularapplication,varyaccording

to the exposure conditions. Areas of high stress and wear, such as sharp turn radii and areas with heavy acceleration and braking

from vehicular traffic, require a greater application thickness of the membrane and aggregate than do areas of lower stress. The

membrane system must be applied at a thickness great enough to withstand the conditions of use.The actual thickness of each coat

requiredforaparticularapplicationandtheuseofaggregateintopcoatsshouldbeestablishedbetweenthepurchaserandtheseller.

The purchaser should specify that the minimum membrane or film thickness meets or exceeds the requirements for the particular

application and substrate.

5.5 Membrane Wear—The liquid-applied elastomeric membrane forms the wearing surface of the building deck and therefore

can be expected to show wear and deterioration. The installed membrane system requires maintenance to provide maximum life

and waterproofing protection. A program of regularly scheduled inspections (that is, annual, semi-annual, or quarterly) shall be

established to detect problems before major damage occurs to the membrane. Small areas of high wear (such as a sharp turn in

a parking deck) or areas subjected to abuse can and should be repaired. If the top coat or wearing surface has begun to deteriorate,

the wearing surface (including aggregate) can be rehabilitated. Should the membrane system become worn to the point where large

areas of the deck substrate are visible, the membrane system probably will have to be completely replaced and structural repairs

may be required. Loss of watertight integrity should not be permitted as corrosion of reinforcing steel can occur, causing spalling

and thereby jeopardizing the structural integrity of the deck.

6. Cast-In-Place Concrete

6.1 General—The concrete substrate or building deck referred to in this guide is reinforced, cast-in-place structural concrete,

which should conform to all requirements of ACI Specification 301.

6.2 Strength—The strength of concrete is an important factor since liquid-applied elastomeric membranes have a much higher

modulus and tensile strength than a typical building sealant or a waterproofing membrane normally used with a separate wearing

course.(Forexample,the100 %(tensile)modulusvaluemayrangeupto34.47MPa(5000psi).)Theconcretemusthavesufficient

strength to avoid rupture at the bond line of the membrane when the membrane is under tensile or shear stress. The strength of

concrete is also a factor to be considered insofar as it relates to finish, bond strength, and continuing integrity (absence of cracks

and other defects that could affect the integrity of the membrane after installation). Thus, the concrete should have a minimum

compressive strength of 20.68 MPa (3000 psi) when the membrane is applied.

6.3 Aggregates and Moisture Content —Concrete is a complex mixture of portland cement, water, aggregates and, optionally,

admixtures. The portland cement used should be in conformance with Specification C 150, Type I or III. (Types II, IV, and V are

rarely, if ever, used in building deck construction.) Aggregates generally available for use in concrete are in conformance with

Specifications C 33, C 330, and C 332. The moisture content of the cured concrete, which is related to the type of aggregate used,

can affect the adhesion of the waterproofing membrane to the substrate. With an excessively high moisture content, moisture may

condenseattheinterfaceofthemembraneandconcrete,andcausemembranedelamination.Thisisparticularlysoifthetopsurface

is cooler than the concrete below. Lower moisture contents are achieved with the use of dense stone aggregates conforming to

Specification C 33, which generally provides structural concrete witha3to5% moisture content when cured. Aggregates

FIG. 1 Basic Components of Cold-Applied Elastomeric

Waterproofing Membrane with Integral Wearing Course (see 5.2

and 5.4)

C 1127 – 01 (2009)

conformingtoSpecificationC 330willprovidelightweightstructuralconcretegenerallyhavinga5to20%moisturecontentwhen

cured. Aggregates conforming to Specification C 332 provide lightweight insulating concrete, generally having a relatively low

compressive strength and capable of having ove

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1127–95 Designation: C 1127 – 01 (Reapproved 2009)

Standard Guide for

Use of High Solids Content, Cold Liquid-Applied

Elastomeric Waterproofing Membrane with an Integral

Wearing Surface

This standard is issued under the fixed designation C 1127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide describes the design and installation of cold liquid-applied elastomeric waterproofing membrane systems that

have an integral wearing surface. The cold liquid-applied elastomeric waterproofing membrane (membrane) to which this guide

refers is specified in Specification C 957.

1.2 Concrete Slab-on-Grade—Waterproofing the upper surface of a concrete slab on grade presents special problems due to the

possibility of negative hydrostatic pressure causing loss of bond to the substrate. Consideration of these problems is beyond the

scope of this guide. Consult the membrane manufacturer for recommendations when this situation exists.

1.3The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4

1.3 The committee having jurisdiction for this guide is not aware of any similar ISO standard.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements see Note in 15.4.

2. Referenced Documents

2.1 ASTM Standards:

C33 Specification for Concrete Aggregates

C 150 Specification for Portland Cement

C 330 Specification for Lightweight Aggregates for Structural Concrete

C 332 Specification for Lightweight Aggregates for Insulating Concrete

C 717 Terminology of Building Seals and Sealants

C 755 Practice for Selection of Water Vapor Retarders for Thermal Insulation

C 920 Specification for Elastomeric Joint Sealants

C 957 Specification for High-Solids Content, Cold Liquid-Applied Elastomeric Waterproofing Membrane withWith Integral

Wearing Surface

C 962 Guide for Use of Elastomeric Joint Sealants

C1193 1193 Guide for Use of Joint Sealants

D 653 Terminology Relating to Soil, Rock, and Contained Fluids

D 1752 Specification for Preformed Sponge Rubber Cork and Cork Recycled PVC Expansion Joint Fillers for Concrete Paving

and Structural Construction

D 2628 Specification for Preformed Polychloroprene Elastomeric Joint Seals for Concrete Pavements

2.2 U.S. Department of Commerce Standard:

This guide is under the jurisdiction ofASTM Committee C-24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.80 on Building Deck

Waterproofing Systems.

Current edition approved Dec. 10, 1995. Published February 1996. Originally published as C1127–89. Last previous edition C1127–89.

This guide is under the jurisdiction ofASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.22 on Waterproofing

and Dampproofing Systems.

Current edition approved Jan. 1, 2009. Published January 2009. Originally approved in 1989. Last previous edition approved in 2001 as C 1127 – 01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 04.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 1127 – 01 (2009)

Product Standard PS 1-74 Construction and Industrial Plywood

2.3 American Concrete Institute (ACI) Standard:

301-84 (1985) Specification for Structural Concrete for Buildings

2.4 Steel Structures Painting Council (SSPC) Standards:

Steel Structures Painting Manual, Systems and Specifications:

Specification SSPC SP-2 Wire Brush Cleaning

Specification SSPC SP-6 Commercial Blast Cleaning

2.5 American Plywood Association (APA) Standard:

APA Plywood Construction Guide

3. Terminology

3.1 Definitions—Refer to Terminology C 717 for the following terms used in this guide: bond breaker; cellular; cold joint;

compatibility; compound; construction joint; control joint; creep; dry film thickness; elastomer; expansion joint; gasket; isolation

joint; joint; laitance; primer; reglet; reinforced joint; sealant; spalling.

3.2 Description of Terms Specific to This Standard:

3.2.1 cold-applied—capable of being applied without heating as contrasted to hot-applied.

3.2.1.1 Discussion—Cold-applied products are furnished in a liquid state, whereas hot-applied products are furnished as solids

that must be heated to liquefy them.

3.2.2 curing time—the period between application and the time when the material attains its intended physical properties.

3.2.3 deck—the horizontal structural substrate supporting the plaza deck system.

3.2.4 deflection—the deviation of a structural element from its original shape or plane due to physical loading, temperature

gradients, or rotation of its support.

3.2.5 finish—the exposed top surface of the plaza deck system, or traffic or wearing surface.

3.2.6 flashing—a generic term describing the transitional area between the waterproofing membrane and surfaces above the

wearing surface of the plaza; a terminal closure or barrier to prevent ingress of water into the system.

3.2.7 floated finish—a concrete finish provided by consolidating and leveling the concrete with only a power driven or hand

float, or both.

3.2.7.1 Discussion—A floated finish is more coarse than a troweled finish. For specifications, see ACI Specification 301.

3.2.8 freeze-thaw cycle—the freezing and subsequent thawing of a material.

3.2.9 grout—concrete containing no coarse aggregate; a thin mortar.

3.2.10 preparatory coat—an initial coat of the liquid-applied membrane which is applied at cracks, joints, or terminal points

to provide reinforcement to the membrane at these critical areas.

3.2.11 structural slab—a horizontal, supporting, cast-in-place concrete building deck.

3.2.12 traffıc surface—a surface exposed to traffic, either pedestrian or vehicular.

3.2.13 troweled finish—a concrete finish provided by smoothing the surface with power-driven or hand trowels, or both, after

the float finishing operation.

3.2.13.1 Discussion—A troweled finish is smoother than the floated finish. For specifications, see ACI Specification 301.

3.2.14 wearing surface—see traffıc surface.

3.2.15 wet-film thickness—the thickness of a liquid coating as it is applied.

3.2.16 wet-film gauge—a gauge for measuring the thickness of a wet film.

4. Significance and Use

4.1 This guide is divided into two sections which provide design and specification guidelines for the use of a cold liquid-applied

elastomeric membrane with integral wearing surface for waterproofing building decks in building areas to be occupied by

personnel, vehicles, or equipment.

4.2 The intent of Sections 5-11, Design Considerations, is to provide information and design guidelines where a waterproofing

membrane with integral wearing surface is to be used. The intent of the remaining sections is to provide minimum guide

specifications for the use of the purchaser and the seller in contract documents.

4.3 Where the state of the art is such that criteria for a particular condition is not as yet firmly established or has numerous

variables that require consideration, reference is made to the applicable portion of Sections 5-11 that covers the particular area of

concern. Section 16 describes the repair, rehabilitation, and replacement of the membrane.

Annual Book of ASTM Standards, Vol 04.07.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 1070, Gaithersburg, MD 20899-1070, http://www.nist.gov.

Annual Book of ASTM Standards, Vol 04.06.

Available from American Concrete Institute (ACI), P.O. Box 9094, Farmington Hills, MI 48333-9094, http://www.concrete.org.

Discontinued. See 1992 Annual Book of ASTM Standards , Vol 04.07. Replaced by C1193.

Available from Society for Protective Coatings (SSPC), 40 24th St., 6th Floor, Pittsburgh, PA 15222-4656, http://www.sspc.org.

Annual Book of ASTM Standards, Vol 04.08.

Available from American Plywood Assoc. (Forest Industries), P.O. Box 11700, Tacoma, WA 98411.

C 1127 – 01 (2009)

DESIGN CONSIDERATIONS

5. General

5.1 Major Components, Subsystems, and Features—Design of plaza deck waterproofing includes consideration of several

subsystems, with their material components and interrelationships. The specific project requirements, types of substrates exposed

to weather, difference in climatic conditions to which the deck is exposed, and interior environmental requirements of the occupied

space, are major determinants in the selection of components. Information needed to design the deck subsystems includes

temperature extremes of the inner and outer surfaces, precipitation rates, solar exposure, prevailing wind direction, the pattern and

reflectivity of adjacent structures, anticipated amount and intensity of vibration resulting from function or adjacent occupancies,

and design live loads.

5.2 Major Subsystems—The major subsystems to be considered in waterproofing a building deck are the structural building

deck or substrate to be waterproofed, deck supports, traffic-bearing waterproofing membrane, drainage, membrane terminations,

and joint systems (see Fig. 1). The design guidelines, as well as the details, components, and drawings which follow, illustrate a

principle but are not necessarily the only solutions for a diversity of environments.

5.3 Compatibility—Components and contiguous elements should be compatible and coordinated to form a totally integrated

waterproofing system.

5.4 Waterproofing Membrane—The waterproofing membrane may be composed of several components, such as substrate

primer(s), base coat(s), top coat(s), and antiskid aggregate(s), and each material may be single or multi-component. The thickness

ofeachcoat,theuseofprimers,aswellasthetypeandamountofaggregatesneededforeachparticularapplication,varyaccording

to the exposure conditions. Areas of high stress and wear, such as sharp turn radii and areas with heavy acceleration and braking

from vehicular traffic, require a greater application thickness of the membrane and aggregate than do areas of lower stress. The

membrane system must be applied at a thickness great enough to withstand the conditions of use.The actual thickness of each coat

requiredforaparticularapplicationandtheuseofaggregateintopcoatsshouldbeestablishedbetweenthepurchaserandtheseller.

The purchaser should specify that the minimum membrane or film thickness meets or exceeds the requirements for the particular

application and substrate.

5.5 Membrane Wear—The liquid-applied elastomeric membrane forms the wearing surface of the building deck and therefore

can be expected to show wear and deterioration. The installed membrane system requires maintenance to provide maximum life

and waterproofing protection. A program of regularly scheduled inspections (that is, annual, semi-annual, or quarterly) shall be

established to detect problems before major damage occurs to the membrane. Small areas of high wear (such as a sharp turn in

a parking deck) or areas subjected to abuse can and should be repaired. If the top coat or wearing surface has begun to deteriorate,

the wearing surface (including aggregate) can be rehabilitated. Should the membrane system become worn to the point where large

areas of the deck substrate are visible, the membrane system probably will have to be completely replaced and structural repairs

may be required. Loss of watertight integrity should not be permitted as corrosion of reinforcing steel can occur, causing spalling

and thereby jeopardizing the structural integrity of the deck.

6. Cast-In-Place Concrete

6.1 General—The concrete substrate or building deck referred to in this guide is reinforced, cast-in-place structural concrete,

which should conform to all requirements of ACI Specification 301.

6.2 Strength—The strength of concrete is an important factor since liquid-applied elastomeric membranes have a much higher

modulus and tensile strength than a typical building sealant or a waterproofing membrane normally used with a separate wearing

course.(Forexample,the100 %(tensile)modulusvaluemayrangeupto34.47MPa(5000psi).)Theconcretemusthavesufficient

strength to avoid rupture at the bond line of the membrane when the membrane is under tensile or shear stress. The strength of

concrete is also a factor to be considered insofar as it relates to finish, bond strength, and continuing integrity (absence of cracks

and other defects that could affect the integrity of the membrane after installation). Thus, the concrete should have a minimum

compressive strength of 20.68 MPa (3000 psi) when the membrane is applied.

6.3 Aggregates and Moisture Content —Concrete is a complex mixture of portland cement, water, aggregates and, optionally,

admixtures. The portland cement used should be in conformance with Specification C 150, Type I or III. (Types II, IV, and V are

rarely, if ever, used in building deck construction.) Aggregates generally available for use in concrete are in conformance with

FIG. 1 Basic Components of Cold-Applied Elastomeric

Waterproofing Membrane with Integral Wearing Course (see 5.2

and 5.4)

C 1127 – 01 (2009)

Specifications C 33, C 330, and C 332. The moisture content of the cured concrete, which is related to the type of aggregate used,

can affect the adhesion of the waterproofing membrane to the substrate. With an excessively high moisture content, moisture may

condenseattheinterfaceofthemembraneandconcrete,andcausemembranedelamination.Thisisparticularlysoifthetopsurface

is cooler than the concrete below. Lower moisture contents are achieved with the use of dense stone aggregates conforming to

Specification C 33, which generally provides structural concrete witha3to5% moisture content whe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.